Method for preparing high grade non-oriented electrical steel adding rare earth cerium

A technology of grain-oriented electrical steel and high grade, applied in the field of electrical steel, can solve the problems of high cost, increased cost and high alloying elements, and achieve the effect of improving magnetic properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

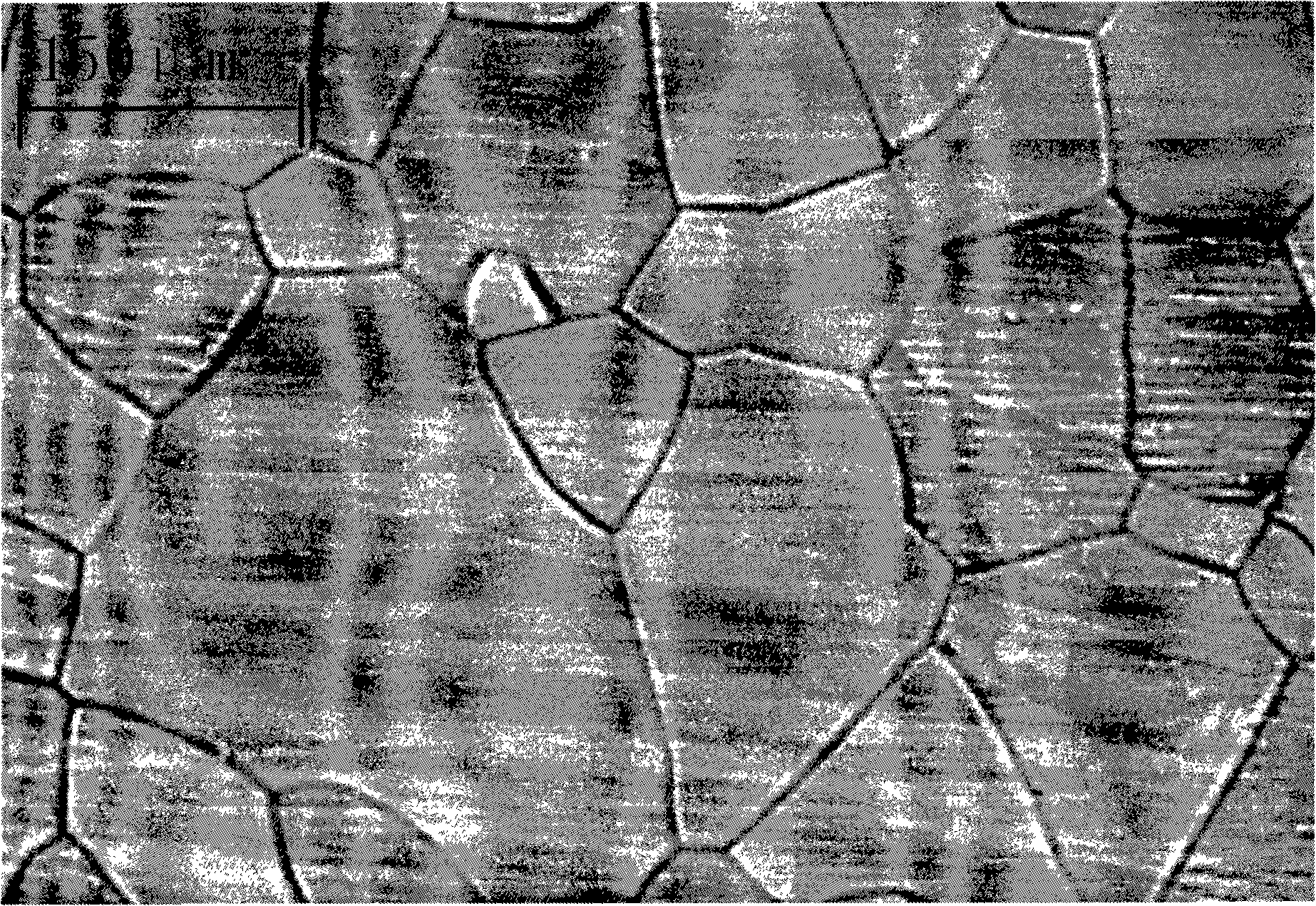

Image

Examples

Embodiment 1

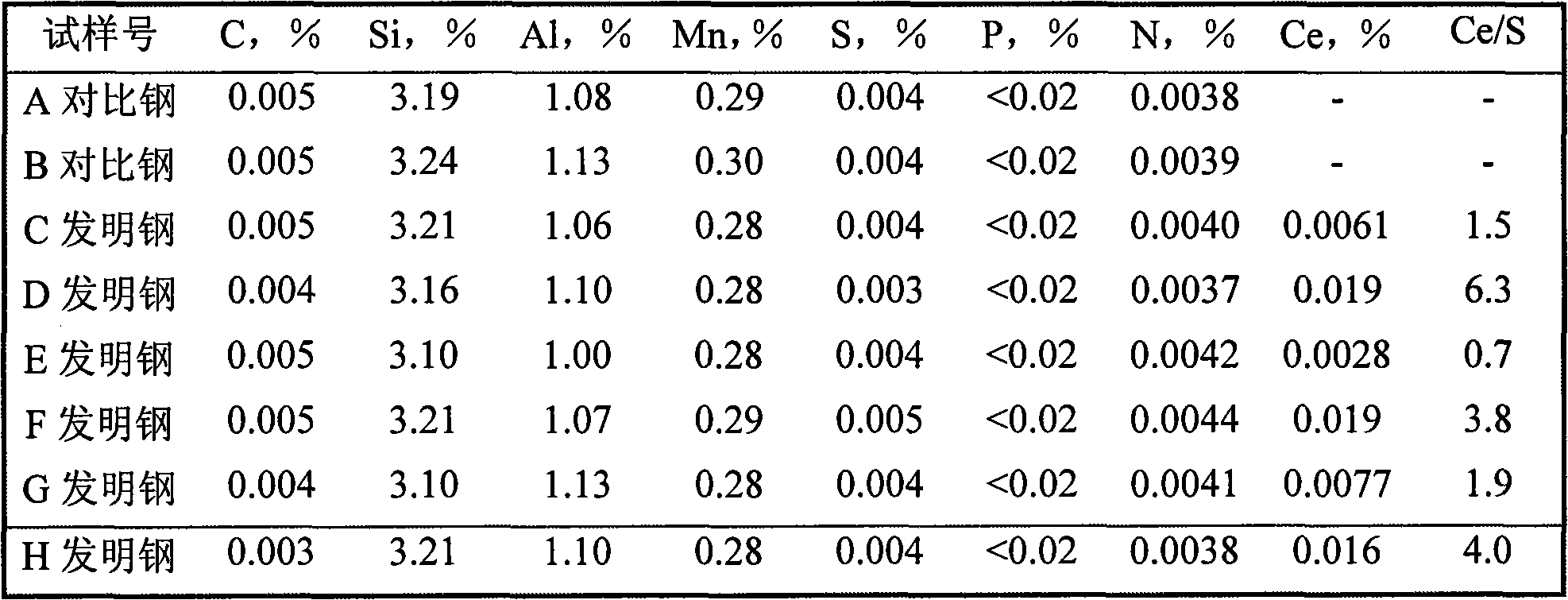

[0021] The chemical composition of the experimental steel slab is as follows:

[0022] Table 1 Main chemical composition of experimental steel slabs

[0023]

[0024] The experimental steel was heated to 950-1150°C, kept warm for 0.5-5h, and then hot-rolled to a thickness of 2.0-2.5mm. After normalization at 900-1050°C×60-300s, it was pickled and cold-rolled to 0.35mm, and the annealing temperature was 900-1050 ℃×60~180s, the annealing atmosphere is 30%H 2 +70%N 2 Mixed gas, without decarburization annealing, the cooling method is to cool the furnace mouth to 500-400 ℃, and then air-cool to room temperature for magnetic detection. The magnetic properties of 0.35mm experimental steel products are shown in Table 3.

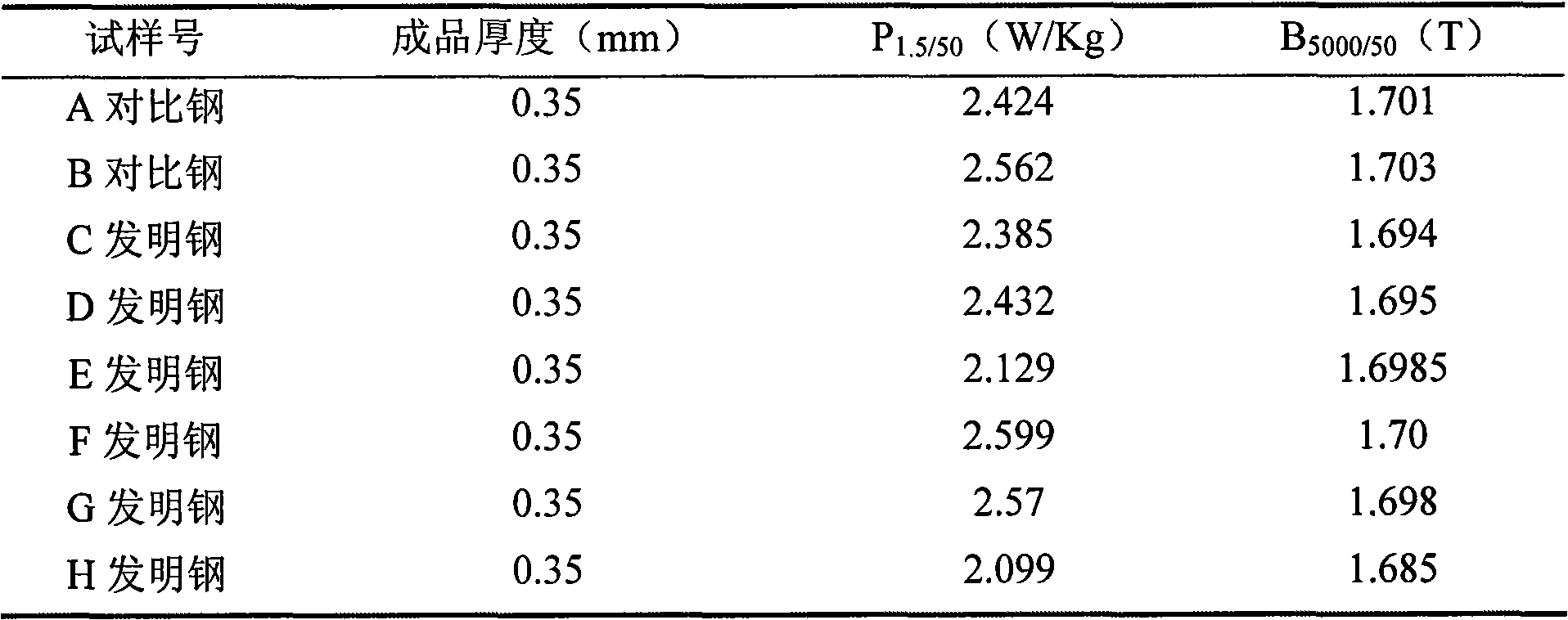

[0025] Table 2 Magnetic properties of finished 0.35mm experimental steel

[0026]

Embodiment 2

[0028] The experimental steel is heated to 1100-1150°C, heat-retained for 0.5-5h, and then hot-rolled to a thickness of 2.0-2.5mm. After normalization at 900-1050°C×60-300s, it is pickled and cold-rolled to 0.50mm, and the annealing temperature is 900-1050°C. ×60~180s, the annealing atmosphere is 30%H 2 +70%N 2 Mixed gas, without decarburization annealing, the cooling method is to cool the furnace mouth to 500-400 ℃, and then air-cool to room temperature for magnetic detection. The magnetic properties of 0.50mm experimental steel products are shown in Table 3:

[0029] Table 3 Magnetic properties of finished 0.50mm experimental steel

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com