YSZ-rare earth zirconate thermal barrier coating of gradient structure and preparation method thereof

A technology of thermal barrier coating and gradient structure, applied in coating, metal material coating process, fusion spraying, etc., can solve problems such as low thermal conductivity, affecting service life, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

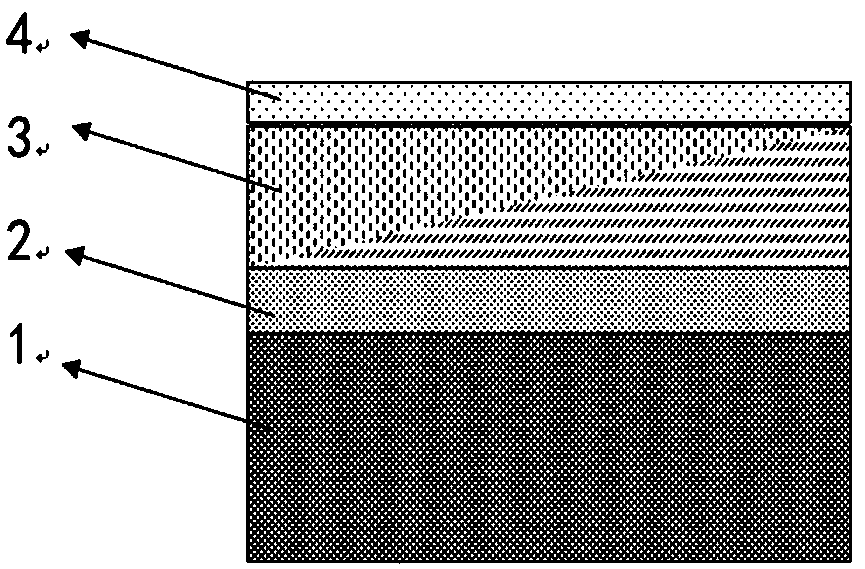

[0027] A multilayer gradient thermal barrier coating and a preparation method thereof, comprising the following steps:

[0028] (1) Substrate surface treatment: soak the cobalt-based superalloy substrate in NaOH solution for degreasing treatment, perform ultrasonic cleaning with ethanol, dry and clean the superalloy substrate, and then spray the treated superalloy substrate surface sand coarsening;

[0029] (2) Feed mixing ball mill: use plasma-densified spherical 8YSZ powder and sintered crushed La 2 Zr 2 o 7 The powders are respectively by mass percentage 8YSZ: rare earth zirconate (=100%8YSZ, 80%: 20%, 60%: 40%, 40%: 60%, 20%: 80%, 100% La 2 Zr 2 o 7 ) Weigh and mix as the gradient raw material, then add 40wt% alcohol, put it into a ball mill for ball milling, the ball milling speed is 150rpm, and the ball milling time is 8h;

[0030] (3) Powder drying: After mixing, dry the above 6 parts of slurry at 80°C for 4 hours to obtain feed powder.

[0031] (4) Thermal spray...

Embodiment 2

[0041] A multilayer gradient thermal barrier coating and a preparation method thereof, comprising the following steps:

[0042] (1) Substrate surface treatment: Soak the nickel-based superalloy substrate in NaOH solution for degreasing treatment, perform ultrasonic cleaning with ethanol, dry and clean the superalloy substrate, and then spray the treated superalloy substrate surface sand coarsening;

[0043] (2) Feed mixing ball mill: use plasma-densified spherical 8YSZ powder with powder particle sizes of 60 μm and 40 μm respectively and sintered crushed Gd 2 Zr 2 o 7 Powder respectively by mass percentage 8YSZ:Gd 2 Zr 2 o 7 (=100%8YSZ, 80%: 20%, 60%: 40%, 40%: 60%, 20%: 80%, 100% Gd 2 Zr 2 o 7 ) Weigh and mix as the gradient raw material, then add 40wt% alcohol, put it into a ball mill for ball milling, the ball milling speed is 150rpm, and the ball milling time is 8h;

[0044] (3) Powder drying: After mixing, dry the above 6 parts of slurry at 80°C for 4 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com