Patents

Literature

43results about How to "Sufficient corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel compound welding steel pipe and manufacturing method thereof

ActiveCN102889434AImprove corrosion resistanceImprove structural strengthRigid pipesStainless steel electrodeUltimate tensile strength

The invention discloses a stainless steel compound welding steel pipe and a manufacturing method thereof. The stainless steel compound welding steel pipe is formed by welding stainless steel compound hotly-rolled rolling plates through a welding line, wherein the welding line is formed by a stainless steel compound welding line and a carbon steel welding line. The manufacturing method comprises the following steps of: milling an edge and arranging a groove; when putting a stainless steel compound layer on the inner layer, firstly utilizing gas shield welding to weld a middle layer; then, utilizing a stainless steel welding strip to weld a stainless steel compound layer welding line in an argon arc welding manner; then, utilizing a carbon steel welding strip to weld the carbon steel welding line by a submerged-arc welding manner; when the stainless steel layer is less than 0.9 mm, directly welding a stainless steel welding line by submerged-arc welding; and when the stainless steel compound layer is located at the outer layer, firstly welding the carbon steel welding line by adopting the carbon steel welding strip and the submerged-arc welding, and adopting the stainless steel welding strip and the argon arc welding manner to weld the stainless steel compound layer welding line. According to the stainless steel compound welding steel pipe and the manufacturing method thereof, the manufactured stainless steel compound welding steel pipe has high structural strength and strong corrosion resistance; and the bonding strength of an inner pipe and an outer pipe is not less than 200 MPa.

Owner:ZHEJIANG KINGLAND & PIPELINE TECH

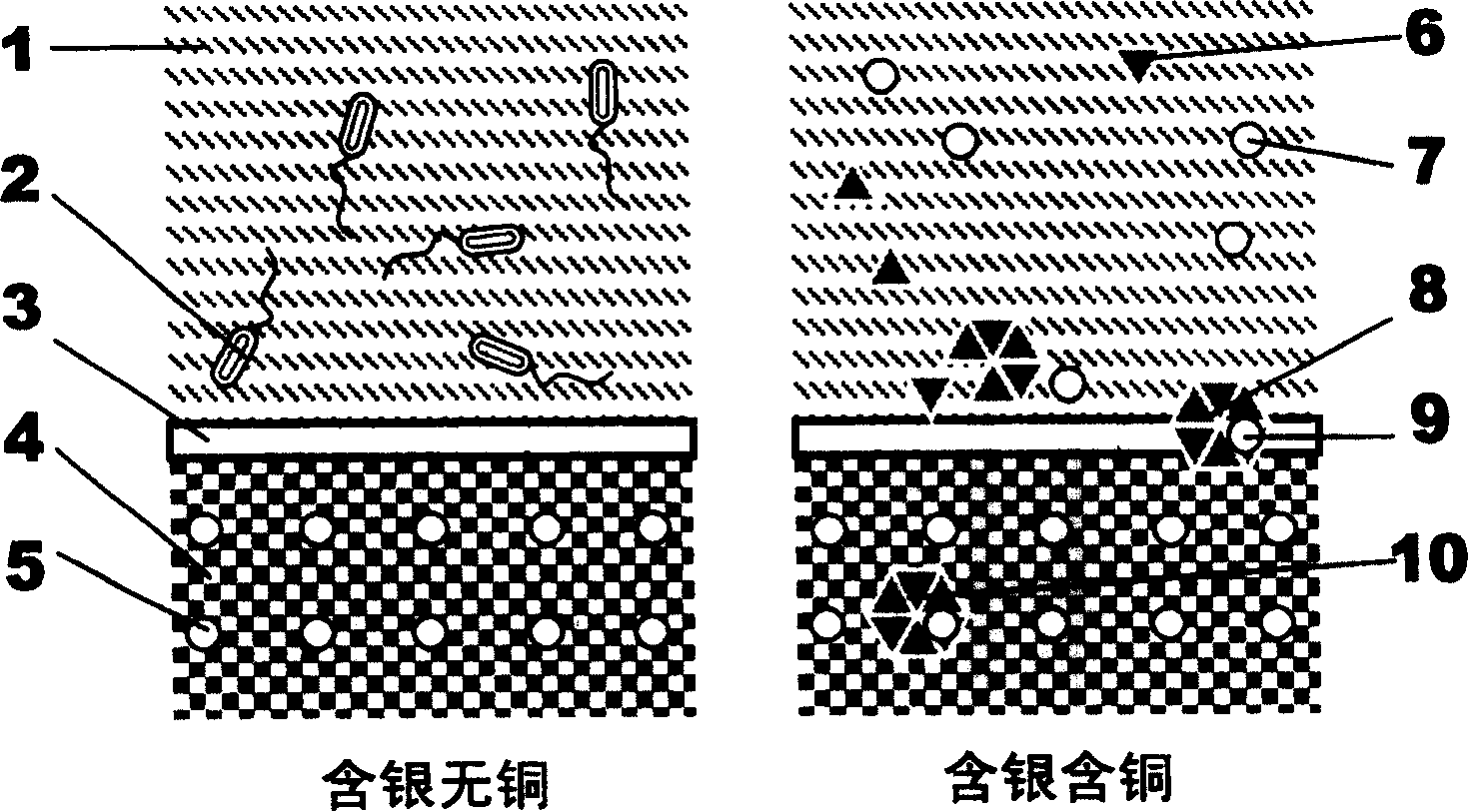

Antibacterial austenitic stainless steel

ActiveCN1664154APrevent chromium depletionGuaranteed anti-corrosion performanceChemical compositionKitchen utensils

The invention relates to a sort of austenitic antibiotic stainless steel, characterized in that it saves the nickel and chromium. The percentage by weight of its chemical composition is: C: 0.03-0.15, Cr: 11-15, Ni: 1.0-3.5, Mn: 7.0-15.0, N: 0.06-0.3, Cu: 1.0-3.0, Ag: 0.01-0.1, Nb: 0-0.10, S<=0.02, P<=0.03, Si: 0.1-1, the balance is Fe. Said invention uses cuprum as the carrier and makes the silver crossing the passivating film, which improves the antibiotic ability through the coupulation of the cuprum and silver, and fills manganese, carbon, columbium to ensure the steel has enough corrosion resistance and austenite tissue. The invention can be used for making water supply pipes, kitchen utensils, medical equipments, architectural electric appliances and so on.

Owner:YONGXING SPECIAL STAINLESS STEEL

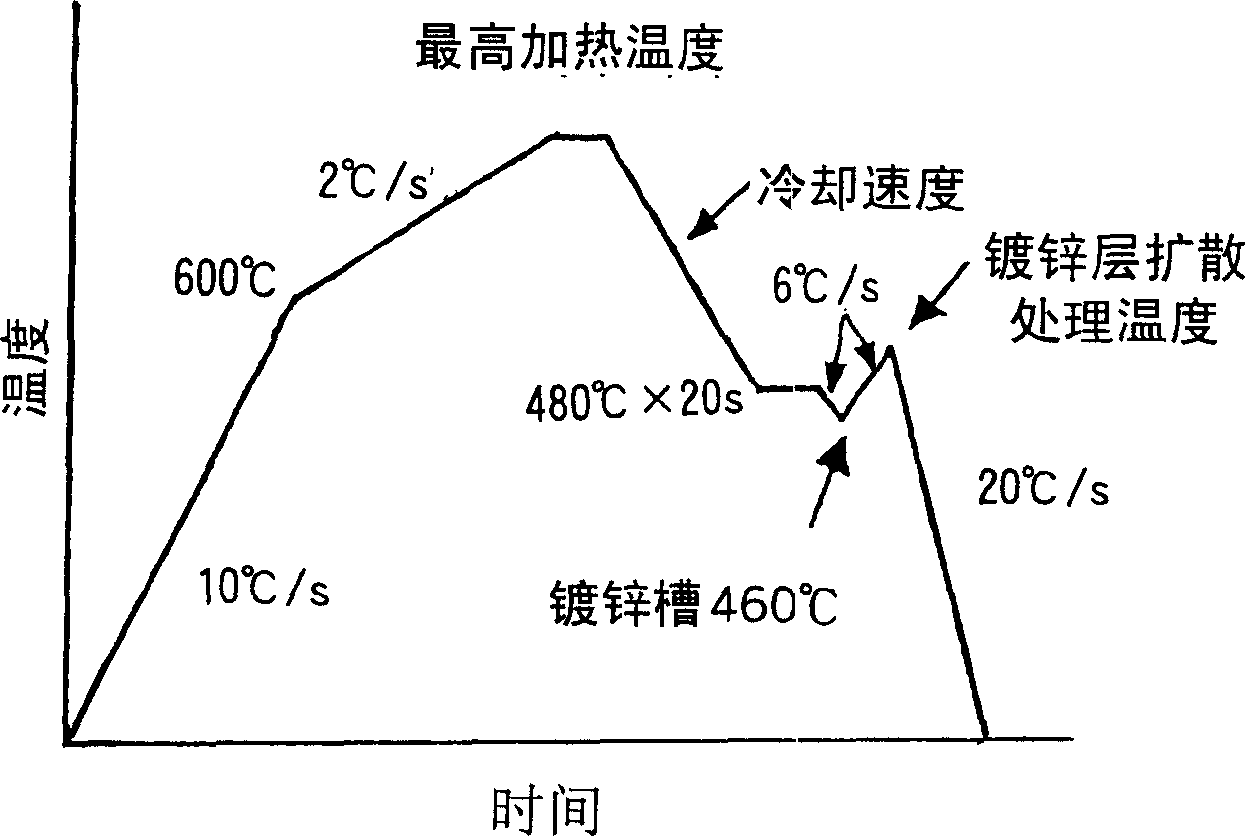

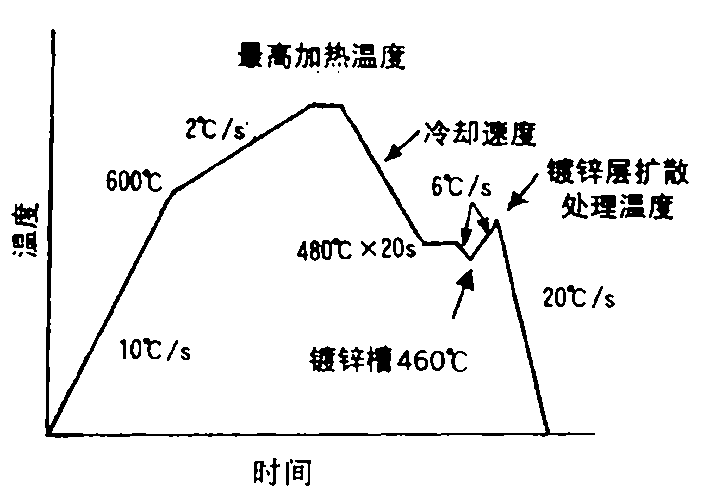

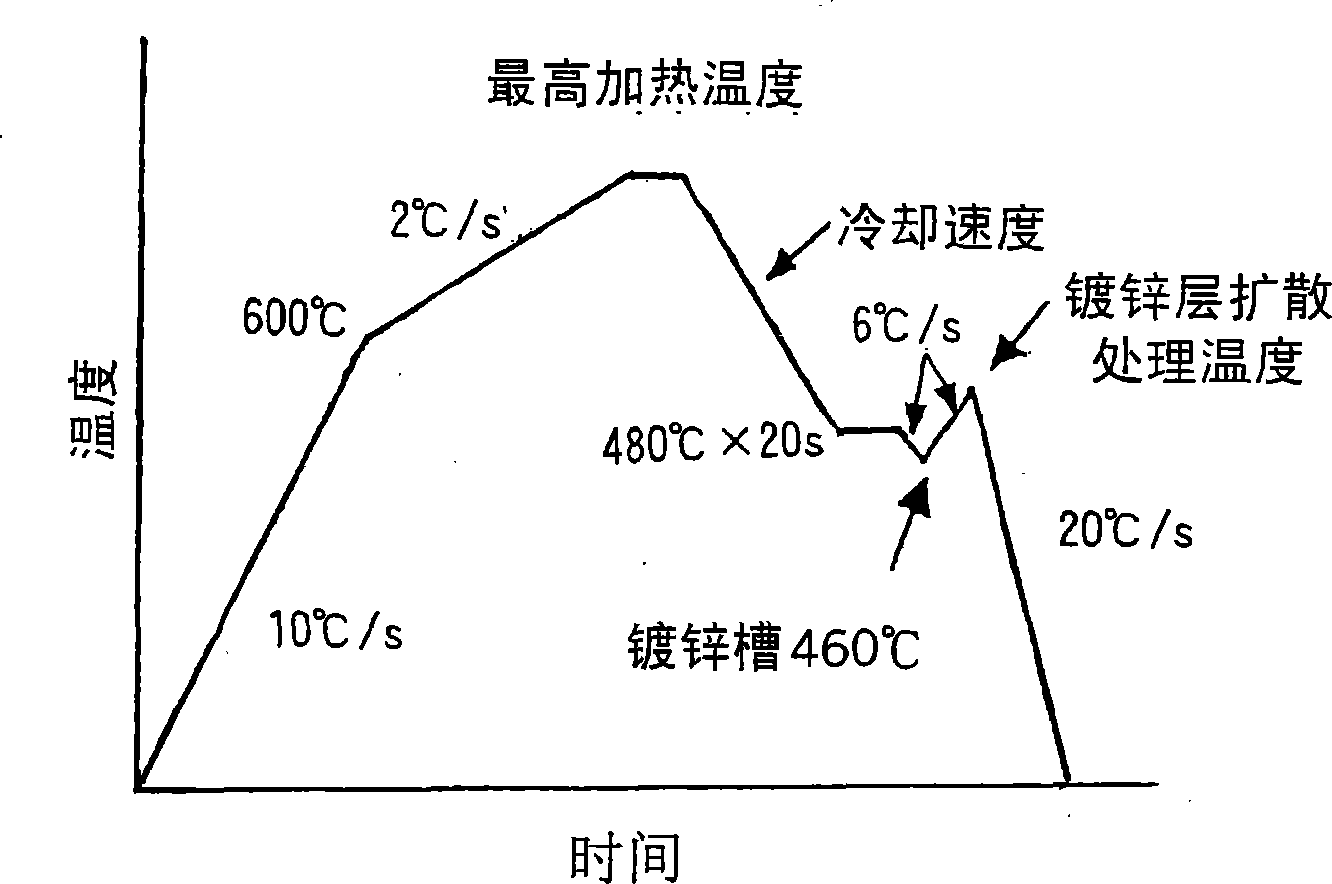

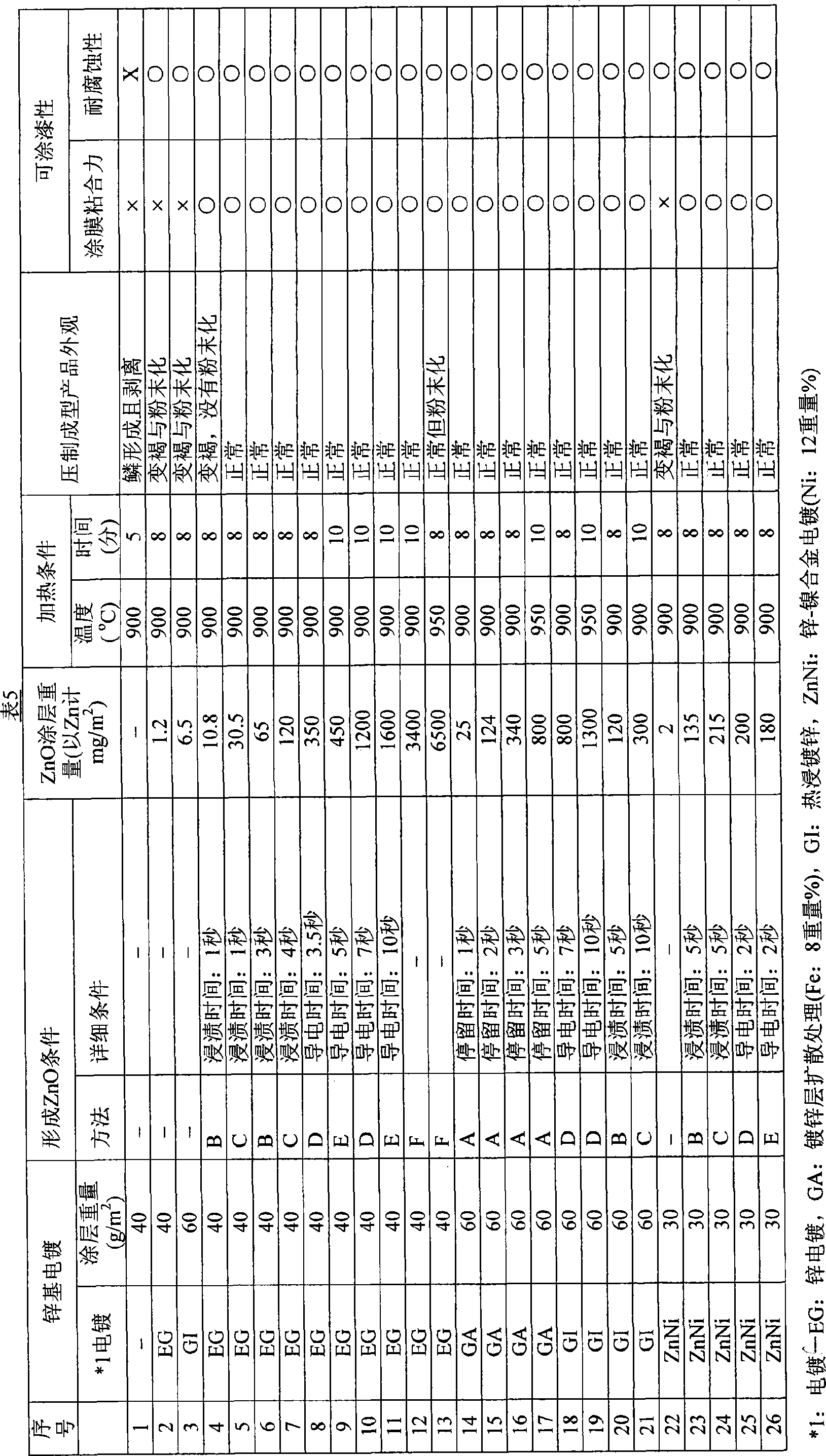

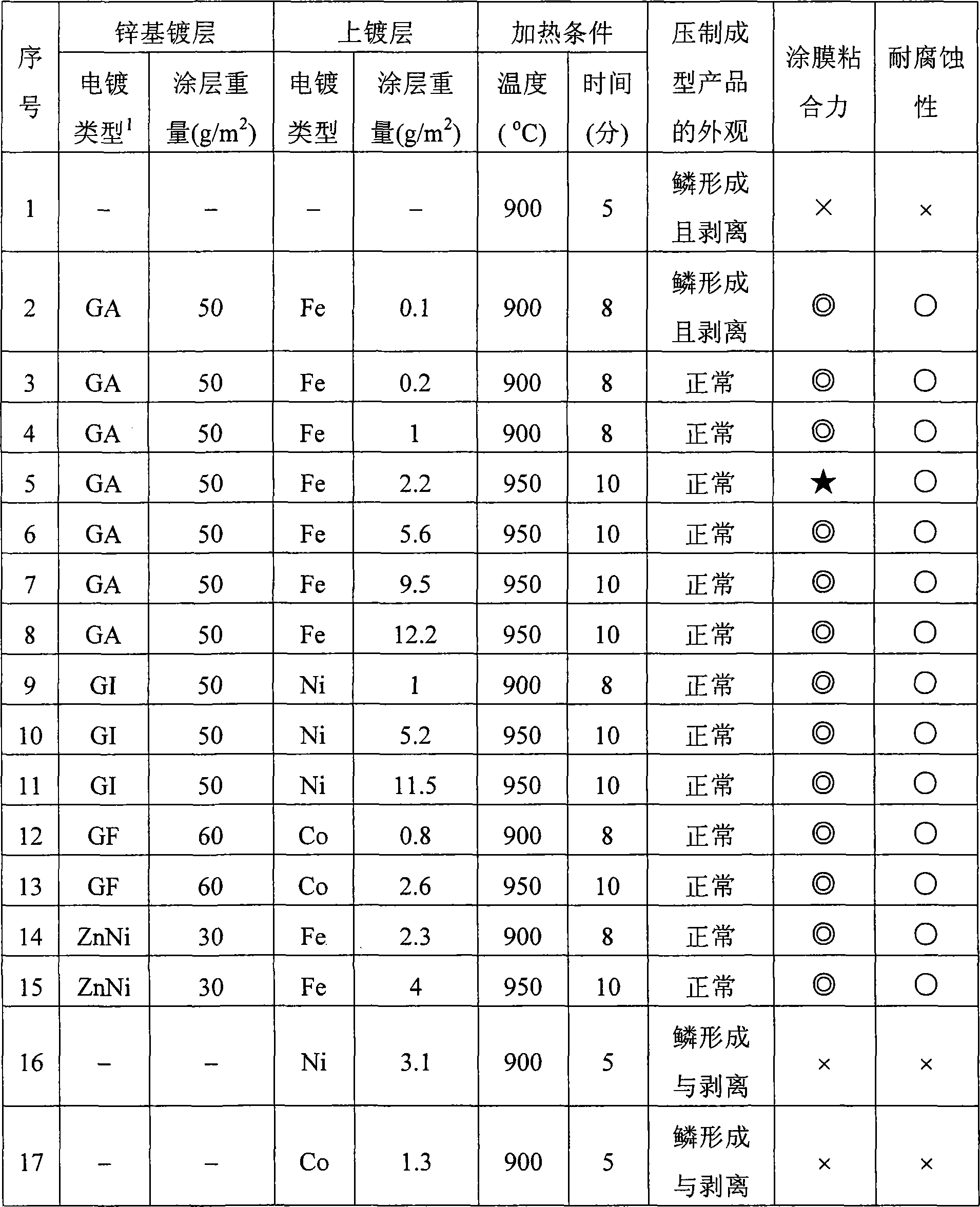

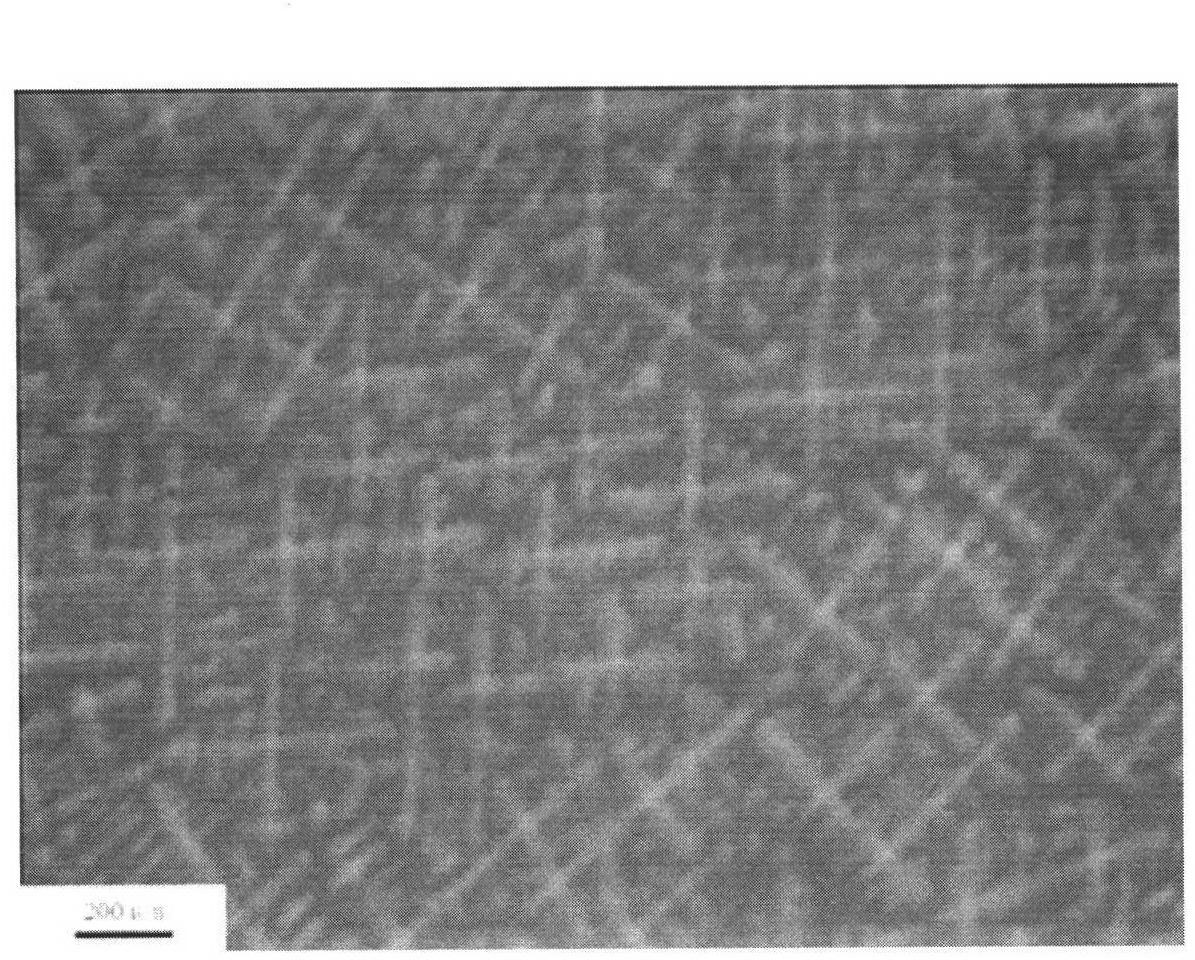

Hot press forming method, and a plated steel material therefor and its manufacturing method

InactiveCN1575348ASufficient corrosion resistanceGuaranteed corrosion resistanceHot-dipping/immersion processesAnodisationElectrolysisSheet steel

Hot press forming of a steel material is made possible by coating the surface of the steel material with a plated layer of zinc or a zinc alloy and forming thereon a barrier layer which prevents the vaporization of zinc even when heated to 700 - 1000 DEG C. Corrosion resistance can also be guaranteed without requiring post treatment, and hot press forming of high tensile steel sheet and stainless steel sheet is made possible. The barrier layer is formed by forming an upper plated layer, by surface oxidation, by contact with an oxidizing agent, by contact with Zn and an oxidizing agent, by anodic electrolysis, by cathodic electrolysis, or by coating with a ZnO sol.

Owner:NIPPON STEEL CORP

Composite surface protecting method for neodymium-iron-boron magnet

ActiveCN102368438AImprove corrosion resistanceExtended service lifeLiquid/solution decomposition chemical coatingInductances/transformers/magnets manufactureSalt spray testBoron

The invention discloses a composite surface protecting method for a neodymium-iron-boron magnet, comprising the following steps of: pretreating a neodymium-iron-boron magnet, electroplating or phosphating the pretreated neodymium-iron-boron magnet, spraying a corrosion-resistant coating on the surface of the electroplated neodymium-iron-boron magnet, pre-curing the sprayed neodymium-iron-boron magnet, curing the pre-cured neodymium-iron-boron magnet and performing vapour phase deposition on the cured neodymium-iron-boron magnet. The composite surface protecting method for the neodymium-iron-boron magnet has the following advantages that: the combining stability between the plating and the neodymium-iron-boron magnet and the corrosion-resistant property of the plating are improved by meansof the corrosion-resistant coating; the electroplating treatment and the spraying treatment are further enhanced by the vapour phase deposition; meanwhile, a circular hole structure of the neodymium-iron-boron magnet is further plated so that the integrated plating on the surface of the neodymium-iron-boron magnet is uniform; and the endurance time of the neutral salt spray test of the compoundedneodymium-iron-boron magnet can reach more than 300 hours.

Owner:NINGBO YUNSHENG HIGH TECH MAGNETICS +2

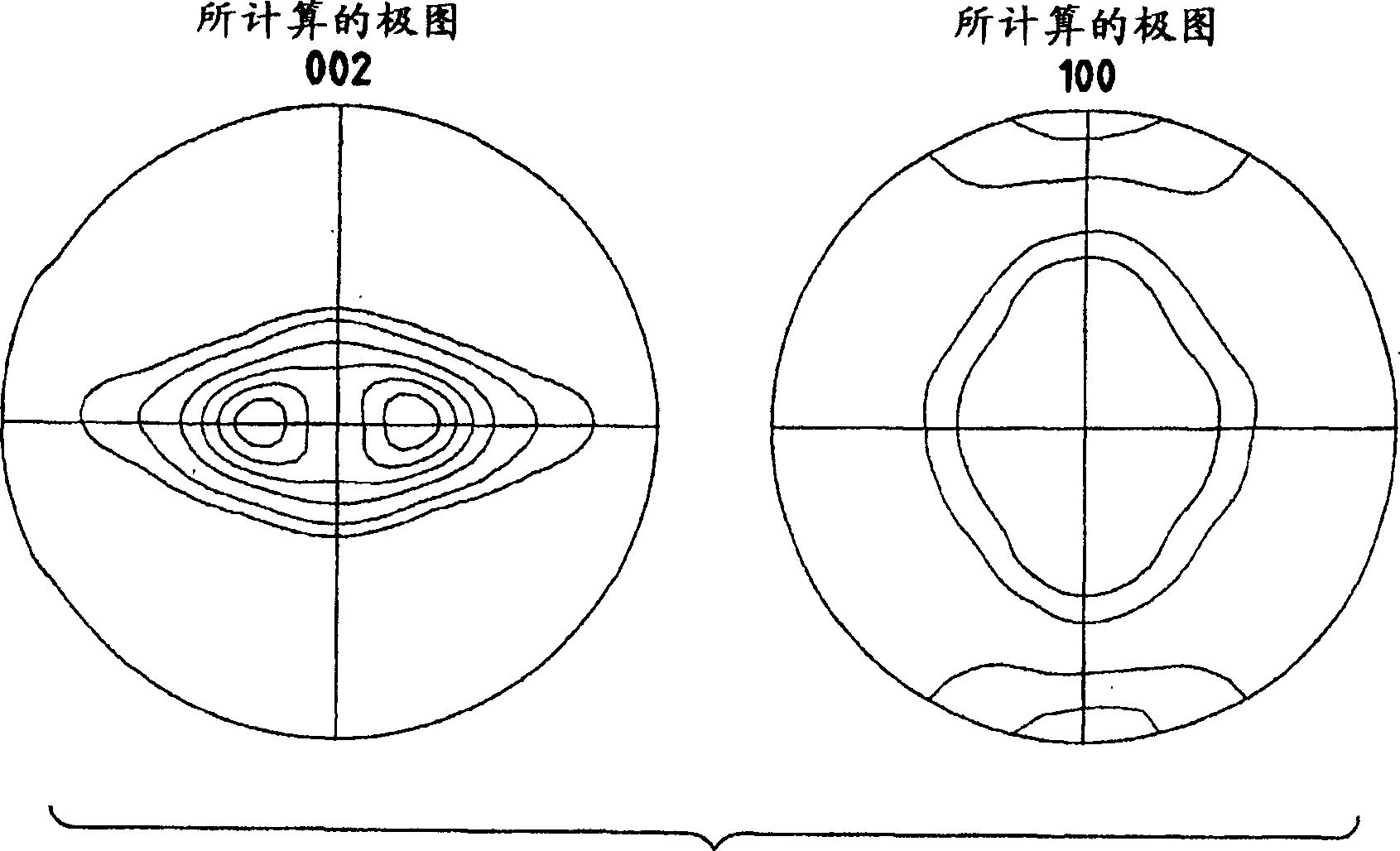

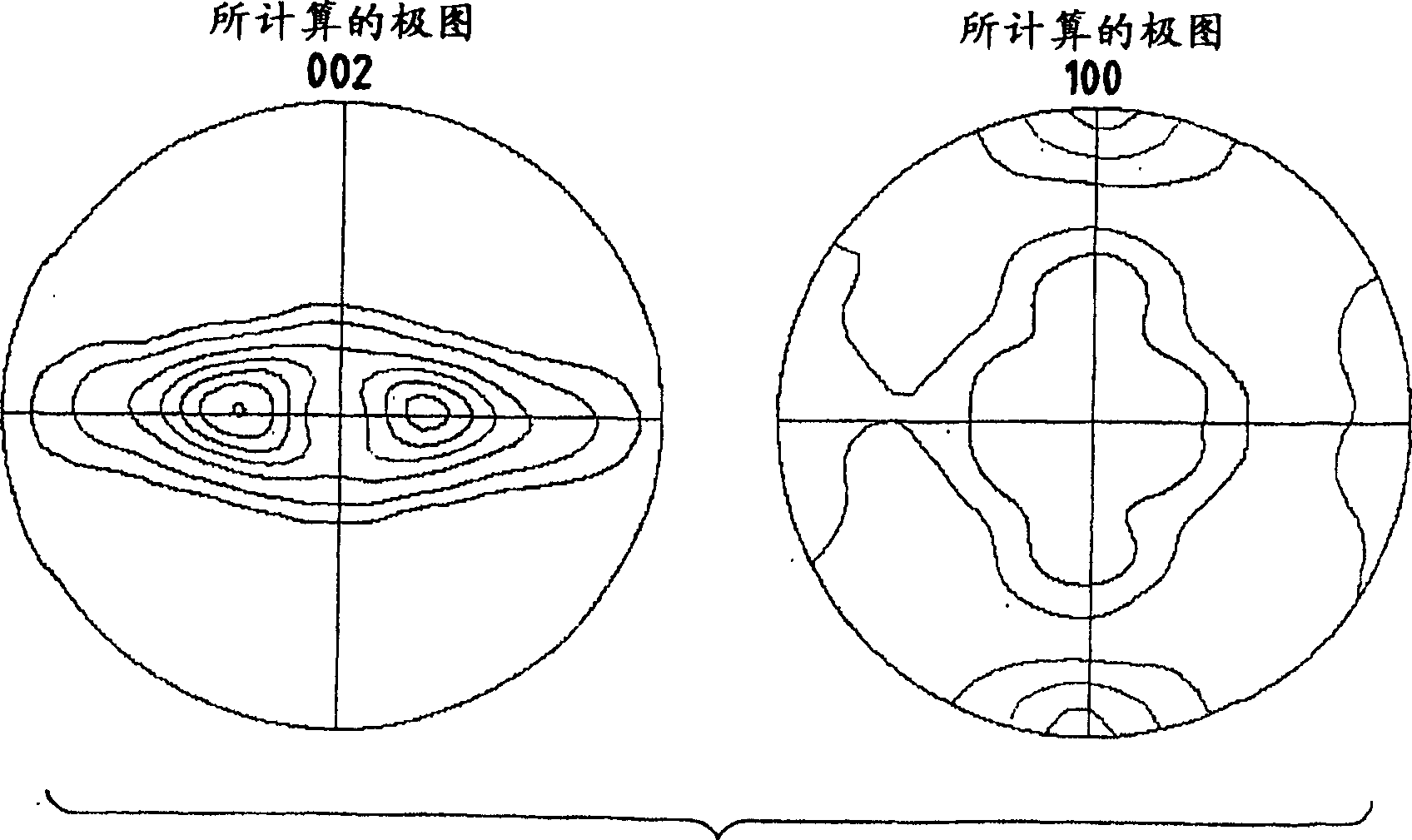

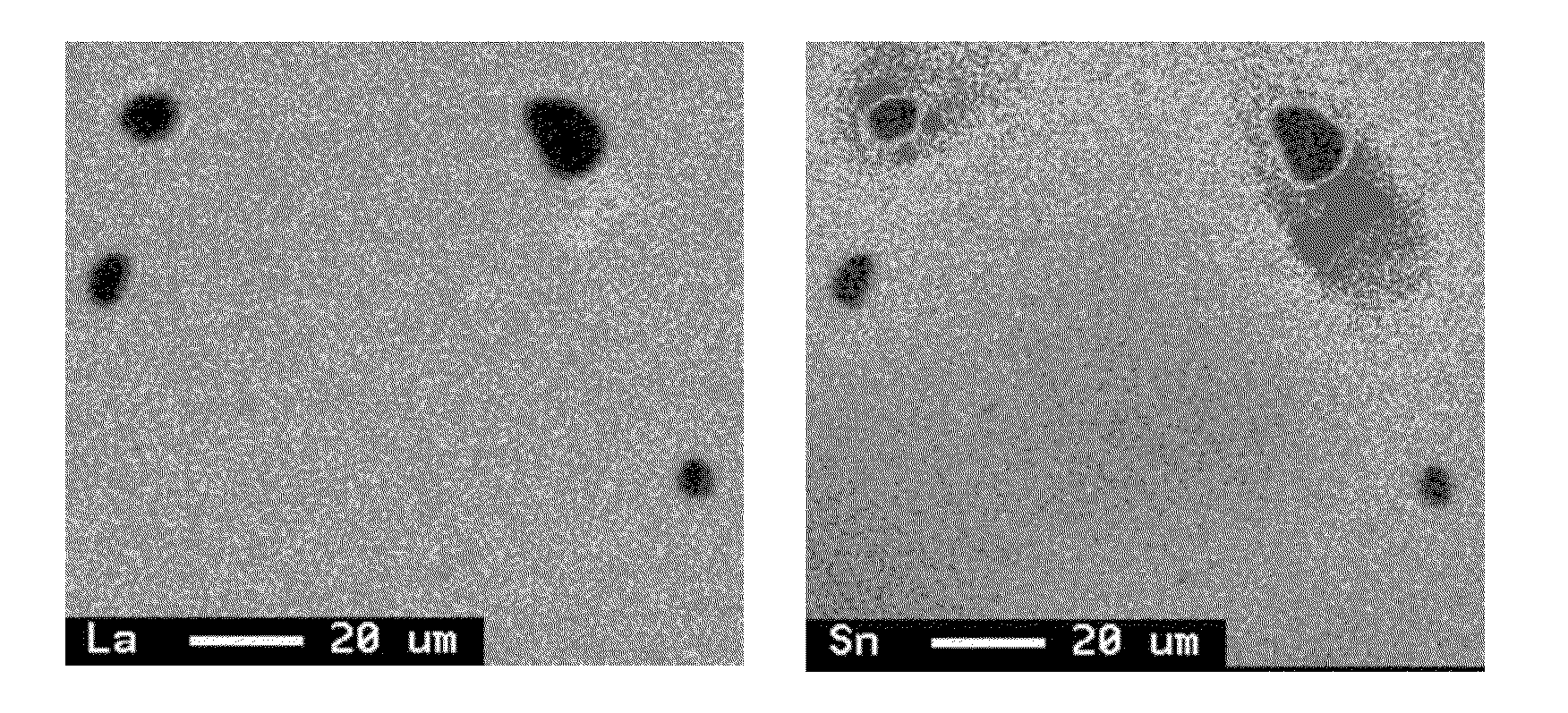

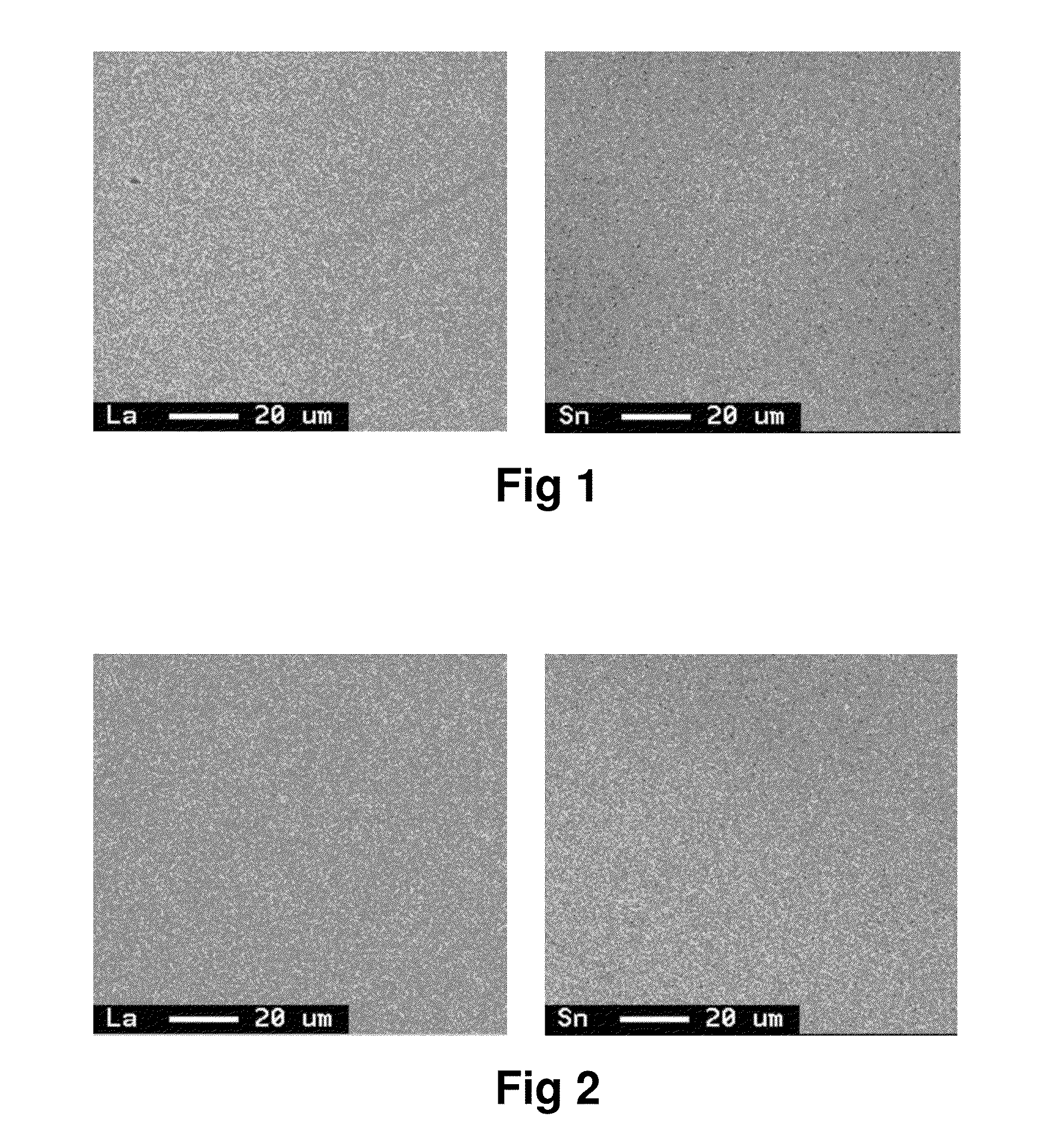

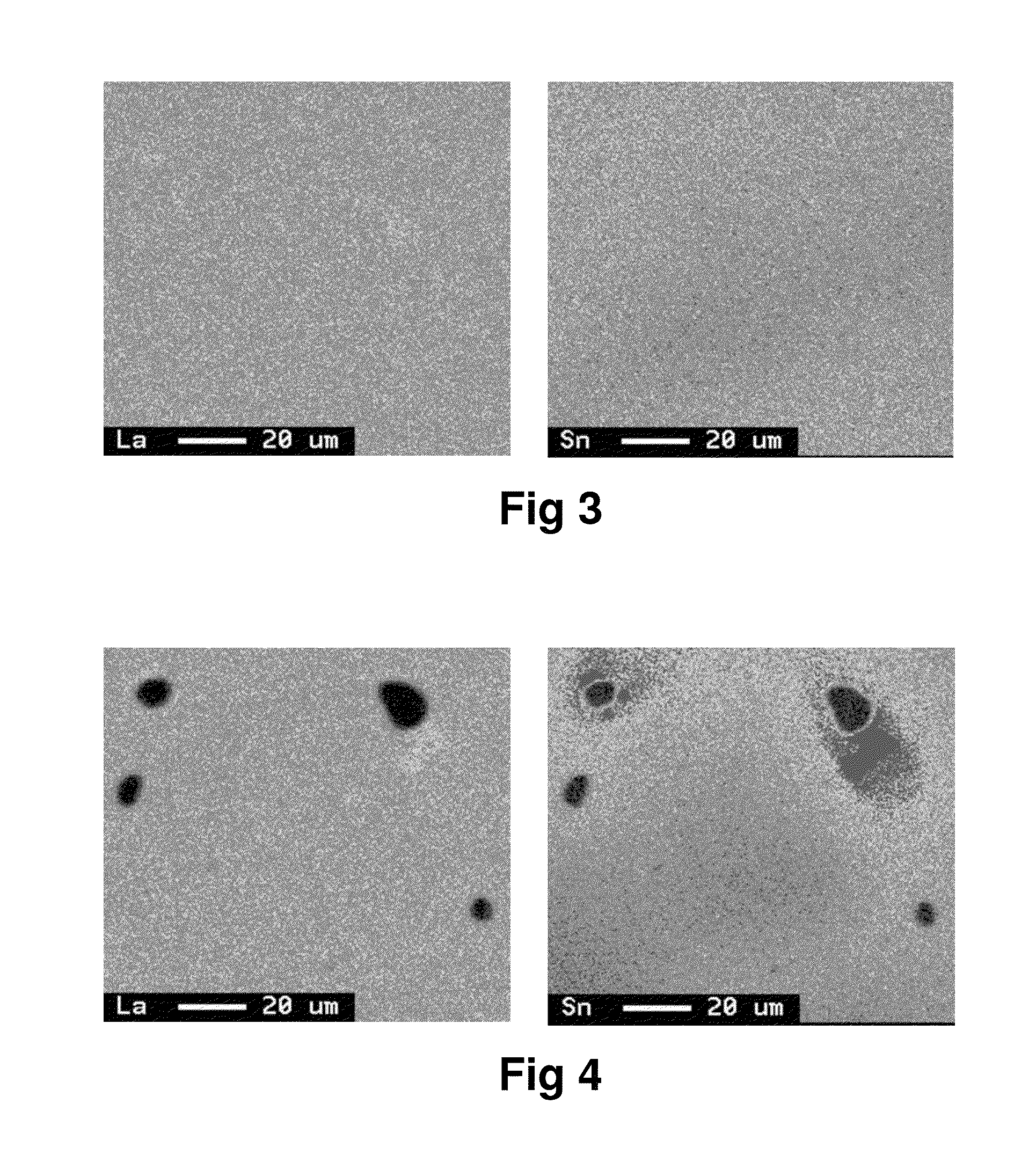

Method of producing a flat zirconium alloy product, flat product thus obtained and a nuclear plant reactor grid which is made from said flat product

InactiveCN1871371AAddressing issues related to radiation-induced growthSufficient corrosion resistanceOptical rangefindersNuclear energy generationNuclear plantIngot

The invention relates to a method of producing a flat zirconium alloy product with a Kearns factor (cross direction) of between 0.3 and 0.7. The inventive method consists in: producing an ingot containing Nb = 0.5 to 3.5 %, Sn = 0 to 1.5 %, Fe = 0 to 0.5 %, Cr + V = 0 to 0.3 %, S = 0 to 100ppm, O = 0 to 2000ppm, Si = 0 to 150ppm, the remainder being zirconium and impurities; shaping the aforementioned ingot; performing one or more hot rolling operations in order to obtain a flat product, whereby the last operation is performed at between (810-20xNb%) DEG C and 1100 DEG C and is not followed by any quenching from phase alpha + beta or beta ; optionally performing an annealing operation at a maximum of 800 DEG C; and performing one or more cold rolling and annealing operations, said annealing operations being performed at a maximum of 800 DEG C. The invention also relates to the flat zirconium alloy product thus obtained. The invention further relates to a support grid for fuel rods in a nuclear plant reactor, which is obtained by shaping the flat product.

Owner:CO EURO ZIRCONIUM ZIRCONIUM CEZUS

Hot press forming method, electroplating steel products thereof and preparation method for the same

InactiveCN101144162ASufficient corrosion resistanceGuaranteed corrosion resistanceHot-dipping/immersion processesAnodisationElectrolysisSheet steel

Hot press forming of a steel material is made possible by coating the surface of the steel material with a plated layer of zinc or a zinc alloy and forming thereon a barrier layer which prevents the vaporization of zinc even when heated to 700-1000 DEG C. Corrosion resistance can also be guaranteed without requiring post treatment, and hot press forming of high tensile steel sheet and stainless steel sheet is made possible. The barrier layer is formed by forming an upper plated layer, by surface oxidation, by contact with an oxidizing agent, by contact with Zn and an oxidizing agent, by anodic electrolysis, by cathodic electrolysis, or by coating with a ZnO sol.

Owner:NIPPON STEEL CORP

Austenite corrosion-resisting nickel-based casting alloy and manufacturing process thereof

InactiveCN102628126APerformance is not affectedSufficient corrosion resistanceElectric arc furnaceNiobium

The invention provides an austenite corrosion-resisting nickel-based casting alloy and a manufacturing process thereof, belonging to the technical field of material engineering. The austenite corrosion-resisting nickel-based casting alloy is composed of the chemical components in mass percentage: less than 0.080% of carbon (C), 21.0-25.0% of chromium (Cr), 8.0-10.0% of cobalt (Co), 5.0-8.0% of molybdenum (Mo), less than 4.0% of iron (Fe), 3.0-4.5% of niobium (Nb), less than 0.6% of silicon (Si), less than 0.6% of manganese (Mn), 0.2-0.5% of titanium (Ti), 0.2-0.5% of aluminum (Al), less than 0.015% of phosphorus (P), less than 0.015% of sulfur (S) and residual amount of nickel (Ni) and unavoidable impurity elements. The austenite corrosion-resisting nickel-based casting alloy is formed by the steps of: smelting in a non-vacuum electric arc furnace, refining by an argon oxygen decarburizing furnace and an LF (Ladle Furnace) steel ladle argon blowing refining process, and directing casting and molding under the protection of argon gas.

Owner:丹阳恒庆复合材料科技有限公司

Electroplating and spraying composite protection method of neodymium iron boron magnet

InactiveCN102383156AImprove corrosion resistanceOvercoming porosity defectsLiquid surface applicatorsInductances/transformers/magnets manufactureSalt spray testElectroplating

The invention discloses an electroplating and spraying composite protection method of a neodymium iron boron magnet, which comprises the following steps of: pretreatment of a neodymium iron boron magnet, electroplating treatment of the pretreated neodymium iron boron magnet, surface spraying of a corrosion-resistant coating on the electroplated neodymium iron boron magnet, procuring of the sprayed neodymium iron boron magnet, and curing of the procured neodymium iron boron magnet; the advantages are that the corrosion-resistant coating overcomes the pore defects of the electroplated layer; a new protective layer is formed outside the electroplated layer; dual protection of the neodymium iron boron magnet is formed by the corrosion-resistant coating and the electroplated layer; the corrosion resistance of the neodymium iron boron magnet is improved; compared with a neodymium iron boron magnet which is only treated by electroplating, the neodymium iron boron magnet which is compositely protected by electroplating and corrosion-resistant coating spraying has tolerance time in a neutral salt spray test that is increased by 2-6 times, long service life, high running reliability, and wide application fields.

Owner:NINGBO YUNSHENG HIGH TECH MAGNETICS +2

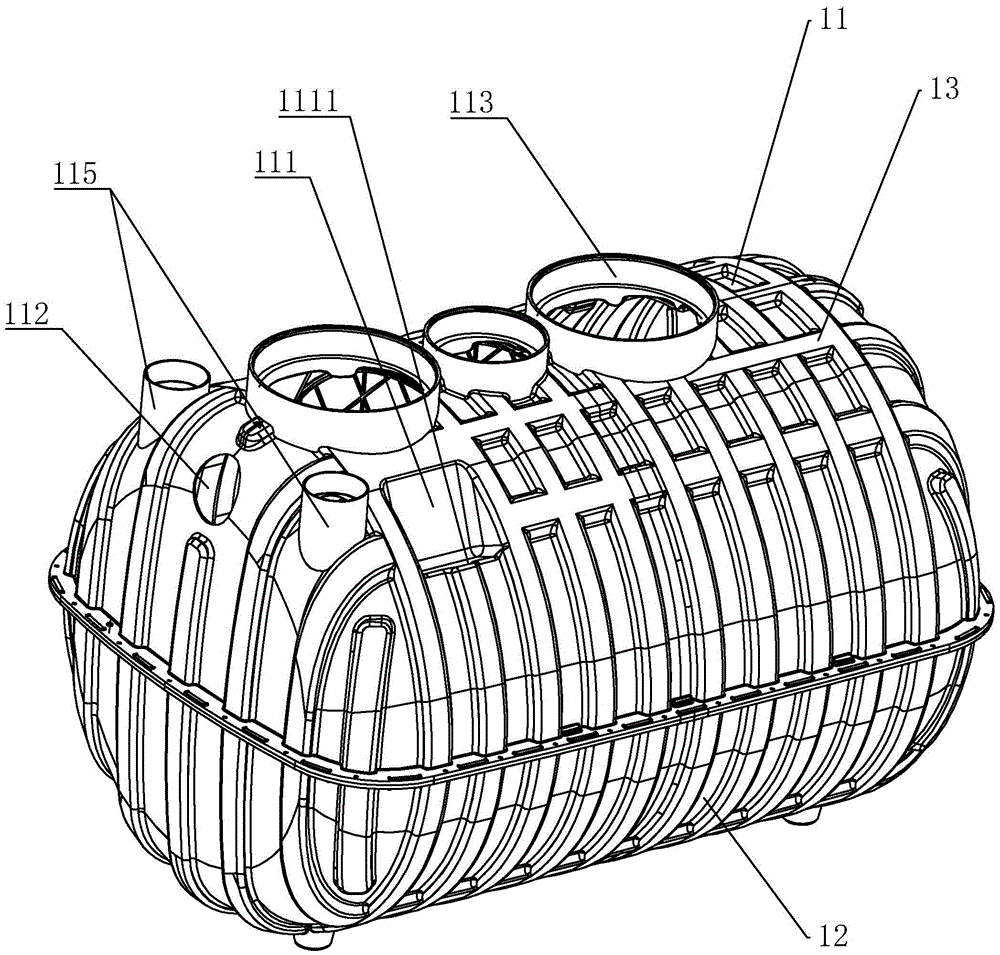

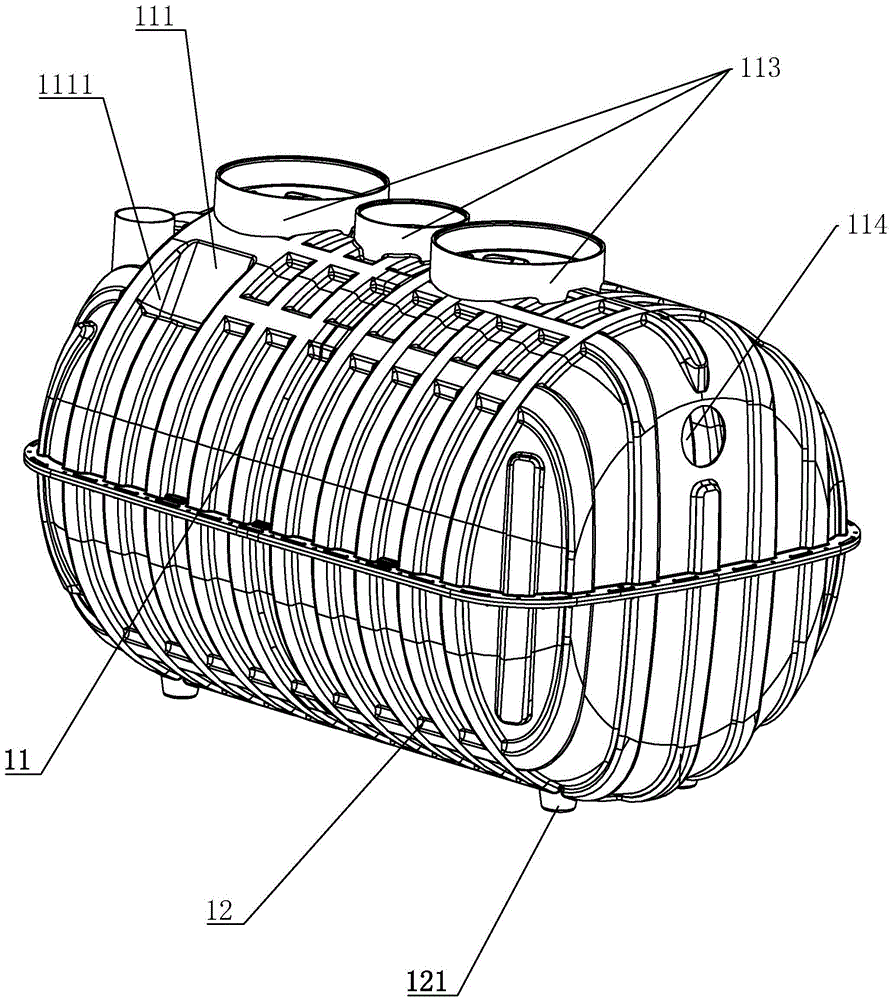

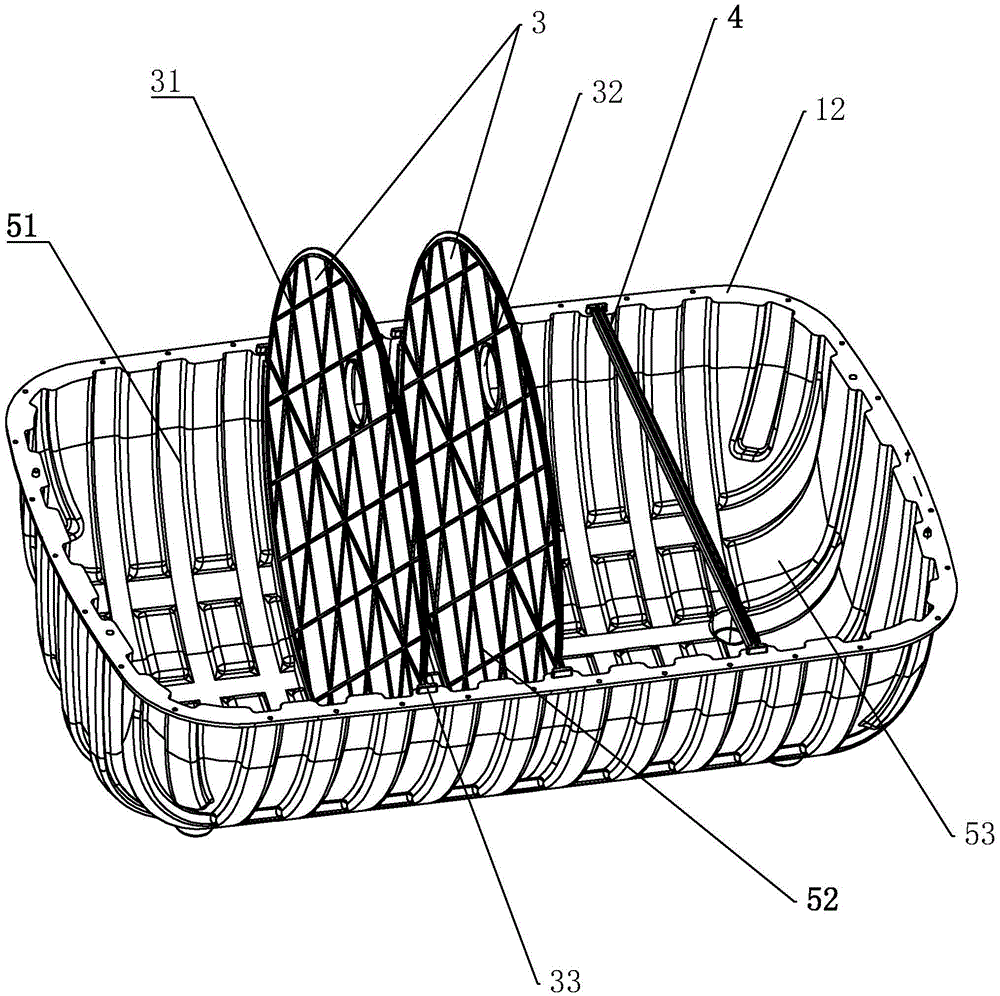

Three-cavity septic tank

InactiveCN105541069AEasy to connect and layRaise the ratioBiological sludge treatmentBiochemical engineeringButt joint

The invention discloses a three-cavity septic tank. According to the technical scheme, the three-cavity septic tank is characterized by mainly comprising a tank main body, the tank main body comprises an upper tank body and a lower tank body which can in butt joint with each other, the upper tank body and the lower tank body are both made of plastic through integral injection molding, two partition boards are arranged in the tank main body, the partition boards separates internal space defined by the upper tank body and the lower tank body into a first cavity, a second cavity and a third cavity which can allow water flow to sequentially pass through, main sewage inlets allowing sewage to enter are formed in the two sides of the upper tank body, the main sewage inlets communicate the first cavity with the outside, and each main sewage inlet is internally provided with a flange facilitating pipe placement. By means of the upper tank body and the lower tank body which are of plastic structures, cost of the whole septic tank can be greatly saved, the septic tank is convenient to process and can be produced in batches, and sufficient corrosion resistance is achieved. In practical application, openings can be formed in the side faces at multiple angles conveniently, and pipeline connection and laying are facilitated.

Owner:SHANDONG WENYUAN BUILDING MATERIALS TECH

Prefabticated member for coal nozzle of cement kiln and preparation method thereof

InactiveCN102617160ACompact structureSmall coefficient of thermal expansionPulverulent fuel combustion burnersCarbide siliconCarboxylic acid

The invention relates to a prefabticated member for a coal nozzle of a cement kiln and a preparation method thereof. The prefabticated member is prepared from the following raw materials in percentage by weight: 55 to 70 percent of plate type corundum particle, 5 to 10 percent of silicon carbide particle, 5 to 8 percent of corundum fine powder, 5 to 10 percent of alpha-Al2O3 micro powder, 8 to 15 percent of pure calcium aluminate cement, 3 to 5 percent of silicon carbide fine powder, 2 to 4 percent of simple substance silicon powder, 1 to 2 percent of stainless steel fiber and 0.1 to 0.2 percent of polycarboxylate water reducing agent. The preparation method comprises the following steps of: mixing the corundum fine powder, the alpha-Al2O3 micro powder, the pure calcium aluminate cement, the silicon carbide fine powder, the simple substance silicon powder, the stainless steel fiber and the polycarboxylate water reducing agent; mixing the plate type corundum particle and the silicon carbide particle, and mixing together; adding 5-6wt% of water, uniformly mixing, forming and drying; and raising the temperature to 1,200-1,500 DEG C, and performing heat preservation for 2 to 4 hours. The process is simple; the intensity of a product is high; the thermal shock stability is high; the erosion resistance is excellent; and the abrasion resistance is good.

Owner:WUHAN UNIV OF SCI & TECH

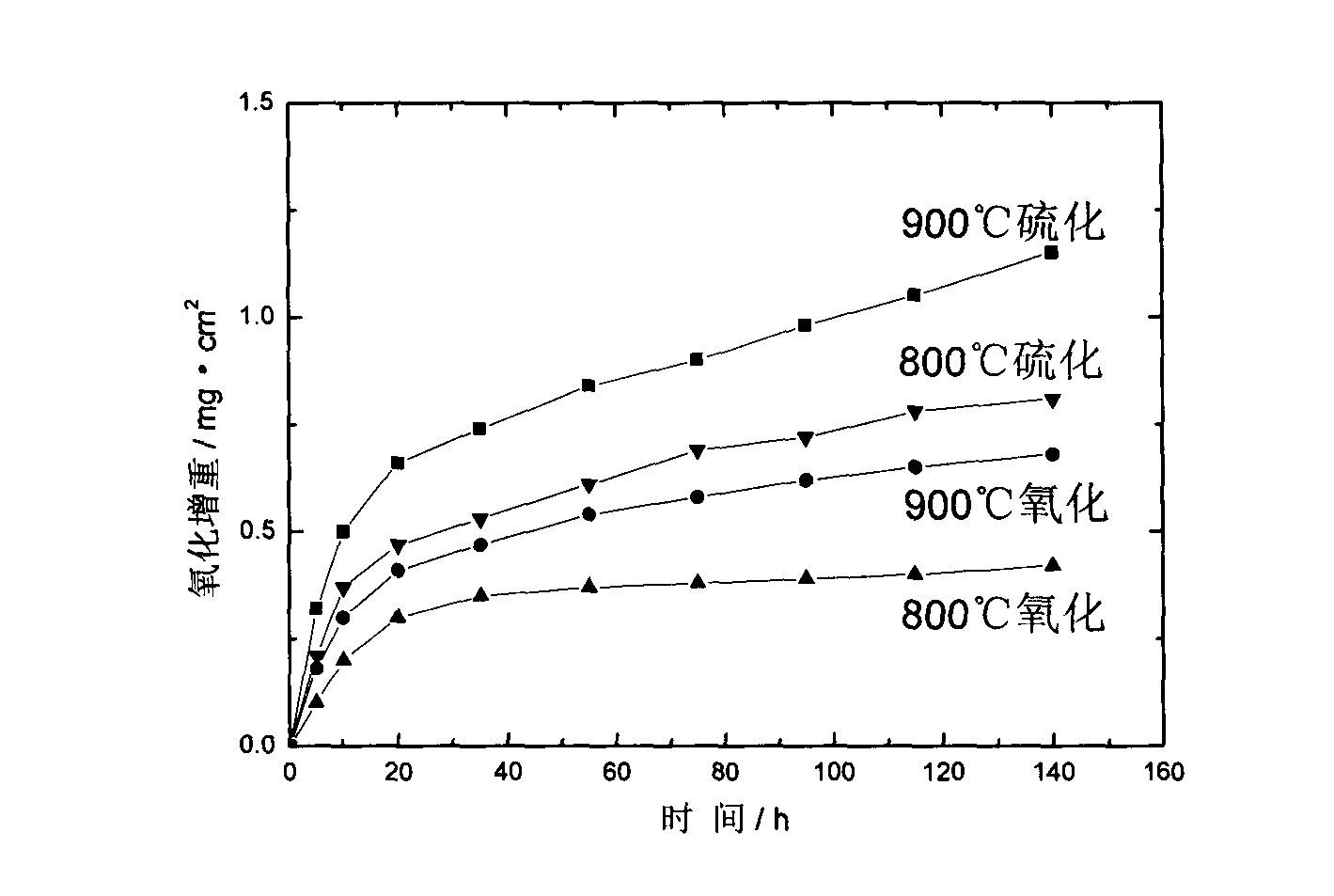

Method for preparing protective coating material of boiler tube

The invention discloses a method for preparing a protective coating material of a boiler tube. The coating material consists of the following components in percentage by weight: 12 to 14 percent of Cr, 0.4 to 0.6 percent of Mn, 2 to 3 percent of Ti, 3 to 5 percent of Al, 2 to 4 percent of Si, 1 to 2 percent of Nb, 8 to 12 percent of Fe, 1 to 3 percent of Co, 3 to 5 percent of Mo, less than or equal to 0.025 percent of S, less than or equal to 0.035 percent of P and the balance of Ni. The method for preparing the protective coating material comprises the following steps of: 1) smelting waste steel, intermediate alloy and nickel ingots according to the components and refining to prepare coating material alloy ingots; 2) placing the prepared alloy ingots in a crucible for prepare powder through atomization, heating and melting, and atomizing to prepare powder by taking helium as atomization gas; and 3) screening the prepared atomization powder to obtain the coating powder with the diameter of -200 meshes.

Owner:NINGBO SUNLIGHT MOTOR PARTS

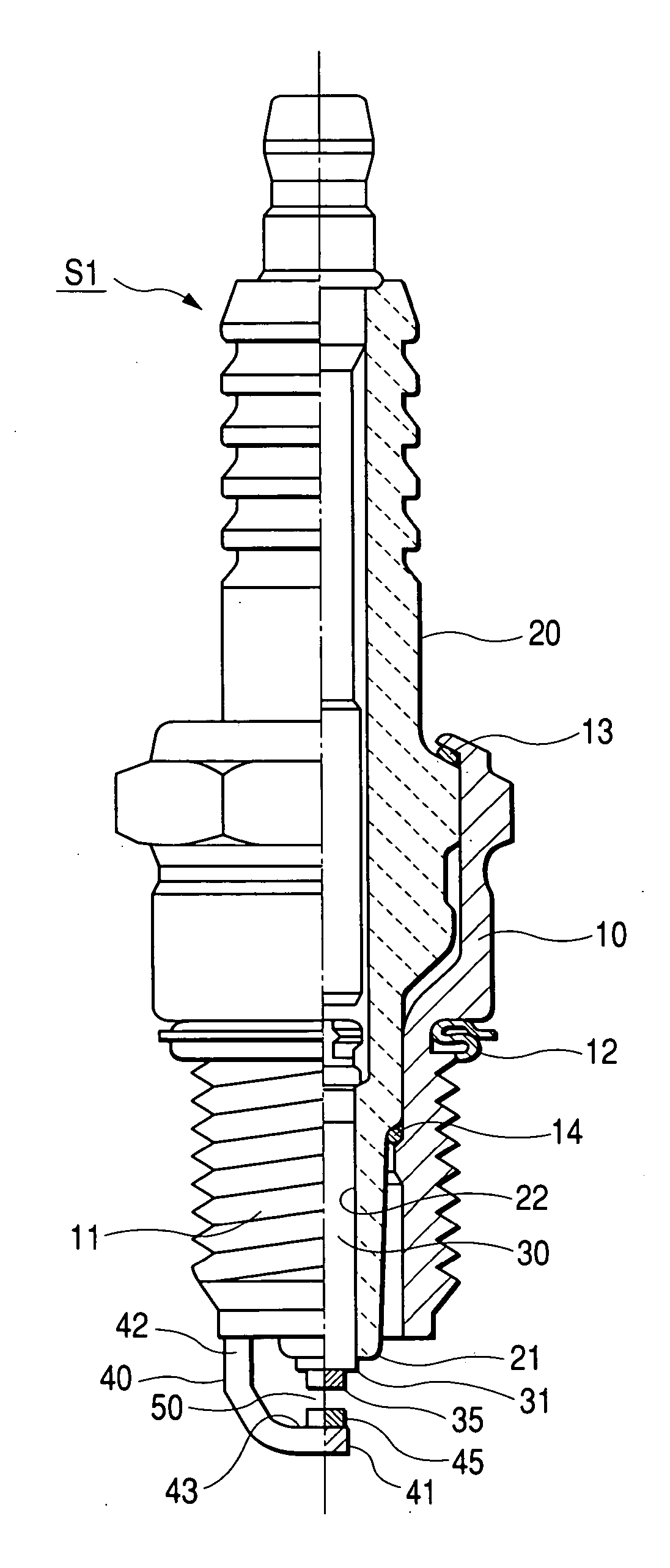

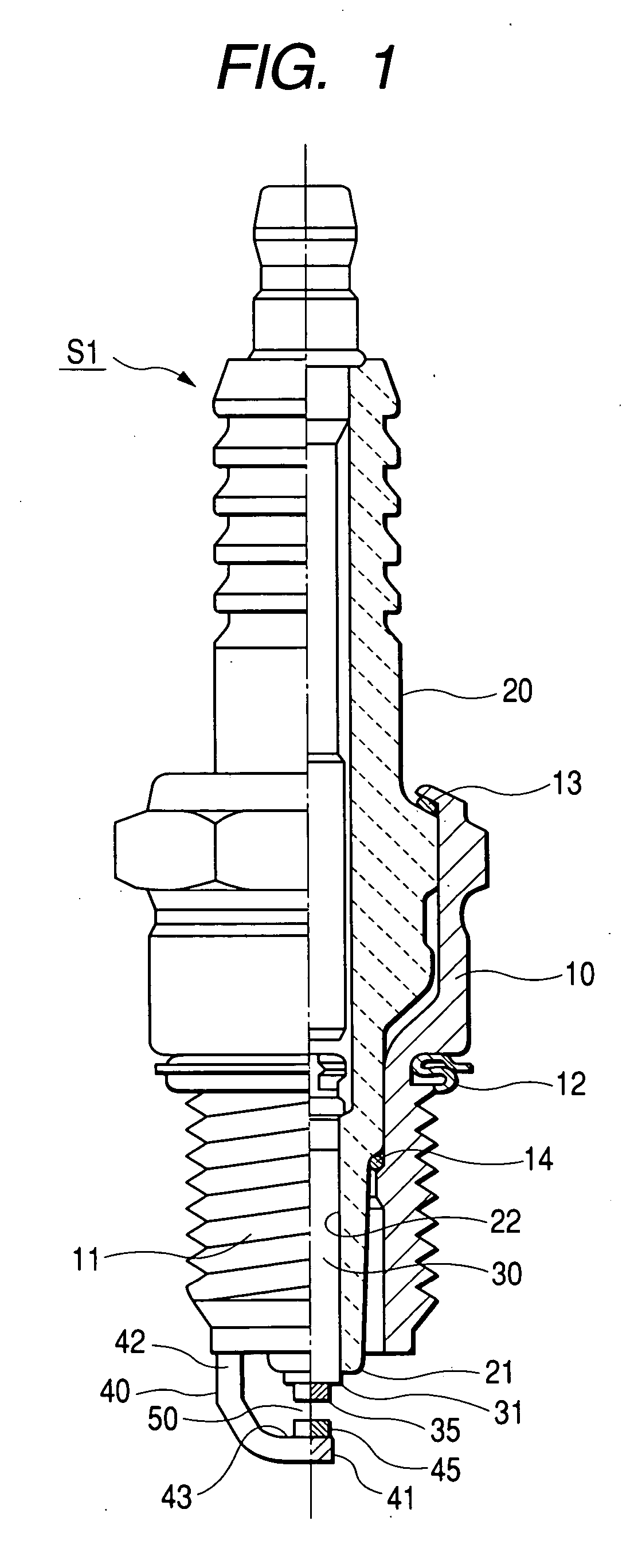

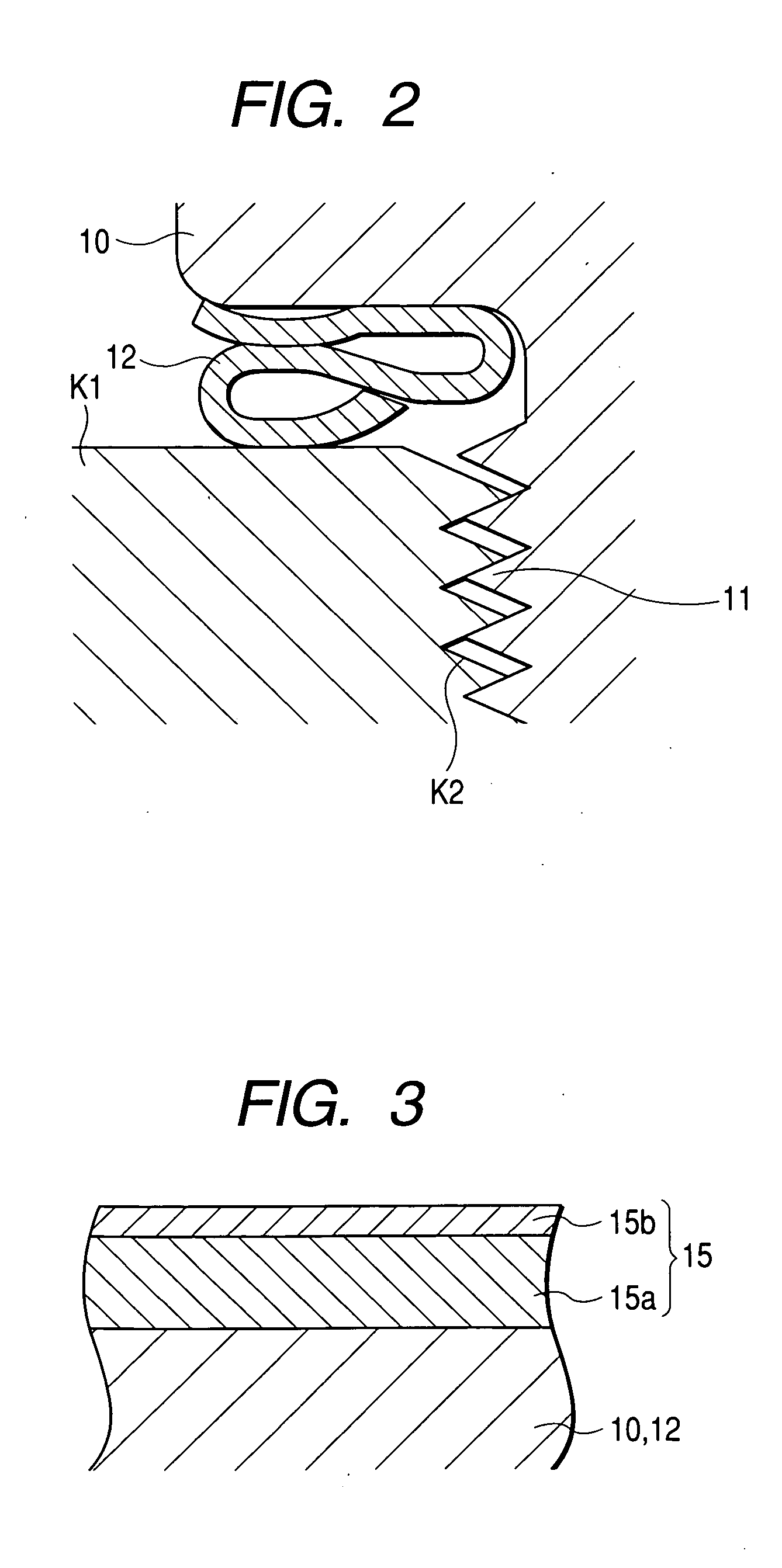

Spark plug

ActiveUS20050127808A1Sufficient corrosion resistanceSolve the lack of resistanceSparking plugsFuel injection apparatusHexavalent chromiumZinc

A spark plug includes a metallic housing, an insulator fixed in the metallic housing, a center electrode fixed in the insulator, a ground electrode opposed to the center electrode via a spark discharge gap, and a protective coat formed on the surfaces of a metallic housing and a gasket. The protective coat includes a galvanized film formed on the surfaces of the metallic housing and the gasket and a chromate film successively laminated on the galvanized film. The chromate film is hexavalent chromium-free and contains trivalent chromium as a major component. The chromate film has a film thickness not smaller than 0.05 μm and not greater than 0.18 μm, and the chromate film contains a metallic component which is robust against oxidation compared with zinc. Furthermore, the chromate film has a film hardness equal to or less than 1 GPa in the temperature range from a room temperature to 180° C.

Owner:DENSO CORP

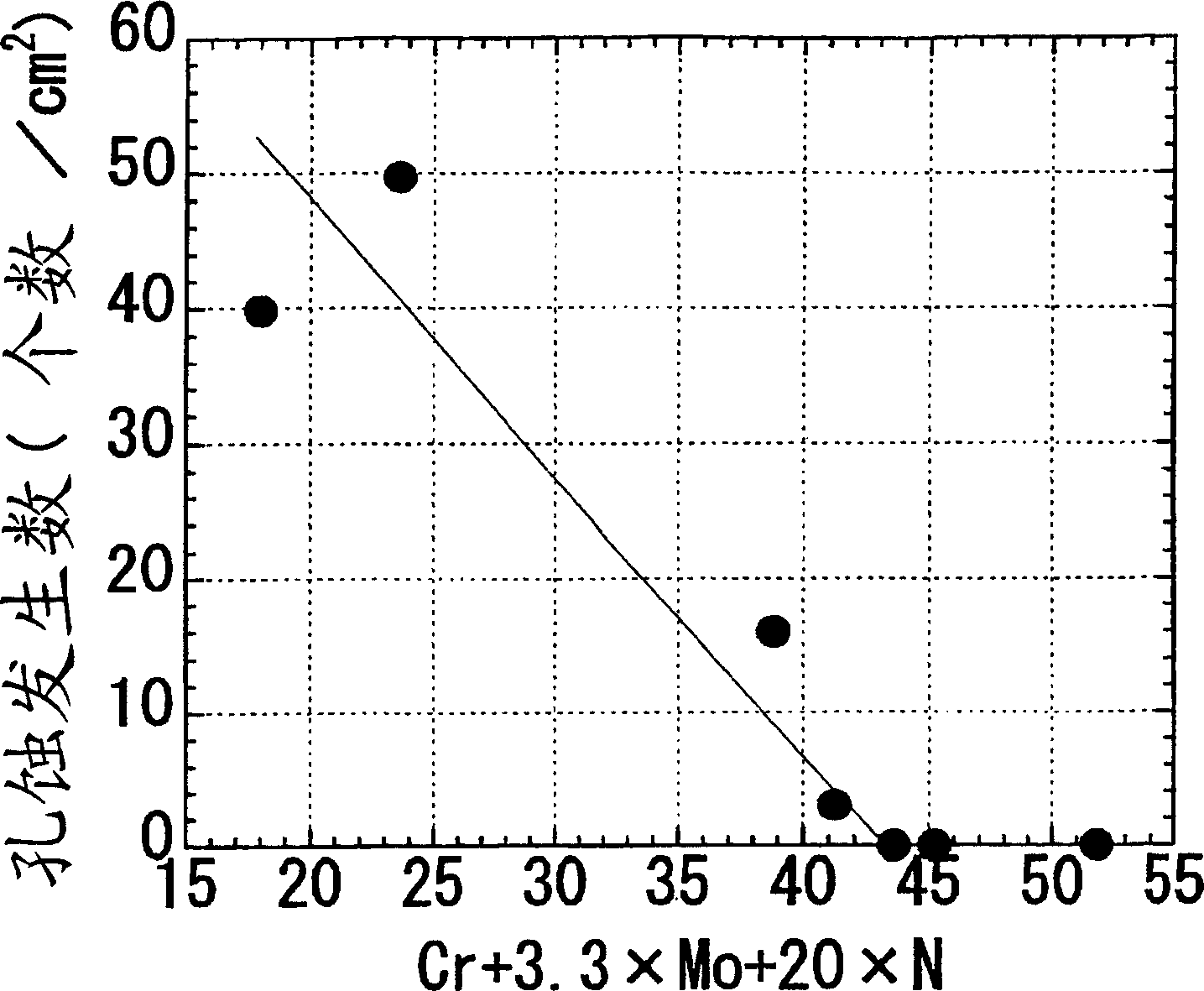

Material of case for storage cell

InactiveCN1898404AReduce contentHigh strengthElectrolytic capacitorsHybrid capacitor electrodesUltimate tensile strengthMechanical engineering

There is provided a casing material for a storage cell having sufficient corrosion resistance and strength even under a charging environment of a high voltage exceeding 2.8 V. This casing material for the storage cell comprises C: not more than 0.03 mass%, Si: 0.01-0.50 mass%, Mn: not more than 0.20 mass%, P: not more than 0.04 mass%, S: not more than 0.0010 mass%, Ni: 20.0-40.0 mass%, Cr: 20.0-30.0 mass%, Mo: 5.0-10.0 mass%, Al: 0.001-0.10 mass%, N: 0.10-0.50 mass%, Ca: not more than 0.001 mass%, Mg: 0.0001-0.0050 mass%, O: not more than 0.005 mass%, provided that contents of Cr, Mo and N satisfy Cr+3.3×Mo+20×N ‰¥ 43, and the balance being substantially Fe and inevitable impurities, in which a content of CaO as an oxide inclusion in steel is not more than 20 mass%.

Owner:PANASONIC CORP +1

Protective coating material for boiler pipeline

The invention discloses a protective coating material for a boiler pipeline. The protective coating material comprises the following components by weight percent: 12%-14% of Cr, 0.4%-0.6% of Mn, 2%-3% of Ti, 3%-5% of Al, 2%-4% of Si, 1%-2% of Nb, 8%-12% of Fe, 1%-3% of Co, 3%-5% of Mo, less than or equal to 0.025% of S, less than or equal to 0.035% of P and the balance of Ni.

Owner:NINGBO SUNLIGHT MOTOR PARTS

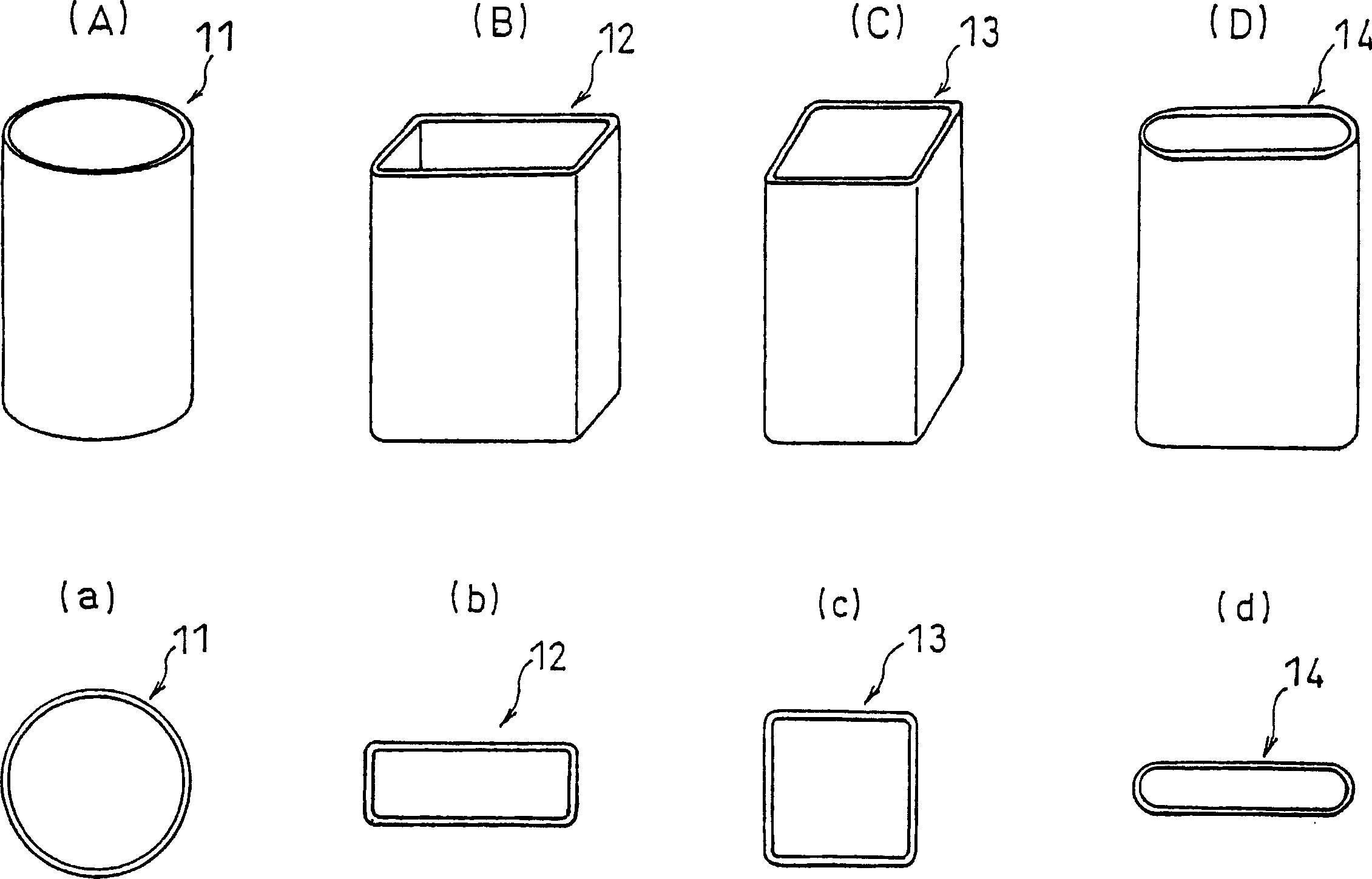

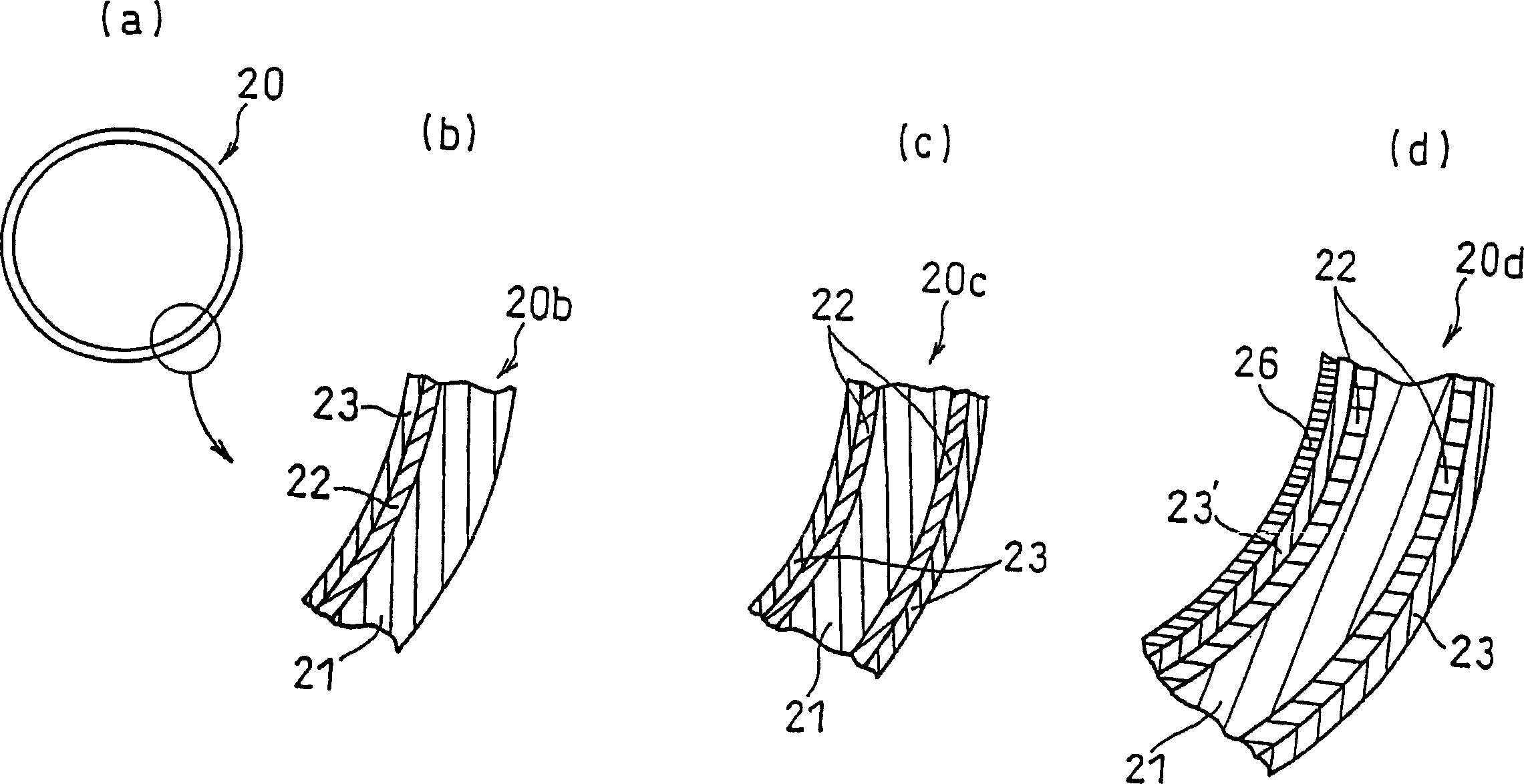

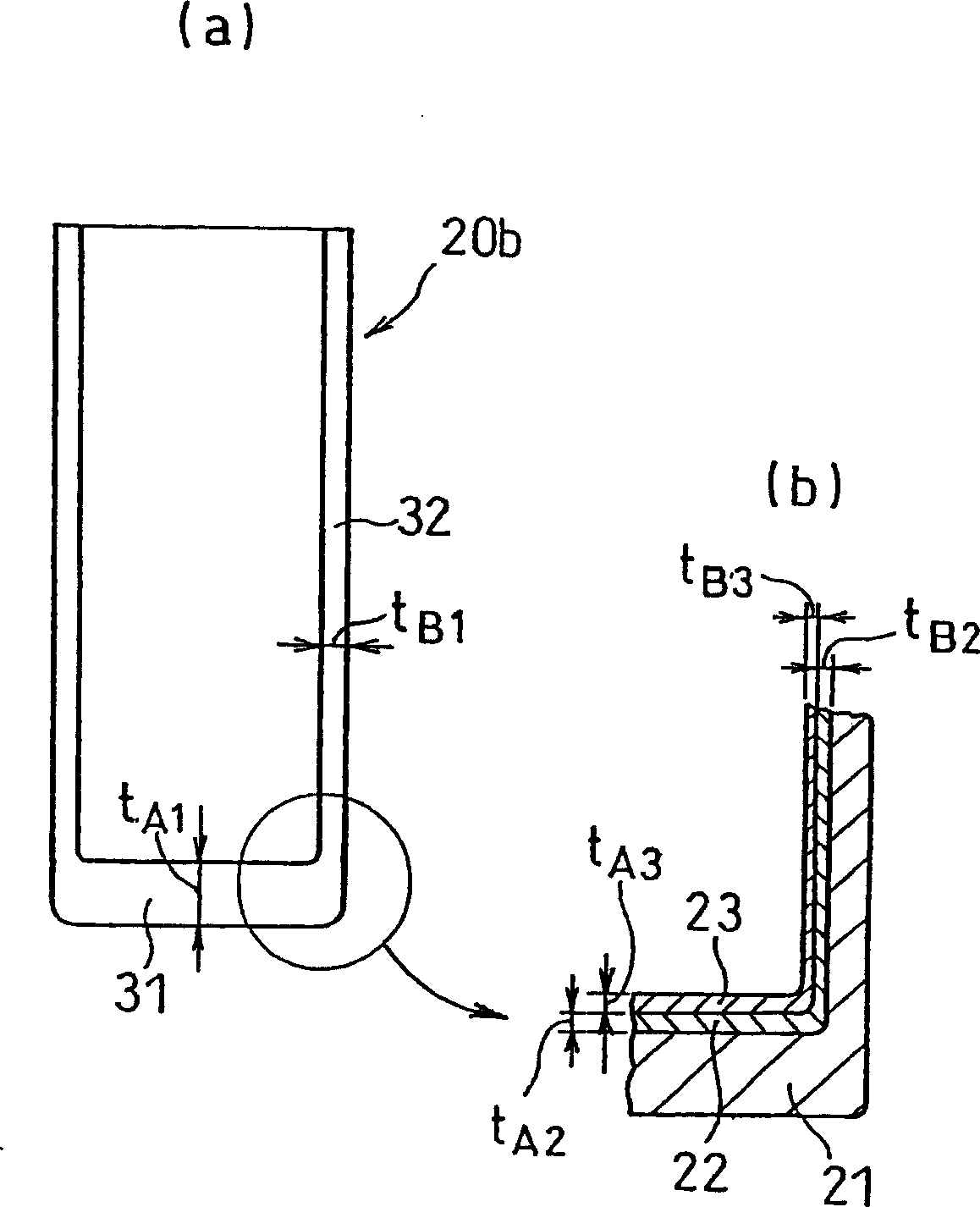

Battery can and manufacturing method thereof and battery using the same

InactiveCN1757125ALow costSufficient corrosion resistanceSmall-sized cells cases/jacketsJackets/cases materialsIron alloysNickel

A battery can having an opening, comprising a cylindrical side wall and a bottom, wherein said battery can is formed from a steel plate, and said steel plate has a carbon content of 0.004% by weight or less, and wherein a matte or semi-bright nickel layer of 0.5 to 3 µm in thickness is formed on an inner face of the battery can, with a nickel-iron alloy layer of 0.5 to 3 µm in thickness interposed between the matte or semi-bright nickel layer and the inner face of the battery can, and a bright nickel layer of 0.5 to 3 µm in thickness is further formed on the matte or semi-bright nickel layer.

Owner:PANASONIC CORP +1

Method for coating a substrate with a spray material and functional layer achievable with this method

ActiveCN104603318AImprove machinabilityGood spray characteristicsMolten spray coatingWelding/cutting media/materialsSulfurMaterials science

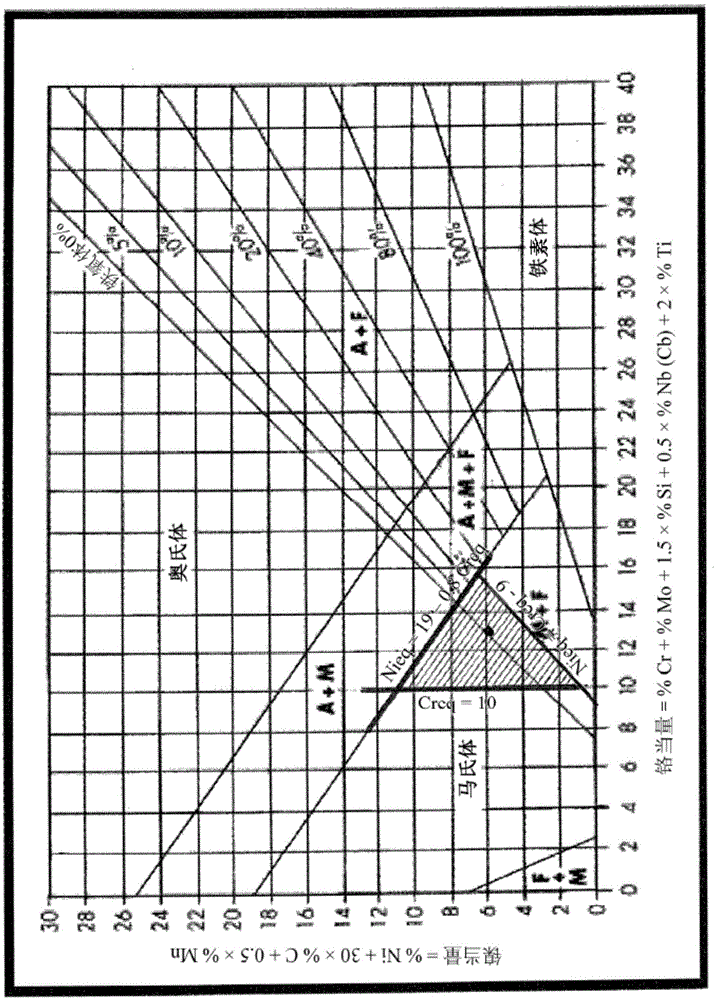

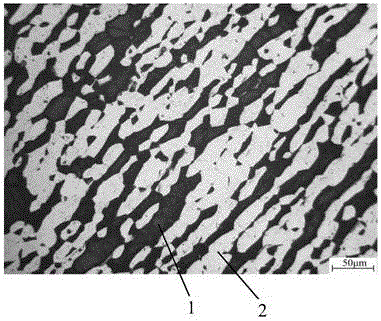

The function layer comprises an iron based alloy having a martensitic structure, and alloy components indicated in characteristics consisting of nickel equivalent and chromium equivalent, where a Schaeffler diagram is based on the total weight of the chromium equivalent (greater than 10) and the nickel equivalent (less than 19). An independent claim is included for a method for coating a substrate.

Owner:梅赛德斯-奔驰集团股份公司

Protective coating material for boiler pipeline

The invention discloses a protective coating material for a boiler pipeline. The protective coating material comprises the following components by weight percent: 12%-14% of Cr, 0.4%-0.6% of Mn, 2%-3% of Ti, 3%-5% of Al, 2%-4% of Si, 1%-2% of Nb, 8%-12% of Fe, 1%-3% of Co, 3%-5% of Mo, less than or equal to 0.025% of S, less than or equal to 0.035% of P and the balance of Ni.

Owner:NINGBO SUNLIGHT MOTOR PARTS

High-carbon high-chromium duplex stainless steel

The invention relates to duplex stainless steel, and particularly relates to duplex stainless steel containing high-carbon and high-chromium elements and a production process thereof. The stainless steel provided by the invention comprises the following chemical components in percentage by weight: 0.20-0.35% of C, 22-26% of Cr, 10-14% of Ni, 2-5% of Mo, 1-5% of Cu, 0.5-4% of V, 0.5-5% of W, less than or equal to 0.015% of S, less than or equal to 0.015% of P, less than or equal to 1% of other impurity elements and the balance of Fe. In the duplex stainless steel provided by the invention, the carbon content of the stainless steel is increased, the alloy strength and hardness are improved, and the wear resistance is enhanced; apart from the commonly used elements Cr, Ni and Mo, the alloy is also added with the elements Cu, W and V, thus the tensile strength and hardness of the alloy are greatly improved under the condition of guaranteeing enough corrosion resistance of the duplex stainless steel.

Owner:SHANDONG JIANZHU UNIV

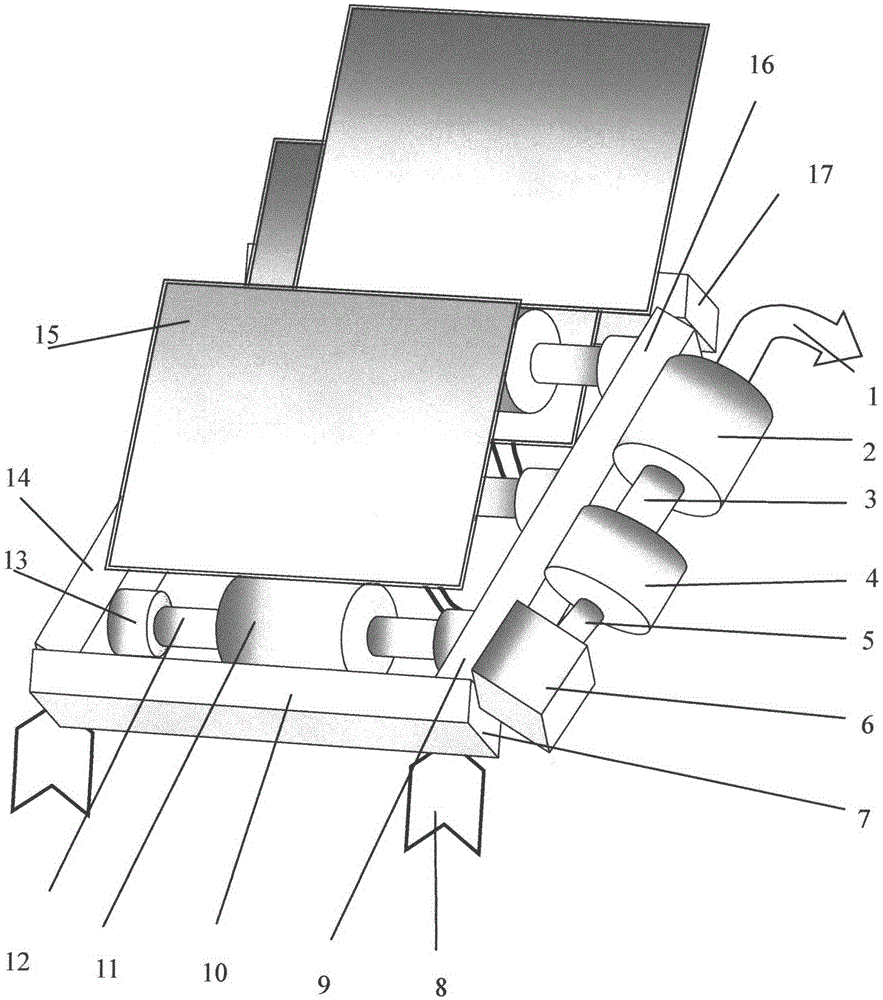

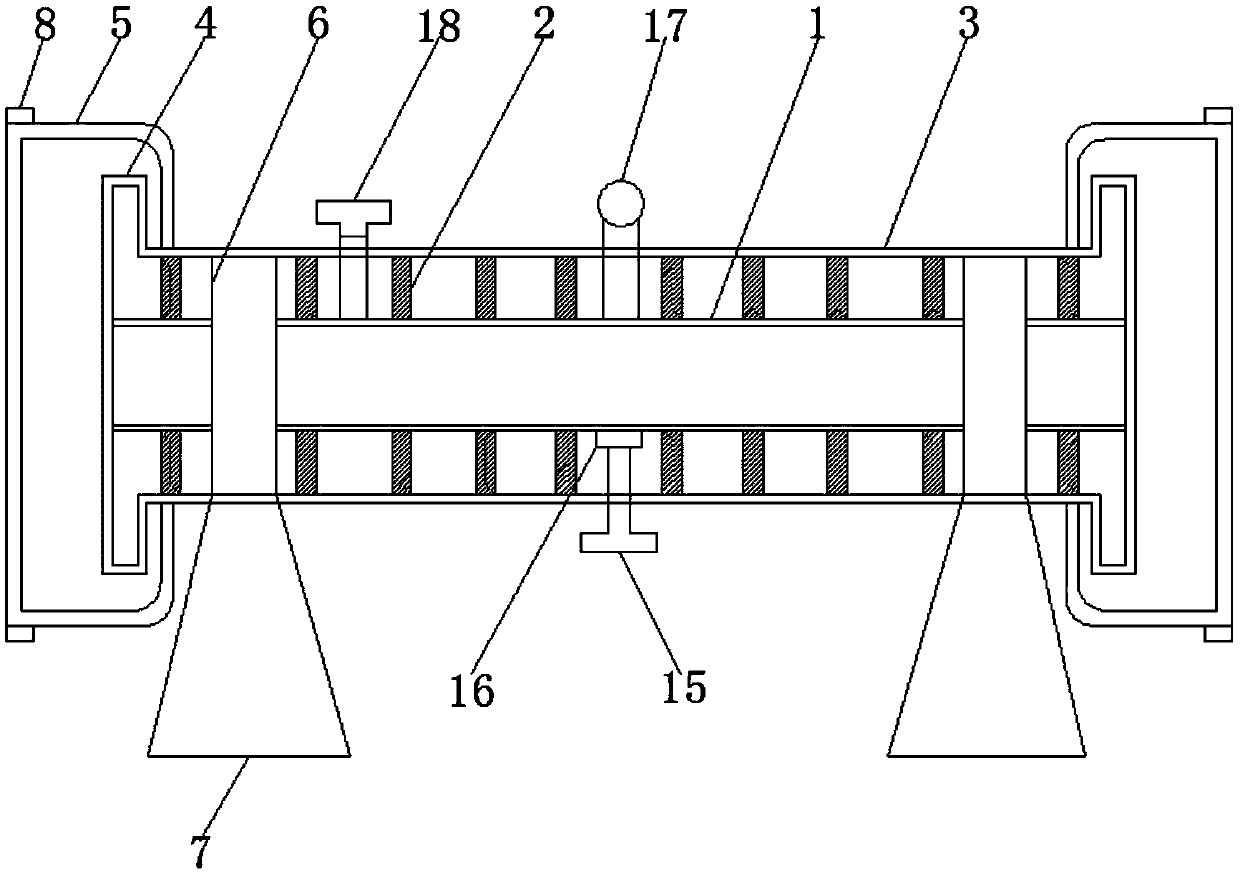

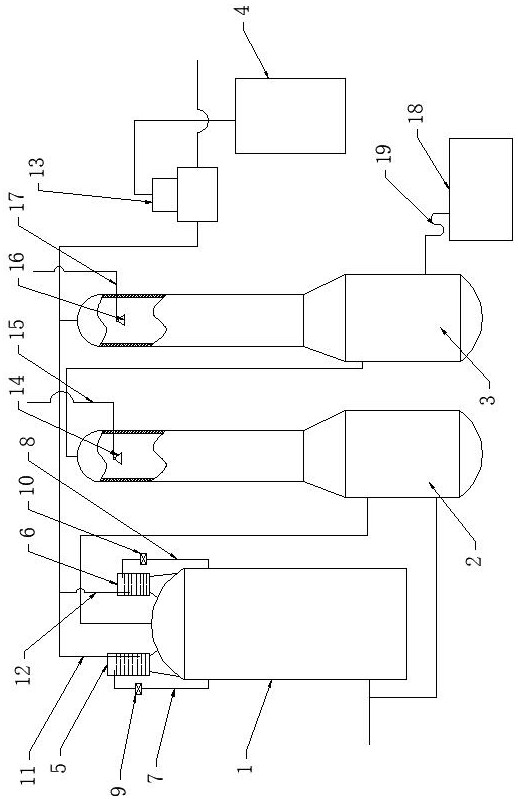

Upper swing plate swinging oil cylinder type sea wave power generator

InactiveCN105370488ASufficient corrosion resistanceReduce weightMachines/enginesEngine componentsHydraulic motorSea waves

An upper swing plate swinging oil cylinder type sea wave power generator mainly comprises a rack, a power generator body, a hydraulic motor and a one-way afflux valve. The rack is provided with a left connecting rod, a middle connecting rod and a right connecting rod. The power generator body, the hydraulic motor and the one-way afflux valve are arranged on the right connecting rod of the rack. The sea wave power generator is fixed to the shallow seabed through ground anchors installed on the rack. Sea waves push a swinging plate to swing left and right. The swinging plate drives a swinging oil cylinder to rotate, the swinging oil cylinder rotates and extrudes pressure oil out, the pressure oil enters the one-way afflux valve through a lower oil conveying pipe, and after the pressure oil is distributed through the one-way afflux valve, the pressure oil is output through an oil feeding opening of the one-way afflux valve. The pressure oil is sucked in through an oil suction opening of the one-way afflux valve, and the one-way performance of oil feeding and oil sucking is achieved. The pressure oil output by the one-way afflux valve is conveyed to the hydraulic motor through an upper oil conveying pipeline, the hydraulic motor is driven to rotate, the hydraulic motor drives the power generator body to rotate to generate power through a connecting shaft, and electric energy is output through a power generation output cable.

Owner:WUXI JINTIANYANG LASER ELECTRONICS

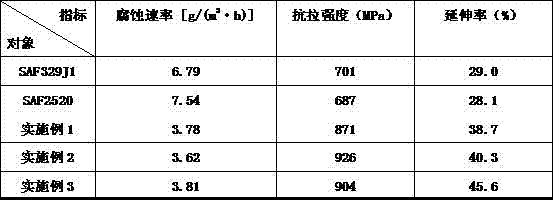

Duplex stainless steel and preparation method thereof

The invention discloses a duplex stainless steel and a preparation method thereof. The duplex stainless steel includes the following components: C, Si, Ni, Mn, Cr, N, Ca, Mg, Ti, Co, Y, with the balance being Fe and insoluble. Impurities to be avoided, and the weight percentage of such impurities is ≤0.1%. The preparation process is to first dehydrate and degas the above raw materials and smelt pure iron, then add other raw materials in an orderly manner, fill the furnace with argon as a protective gas, control the pressure and temperature, and then add the remaining raw materials in sequence. C, Ti, Co, Y, Mn, and then transport the mixed mother liquor to the AOD furnace to blow oxygen for decarburization, nitrogen blowing and composition adjustment. Finally, it is produced by vacuum casting, rolling, solid solution treatment and quenching treatment. Compared with the existing technology, the duplex stainless steel of the present invention not only has good corrosion resistance, but also has greatly improved tensile strength and elongation performance.

Owner:合肥协耀玻璃制品有限公司

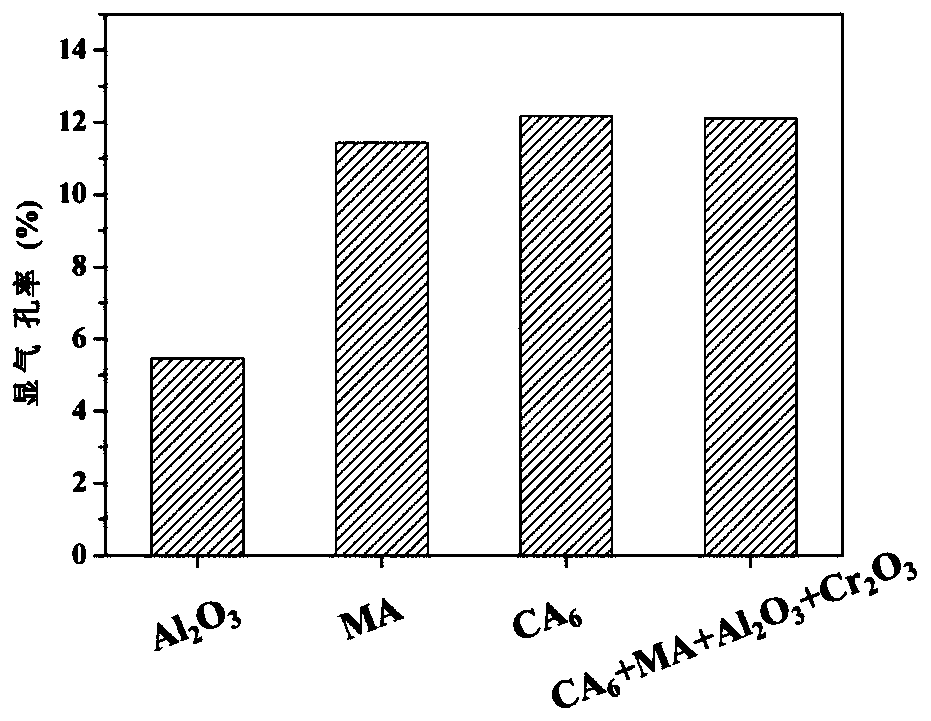

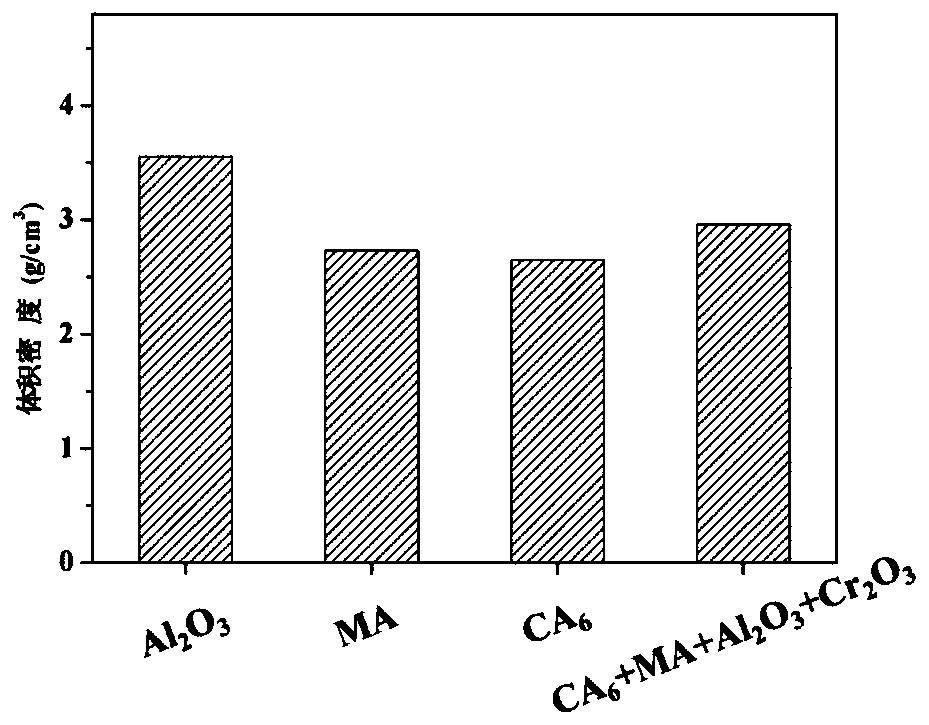

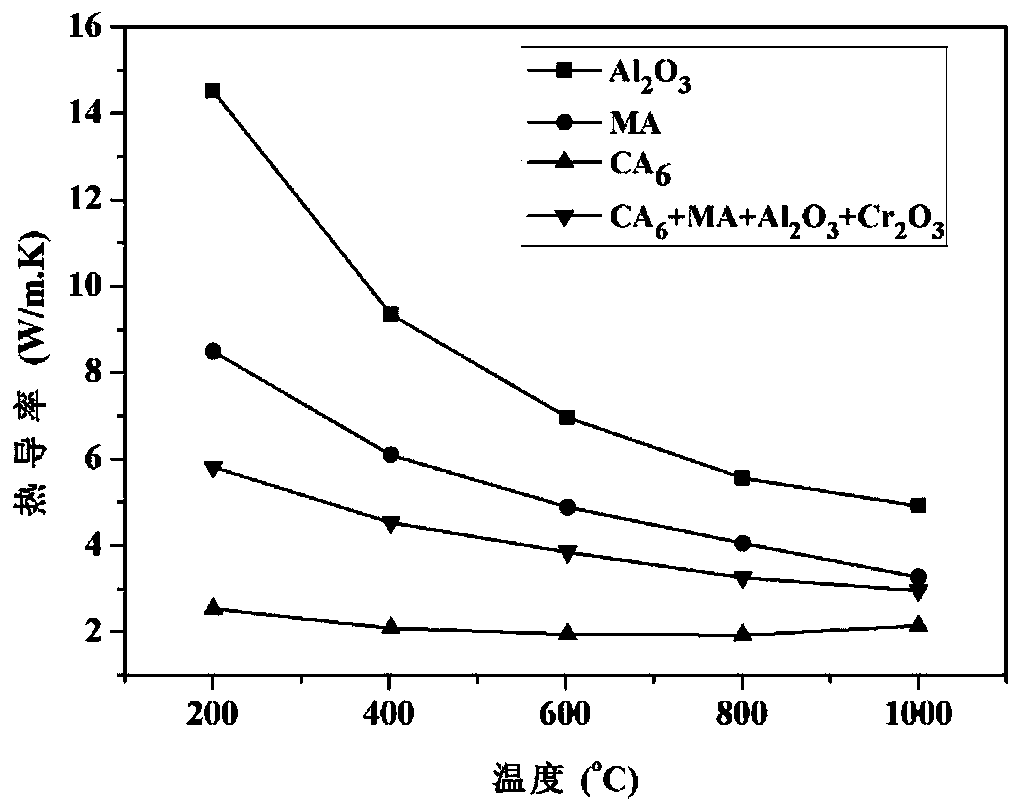

CA6-MA-Cr2O3-Al2O3 ladle lining castable and preparation method thereof

The invention relates to a CA6-MA-Cr2O3-Al2O3 ladle lining castable and a preparation method thereof. According to the technical scheme, 65-75wt% of CA6-MA-Cr2O3-Al2O3 particles, 5-8wt% of alpha-Al2O3micro powder, 3-6wt% of calcium aluminate cement, 7-10wt% of magnesium aluminate spinel fine powder and 8-12wt% of platy corundum fine powder are taken as raw materials, a polycarboxylate water reducing agent and water are added, and stirring, forming, demoulding and baking are carried out to prepare the CA6-MA-Cr2O3-Al2O3 ladle lining castable. The preparation method of the CA6-MA-Cr2O3-Al2O3 particles comprises the following steps of: mixing 60-70wt% of CA6, 4-8wt% of chromium oxide, 10-20wt% of MA and 10-15wt% of aluminum oxide, and ball milling, adding water, granulating, drying, calcining at 1650-1750 DEG C, crushing and screening to obtain the CA6-MA-Cr2O3-Al2O3 particles with three particle size levels respectively. The product prepared by the method has the advantages of high strength, low thermal conductivity, good thermal shock stability, excellent erosion resistance, energy conservation and environmental protection.

Owner:WUHAN UNIV OF SCI & TECH

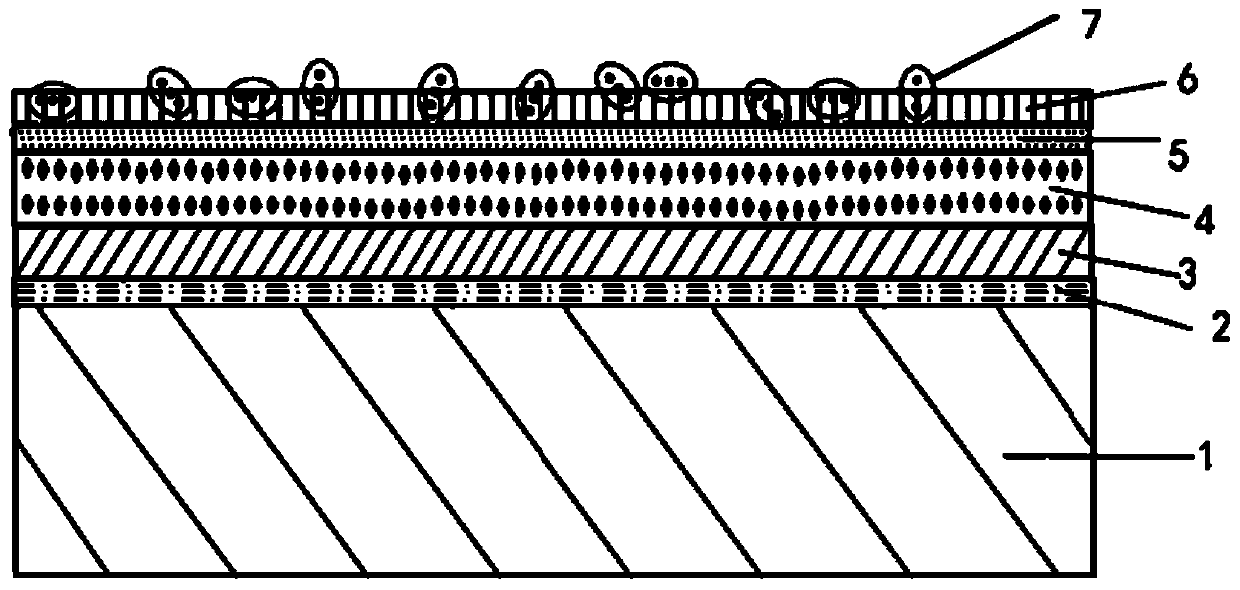

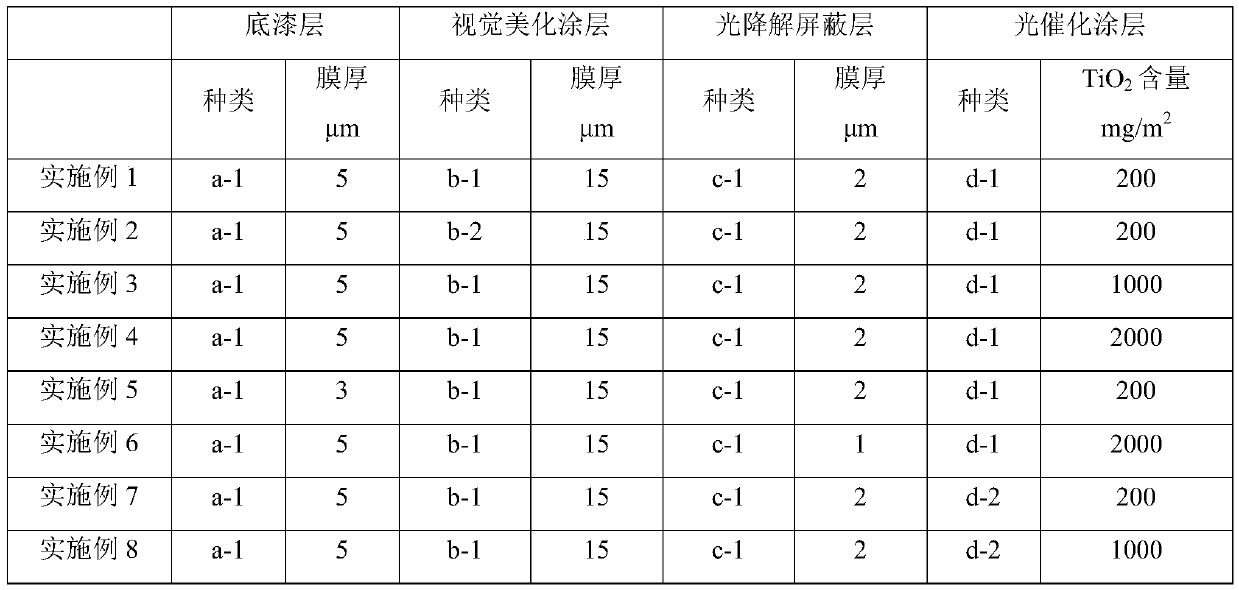

Multi-layer composite steel plate with visible-light response photocatalysis function and manufacturing method thereof

InactiveCN110102455AImprove aestheticsHas photocatalytic efficiencyBiocidePhysical/chemical process catalystsMetal coatingNitric oxide

The invention discloses a multi-layer composite steel plate with a visible-light response photocatalysis function and a manufacturing method thereof, and belongs to the technical field of environmental-friendly new materials. The multi-layer composite steel plate with the visible-light response photocatalysis function comprises a base material, an anti-corrosion leather film, a prime coat, a visual beautifying coating, a light degradation shielding layer and a visible-light response photocatalysis coating; and by adopting the continuous manufacturing method, a metal-coating steel plate is adopted as the base material, and the anti-corrosion leather film, the prime coat, the visual beautifying coating, the light degradation shielding layer and the visible-light response photocatalysis coating are sequentially deposited on at least one surface of the base material. The color steel plate provided by the invention can produce photocatalysis efficacy under the visible-light response, can beused for purifying air, sterilizing and eliminating nitric oxide, organic matters and bacteria in the air, and has the advantages of capability of utilizing sunlight, low energy consumption, no needof extraly adding reactants and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

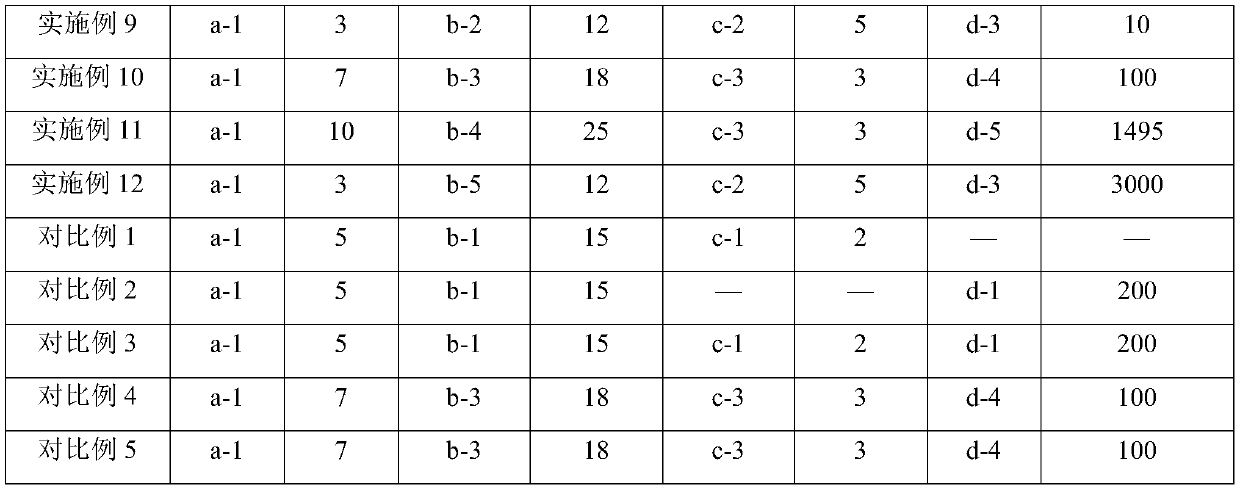

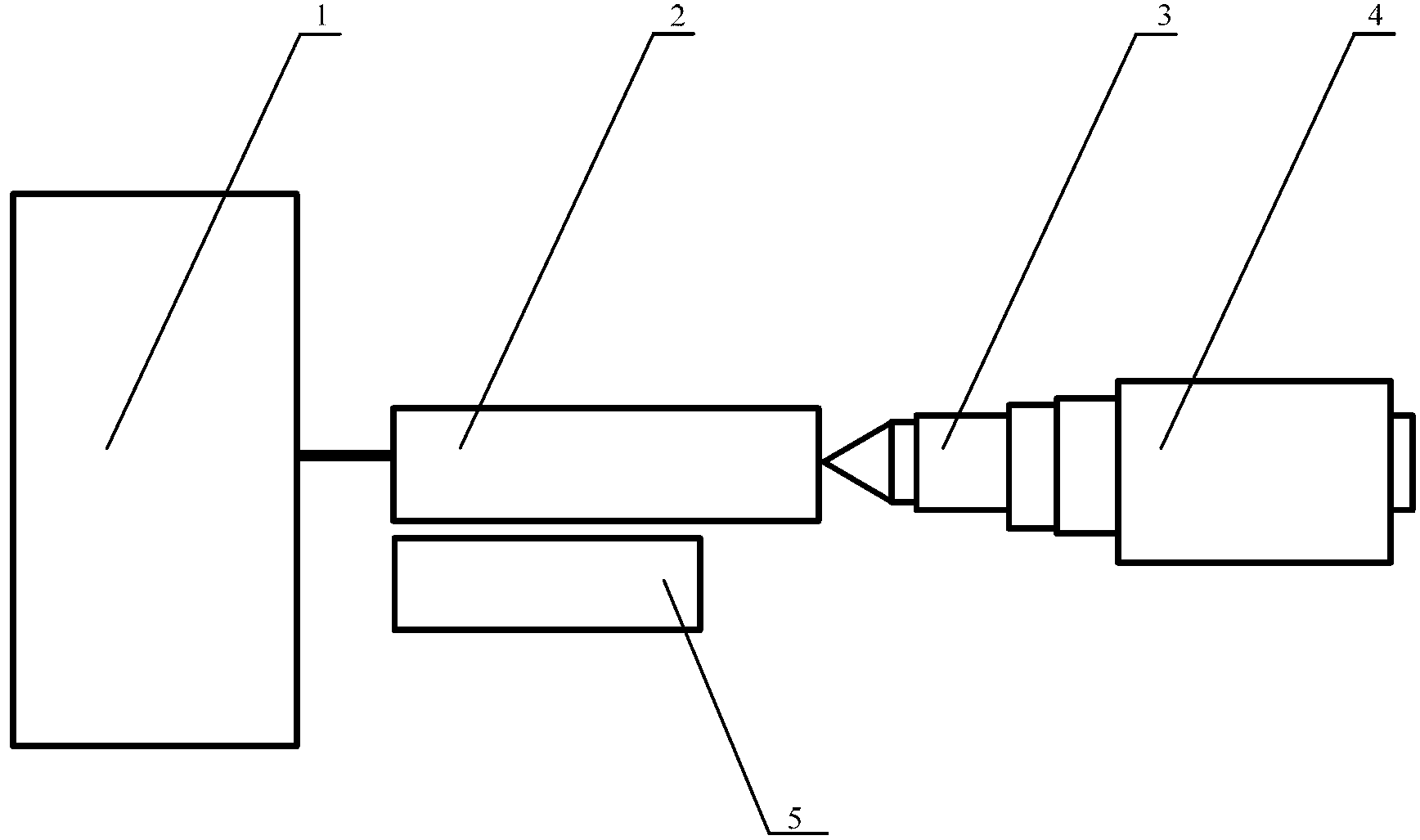

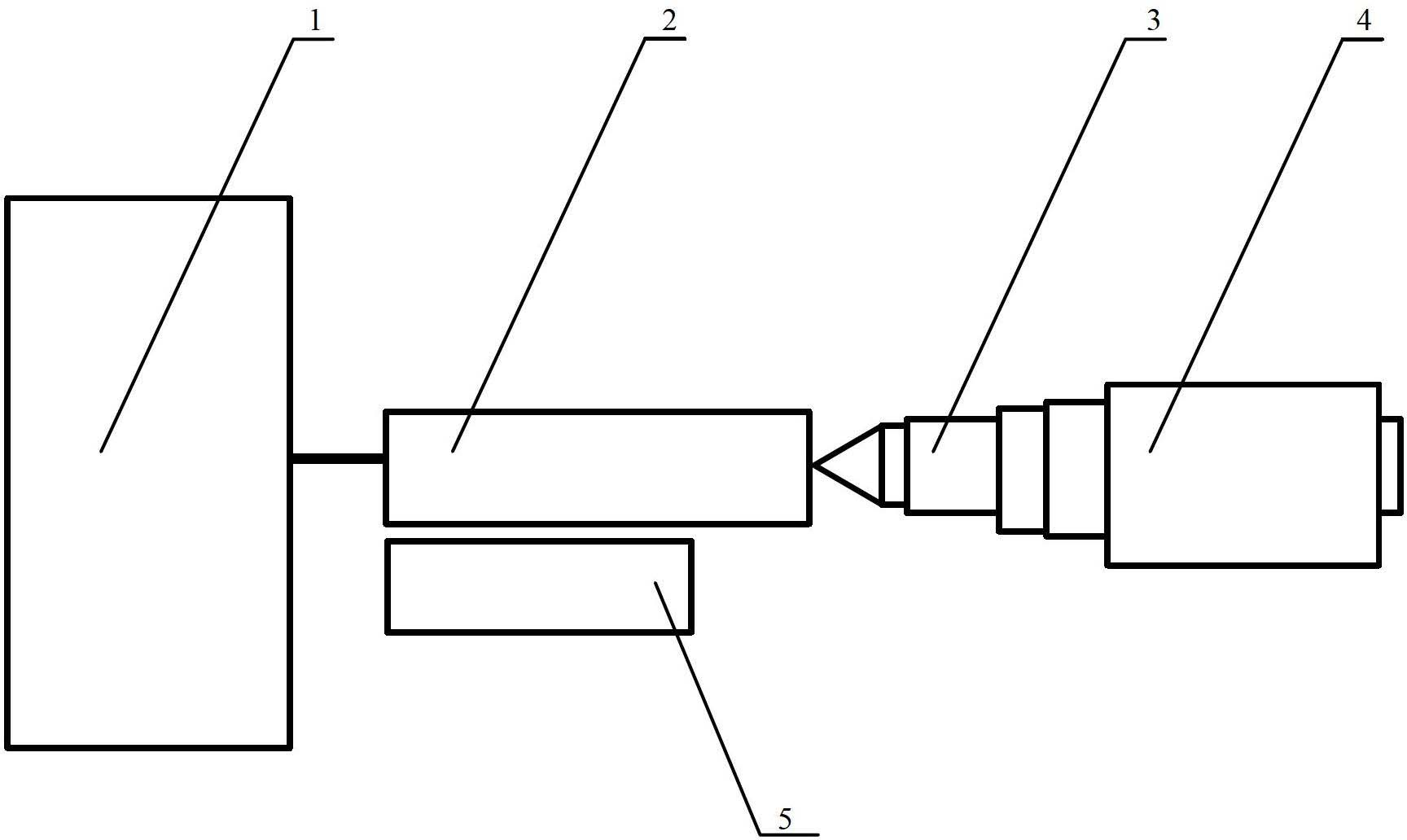

Electrolytic machining system and method for foamed aluminium buffering and energy adsorbing material

InactiveCN102699454AOvercoming deformationOvercome destructionElectrochemical machining apparatusElectrolysisControl system

The invention discloses an electrolytic machining system and an electrolytic machining method for a foamed aluminium buffering and energy adsorbing material. The electrolytic machining system comprises an electrolytic machining machine tool which is formed by a machining system, a control system, an electrolyte system and a fixture device. Firstly, after a foamed aluminium porous material to be machined is fixed, the distance between the foamed aluminium material and an electrode is regulated; and after each machining parameter is set, the electrolytic machining can be carried out. For the foamed aluminium porous material, compared with a conventional turning, planing and grinding scheme, the technical scheme disclosed by the invention overcomes the deformation and the breakage of the porous structure in the machining process.

Owner:TIANJIN UNIV

Hydrogen absorbing alloy, negative pole, and nickel-hydrogen secondary battery

ActiveUS20130202964A1Low costSufficient corrosion resistanceSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrolyteAnode

Owner:SANTOKU CORP

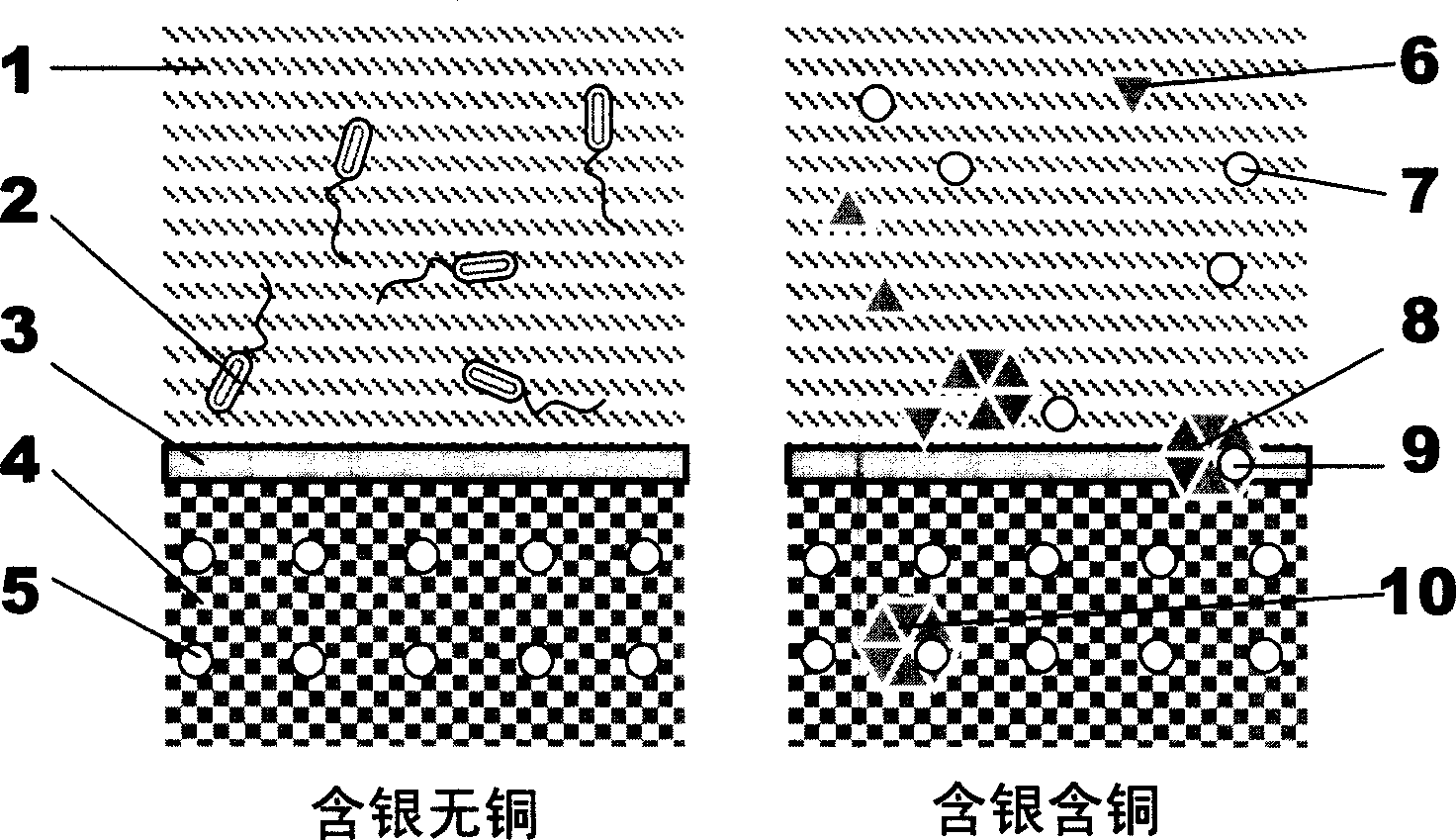

Antibacterial austenitic stainless steel

ActiveCN100410412CImprove antibacterial propertiesSufficient corrosion resistanceChemical compositionKitchen utensils

The invention relates to a sort of austenitic antibiotic stainless steel, characterized in that it saves the nickel and chromium. The percentage by weight of its chemical composition is: C: 0.03-0.15, Cr: 11-15, Ni: 1.0-3.5, Mn: 7.0-15.0, N: 0.06-0.3, Cu: 1.0-3.0, Ag: 0.01-0.1, Nb: 0-0.10, S<=0.02, P<=0.03, Si: 0.1-1, the balance is Fe. Said invention uses cuprum as the carrier and makes the silver crossing the passivating film, which improves the antibiotic ability through the coupulation of the cuprum and silver, and fills manganese, carbon, columbium to ensure the steel has enough corrosion resistance and austenite tissue. The invention can be used for making water supply pipes, kitchen utensils, medical equipments, architectural electric appliances and so on.

Owner:YONGXING SPECIAL STAINLESS STEEL

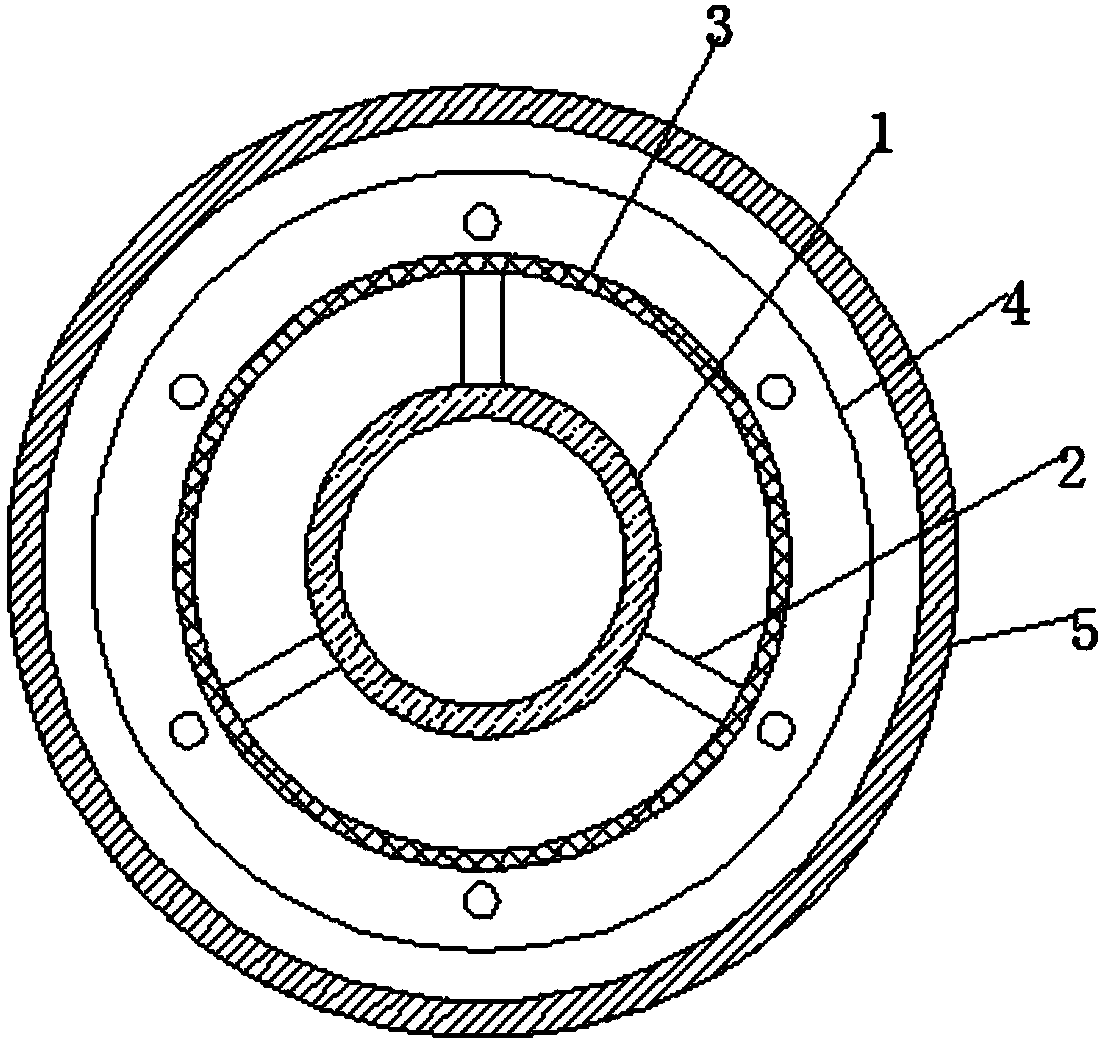

Protective device for pressure pipeline

PendingCN109538882AEasy to useAvoid collisionPipe supportsFlanged jointsArchitectural engineeringSteel bar

The invention discloses a protective device for a pressure pipeline. The protective pipeline includes the pressure pipeline. Support steel bars are vertically welded to the outer side surface of the pressure pipeline. An outer protective steel pipe is vertically welded to the other end of each support bar. The pressure pipeline and the support steel bars are located in the cavity of the outer protective steel pipe. Connection flanges are fixedly welded to the two ends of the outer protective steel pipe. Connection part protective rings are arranged on the outer sides of the connection flanges.The connection part protective rings match the connection flanges. The connection part protective rings are connected to the outer side surface of the outer protective steel pipe. The protective device for a pressure pipeline has the advantages of simple structure, reasonable design, simple operation and convenient use. Through the arrangement of the outer protective steel pipe and the support steel bars, the protective device for a pressure pipeline is provided with a layer of vacuum zone between the pressure pipeline and the outer protective steel pipe under the coordination of the outer protective steel pipe and the support steel bars, which greatly protects the pressure pipeline. The protective device for a pressure pipeline has a broad application prospect.

Owner:NANJING HIGH DRIVE ELECTROMECHANICAL AUTOMATION EQUIP CO LTD

Acidic water treatment device and treatment process based on device

ActiveCN113697880ASufficient corrosion resistanceLow costGas treatmentFatty/oily/floating substances removal devicesAcid waterEnvironmental engineering

The invention provides an acidic water treatment device and a treatment process based on the device. A gas outlet of a raw material water tank of the device is connected with a gas inlet of a water scrubber; a gas outlet of the water washing tower is connected with a gas inlet of the alkaline washing tower; a gas outlet of the alkaline washing tower is connected with a gas inlet of the heating combustion furnace; a water-sealed tank A and a water-sealed tank B are mounted at the top of the raw material water tank; an air leakage pipe A and an air leakage pipe B are arranged at the middle upper part of the raw material water tank, the air leakage pipe A is connected with the water-sealed tank A, and the air leakage pipe B is connected with the water-sealed tank B; a deflation pipe A is arranged in the water-sealed tank A, and a deflation pipe B is arranged in the water-sealed tank B; and the raw material water tank is made of 304 stainless steel. When the treatment device is used for treating acidic water, the purpose of safe, stable and long-period operation can be achieved; in addition, by combining with an acidic water treatment process, the acidic water can meet the emission standard after one-time treatment, and pollution of peculiar smell gas to the environment can be effectively avoided.

Owner:山东恒信科技发展有限公司

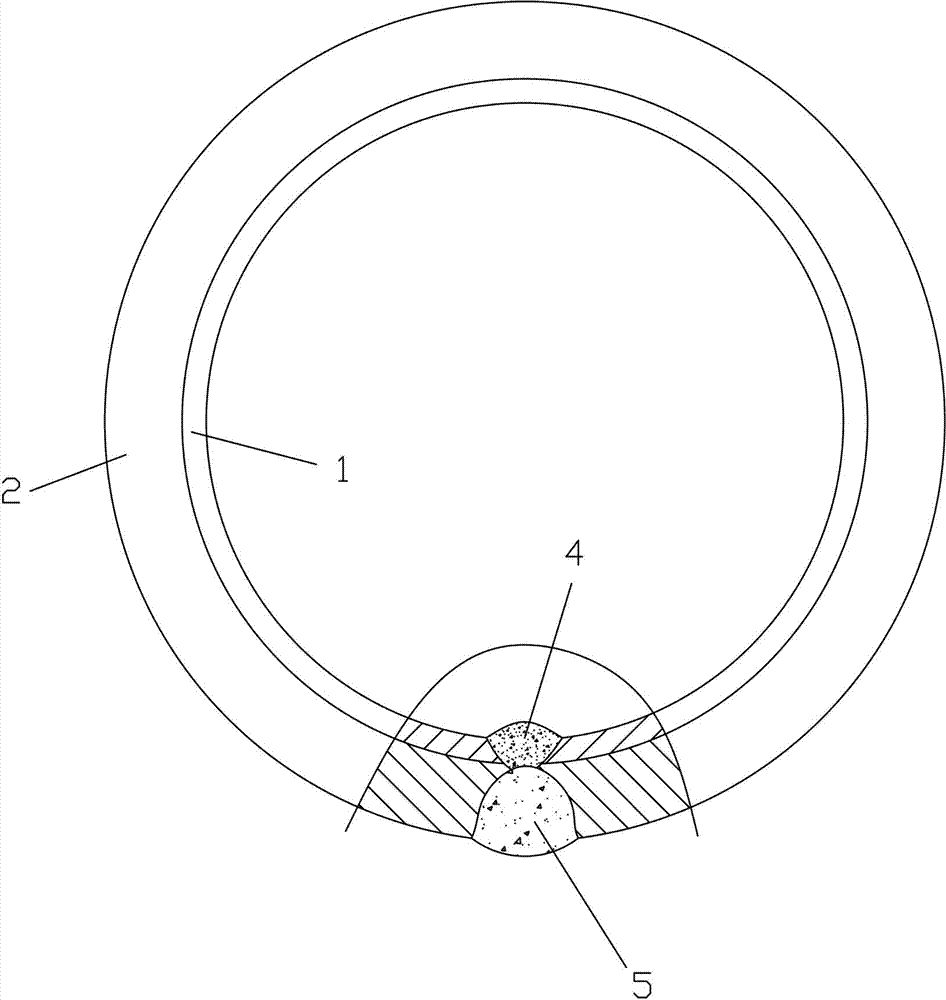

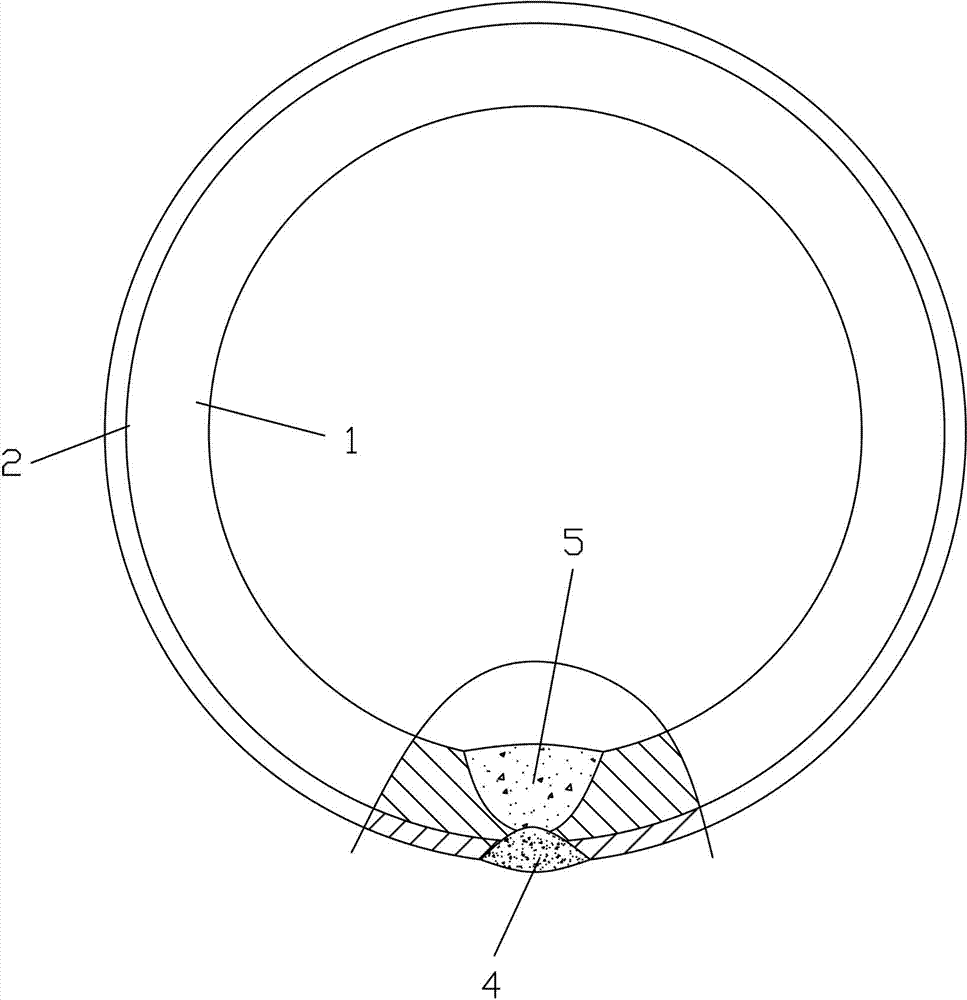

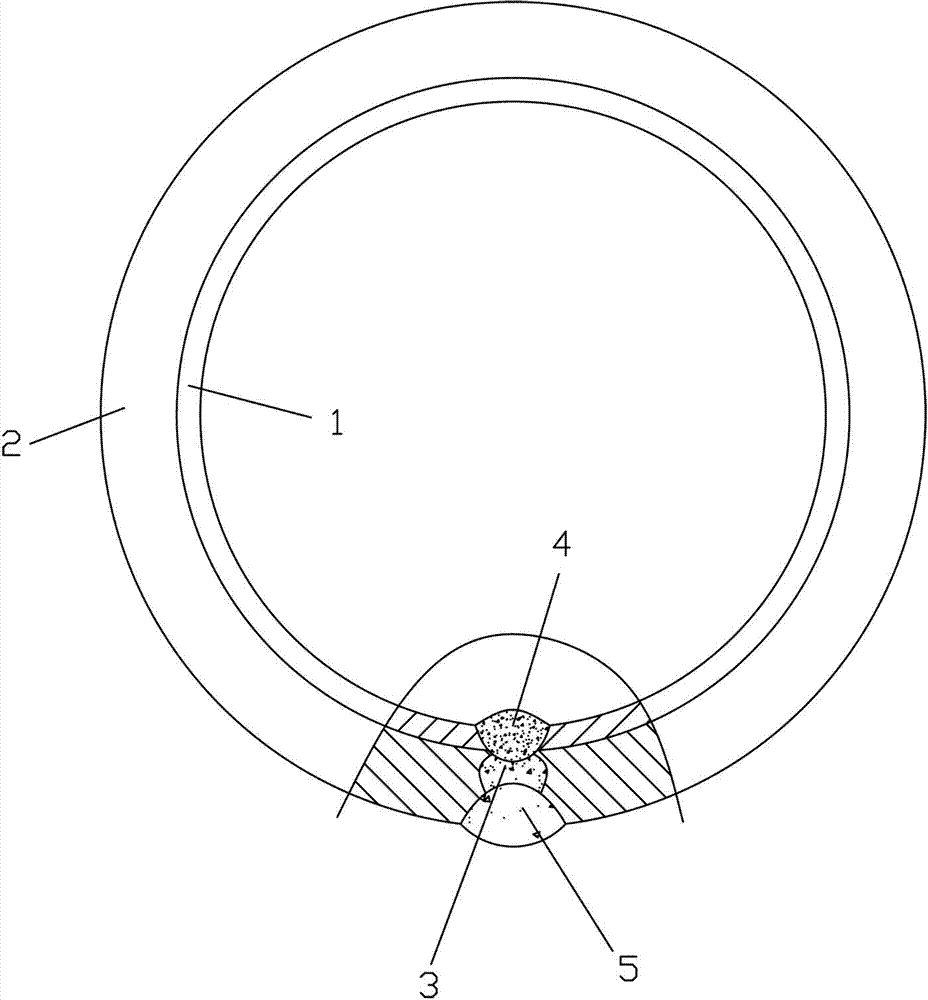

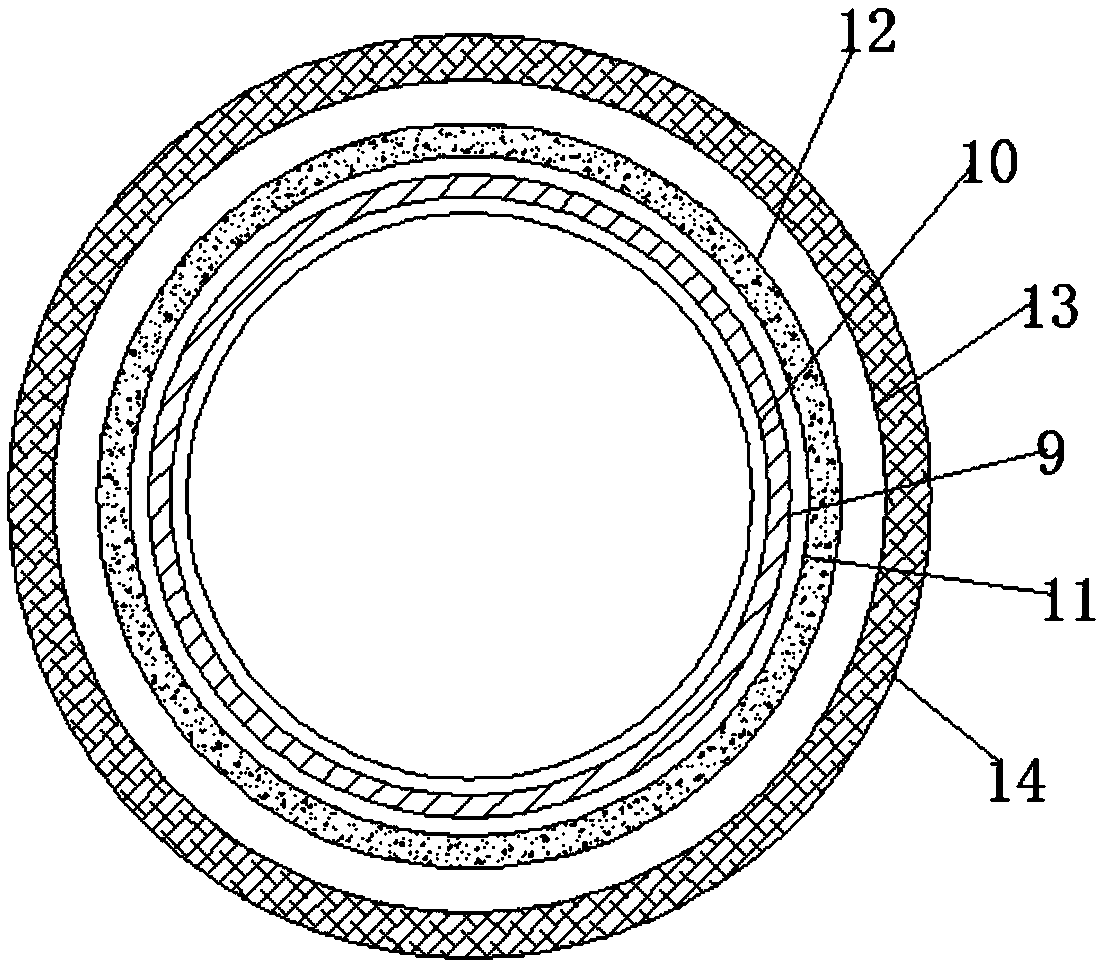

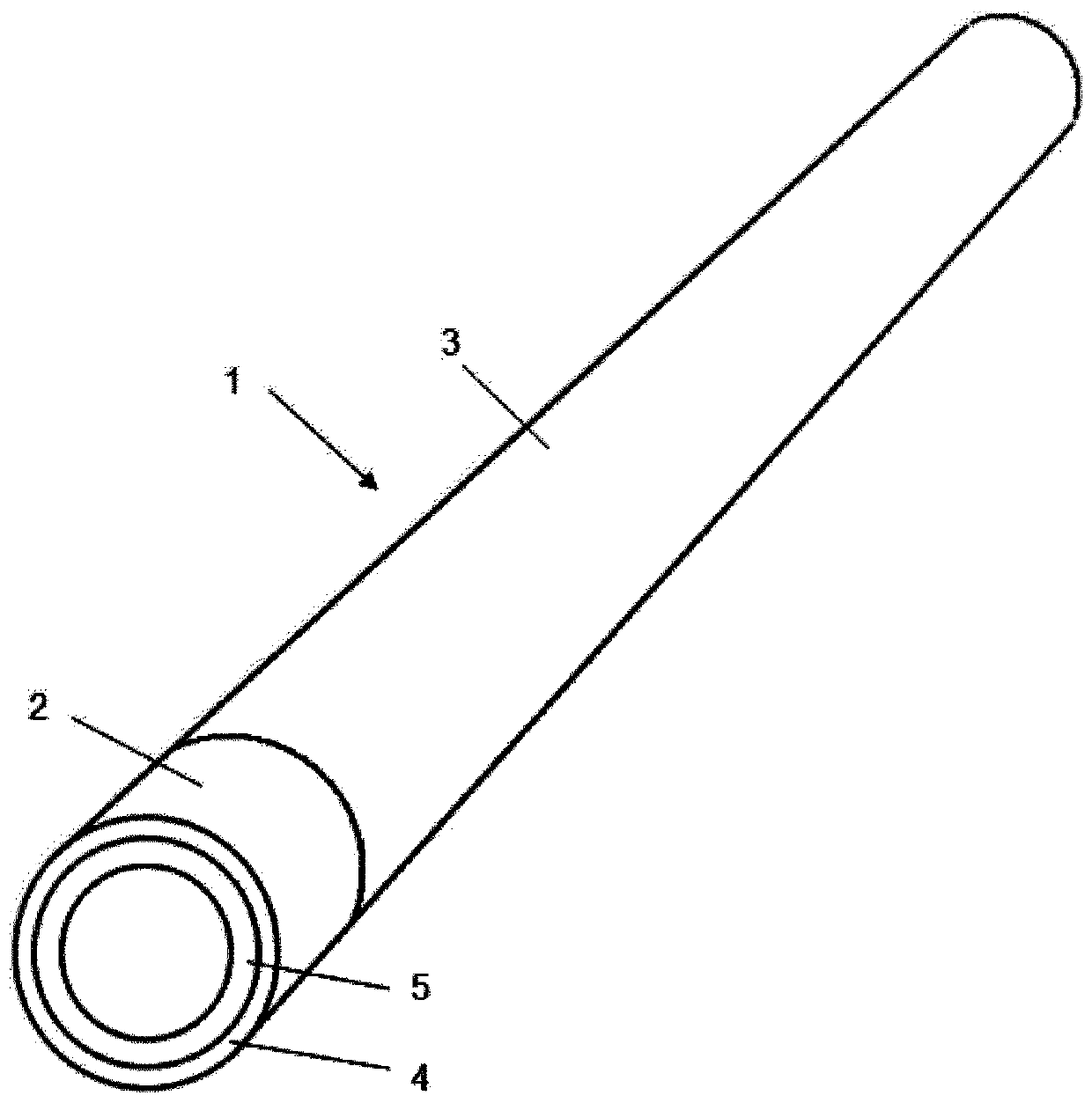

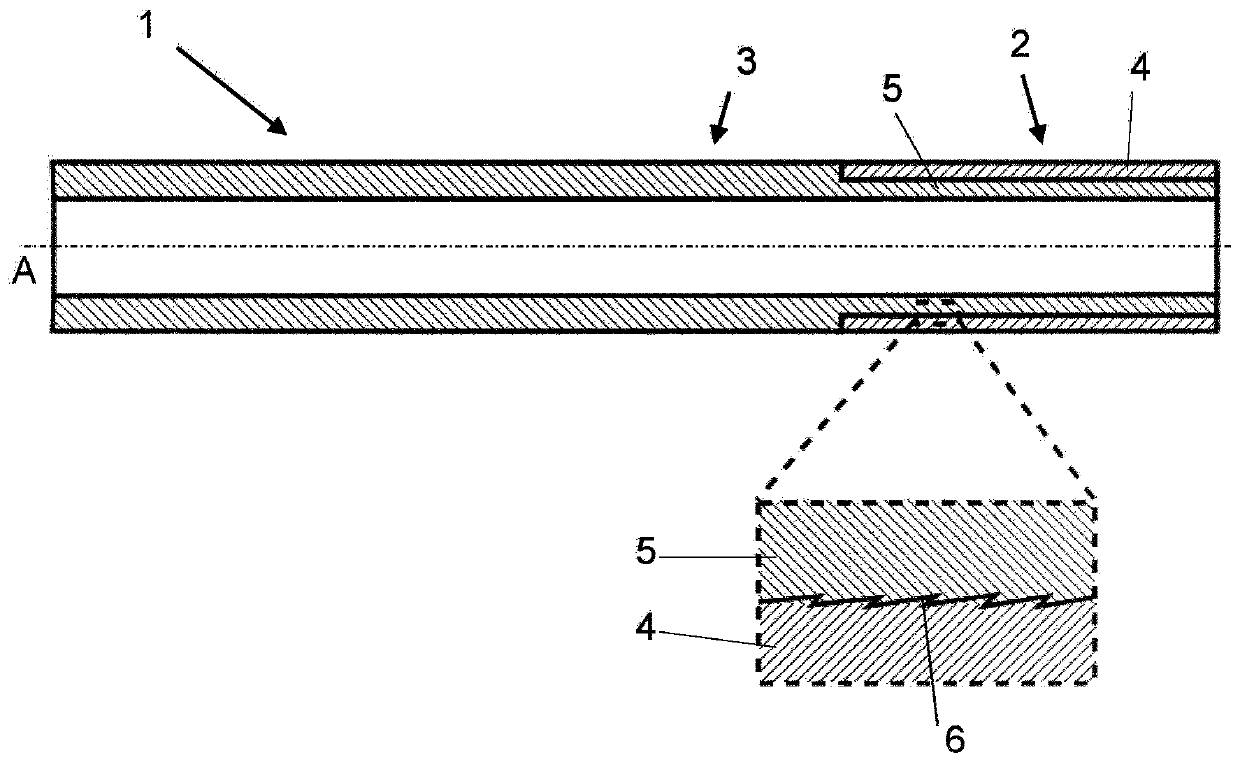

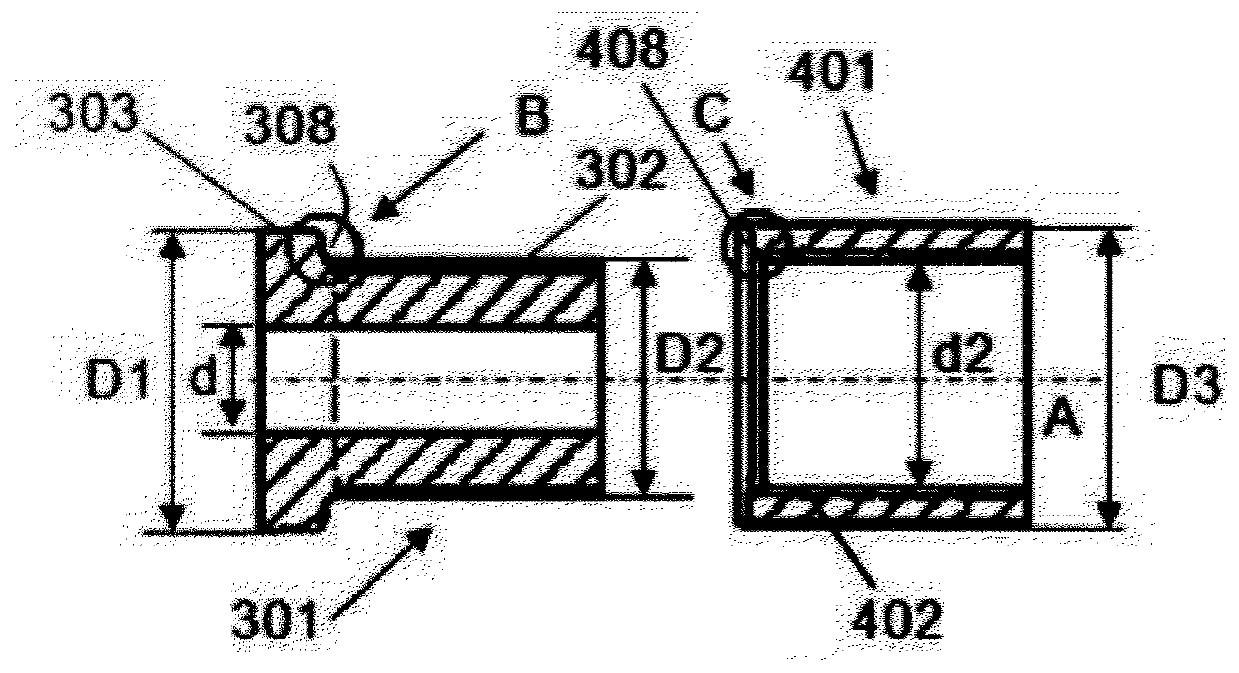

Lance tube

ActiveCN110088550AImprove distributionIncrease the interface areaCharge manipulationManufacturing convertersHot workingHigh-temperature corrosion

The disclosure relates to a lance tube (1) having a central through-hole extending along a longitudinal axis (A). The lance tube has a double-layered end portion (2) having an annular outer layer (4)of a high temperature corrosion resistant first alloy and an annular inner layer (5) of a second alloy, wherein the inner layer and the outer layer are mechanically interlocked, and wherein a metallicbond has been formed between the inner layer and the outer layer by means of hot working, and a mono-layered main portion (3) of the second alloy. The lance tube is suitable for use in a lime kiln.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

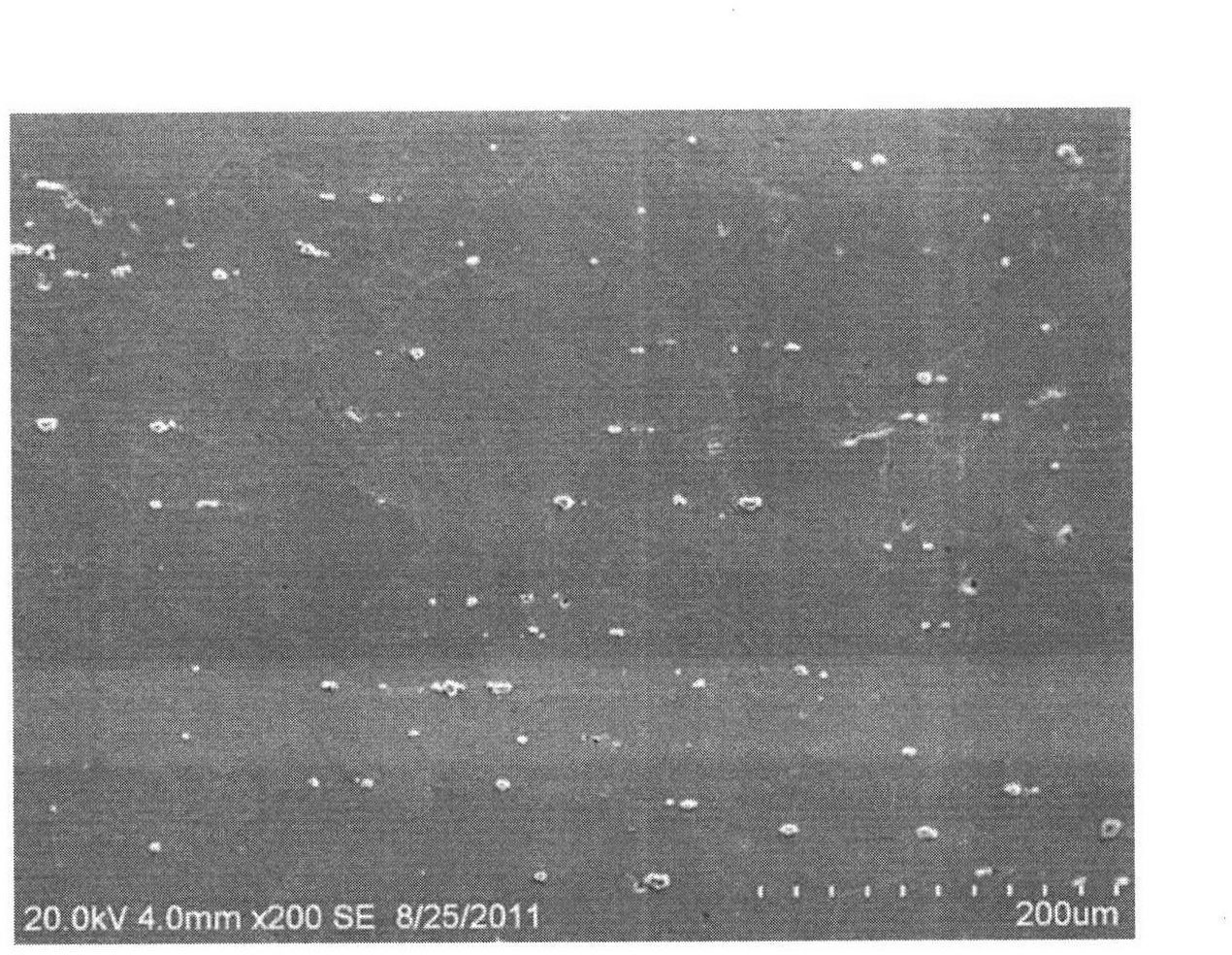

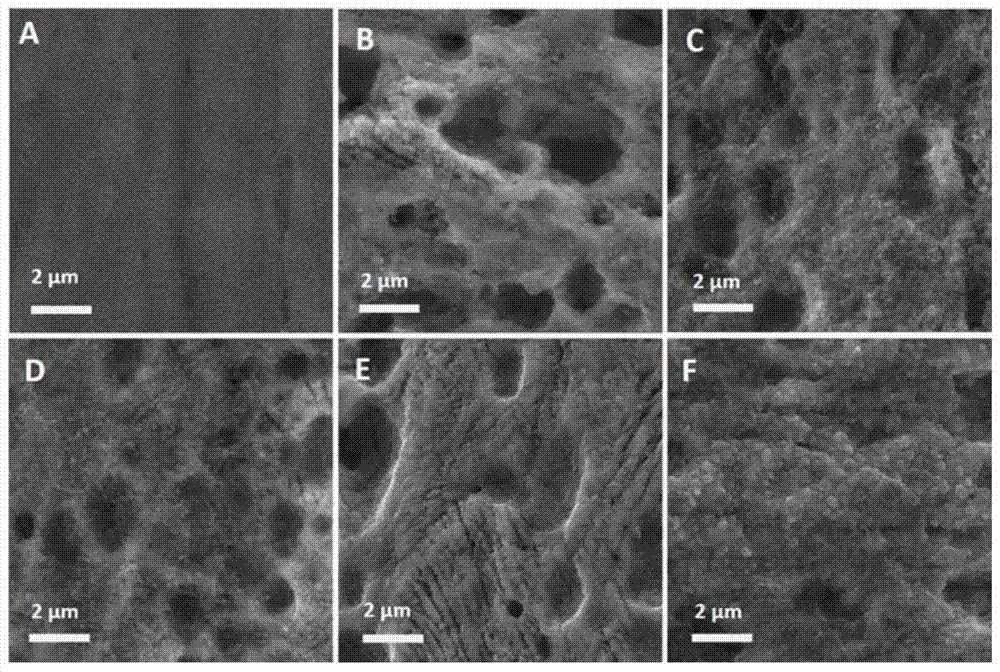

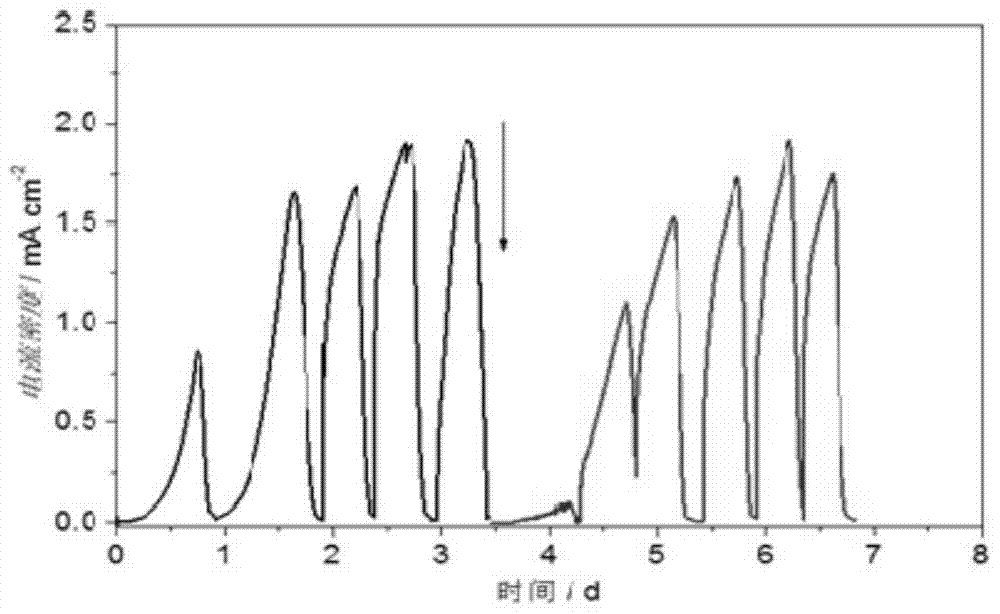

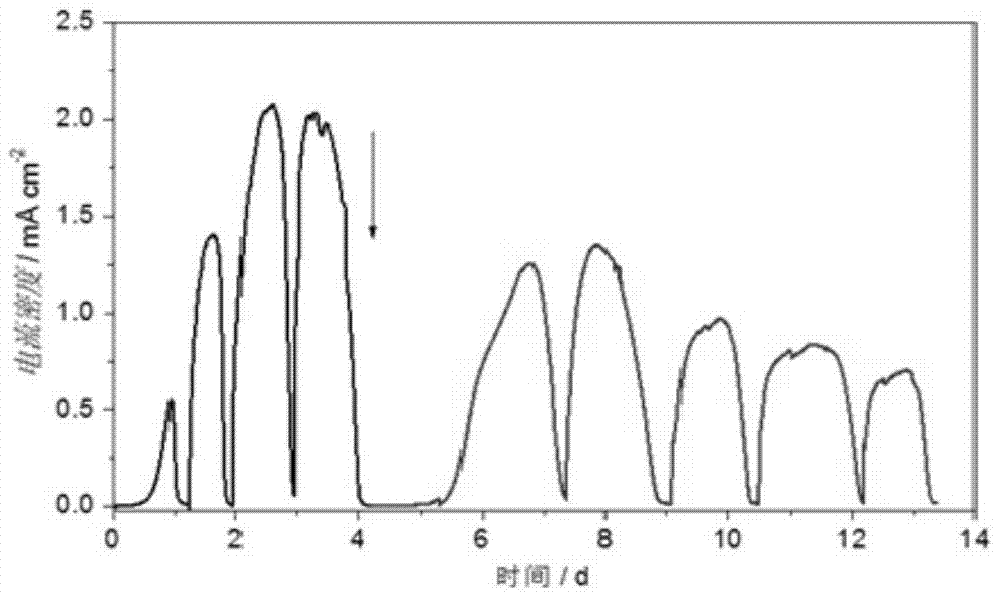

A kind of stainless steel microbial electrode and its preparation method and application

ActiveCN105355931BGuaranteed corrosion resistanceSufficient corrosion resistanceCell electrodesRough surfaceInternal resistance

Owner:JIANGXI NORMAL UNIV

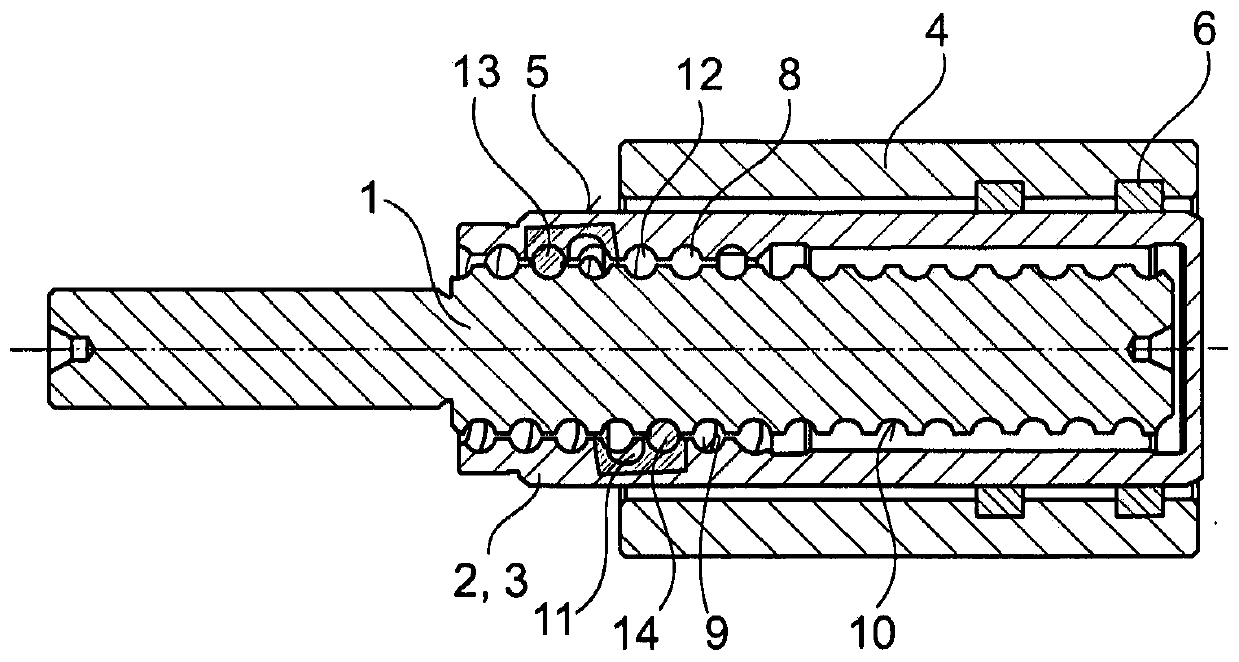

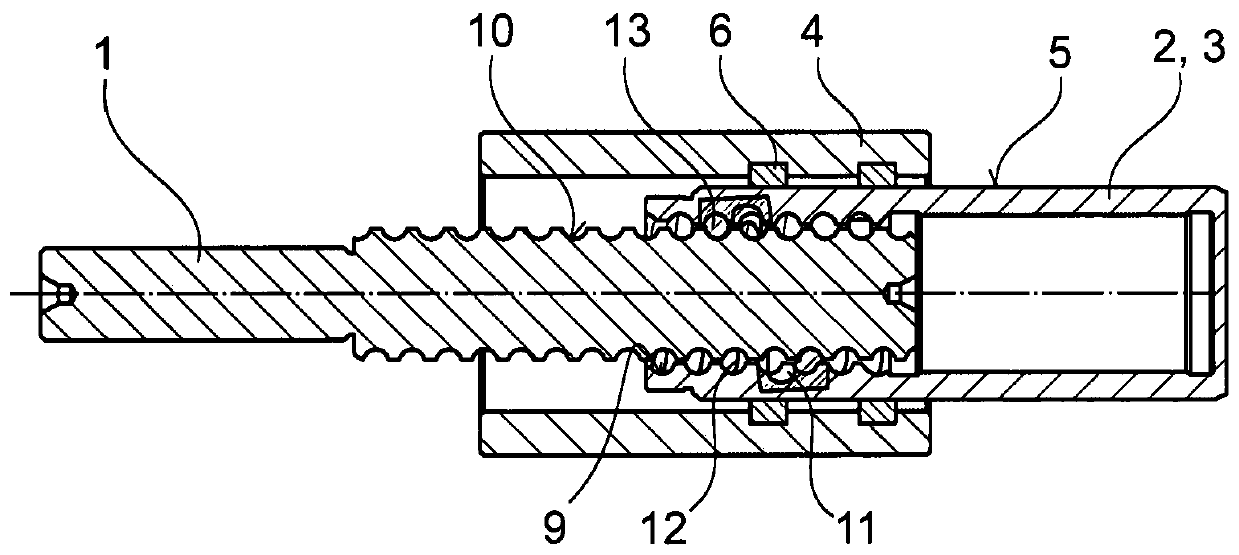

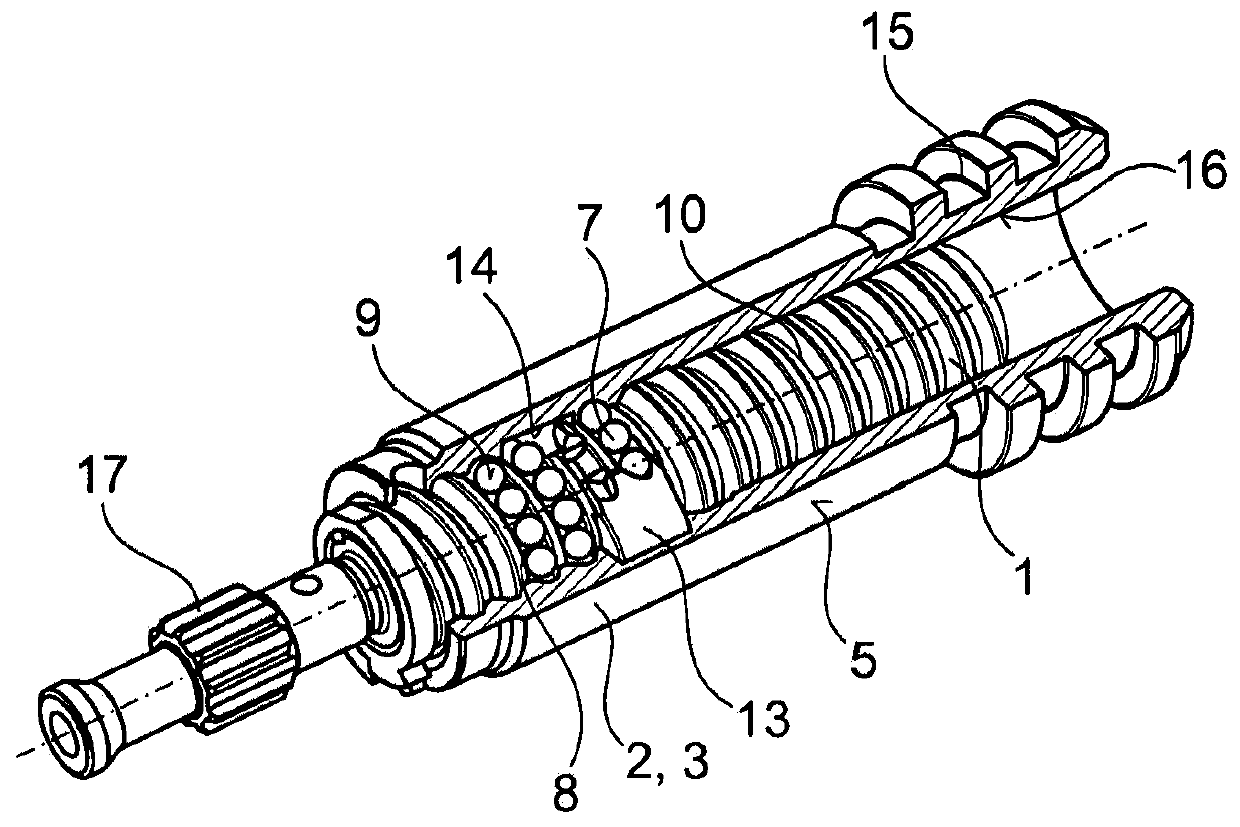

Threaded nut of ball screw drive

InactiveCN111051556ACorrosion resistanceSufficient rolling strengthToothed gearingsBrake actuating mechanismsBall screw driveManganese

The invention relates to a threaded nut (2) of a ball screw drive, having a ball groove (9) which is formed on the internal periphery and is wound helically around a spindle axis of the ball screw drive, the threaded nut (2) being formed as a hydraulic piston (3) from a martensitically hardened steel which is corrosion-resistant with respect to brake fluid and which contains, expressed in percentages by weight: at least 0.4% and up to 1.3% carbon C, and up to 2% silicon Si, and up to 2% manganese Mn, and at least 12% and up to 20% chromium Cr, as well as 0% and up to 2% molybdenum Mo, and 0% and up to 0.2% vanadium V, and 0% and up to 3% nickel Ni, and less than 0.015% phosphorus P and sulfur S combined, the remainder being iron.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com