Method for preparing lead zirconate titanate ceramics fibre

A technology of lead zirconate titanate and ceramic fiber, applied in the field of ceramic fiber, which can solve the problems of harmfulness to human health, high toxicity, and difficulty in control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

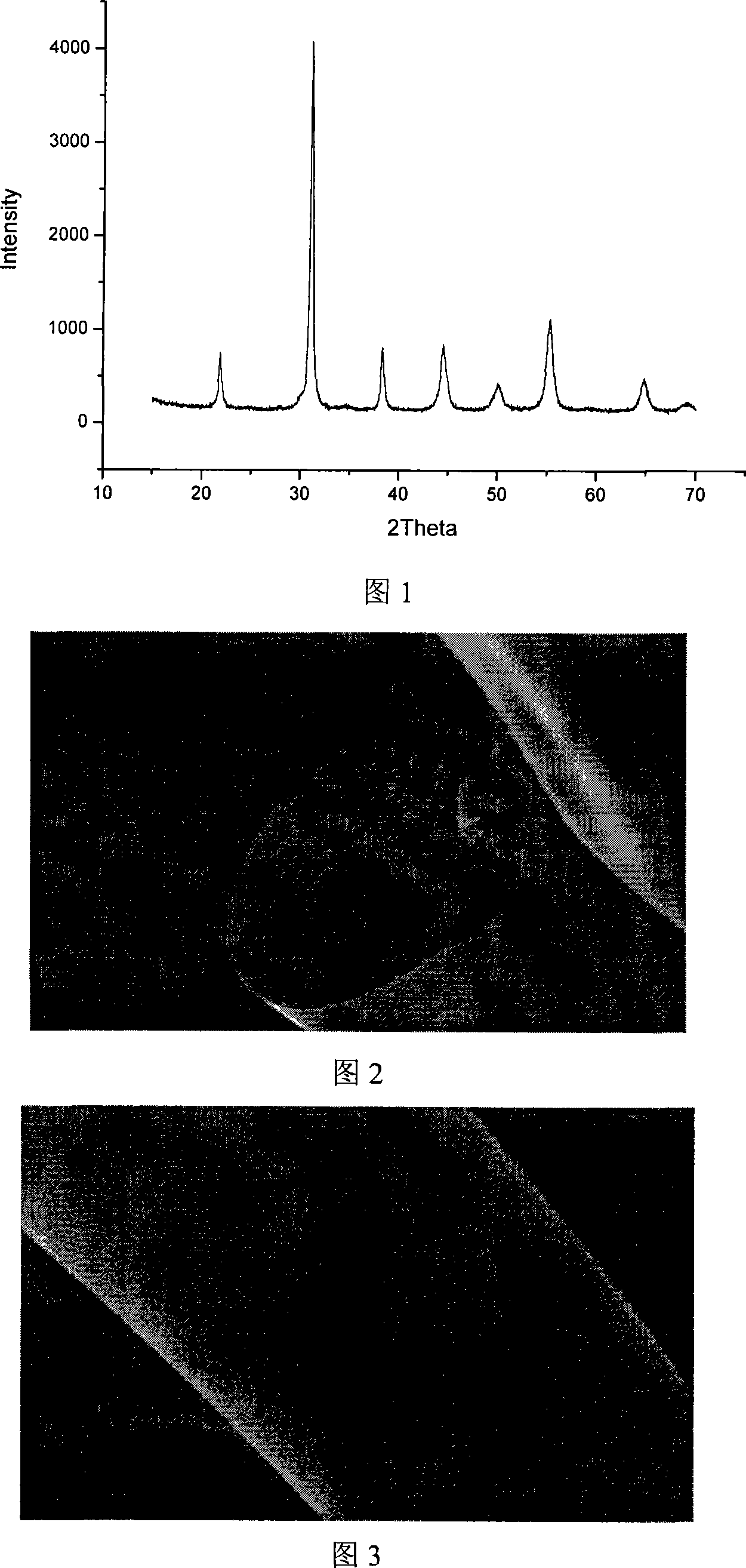

Embodiment 1

[0030] (1), 5.8018 grams of Pb (OOCH 3 ) 2 ·3H 2 O was added to 20ml of n-butanol, after shaking well, 12.85ml of glacial acetic acid was added, and the mixed solution was heated to 80°C until Pb(OOCH 3 ) 2 ·3H 2 O was completely dissolved to obtain a colorless clear solution, which was cooled to room temperature to obtain a lead source solution. Add 3.74ml of zirconium butoxide and 2.53ml of titanium butoxide into 20ml of n-butanol in sequence, stir magnetically for half an hour, add 3.09ml of acetylacetone, stir for half an hour, and then reflux the mixed solution at 75°C for one hour. After cooling, zirconium source and titanium source solutions are obtained. Mix the above-mentioned lead source solution with zirconium and titanium source solutions at room temperature, and then reflux at 120° C. for one hour. The obtained yellow transparent solution is the PZT precursor solution, and the pH value of the solution is 3.5-3.9.

[0031] (2) The precursor solution was magne...

Embodiment 2

[0034] Example 2: Same as Example 1, the difference is that when the sintering temperature is 900° C., the obtained PZT ceramic fiber surface has fine grains (<0.5 μm), and the surface is relatively smooth and flat.

Embodiment 3

[0035] Embodiment 3: Same as Embodiment 1, the difference is that when the sintering temperature is 1000° C., the obtained PZT ceramic fiber has surface grains smaller than 1 μm, and the surface is relatively rough.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com