Duplex stainless steel and preparation method thereof

A duplex stainless steel and preparation technology, which is applied in the field of stainless steel production and processing, can solve the problems of low elongation, poor elongation, insufficient elongation and toughness, etc., to increase the content, increase the tensile strength and elongation, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

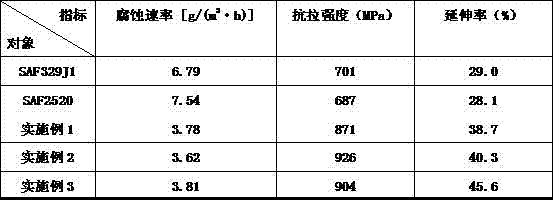

Examples

Embodiment 1

[0034] A duplex stainless steel whose chemical composition by weight percentage is: C: 0.01%, Si: 0.08%, Ni: 4.6%, Mn: 1.0%, Cr: 22.5%, N: 0.04%, Ca: 0.02% , Mg: 0.006%, Ti: 0.004%, Co: 0.007%, Y: 0.001%, the balance is Fe and unavoidable impurities, and the weight percentage of the impurities is ≤0.1%.

[0035] The preparation process of this kind of duplex stainless steel is carried out according to the following steps:

[0036] 1) Prepare the raw materials according to the composition and weight percentage content, and perform high-temperature vacuum dehydration and degassing treatment on the above-mentioned raw materials;

[0037] 2) Add the pure iron in the raw material into the electric arc smelting furnace for melting, the melting temperature is 1100°C, and the melting time is 30 minutes, then add Si, Ni, Cr, N, Ca, Mg in an orderly manner, and fill the furnace with argon As a protective gas, the pressure is controlled at 0.03MPa, and the temperature in the furnace is ...

Embodiment 2

[0041] A duplex stainless steel whose chemical composition by weight percentage is: C: 0.02%, Si: 0.1%, Ni: 6.3%, Mn: 2.0%, Cr: 24.1%, N: 0.05%, Ca: 0.03% , Mg: 0.008%, Ti: 0.006%, Co: 0.009%, Y: 0.002%, the balance is Fe and unavoidable impurities, and the weight percentage of the impurities is ≤0.1%.

[0042] The preparation process of this kind of duplex stainless steel is carried out according to the following steps:

[0043] 1) Prepare the raw materials according to the composition and weight percentage content, and perform high-temperature vacuum dehydration and degassing treatment on the above-mentioned raw materials;

[0044] 2) Put the pure iron in the raw material into the electric arc smelting furnace for melting, the melting temperature is 1200°C, and the melting time is 25 minutes, then add Si, Ni, Cr, N, Ca, Mg in an orderly manner, and fill the furnace with argon As a protective gas, the pressure is controlled at 0.04MPa, and the temperature in the furnace is s...

Embodiment 3

[0048] A duplex stainless steel whose chemical composition by weight percentage is: C: 0.03%, Si: 0.12%, Ni: 7.1%, Mn: 2.8%, Cr: 25.0%, N: 0.06%, Ca: 0.04% , Mg: 0.010%, Ti: 0.008%, Co: 0.01%, Y: 0.003%, the balance is Fe and unavoidable impurities, and the weight percentage of the impurities is ≤0.1%.

[0049] The preparation process of this kind of duplex stainless steel is carried out according to the following steps:

[0050] 1) Prepare the raw materials according to the composition and weight percentage content, and perform high-temperature vacuum dehydration and degassing treatment on the above-mentioned raw materials;

[0051] 2) Put the pure iron in the raw material into the electric arc smelting furnace for melting, the melting temperature is 1300°C, and the melting time is 20 minutes, then add Si, Ni, Cr, N, Ca, Mg in an orderly manner, and fill the furnace with argon As a protective gas, the pressure is controlled at 0.05MPa, and the temperature in the furnace is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com