Transparent medical PVC material suitable for wide-wave shading and preparation method thereof

A technology of PVC material and PVC resin, applied in the field of transparent medical PVC material and its preparation, can solve the problems of narrow light-shielding range and low light transmittance, and achieve the effects of reducing particle diameter, improving dispersibility and good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Formula composition: 100 parts by weight of PVC resin, 50 parts by weight of plasticizer, 2.0 parts by weight of calcium / zinc stabilizer, 8.0 parts by weight of auxiliary heat stabilizer, 1.0 part by weight of lubricant, and 0.01 part by weight of light-shielding agent. Wherein said PVC resin is polyvinyl chloride resin by suspension method, and the degree of polymerization is 800-2500; said calcium / zinc heat stabilizer is 40-50% calcium ricinoleate, 15-20% zinc octylate, 10-20% zinc stearate, 15-25% polyvinyl alcohol composition compound; Described auxiliary thermal stabilizer is epoxy soybean oil (ESBO); Described lubricant is polyethylene wax; Described The light shielding agent consists of 40-60% iron oxide red (Fe 2 o 3 ), 20-30% iron oxide yellow (Fe 2 o 3 ·H 2 O) and 20-30% carbon black compound.

[0016] The specific production steps are:

[0017] (1) Add iron oxide red, iron oxide yellow, and carbon black into the quantitative epoxy soybean oil ...

Embodiment 2

[0022] Embodiment 2 Formula composition: 100 parts by weight of PVC resin, 65 parts by weight of plasticizer, 1.5 parts by weight of calcium / zinc stabilizer, 10 parts by weight of auxiliary heat stabilizer, 0.7 parts by weight of lubricant, and 0.02 parts by weight of light-shielding agent, wherein The PVC resin is a suspension polyvinyl chloride resin with a degree of polymerization of 800-2500; the calcium / zinc heat stabilizer is 40-50% calcium ricinoleate, 15-20% zinc octylate, 10 -20% zinc stearate, 15-25% polyvinyl alcohol composition compound; Described auxiliary heat stabilizer is epoxy soybean oil (ESBO); Described lubricant is polyethylene wax; Described The light shielding agent consists of 40-60% iron oxide red (Fe 2 o 3 ), 20-30% iron oxide yellow (Fe 2 o 3 ·H 2 O) and 20-30% carbon black compound.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] Embodiment 3 Formula composition: 100 parts by weight of PVC resin, 75 parts by weight of plasticizer, 1.0 part by weight of calcium / zinc stabilizer, 12 parts by weight of auxiliary heat stabilizer, 0.5 part by weight of lubricant, and 0.05 part by weight of light-shielding agent, wherein The PVC resin is a suspension polyvinyl chloride resin with a degree of polymerization of 800-2500; the calcium / zinc heat stabilizer is 40-50% calcium ricinoleate, 15-20% zinc octylate, 10 -20% zinc stearate, 15-25% polyvinyl alcohol composition compound; Described auxiliary heat stabilizer is epoxy soybean oil (ESBO); Described lubricant is polyethylene wax; Described The light shielding agent consists of 40-60% iron oxide red (Fe 2 o 3 ), 20-30% iron oxide yellow (Fe 2 o 3 ·H 2 O) and 20-30% carbon black compound.

[0026] The preparation method is the same as in Example 1.

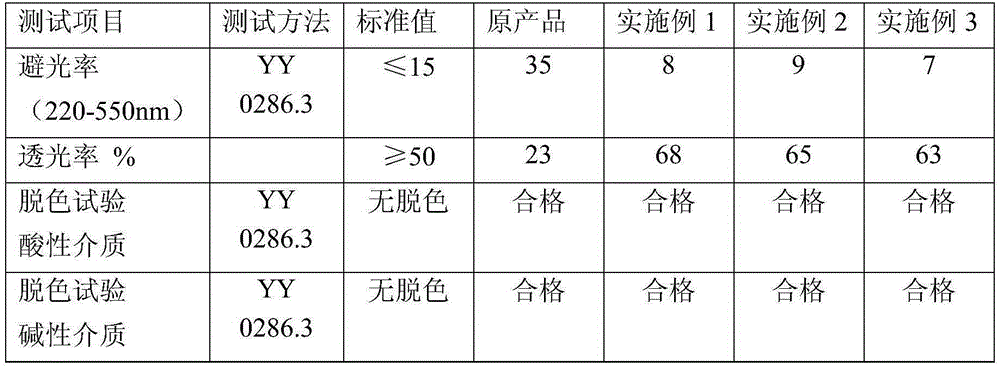

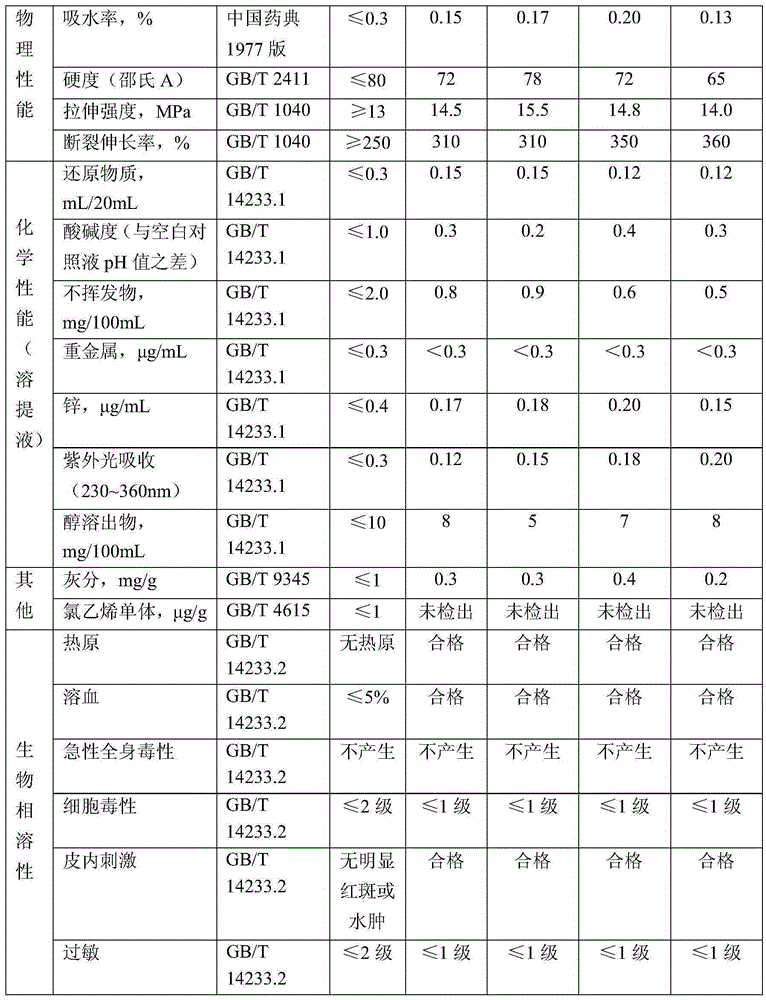

[0027] Select 3 examples with the basic formula of the present invention to carry out implementation ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com