Method of producing a flat zirconium alloy product, flat product thus obtained and a nuclear plant reactor grid which is made from said flat product

一种锆合金、扁平的技术,应用在制造轻水核电站中反应堆的元件领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The applicable zirconium alloy of the present invention contains (percentage is by weight):

[0040] - 0.5-3.5%, especially 0.5-1.5% Nb;

[0041] - preferably at most 1.5% Sn;

[0042] - preferably at most 0.5% Fe;

[0043] - preferably Cr and / or V, where Cr+V≤0.3%;

[0044] - optionally, sulfur, up to 100 ppm;

[0045] - optionally, oxygen, up to 2000 ppm;

[0046] - optionally, silicon, up to 150 ppm; and

[0047] - Unavoidable impurities produced by smelting.

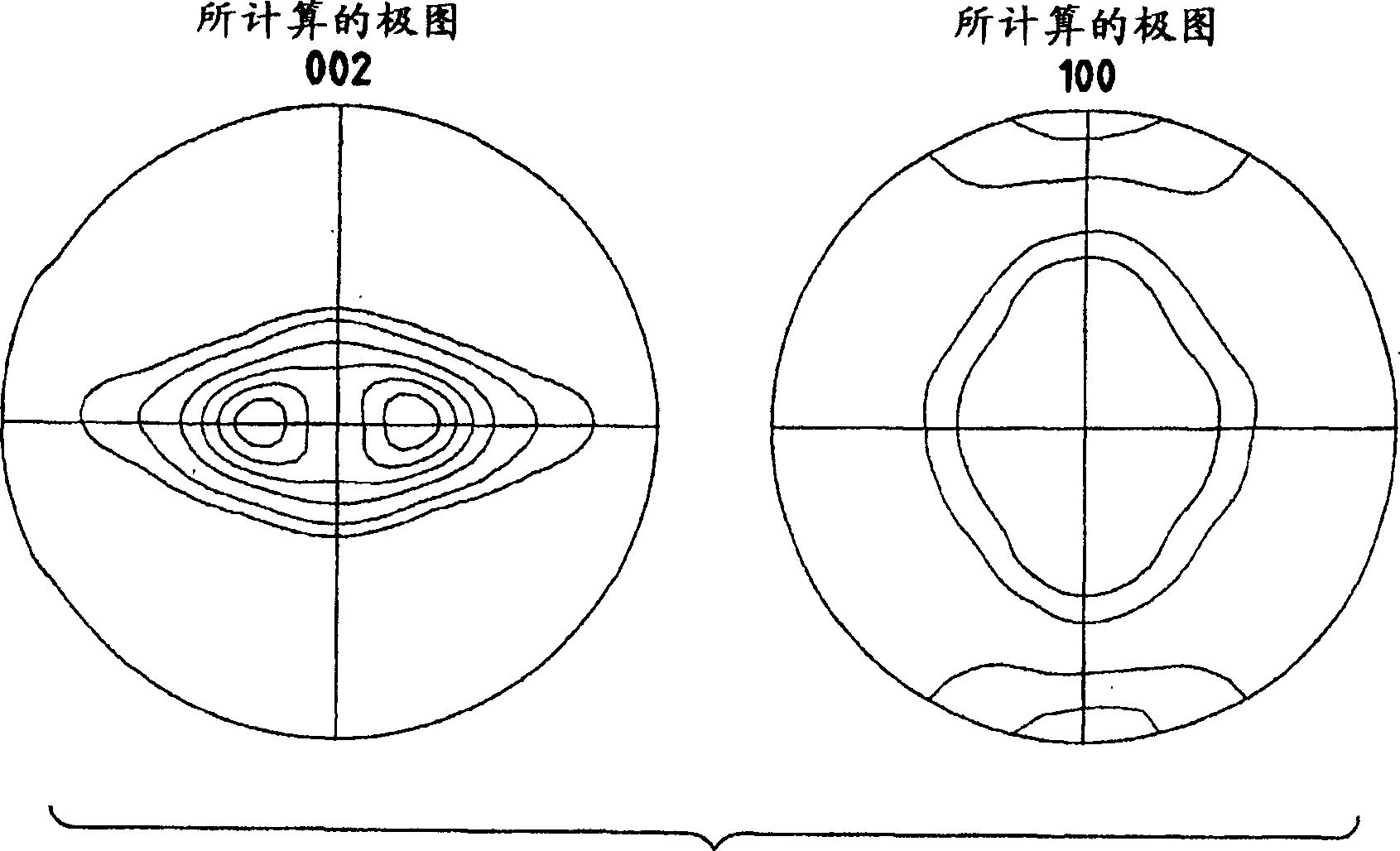

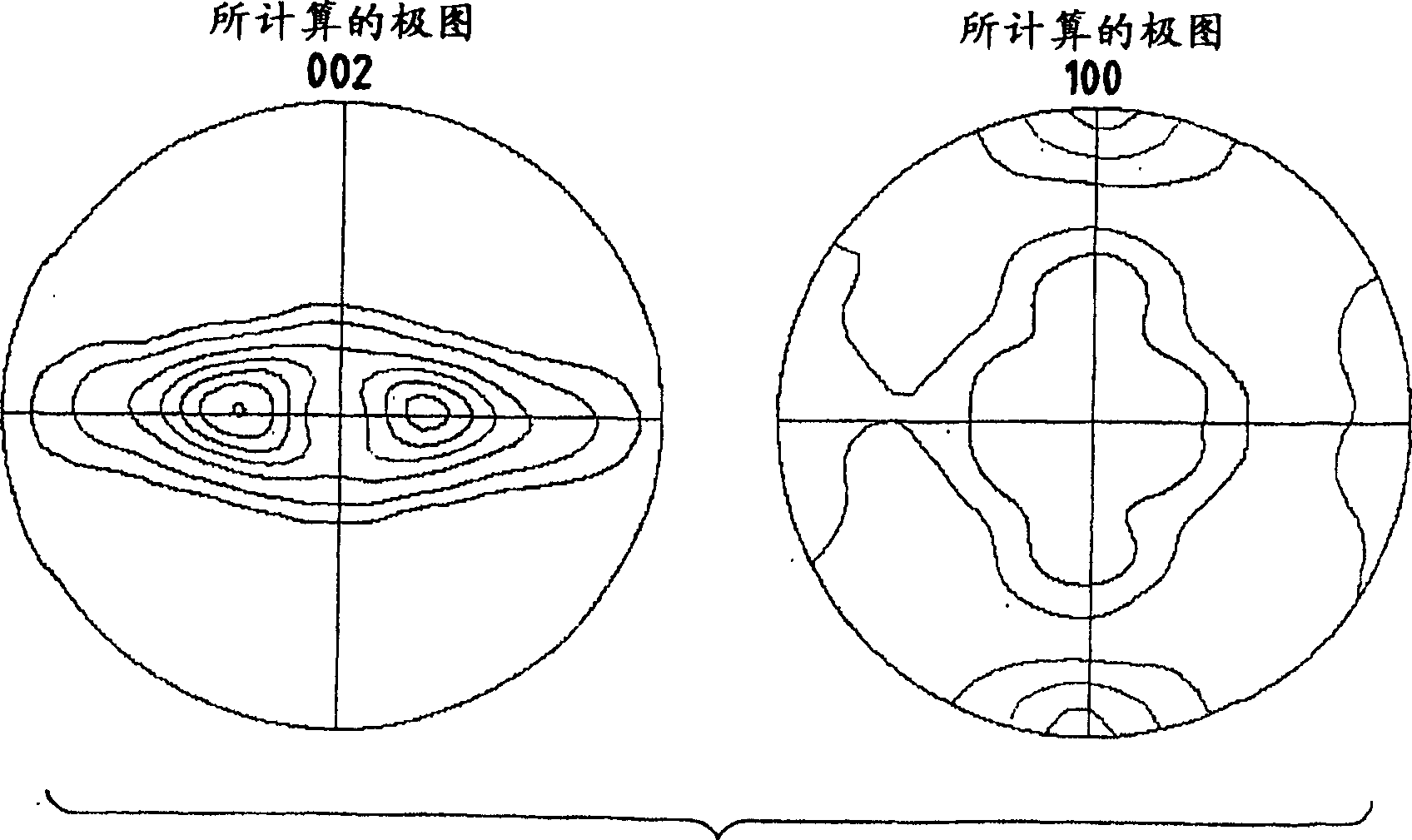

[0048] According to the present invention, one or more hot rolling operations are carried out after the ingot having the above composition has been smelted and formed. This hot rolling (or its last hot rolling if there are several hot rollings) must therefore be carried out while the zirconium alloy is in one of the α+β or β regions, more precisely, according to the invention, in the alloy according to the Nb content Depending on the minimum temperature to be performed between 1100°C. The minimum tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com