Method for coating a substrate with a spray material and functional layer achievable with this method

A technology of functional layer and friction power, applied in the field of coated substrates, can solve the problems that the diesel engine cannot reach the degree of benefit, and the functional layer does not reach the sufficient hardness of the diesel engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] According to this embodiment, the functional layer is deposited using arc wire spraying (LDS). In arc wire spraying, two wires of spray material are fed into the applicator head. An electric arc is ignited between the lines of sprayed material. In this case, the linear spray material melts and is applied / coated in a targeted manner by the carrier gas onto the substrate to be coated, where it cools, solidifies and forms the functional layer.

[0029] The linear spraying material mainly includes iron-chromium alloy. The sprayed material is microalloyed in such a way, at least by means of carbon, that when the sprayed material cools, the majority of martensite is already formed, austenite is practically absent and only minor ferrite is present Proportion.

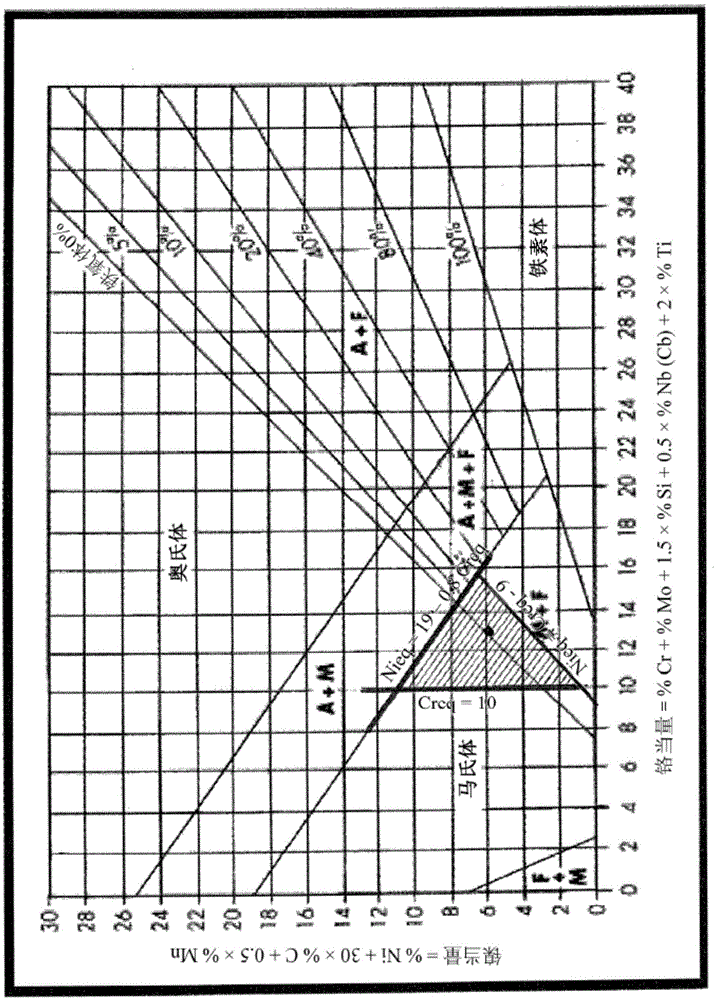

[0030] The composition of the functional layers derived from the characteristic parameters of the Scheffler diagram is as follows:

[0031] Creq=12.9 and Nieq=5.9

[0032] Here, the chromium equivalent is derived f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com