Threaded nut of ball screw drive

A technology of ball screw and transmission device, which is applied in the direction of transmission device, gear transmission device, brake, etc., to achieve the effect of small size and uniform property characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

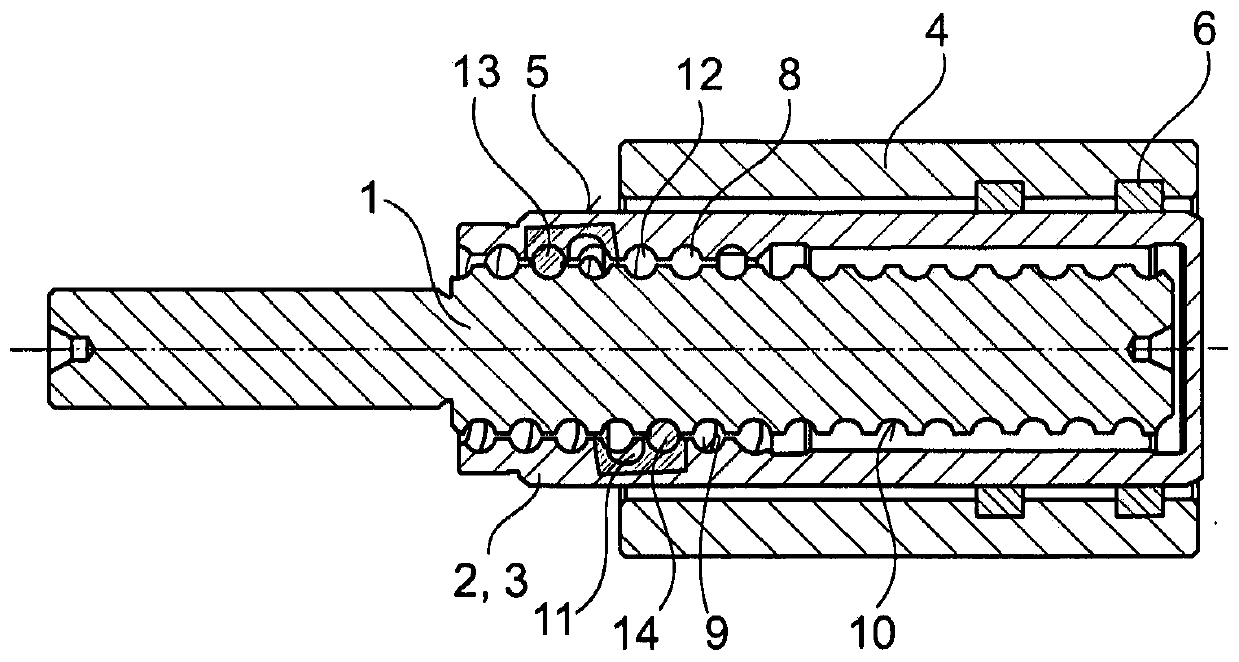

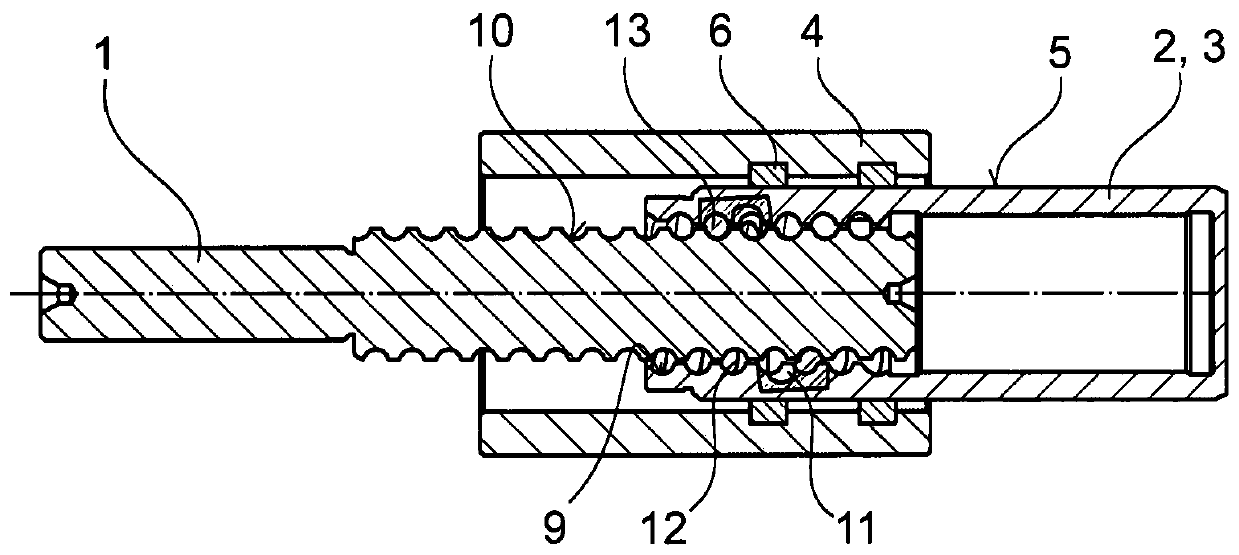

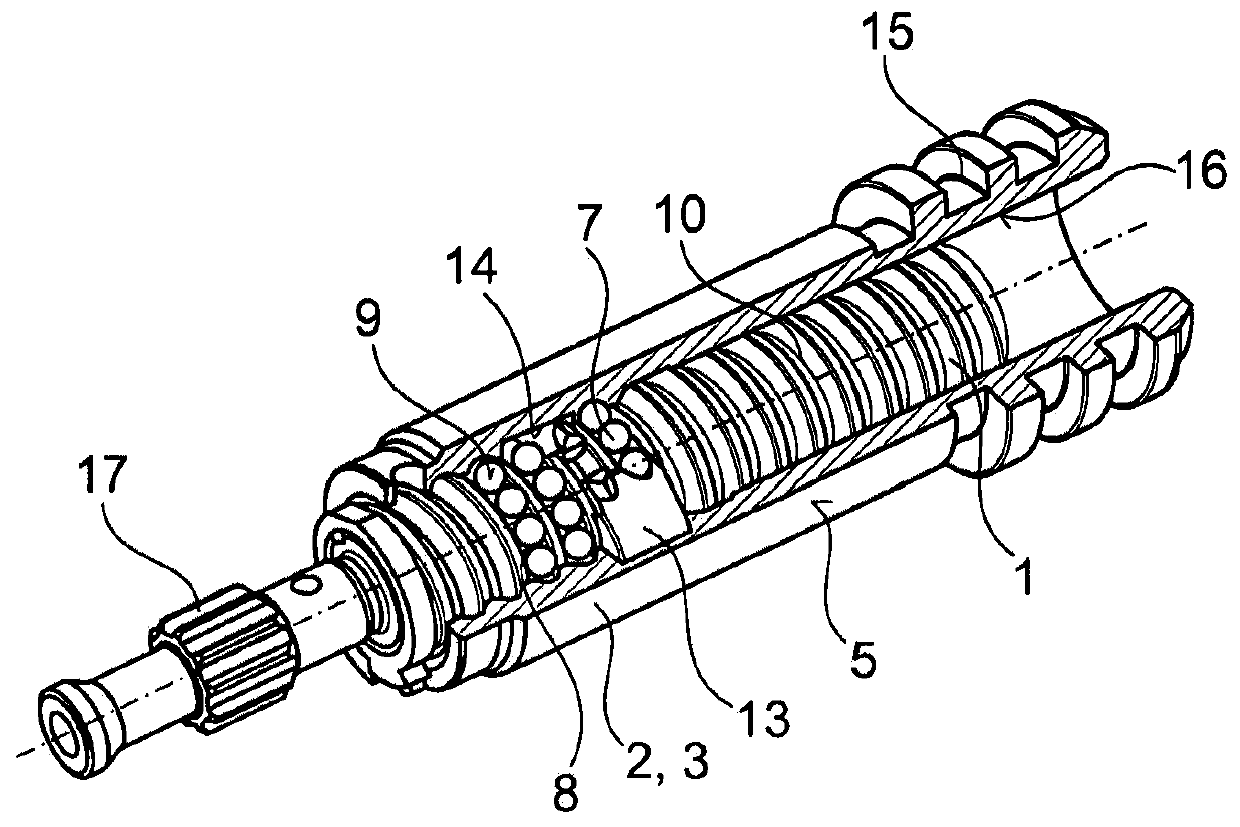

[0031] figure 1 with figure 2 A first embodiment of the ball screw transmission device according to the present invention is shown. The ball screw transmission device has a screw 1 driven in rotation and a nut 2 arranged on the screw 1 to be movable in the axial direction. figure 1 Shows a ball screw drive with a nut 2 that has been moved in and figure 2 The ball screw drive with the nut 2 pulled out is shown.

[0032] The nut 2 is configured as a piston 3 which engages in a cylinder 4 which is only schematically shown. Instead of the cylinder ground, a housing may also be provided. The outer peripheral surface of the nut 2 is configured as a cylindrical sealing surface 5 of the piston 3. The hydraulic pressure chamber defined by the piston 3 and the cylinder 4 is not shown. The pressure chamber is connected to the right end of the cylinder 4. When the ball screw drive is operated (that is, when the screw 1 is driven in rotation), the piston 3 is displaced relative to the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com