Rare earth zirconate high-temp heat barrier coating material and its preparation method

A coating material and zirconate technology, applied in the field of rare earth zirconate high temperature thermal barrier coating material and its preparation, can solve the problems of grain growth, interface thermal stress increase, thermal conductivity increase, etc. Effects of low sintering activity, high phase transition temperature, good high temperature chemical stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

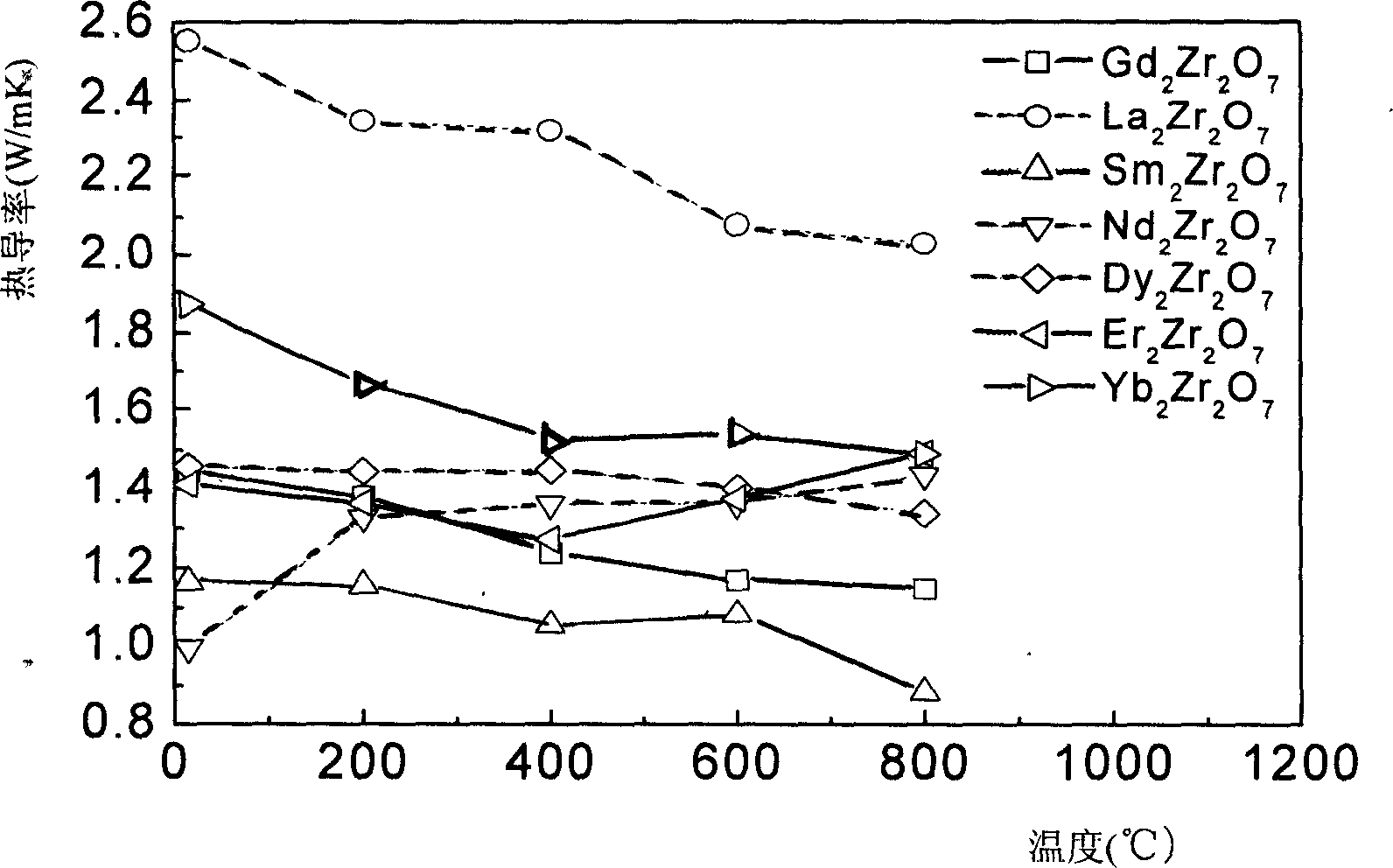

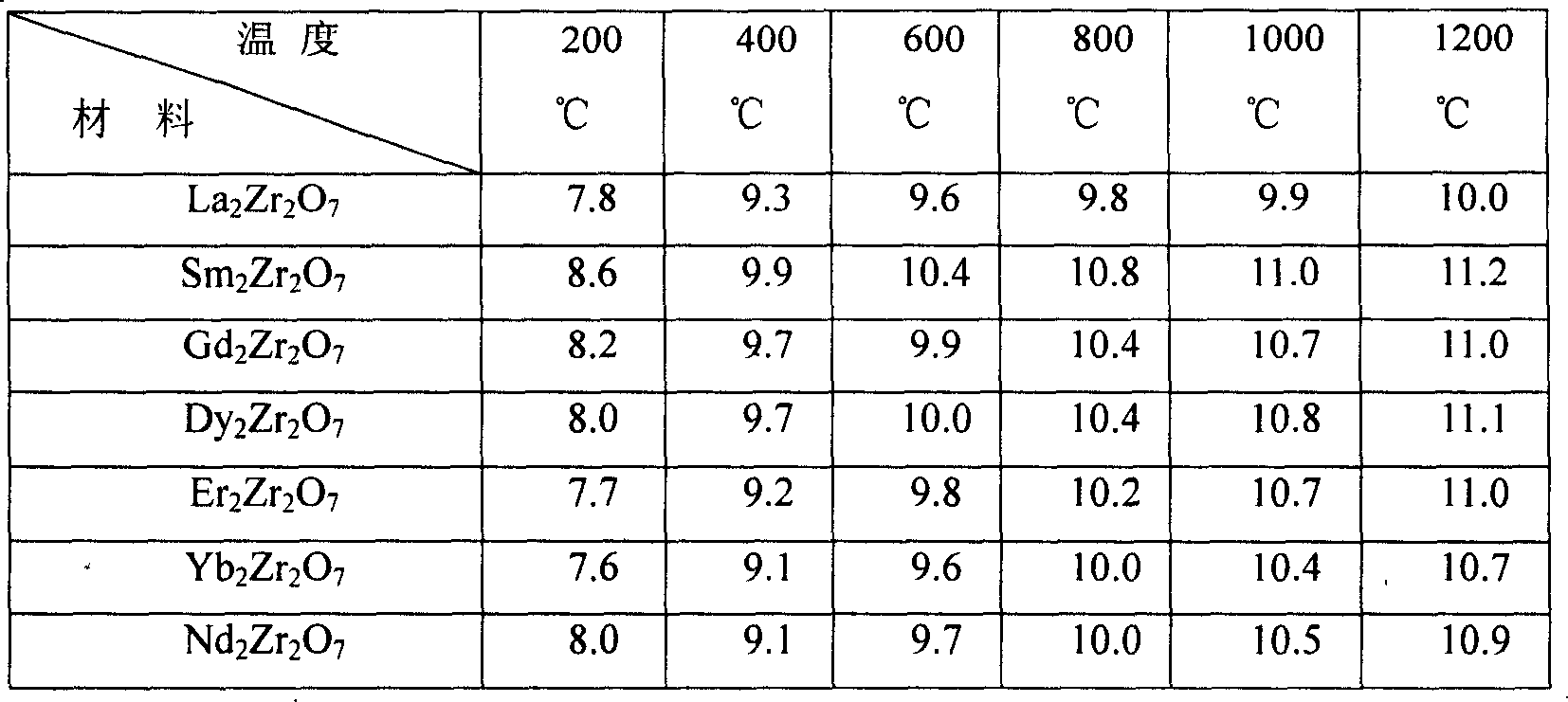

[0013] The present invention provides chemical composition as A 2 B 2 o 7 A rare earth zirconate high-temperature thermal barrier coating material whose crystal structure is pyrochlore or fluorite and a preparation method thereof. The rare earth zirconate high temperature thermal barrier coating material includes a rare earth oxide (La 2 o 3 ,Nd 2 o 3 , Sm 2 o 3 , Gd 2 o 3 , Dy 2 o 3 , Er 2 o 3 or Yb 2 o 3 ) powder and zirconia powder with a purity of 99wt%, the molar ratio is 1:2; wherein A is rare earth elements La, Nd, Sm, Gd, Dy; Er or Yb, etc., B is Zr. The preparation method of the rare earth zirconate thermal barrier coating material comprises the following steps:

[0014] 1) After weighing according to the molar ratio of a rare earth oxide and zirconia powder being 1:2, mixing by wet ball milling;

[0015] 2) After the above mixture is dried, it is pressed to obtain a compact blank.

[0016] 3) Put the above-mentioned blank in a zirconia container, pu...

Embodiment 1

[0019] Dysprosium oxide and zirconia as raw materials

[0020] a the mass percentage is 99wt% dysprosium oxide (Dy 2 o 3 ) and zirconia in a molar ratio of 1:2, added a certain amount of deionized water to ball mill for 24 hours, and dried.

[0021] b Dry pressing under 100MPa to form a blank.

[0022] c Place the zirconia crucible with the blank in the electric furnace, raise the temperature to 1600°C, and perform a high-temperature reaction at 1600°C in an air atmosphere for 10 hours, and then cool with the furnace.

[0023] d After cooling, take out the reactant, then pulverize and grind to a powder below 5 microns.

[0024] e obtains the chemical molecular formula as: Dy 2 Zr 2 o 7 Material, the thermal conductivity of the sample is 1.20W / m K (600°C), and the thermal expansion coefficient is 8.2~11.0×10 -6 / K, the modulus of elasticity is 145GPa.

[0025] f After adding a certain amount of binder to the above-mentioned powder, obtain spherical granular substances w...

Embodiment 2

[0027] Using gadolinia and zirconia as raw materials

[0028] a the mass percent is 99wt% gadolinium oxide (Gd 2 o 3 ) and zirconia in a molar ratio of 1:2, added a certain amount of deionized water to ball mill for 24 hours, and dried.

[0029] b Dry pressing under 100MPa to form a blank.

[0030] c Place the zirconia crucible with the blank in the electric furnace, raise the temperature to 1650°C, and perform a high-temperature reaction at 1650°C in an air atmosphere for 8 hours, and then cool with the furnace.

[0031] d After cooling, take out the reactant, then pulverize and grind to a powder below 5 microns.

[0032] e obtains the chemical molecular formula as: Gd 2 Zr 2 o 7 Material, the thermal conductivity of the sample is 1.39W / m K (600°C), and the thermal expansion coefficient is 11.1×10 -6 / °C, the modulus of elasticity is 182Pa.

[0033] f After adding a certain amount of binder to the above-mentioned powder, obtain spherical granular substances with an av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com