Lance tube

A spray gun and ring-shaped technology, applied in the direction of furnace, furnace type, charge manipulation, etc., can solve the problems of expensive and difficult welding, achieve the effect of improving force distribution, ensuring corrosion resistance, and increasing the interface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

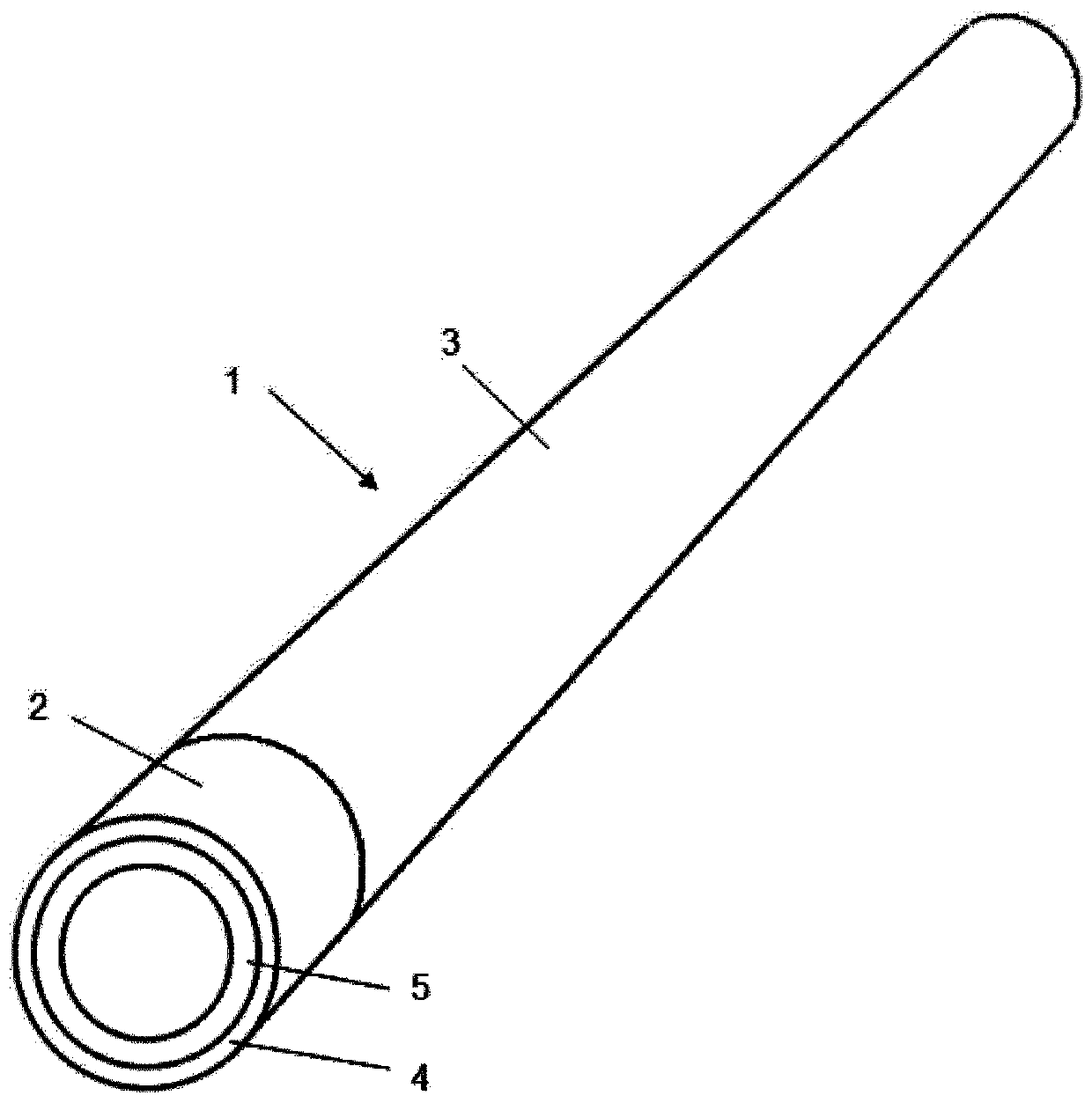

[0040] figure 1 A spray gun barrel 1 according to an embodiment of the present disclosure is shown schematically and not to scale. The lance barrel has a relatively short double-layered end portion 2 and a single-layered main portion 3 . The double-layered end portion 2 has an annular outer layer 4 made of a first alloy and an annular inner layer 5 made of a second alloy. The single-layer main part 3 is formed entirely of the second alloy forming the inner layer 5 of the double-layer end part 2 .

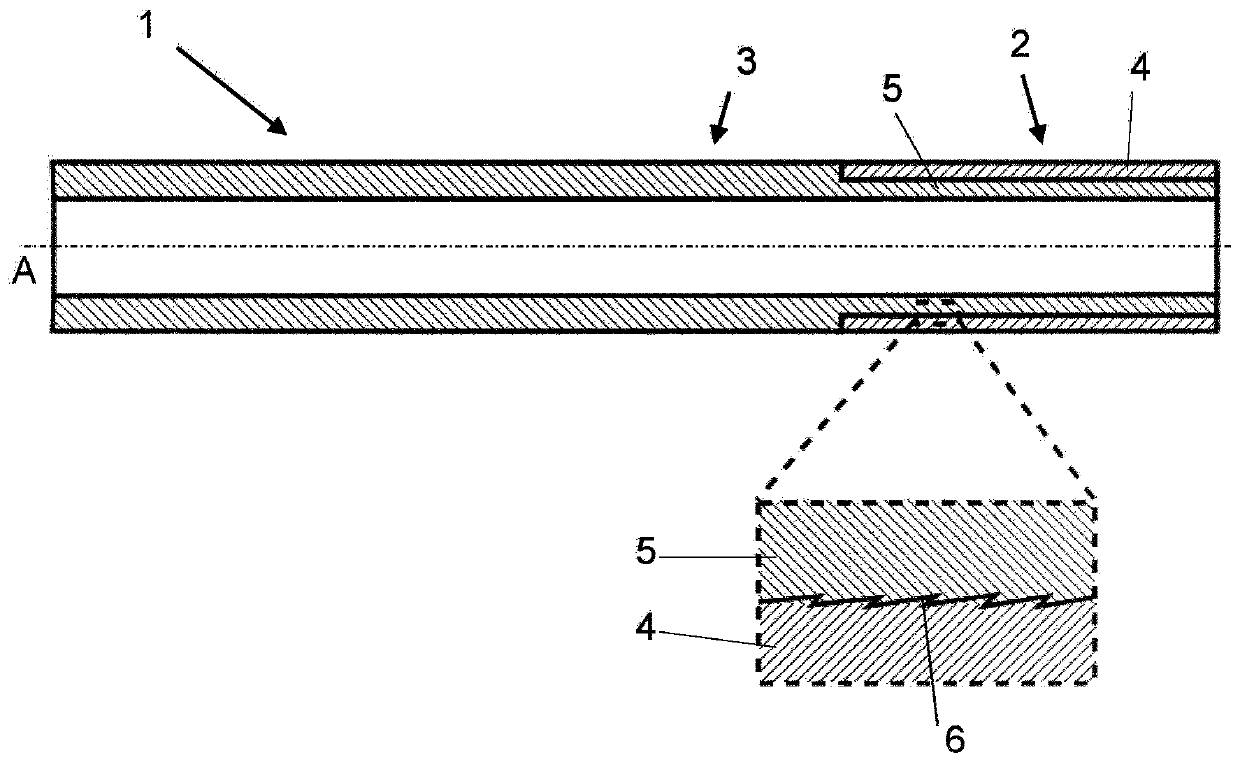

[0041] figure 2 A straight lance tube 1 is shown schematically in a section taken along its longitudinal axis A. It can be seen from the enlarged view of the marked area that the helically extending thread 6 runs in the interface between the annular outer layer 4 and the annular inner layer 5 . A helically extending thread 6 serves to mechanically interlock the two layers 4 , 5 . However, the layers 4, 5 are also joined by a metallic bond formed in the interface by thermal pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com