Plumbum niobate-nicklate (PNN)-plumbum zirconate titanate (PZT) piezoelectric ceramic capable of being sintered at low temperature and preparation method thereof

A low-temperature sintering technology of lead niobate nickelate, applied to piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of performance deterioration and achieve the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention is as follows:

[0033] (1) Ingredients

[0034] Raw material Pb 3 o 4 、Ni 2 o 3 , Nb 2 o 5 , ZrO 2 、TiO 2 , CuO by 0.3Pb(Ni1 / 3 Nb 2 / 3 )O 3 -0.7Pb(Zr 0.44 Ti 0.56 )O 3 +xCuO, wherein 0<x≤0.03 stoichiometric ratio, put into the ball mill tank after mixing, the ball milling medium is water and agate balls, the weight ratio of ball:material:water is 2:1:0.6, ball milling 4h, rotating speed is 750 rpm, put the mixture into an oven to dry at 80°C, then put it into a mortar for grinding, and pass through a 40-mesh sieve;

[0035] (2) synthesis

[0036] Put the ground and sieved powder in step (1) into a crucible, compact it, cover it, seal it, synthesize it in a muffle furnace at 900°C, keep it warm for 2 hours, cool it down to room temperature naturally, and take it out of the furnace;

[0037] (3) Tablet

[0038] Secondary ball milling, drying and sieving of the synthetic material in step (2), adding 5wt% to 7w...

specific Embodiment

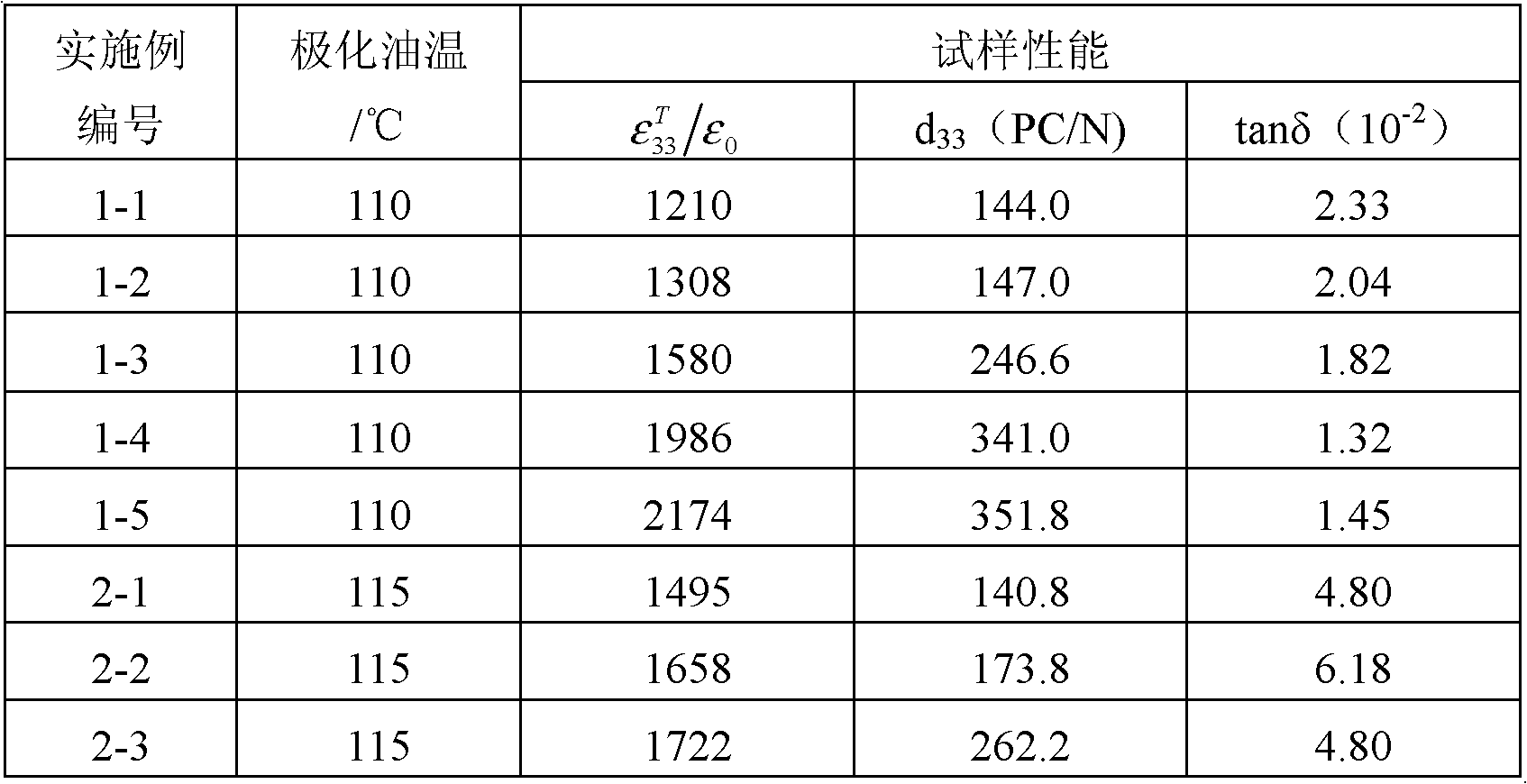

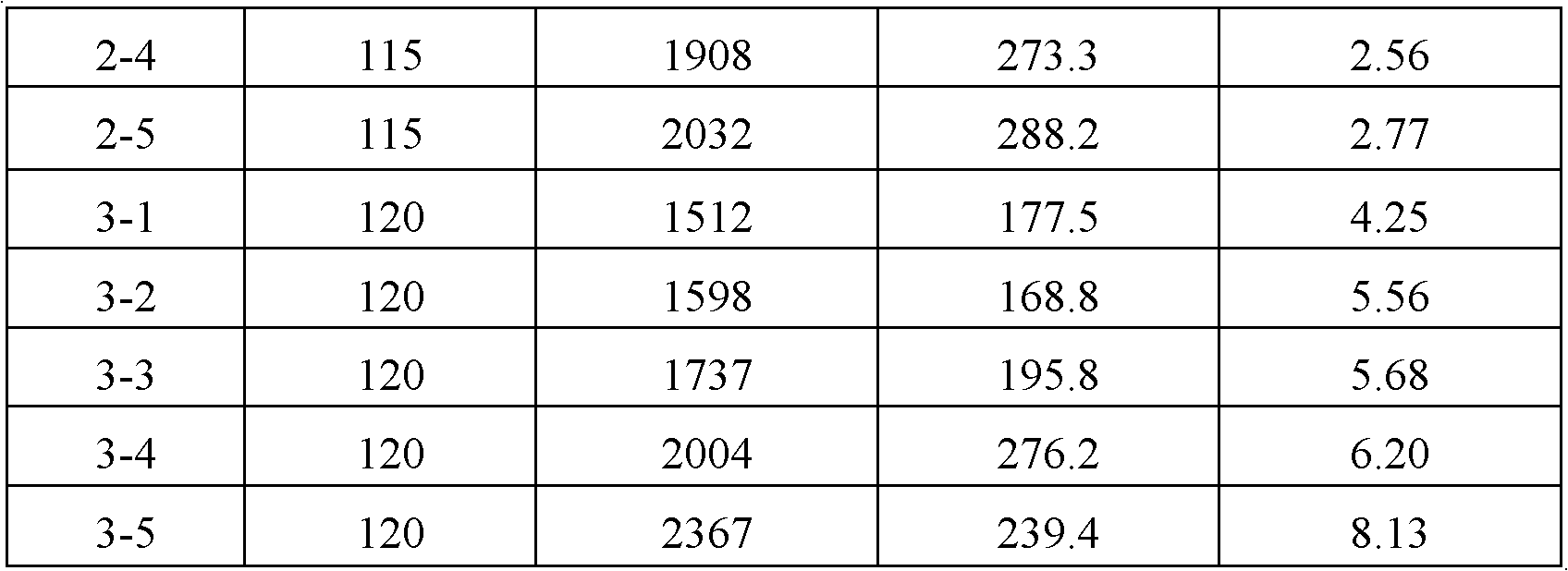

[0050] x=0.01, the sintering temperature is 900°C, 950°C, 1000°C, 1050°C, 1100°C, which are respectively recorded as Examples 1-1, 1-2, 1-3, 1-4, 1-5

[0051] x=0.02, the sintering temperature is 900°C, 950°C, 1000°C, 1050°C, 1100°C, respectively recorded as Examples 2-1, 2-2, 2-3, 2-4, 2-5;

[0052] x=0.03, the sintering temperature is 900°C, 950°C, 1000°C, 1050°C, and 1100°C, which are respectively recorded as Examples 3-1, 3-2, 3-3, 3-4, and 3-5;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com