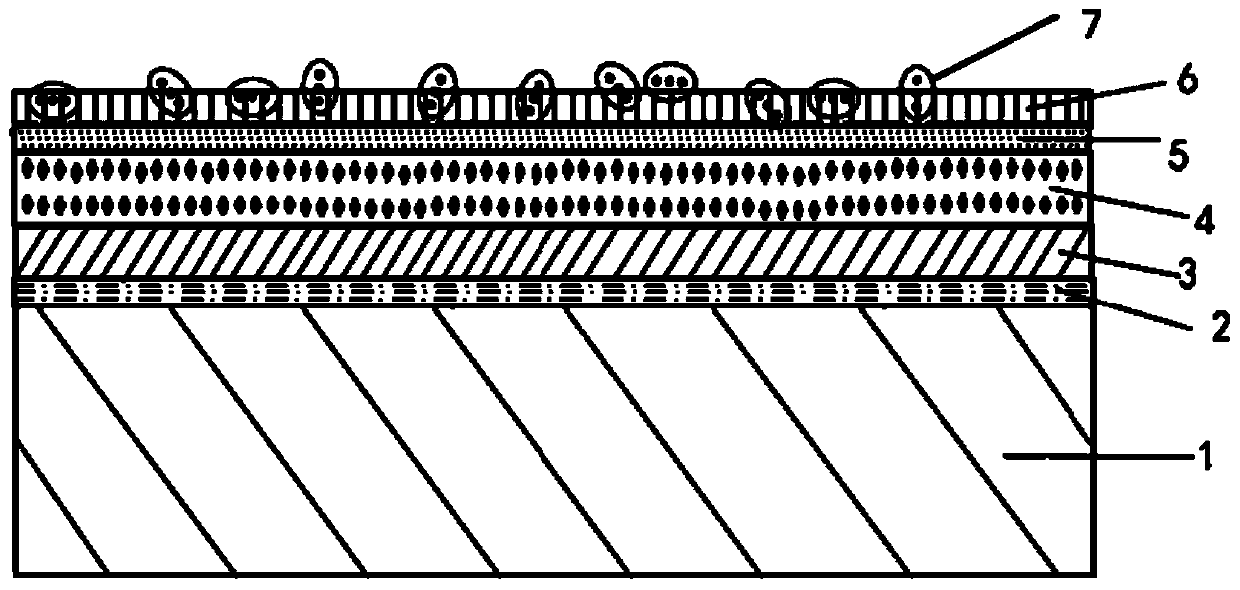

Multi-layer composite steel plate with visible-light response photocatalysis function and manufacturing method thereof

A multi-layer composite and photocatalytic technology, which is applied in chemical instruments and methods, separation methods, botanical equipment and methods, etc., can solve the problems that the long-term beauty of color steel plates cannot be guaranteed, and achieve the elimination of organic pollutants and increase the aesthetics , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

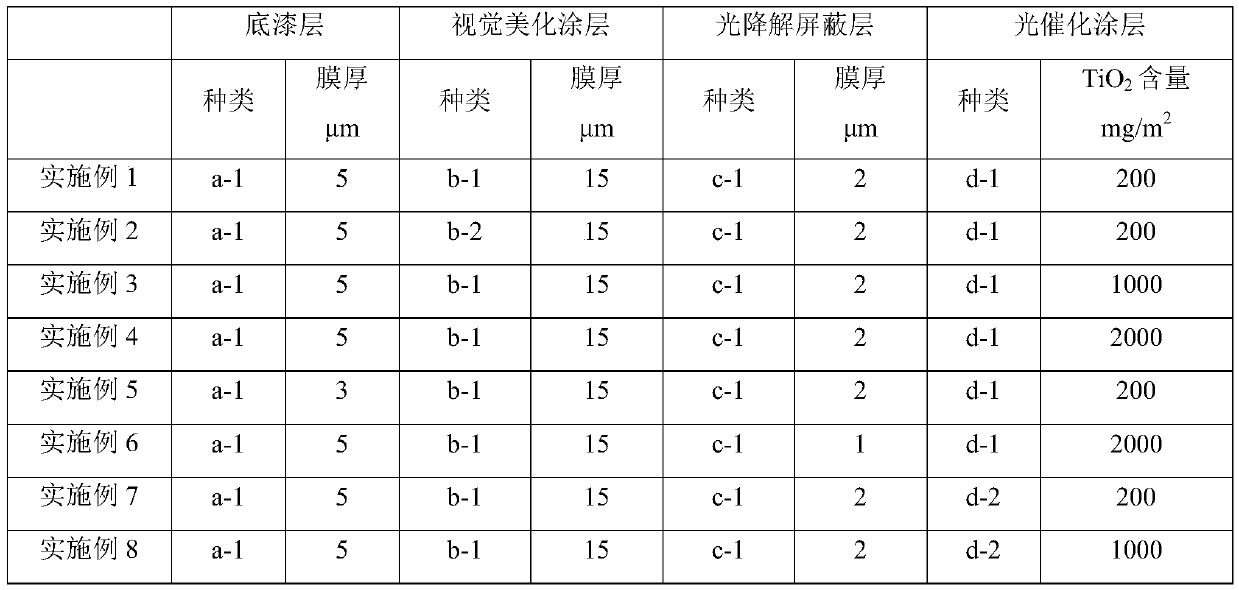

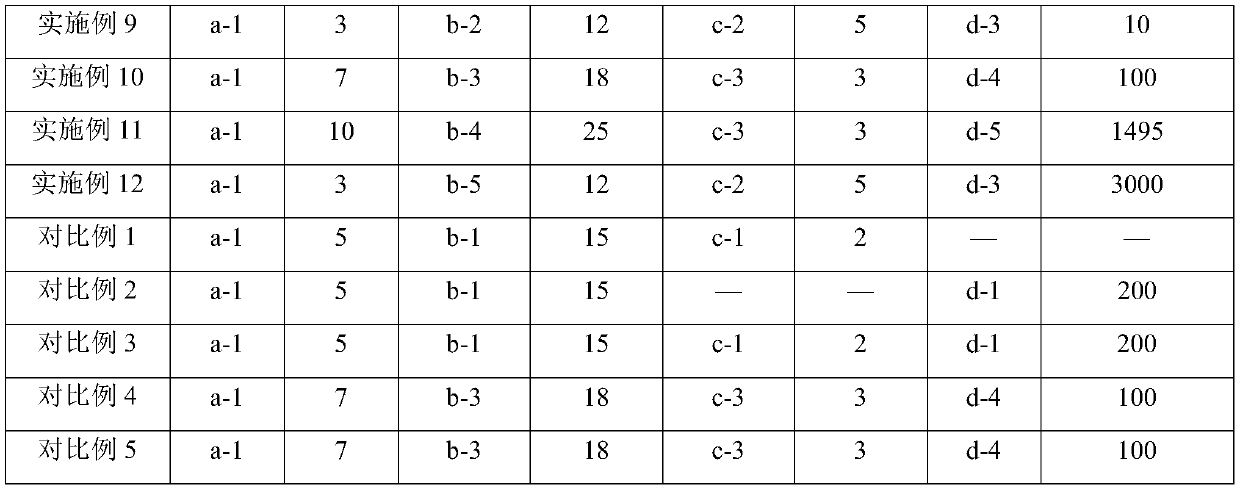

Embodiment 1

[0056] Step 1: Use a hot-dip galvanized steel sheet with a thickness of 0.5mm (zinc adhesion is 60g / m 2 , surface roughness Ra is 0.8 μ m ~ 1.2 μ m) as the substrate 1, the chromate treatment solution is applied by roller coating with an adhesion amount of 30 mg / m 2 The surface is treated (in terms of chromium) to form a corrosion-resistant film 2 .

[0057] Step 2: adopt the method for vertical roller coating, apply the coating (a- 1. Main ingredients: 20% to 40% polyurethane resin, 10% zinc butyrate antirust pigment and 10% to 15% ethylene glycol butyl ether, and the balance is xylene and butyl acetate) to be applied to galvanized steel by roller coating On the steel plate, the coated coating is then baked in a circulating hot air oven at 280°C for 30s to form a primer layer 3 with a thickness of 5 μm. The main film-forming resin of the primer layer 3 is preferably a polyurethane resin thermosetting resin, which is to improve the flexibility of the primer layer 3 and is co...

Embodiment 2

[0062] Step 1: Same as Example 1.

[0063] Step 2: Same as Example 1.

[0064] Step 3: the main components (the balance is xylene and butyl acetate) containing 20% polyurethane resin, 6% indigo pigment, 10% amino resin, 10% butyl acetate, and about 5% filler The organic solvent-based visual beautification paint (b-2) was coated on the above-mentioned primer coat 3 and heated at 380° C. for 25 s to form a visual beautification coat 4 .

[0065] Step 4: Same as Example 1.

[0066] Step 5: Same as Example 1.

Embodiment 3

[0068] Step 1: Same as Example 1.

[0069] Step 2: Same as Example 1.

[0070] Step 3: Same as Example 1.

[0071] Step 4: Same as Example 1.

[0072] Step 5: On the photodegradable shielding coating, the content of visible light-responsive nano-scale titanium dioxide photocatalytic particles is 5%, the mass percentage of anionic phosphate ester type dispersant is 0.5%, polytetrafluoroethylene particles (diameter 3-10 μm, content 10%), the mass percentage of silica sol is 7% and the balance is the aqueous solution (d-1) of deionized water with the adhesion amount being: 1000 mg / m 2 (with TiO 2 According to the method of roll coating, it is applied by a roller coating process, and heated at 350°C for 10 seconds to form a photocatalytic coating 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com