Composite carbon material having metal carbide particles dispersed therein and method for preparation thereof

A carbon composite material, metal carbide technology, applied in the direction of brake disc, thin material processing, mechanical equipment, etc., can solve the problem of impossible to prepare composite material, achieve high friction coefficient, high thermal stability, wear resistance light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

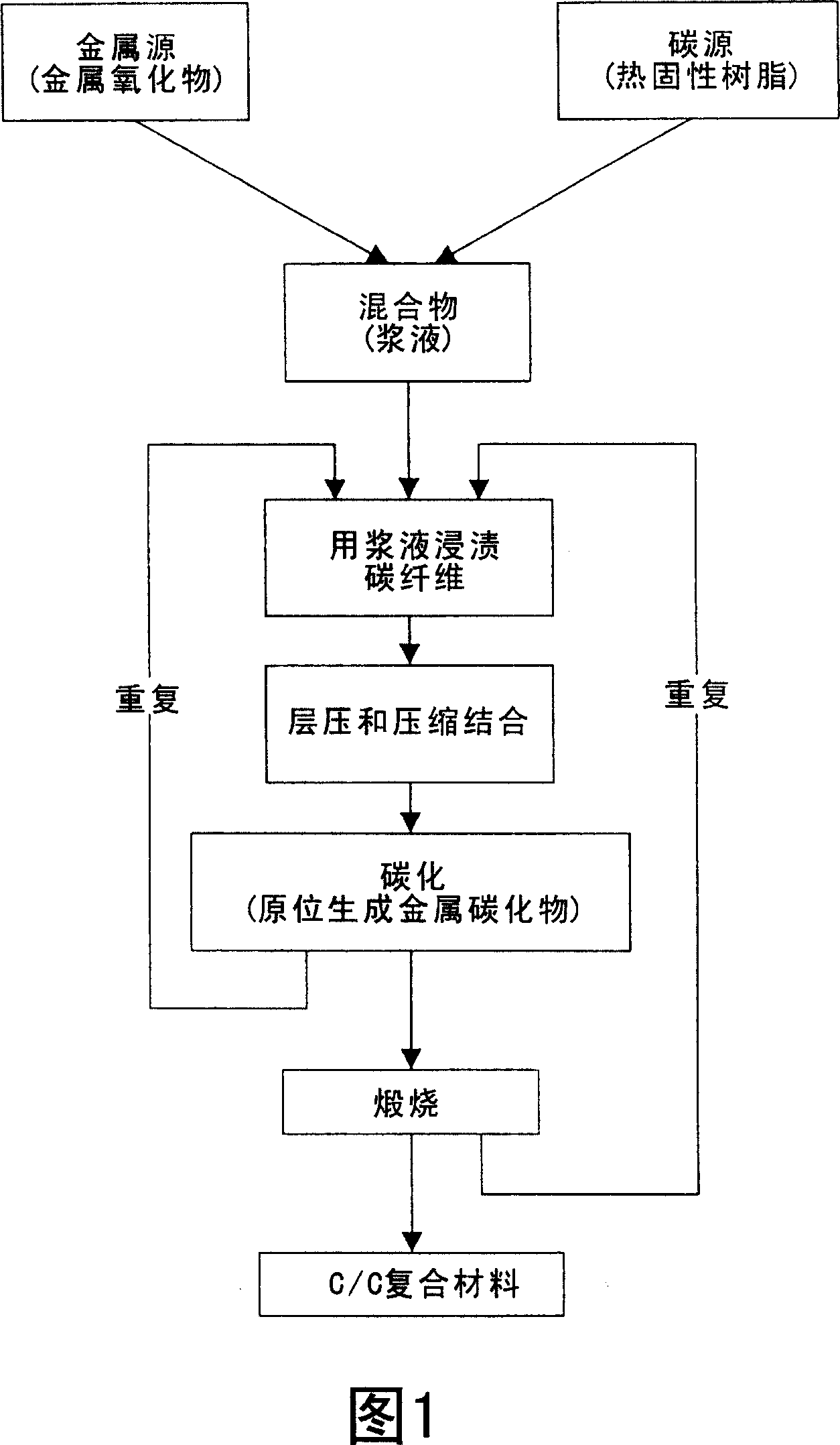

Method used

Image

Examples

Embodiment

[0064] 1) Silica particles with an average particle size of 3 μm and 2) liquid phenolic resin were used as starting materials. Silica particles are introduced into the liquid phenolic resin along with a dispersant to adjust its concentration to a C:Si ratio (molar ratio) of at least 3:1. In this example, silica particles were mixed at a C:Si molar ratio of 9:1.

[0065] The carbon plate is impregnated with the slurry described above and shaped by heating. After molding, the dispersion state of the silica particles was observed under an electron microscope, and an image as shown in FIG. 2 was obtained.

[0066] The shaped product was carbonized at 1000 °C in an inert atmosphere.

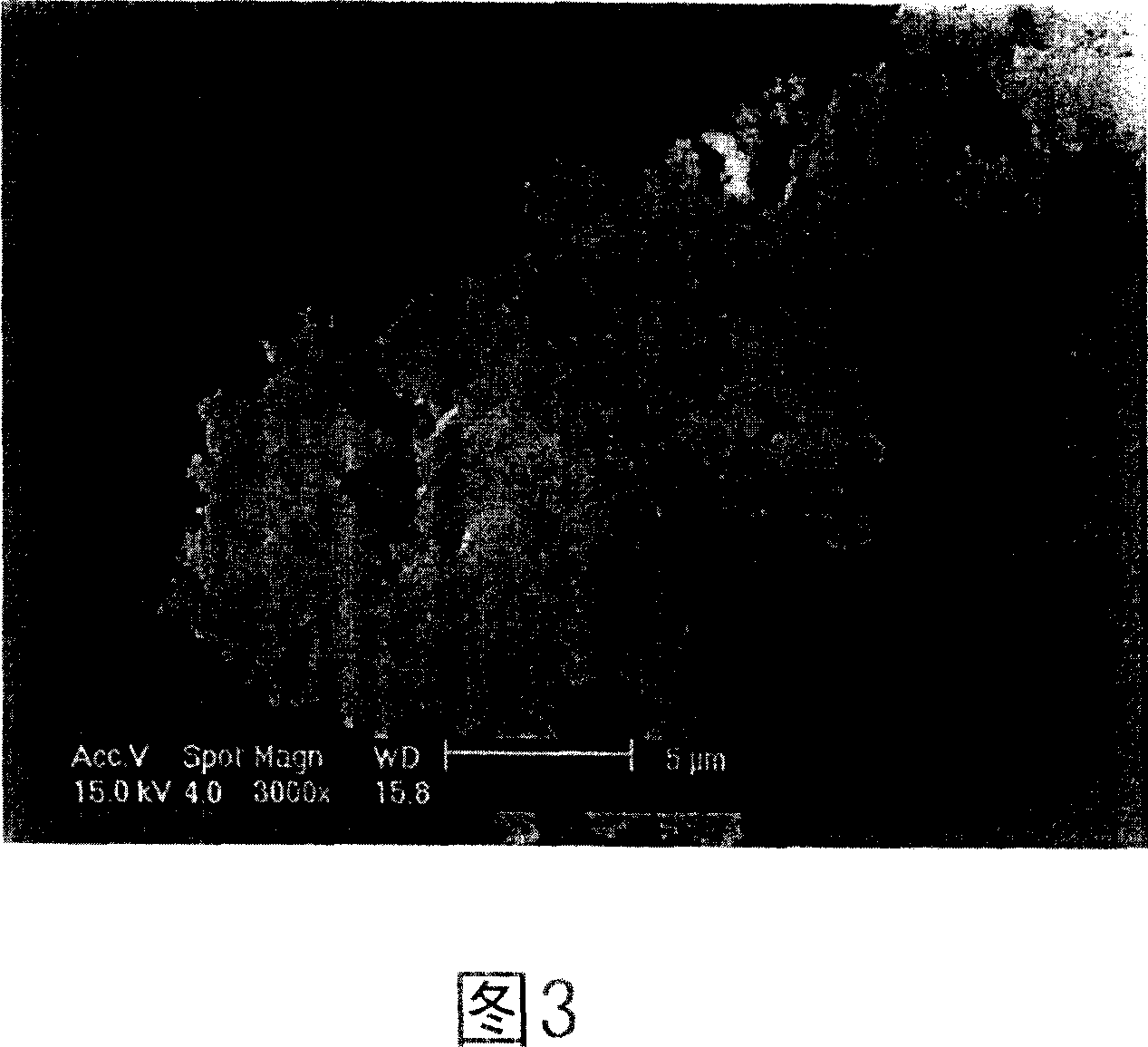

[0067] The carbon plates were impregnated again with phenolic resin in a vacuum vessel and then carbonized again. The shaped product was then calcined at 1650° C. in an inert atmosphere. The particle shape of the resulting test sample was observed under an electron microscope. At the same time, X...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com