Electrolytic machining system and method for foamed aluminium buffering and energy adsorbing material

An energy-absorbing material and processing system technology, which is applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of non-conformity of foamed aluminum with subsequent processes, damage, and deformation of pore structure on the surface of foamed aluminum, so as to achieve processing Wide range, no loss of electrolytic electrodes, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

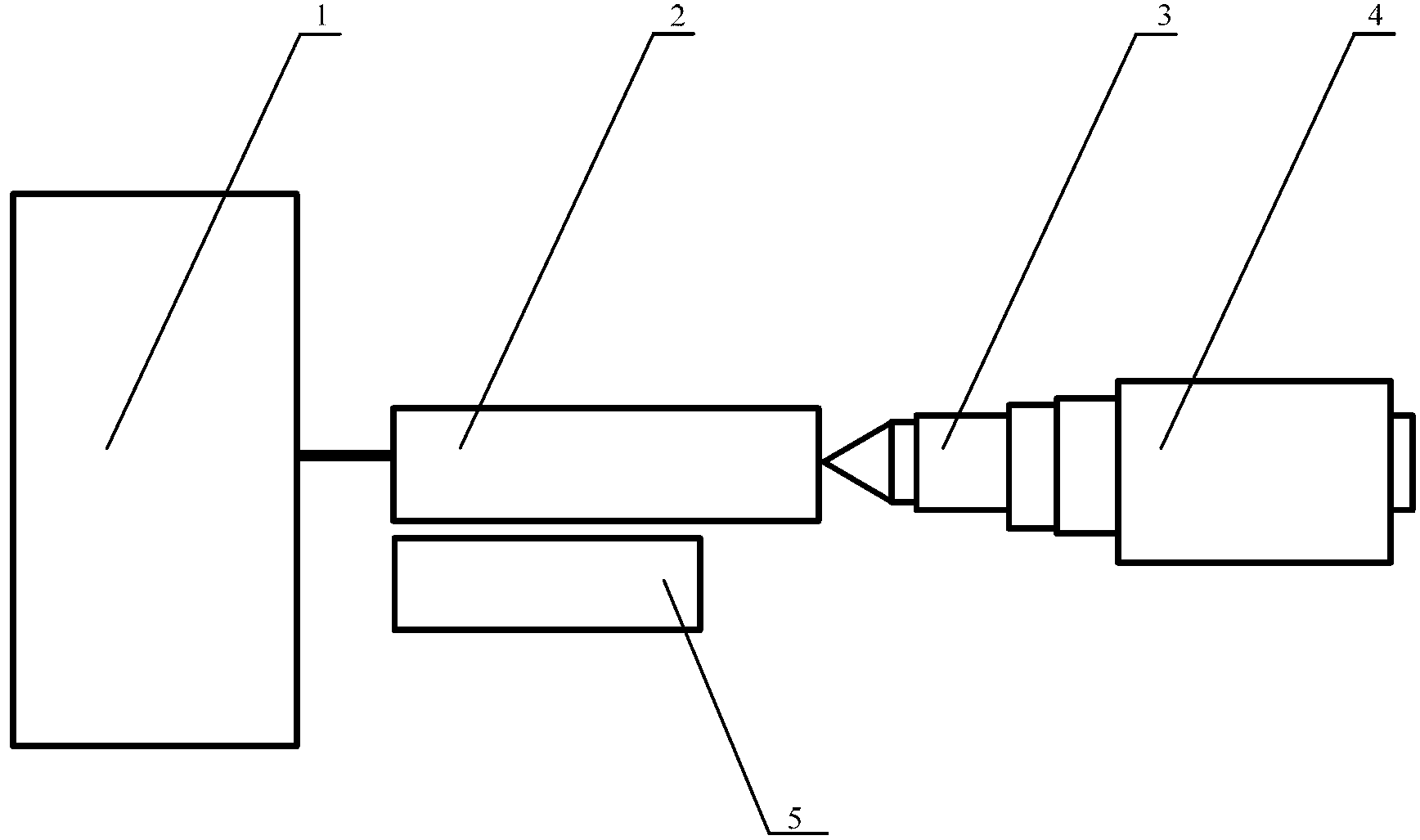

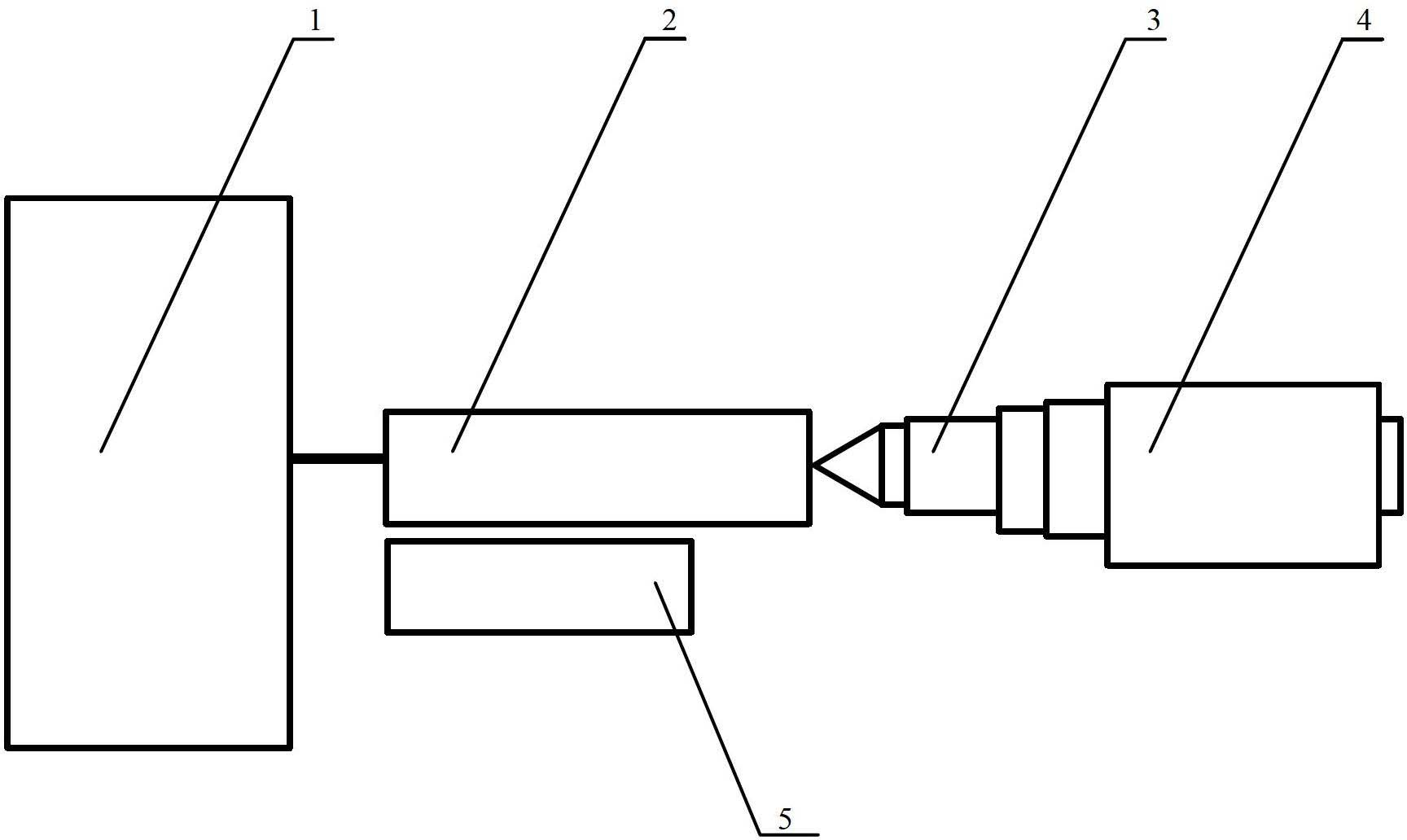

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0039] The electrolytic machining machine tool used is the electrolytic machining special machine tool PHECMC 6132-750 of Dongguan Huidie Automation Technology Co., Ltd. The processing electrode (ie electrolysis electrode) used is made of stainless steel 1Cr18Ni9Ti, and the two sides of the electrode are pasted with epoxy resin for insulation. The foamed aluminum porous material used is prepared by a melt foaming method with a grade of ZL111 aluminum alloy as a base material. The density of the aluminum foam is 0.65×10 3 kg / m 3 , and its main chemical composition is shown in Table 1.

[0040] Table 1 Chemical composition of ZL111 aluminum alloy (wt%)

[0041] Si

Mg

Ti

mn

Cu

Al

8.0~10.0

0.4~0.6

0.1~0.35

0.1~0.35

1.3~1.8

margin

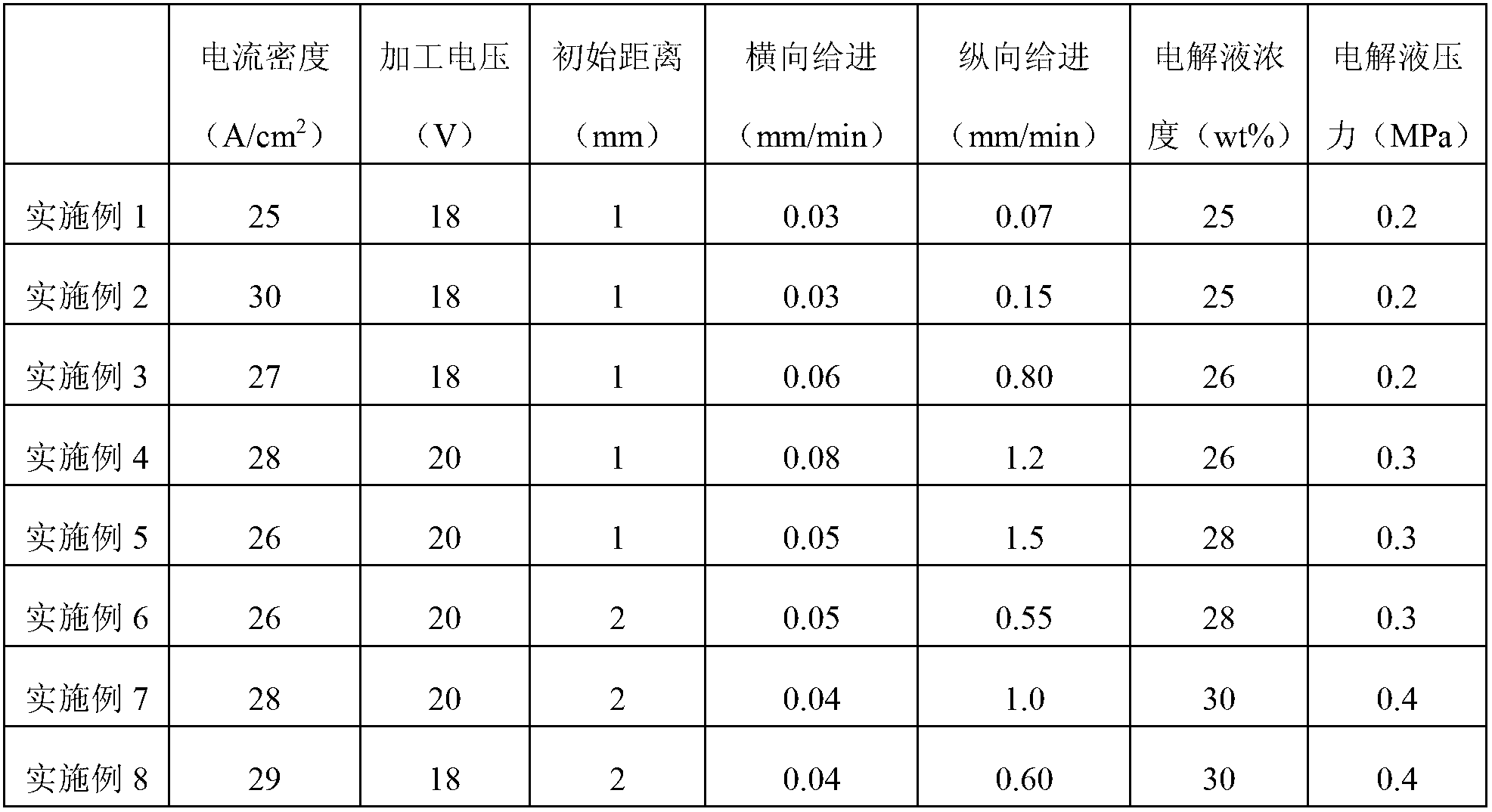

[0042] According to the implementation pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com