Preparation method of metal-loaded nitrogen-doped bulk porous carbon material

A porous carbon material and block technology, which is applied in the field of preparation of metal-loaded nitrogen-doped block porous carbon materials, can solve problems such as difficult circulation and separation, and achieve high specific surface area, high porosity, and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

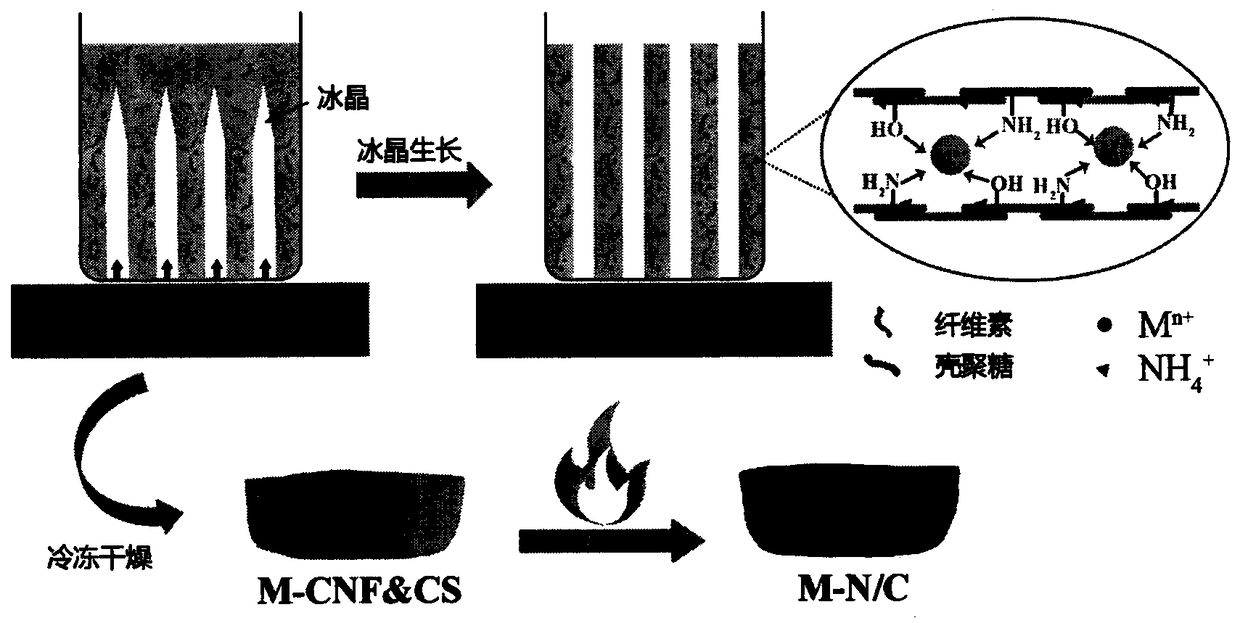

[0028] A method for preparing a metal-loaded nitrogen-doped bulk porous carbon material:

[0029] (1) Take 10.0 g of cellulose nanowire suspension with a solid content of 3.0 wt.%, add 3.0 wt.% chitosan acetic acid solution (10.0 g), cobalt acetate tetrahydrate (46.7 mg), and stir magnetically at 60° C. for 4 h;

[0030] (2) Place the suspension prepared in (1) into liquid nitrogen for quick freezing, the cooling time is 10 minutes, and then freeze-dry in a freeze dryer for 30 hours to obtain a cobalt-loaded natural polymer-based porous material;

[0031] (3) Put the porous material prepared in (2) in an atmosphere furnace, under the condition of nitrogen protection, the heating rate is 5°C / min to 800°C, and keep it for 3h, to obtain cobalt-supported nitrogen-doped massive porous carbon Co-N / C 0-800(M-N / Cx y-z: M is the loaded metal element, x is the natural polysaccharide polymer, where x is the default raw material is cellulose nanowire, y is the mass percentage of ammonium...

Embodiment 2

[0039] A method for preparing a metal-loaded nitrogen-doped bulk porous carbon material:

[0040] (1) Get 10.0g solid content 3.0wt.% cellulose nanowire suspension, add 3.0wt.% chitosan acetic acid solution (10.0g), cobalt acetate tetrahydrate (46.7mg), ammonium chloride (0.3g) , 60 ℃ magnetic stirring for 4h;

[0041] (2) Place the suspension prepared in (1) into liquid nitrogen for quick freezing, the cooling time is 10 minutes, and then freeze-dry in a freeze dryer for 30 hours to obtain a cobalt-loaded natural polymer-based porous material;

[0042] (3) Put the porous material prepared in (2) in an atmosphere furnace, under the condition of nitrogen protection, the heating rate is 5°C / min to 800°C, and keep it for 3h, to obtain cobalt-supported nitrogen-doped massive porous carbon Co-N / C 50-800.

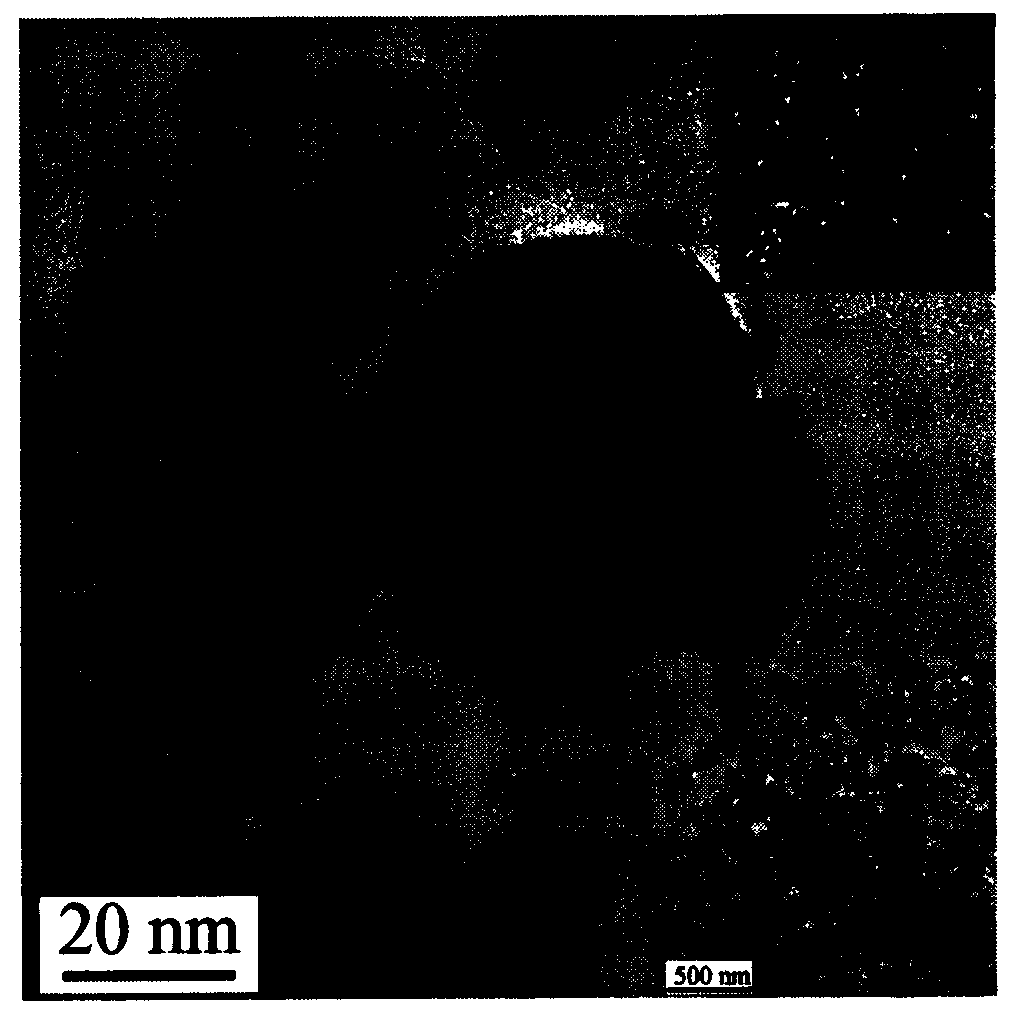

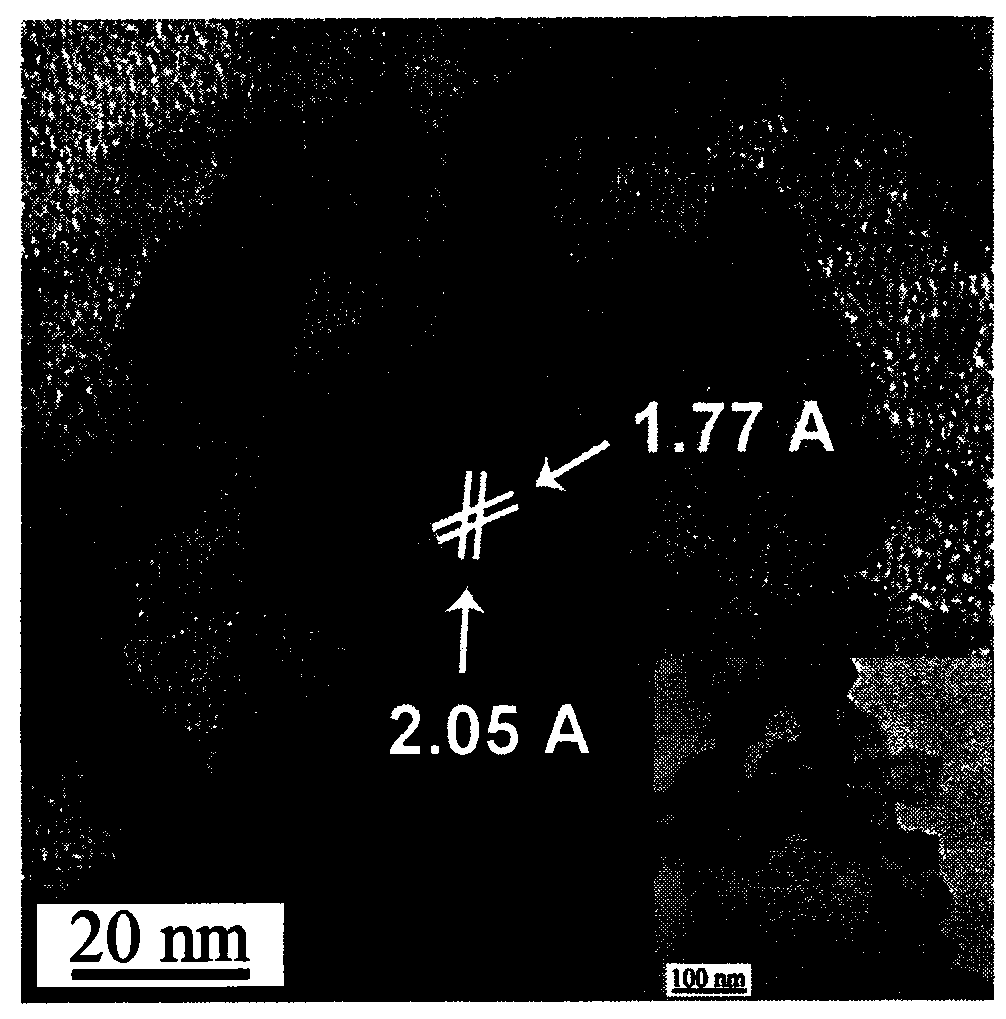

[0043] Depend on image 3 It shows that the prepared Co-N / C 5-800 cobalt nanoparticles are embedded in the porous carbon surface, and there are a lot of holes on the surface ...

Embodiment 3

[0050] A method for preparing a metal-loaded nitrogen-doped bulk porous carbon material:

[0051] (1) Take 10.0g solid content 3.0wt.% cellulose nanowire suspension, add 3.0wt.% chitosan acetic acid solution (10.0g), nickel chloride hexahydrate (217.0mg), ammonium chloride (0.3g ), stirred at room temperature for 12h;

[0052] (2) Place the suspension prepared in (1) into liquid nitrogen for quick freezing, the cooling time is 10 minutes, and then freeze-dry in a freeze dryer for 30 hours to obtain a nickel-loaded natural polymer-based porous material;

[0053] (3) Put the porous material prepared in (2) in an atmosphere furnace, under the condition of nitrogen protection, the heating rate is 5°C / min to 800°C, and keep it warm for 3h to obtain nickel-supported nitrogen-doped bulk porous carbon Ni-N / C 50-800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com