Material of case for storage cell

A shell material and storage battery technology, applied in the direction of battery box/case material, battery pack parts, battery box/coat, etc., can solve problems such as insufficient corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

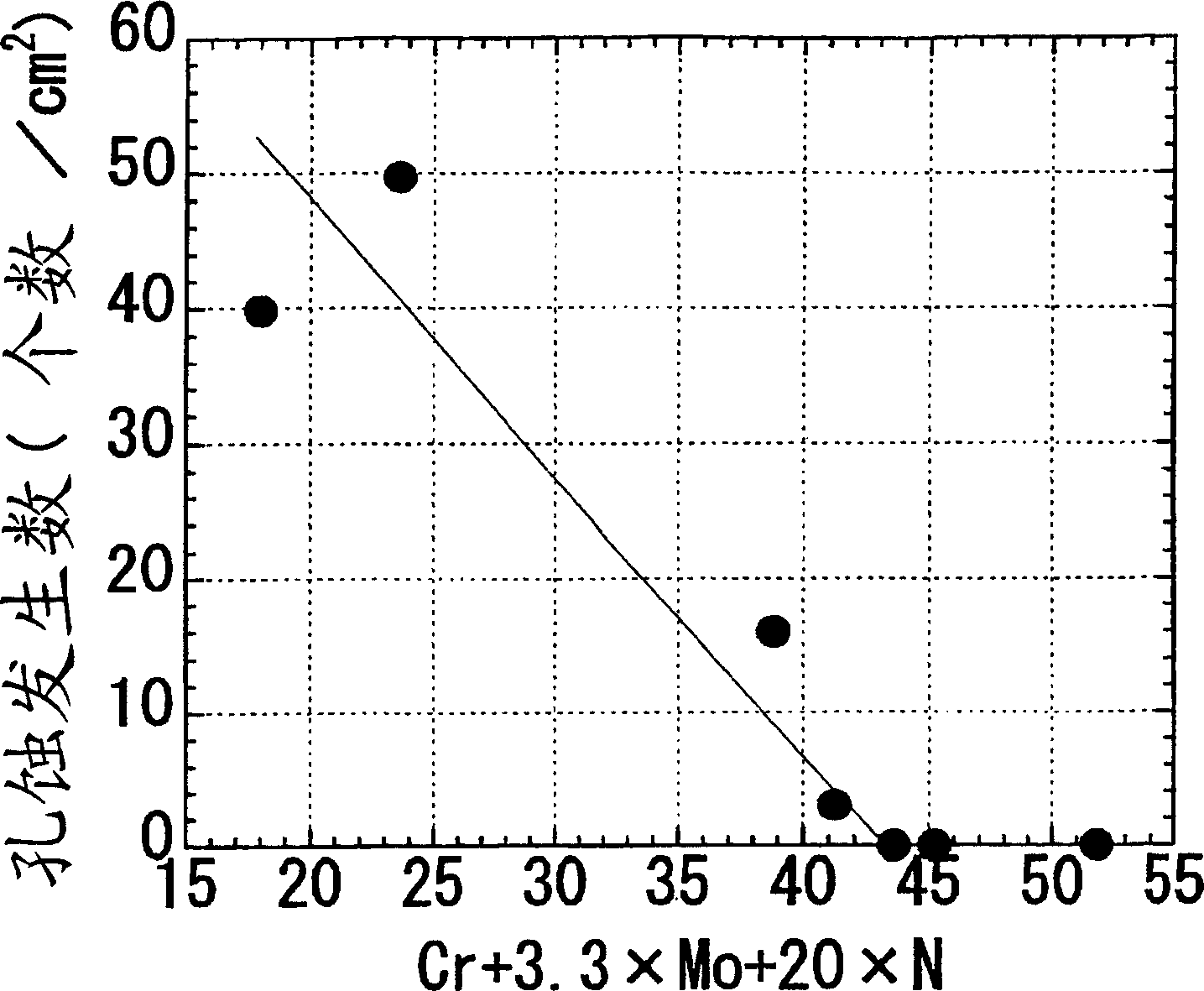

Problems solved by technology

Method used

Image

Examples

Embodiment

[0103] Hereinafter, examples of the present invention will be described.

[0104] First, the case material of the present invention and the comparative material made of austenitic stainless steel having the composition shown in Table 4 were made into samples with a thickness of 0.15 mm by the same manufacturing method as the above-mentioned tests 1 to 3. Material. The composition of oxide-like inclusions in steel is identified by an energy-dispersive X-ray spectroscopic analysis device. The sample material is a material that was subjected to bright heat treatment as final annealing after the first cold rolling, but a part of it was subjected to bright heat treatment after the first cold rolling was applied to reach the specified thickness, and then the second cold rolling was applied until the thickness becomes 0.15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com