Anti-fouling anti-dazzle film

An anti-glare film and anti-fouling technology, applied in optics, optical components, instruments, etc., can solve the problems of easy scratches, sticky dirt, glare and glare on the surface of the touch panel, so as to avoid whitening and improve wettability , The effect of water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

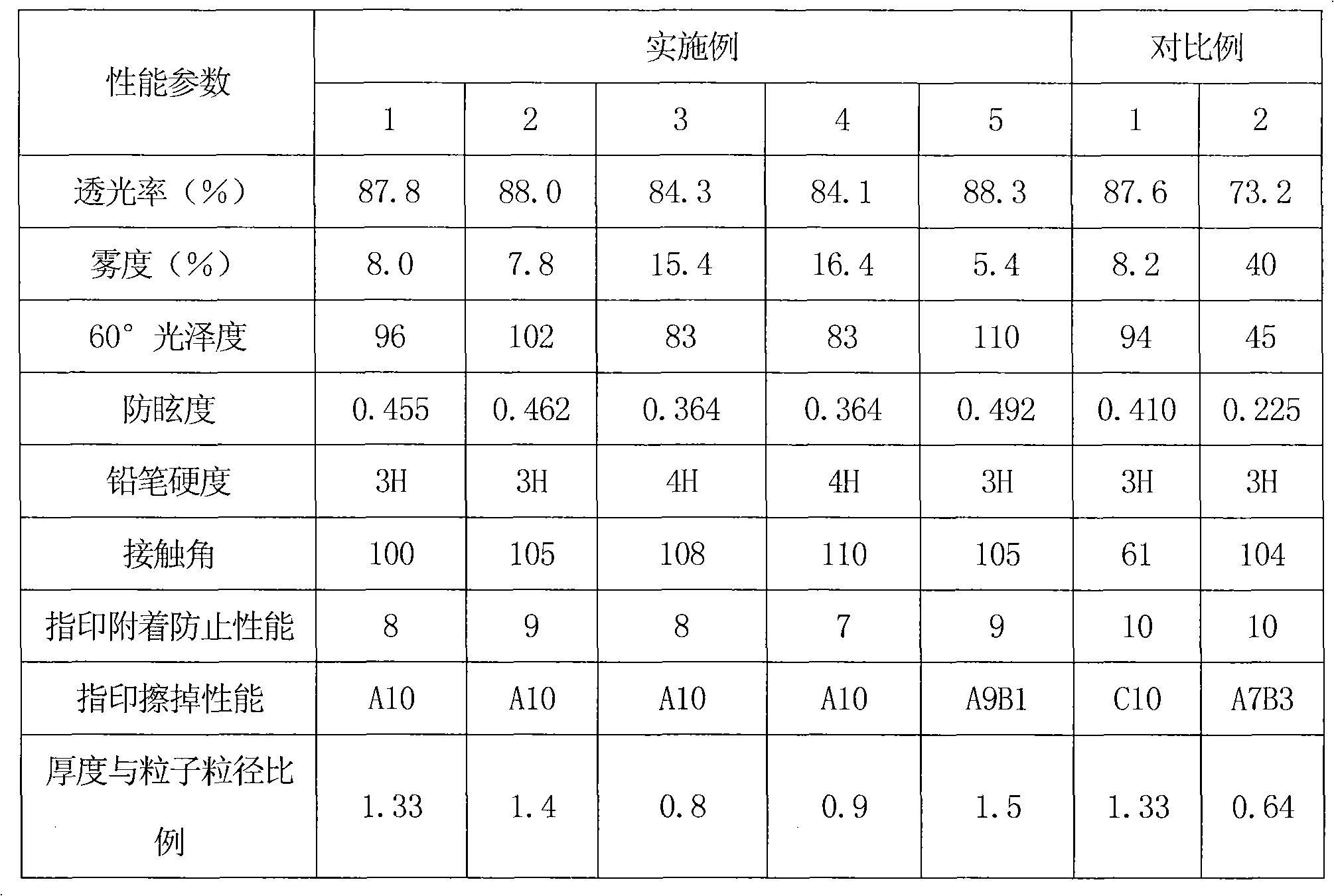

Examples

Embodiment 1

[0044] 50 parts of dipentaerythritol penta- and hexaacrylates;

[0045] BYK-486 1.5 copies;

[0046] Silica particles (model 720) 3.0 parts;

[0047] Irgacure 1173 6.0 parts;

[0048] Butanone 20 parts;

[0049] 20 parts of isopropanol.

[0050] In 50 parts by weight of dipentaerythritol penta- and hexaacrylate (DPHA, Nippon Kayaku) (solid component concentration: 100%), add 1.5 parts by weight of organosilicon-modified polyacrylate BYK-486 ( German BYK company), while adding 3.0 parts by weight of silicon dioxide particles (German Degussa company, model 720) with an average particle diameter of 3.0 microns. Dilute the above mixture with a mixed solvent of 20 parts of methyl ethyl ketone and 20 parts of isopropanol, carry out high-shear dispersion for 30 minutes, add 4 parts by weight of photoinitiator Irgacure 1173 (Nanjing Jiean Chemical Co., Ltd.) after dispersion, and obtain a coating cloth liquid.

[0051] The resulting coating liquid was applied to one side of a po...

Embodiment 2

[0053] Three, 30 parts of pentaerythritol tetra(meth)acrylates;

[0054] BYK 436 0.8 parts;

[0055] 1.5 parts of silicon dioxide particles (model 720);

[0056] 184 5 copies;

[0057] Butanone 33 parts;

[0058] Ethyl Cellosolve 30 parts.

[0059] In 30 parts by weight of three and tetra(meth)acrylate pentaerythritol esters (Yixing Honghui Chemical Co., Ltd.), add 0.8 parts by weight of organosilicon-modified polyacrylate BYK-486 (Germany BYK) containing hydroxyl functional groups , while adding 1.5 parts by weight of silicon dioxide particles with an average particle size of 3.0 microns (Degussa, Germany, model 720). Dilute the above mixture with a mixed solvent of 33 parts of methyl ethyl ketone and 30 parts of ethyl cellosolve, carry out high-shear dispersion for 50 minutes, add 5 parts by weight of photoinitiator 184 (Changzhou Huatai Company) after dispersion, and obtain a coating solution .

[0060] The resulting coating liquid was applied to one side of a polyeth...

Embodiment 3

[0062] 35 parts of dipentaerythritol penta- and hexaacrylates;

[0063] 30 parts of polyurethane acrylate;

[0064] BYK 486 1.5 copies;

[0065] Silica particles (Jinyuan 3#) 2.5 parts;

[0066] Irgacure 1173 6.0 parts;

[0067] Butanone 13 parts;

[0068] 13 parts of isopropanol.

[0069] To 35 parts by weight of dipentaerythritol penta- and hexaacrylates and 30 parts by weight of urethane acrylates, add 1.5 parts by weight of organosilicon-modified polyacrylate BYK-486 containing hydroxyl functional groups, and add 2.5 parts by weight, average particle size The 5.6-micron silicon dioxide particle Jinyuan 3# (manufactured by Tianjin Research Institute of Chemical Industry). The above mixture was diluted with a mixed solvent of 13 parts of methyl ethyl ketone and 13 parts of isopropanol, and subjected to high-shear dispersion for 40 minutes. After dispersion, 6 parts by weight of photoinitiator Irgacure 1173 was added to obtain a coating liquid.

[0070] The resulting co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com