Graphene/titanium composite material and preparation method thereof

A composite material and graphene technology, applied in the field of graphene/titanium composite materials and their preparation, can solve problems such as hindering the development of graphene composite materials, difficulty in uniformly dispersing graphene, and reducing the mechanical properties of materials, so as to improve mechanical properties, The effect of low resistivity and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

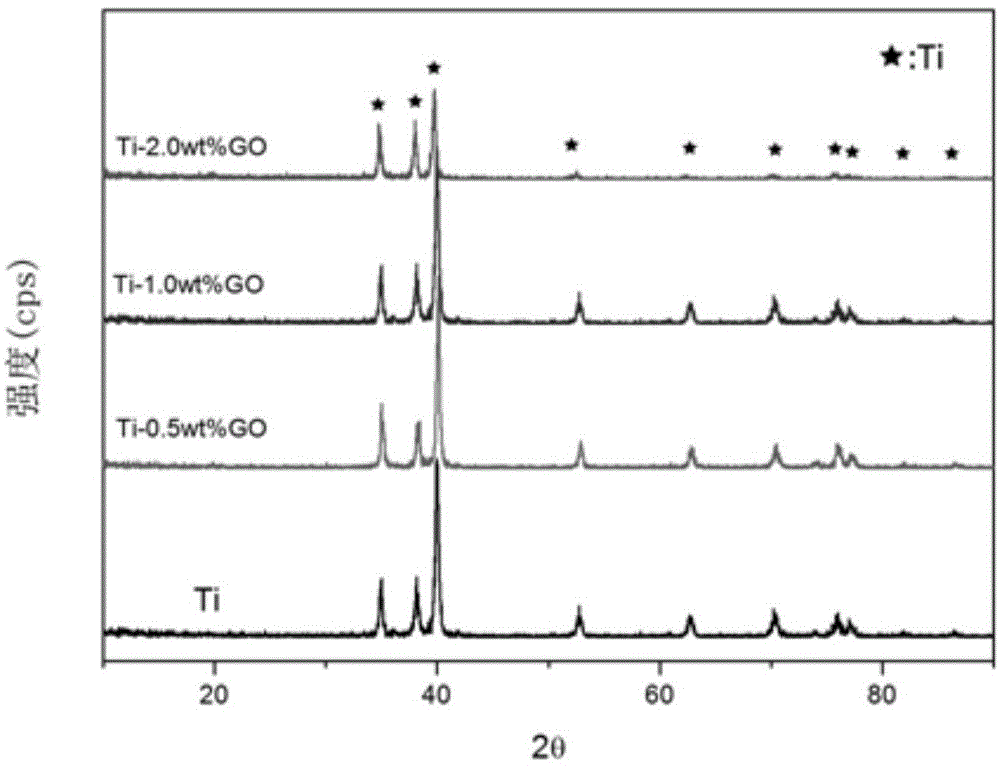

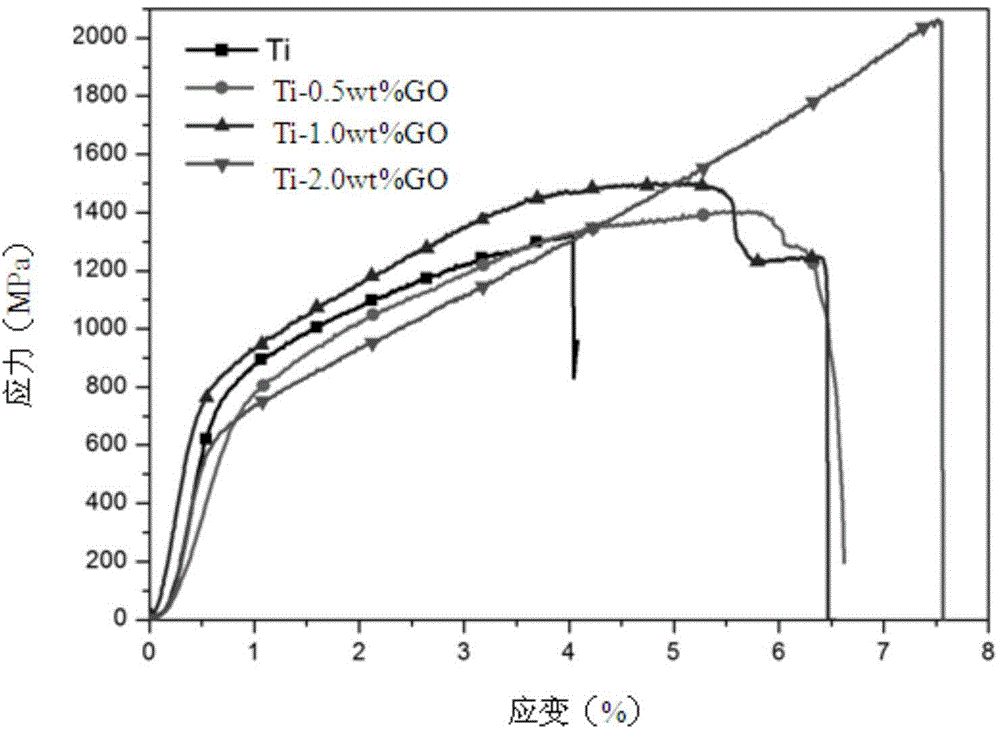

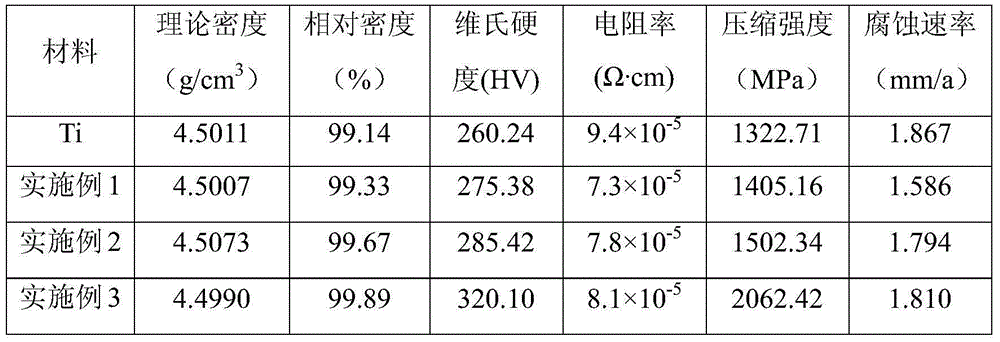

Embodiment 1

[0047] A kind of graphene / titanium composite material, its preparation method comprises the following steps:

[0048] 1) Weigh graphene oxide and deionized water with a solid-to-liquid ratio of 0.2mg:1ml, add graphene oxide to deionized water, and carry out ultrasonic dispersion for 20min (power is 150W), and the concentration of graphene oxide is 0.2mg / ml dark yellow clear solution.

[0049] 2) Mix hydrofluoric acid (40wt%), water and nitric acid (65wt%) at a ratio of 1ml:3ml:5ml, put titanium powder into it, ultrasonically vibrate for 1min, then place in water for ultrasonic vibration for 2min to remove titanium The oxide film on the surface of the powder is then vacuum-dried to obtain titanium powder with the oxide film removed from the surface.

[0050]3) Add the titanium powder for removing the surface oxide film to the graphene oxide weight ratio of 0.005:1 into the dark yellow clear solution obtained in step 1), and configure the graphene oxide / titanium mixed solution....

Embodiment 2

[0055] A kind of graphene / titanium composite material, its preparation method comprises the following steps:

[0056] 1) Take graphene oxide and deionized water with a solid-to-liquid ratio of 0.5mg:1ml, place graphene oxide in deionized water, and carry out ultrasonic dispersion for 30min (power is 150W), and the concentration of graphene oxide is 0.5mg / ml of a dark yellow clear solution.

[0057] 2) Mix hydrofluoric acid (40wt%), water and nitric acid (65wt%) at a ratio of 1ml:3ml:4ml, put titanium powder into it, vibrate ultrasonically for 2min, then vibrate ultrasonically with water for 1min, remove the surface of titanium powder oxide film, and then vacuum-dried to obtain titanium powder that removes the oxide film on the surface.

[0058] 3) Add the titanium powder for removing the surface oxide film to the graphene oxide weight ratio of 0.01:1 into the dark yellow clear solution obtained in step 1), and configure the graphene oxide / titanium mixed solution.

[0059] 4...

Embodiment 3

[0063] A kind of graphene / titanium composite material, its preparation method comprises the following steps:

[0064] 1) Weigh graphene oxide and deionized water with a solid-to-liquid ratio of 0.5mg:1ml, place graphene oxide in deionized water, and carry out ultrasonic dispersion for 30min (power is 150W) to obtain a concentration of graphene oxide of 0.5mg / ml dark yellow clear solution.

[0065] 2) Mix hydrofluoric acid (40wt%), water and nitric acid (65wt%) at a ratio of 1ml:4ml:4ml, put titanium powder into it, vibrate ultrasonically for 1min, then vibrate ultrasonically with water for 1min to remove the surface of titanium powder oxide film, and then vacuum-dried to obtain titanium powder that removes the oxide film on the surface.

[0066] 3) Add the titanium powder for removing the surface oxide film to the graphene oxide weight ratio of 0.02:1 into the dark yellow clear solution obtained in step 1), and configure the graphene oxide / titanium mixed solution.

[0067] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com