Preparation method of zinc ion-porphyrin nanometer complex

A nanocomplex and zinc ion technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the potential value of no large-scale production, poor method repeatability, irregular arrangement, etc. problems, to achieve the effect of regular arrangement, uniform distribution and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, when preparing the zinc ion-porphyrin nanocomplex, the reaction vessel used is a microreactor. Specifically, the zinc ion source solution and the porphyrin source solution are mixed and reacted in the microreactor to finally obtain zinc Ion-porphyrin nanocomplexes.

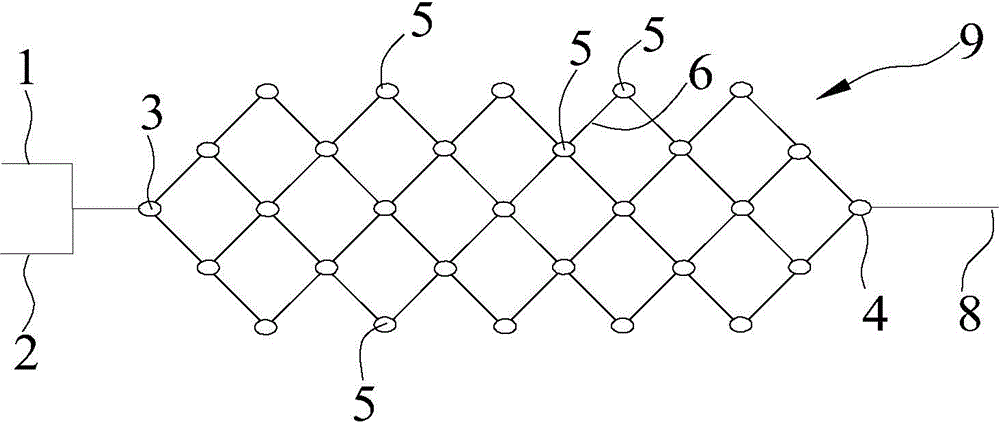

[0021] The structure of the microreactor of the present embodiment, as figure 1 Shown, comprise the first material inlet pipe 1, the second material inlet pipe 2, the material outlet pipe 8 and a group of reaction channels 9, this group of reaction channels 9 includes the first hollow microchannel ball 3 and the second microchannel ball 4 27 hollow third microchannel balls 5 are arranged between the first microchannel ball 3 and the second microchannel ball 4, and the first microchannel 6 is respectively connected between two adjacent third microchannel balls 5 , four adjacent third microchannel balls 5 and the first microchannel 6 form a rhombus, and the first microchannel ball 3 is conne...

Embodiment 2

[0029] The difference between the structure of the microreactor of the present embodiment and embodiment 1 is:

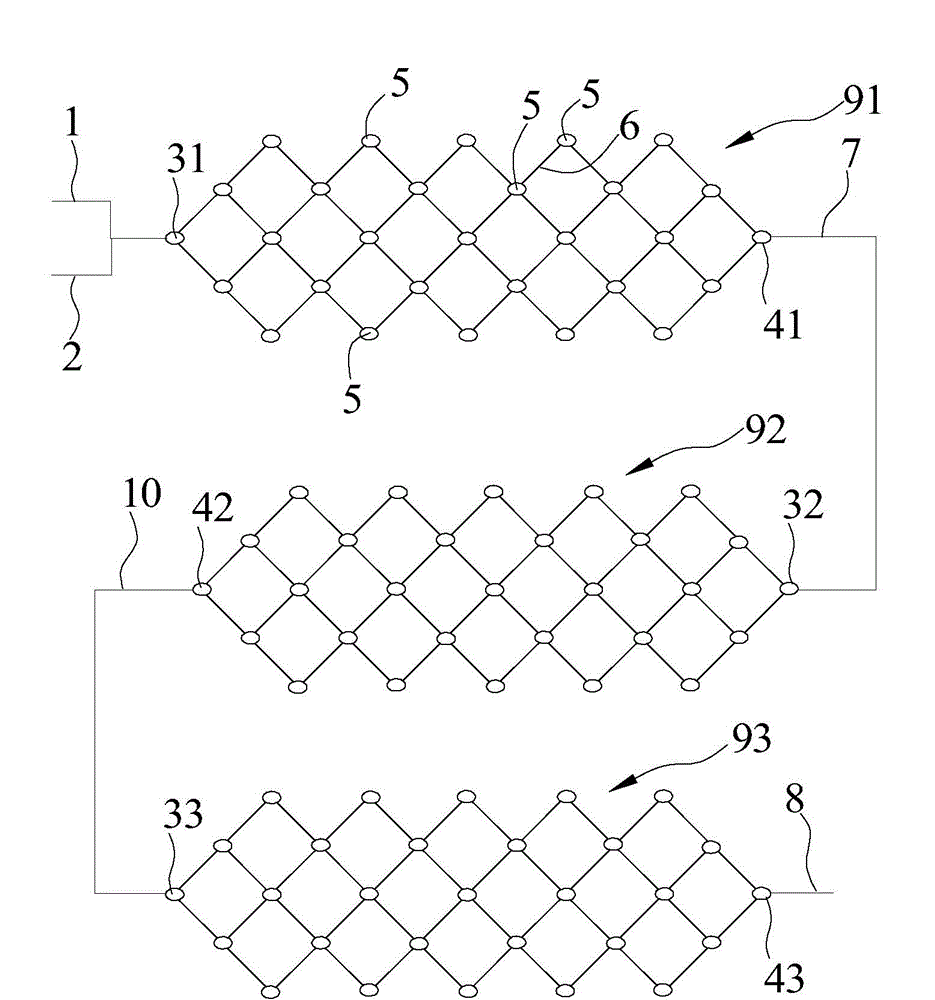

[0030] The microreactor of the present embodiment comprises three groups of reaction passages, is respectively the first group of reaction passages 91, the second group of reaction passages 92 and the third group of reaction passages 93, the first material inlet pipeline 1, the second material inlet pipeline 2 respectively Connected with the first microchannel ball 31 of the first group of reaction channels 91, the second microchannel ball 41 of the first group of reaction channels 91 is connected with the first microchannel ball 32 of the second group of reaction channels 92 through the second microchannel 7 Connect, the second microchannel ball 42 of the second group of reaction channels 92 is connected with the first microchannel ball 33 of the third group of reaction channels 93 by the third microchannel 10, the second microchannel ball 43 of the third group of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com