Rubber composition and tire

A technology of rubber composition and diene rubber, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of mold contamination, easy contamination of molds, uneven color and gloss of rubber composition, etc. The effect of preventing mold contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

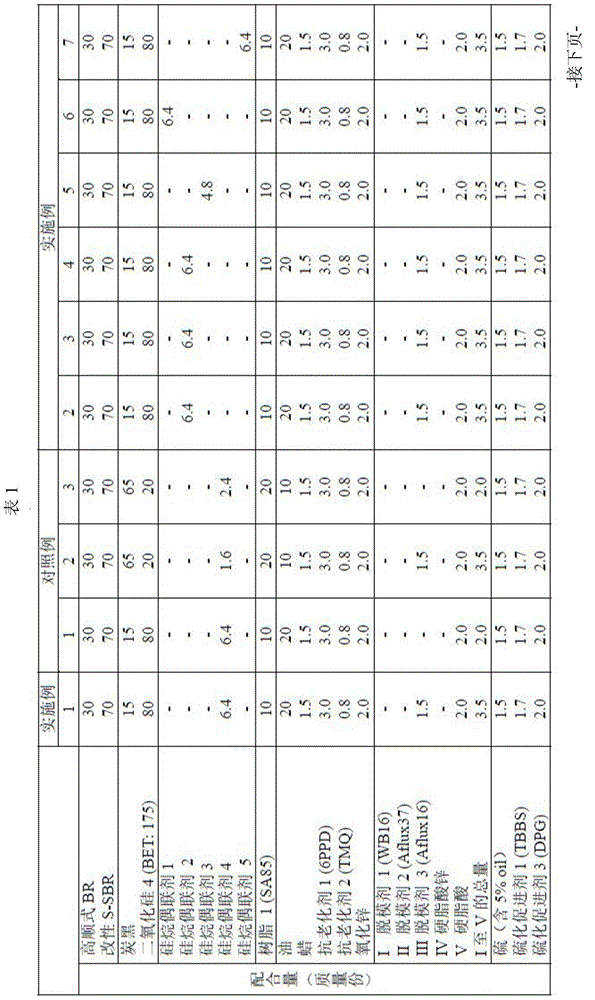

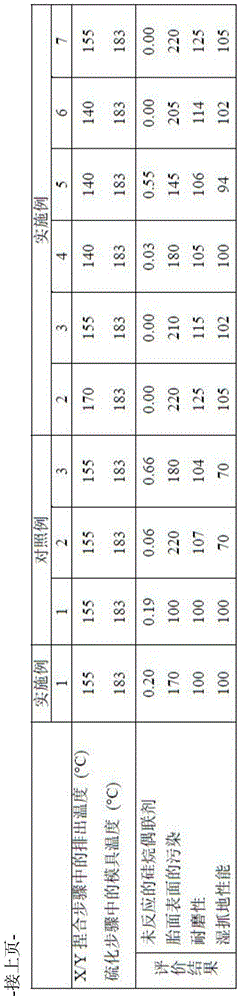

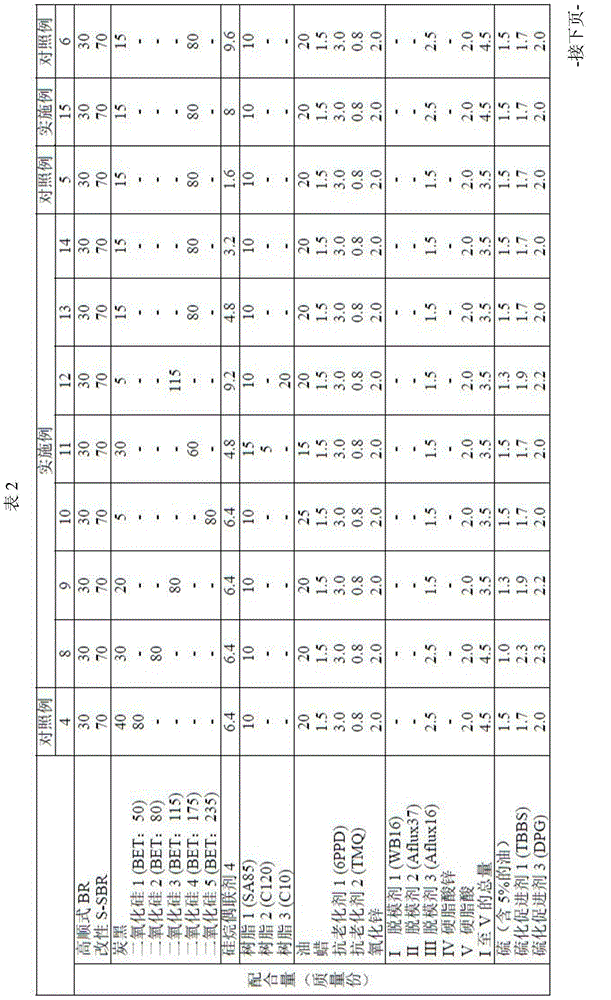

Examples

Embodiment

[0089] Although the present invention has been described based on the examples, the present invention is not limited to the examples.

[0090] Various chemical reagents used in Examples and Comparative Examples are described below.

[0091] NR:TSR20

[0092] High cis BR: CB25 (Nd catalyzed high cis BR, Mooney viscosity ML 1+4 : 44, Mw / Mn: 1.78, Mw: 500,000, Mn: 280,000, cis 1,4 bond content: 96.2 mass%, trans 1,4 bond content: 3.1 mass%, vinyl content: 0.7 mass% ), manufactured by Lanxess

[0093] Modified S-SBR: Modified S-SBR prepared by the following preparation example of modified S-SBR (styrene content: 37% by mass, vinyl content: 56% by mass, Mw: 270,000)

[0094] Carbon black: SHOBLACK N220 (N220, BET: 114m 2 / g), manufactured by CABOT Japan

[0095] Silica 1: ULTRASILU360 (BET: 50m 2 / g), manufactured by Evonik Degussa

[0096] Silica 2: Z1085Gr (BET: 80m 2 / g), manufactured by Rhodia Corporation

[0097] Silica 3: Z115Gr (BET: 115m 2 / g), manufactured by Rho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com