Plasma processing apparatus

a processing apparatus and plasma technology, applied in the direction of electrical apparatus, electric discharge tubes, basic electric elements, etc., can solve the problem of non-uniform gas supply amount, and achieve the effect of uniform processing rate and sample processing shap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

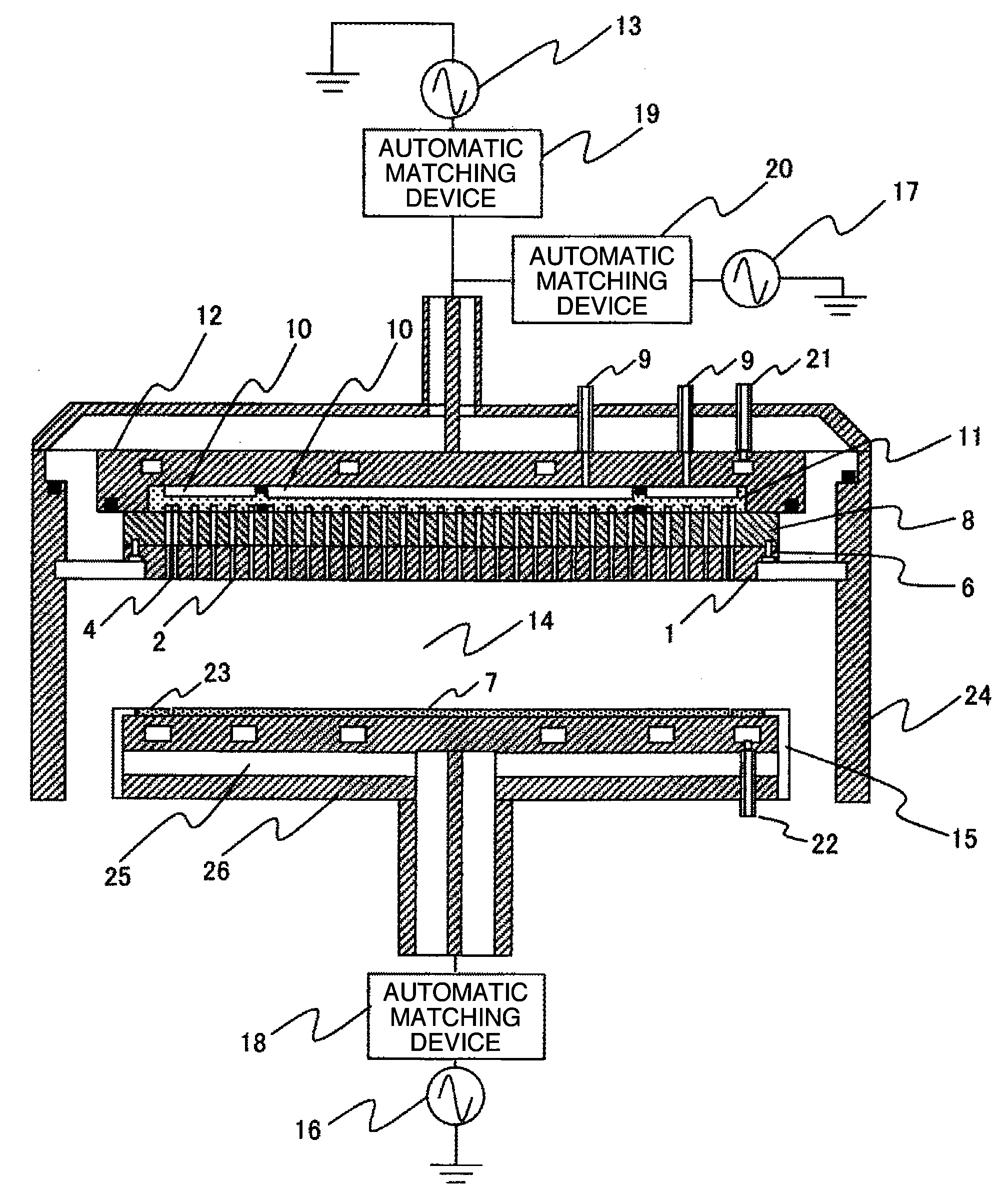

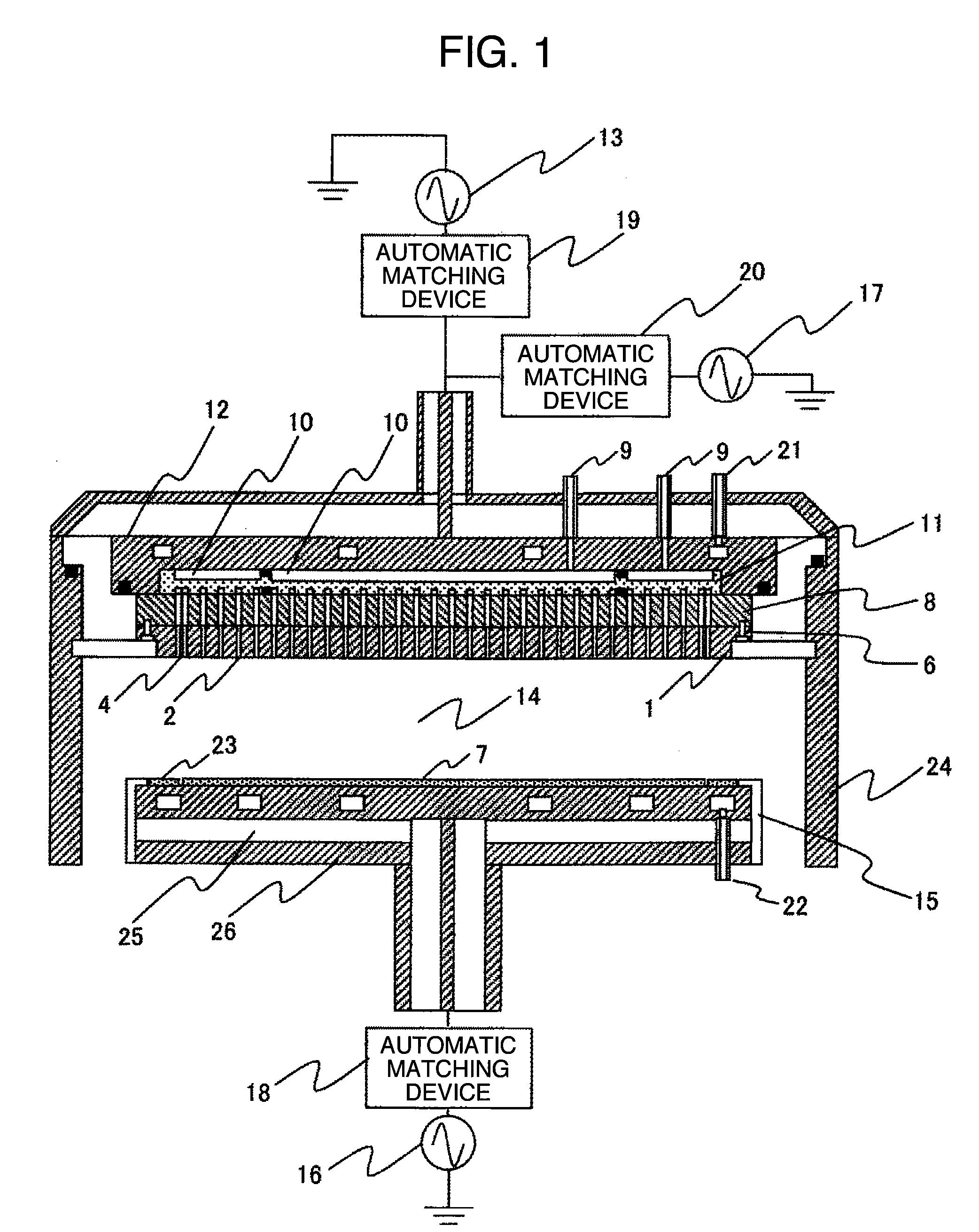

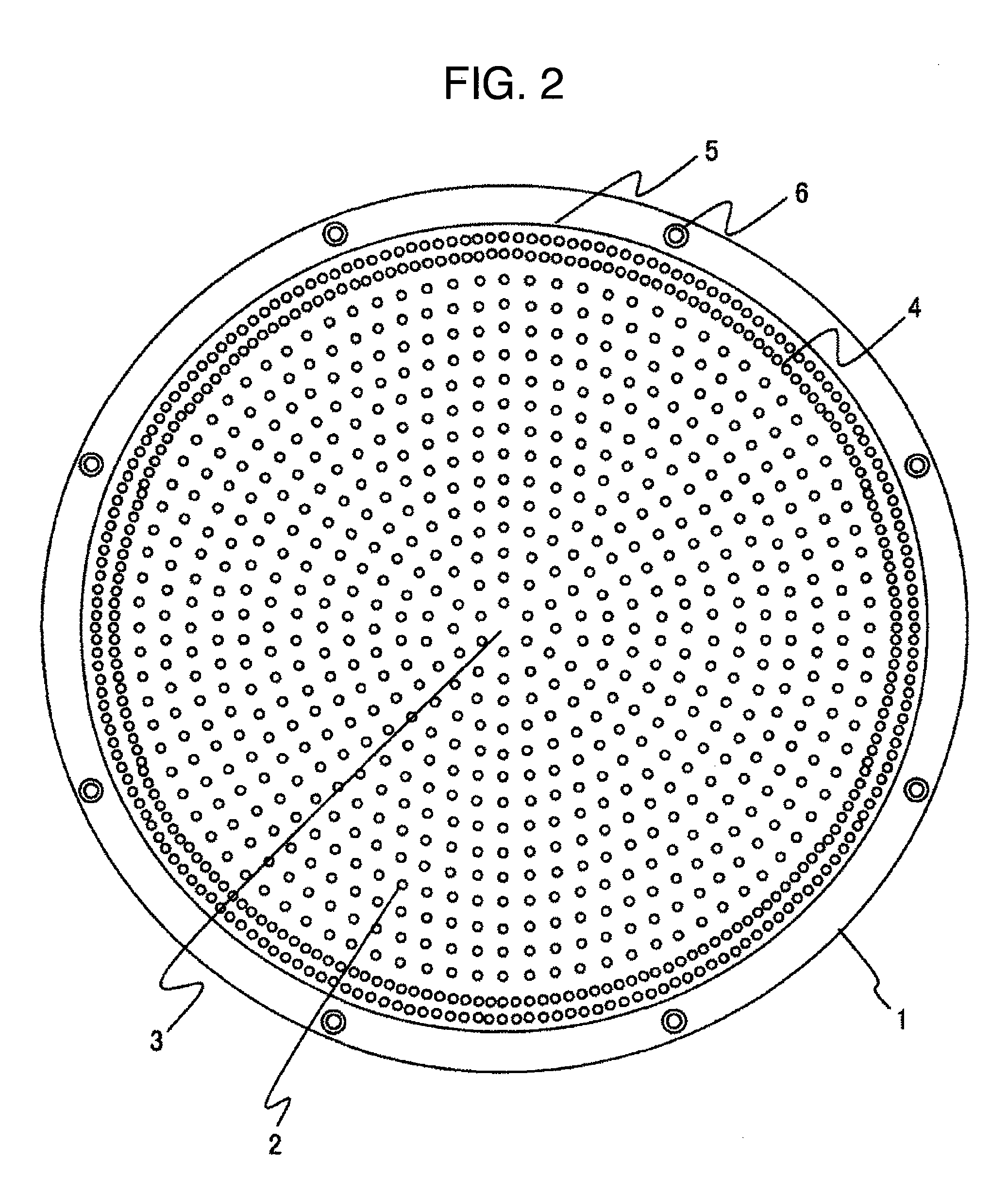

[0040]A first embodiment of the invention will be described with use of FIG. 1 and FIG. 2.

[0041]FIG. 1 is shows a section view of a plasma processing apparatus in one embodiment of the invention. The plasma processing apparatus includes an electrostatic chucking function built-in electrode (sample table) 15 for placing a sample 7 in a vacuum chamber 24 and a shower plate (gas supply unit) 1 faced to the sample table 15. In this way, a 200 MHz high-frequency power is supplied from a discharge-use high-frequency power source 13 to a conductor-type antenna 12 incorporated with a plate 8 and a dispersion plate 11 to turn a gas supplied from the shower plate 1 into a plasma in a discharge space 14. Further, a 4 MHz high-frequency voltage is applied to the sample 7 from a high-frequency power source 16 via the electrostatic chucking function built-in electrode 15 to accelerate ions in the plasma and to be incident to the surface of the sample 7. The 4 MHz high-frequency voltage is also ap...

embodiment 2

[0073]A second embodiment of the invention will be described with use of FIG. 15.

[0074]FIG. 15 is a schematic diagram showing a shower plate 1 in the second embodiment of the invention.

[0075]In the case of this embodiment, each diameter of gas injection holes 27 faced to the wafer edge portion and formed on the periphery portion of the shower plate 1 is 1.3 times that of the other gas injection holes 2, that is, the hole diameter at the periphery portion is 0.65 mm while the other hole diameter is set to 0.5 mm, and the gas-injection-hole number density is set to uniformity. In the case of the first embodiment, the gas supply amount to the wafer edge portion is adjusted by the gas-injection-hole number density of the gas injection holes 4 each having the same diameter and formed at the periphery portion of the shower plate 1. In the case of the second embodiment, the gas supply amount is adjusted by the hole diameter.

[0076]A conductance at a time when the gas passes through the gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com