Acidic water treatment device and treatment process based on device

A treatment device and acid water technology, which is applied in natural water treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of potential safety hazards, difficult construction, and damage of the device, and reduce equipment cost, reduce processing difficulty, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

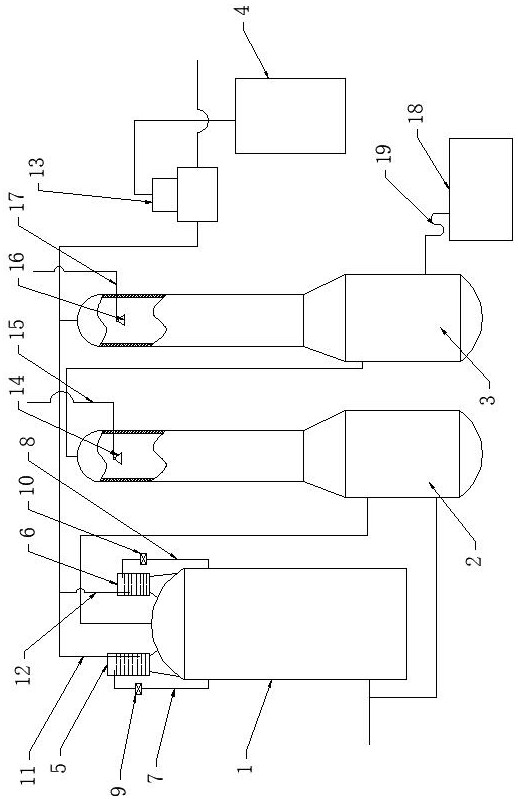

[0039] Such as figure 1 As shown, the present invention provides a kind of acidic water treatment device, comprises raw water tank 1, water washing tower 2, alkali washing tower 3, heating combustion furnace 4;

[0040] The gas outlet of the raw material water tank 1 is connected with the gas inlet of the washing tower 2;

[0041] The gas outlet of water washing tower 2 is connected with the gas inlet of alkali washing tower 3;

[0042] The gas outlet of alkali washing tower 3 is connected with the gas inlet of heating combustion furnace 4;

[0043] Water-sealed tank A5 and water-sealed tank B6 are installed on the top of raw material water tank 1;

[0044] The raw material water tank 1 is made of 304 stainless steel; after testing, it is found that the chloride ion content in the acidic water produced by crude oil and coal tar processing is below 20 mg / L, and the raw material water tank 1 made of 304 stainless steel meets the anti-corrosion requirements. Therefore, on the ...

Embodiment 2

[0057] Based on the acidic water treatment process of the above-mentioned device, the process is as follows:

[0058] (1) Desalted water is injected into water-sealed tank A5 and water-sealed tank B6 respectively; the liquid level in water-sealed tank A5 is 30 cm, and the bottom end of vent pipe A11 extends 20 cm below the liquid level of water-sealed tank A5 as a positive Pressurized water-sealed tank is used; the liquid level in water-sealed tank B6 is 15cm, and the bottom end of vent pipe B12 extends 5cm below the liquid level of water-sealed tank B6, which is used as a negative pressure water-sealed tank;

[0059] (2) Pass the acidic water into the raw material water tank 1 made of 304 stainless steel, heat and deoil the raw material water tank 1, and adjust the opening of the valve A9 and valve B10 so that the water in the raw material water tank 1 The pressure is maintained between -500Pa-2000Pa; during this treatment process, the oil content in the acidic water can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com