Supramolecular perfluorinated gel and preparation method thereof

A perfluorinated gel and supramolecular technology, applied in coatings and other directions, can solve the problems of complicated calendering operation process and no antibacterial properties, and achieve the effect of good ductility, soft and wear-resistant material, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

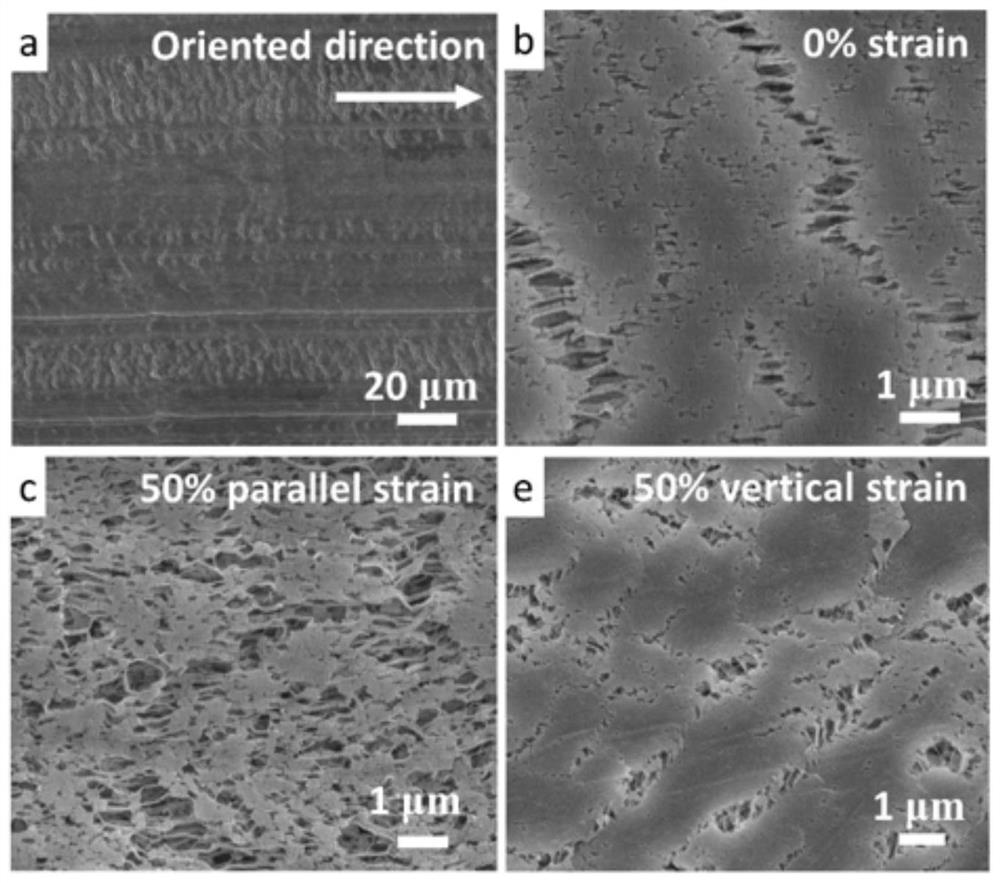

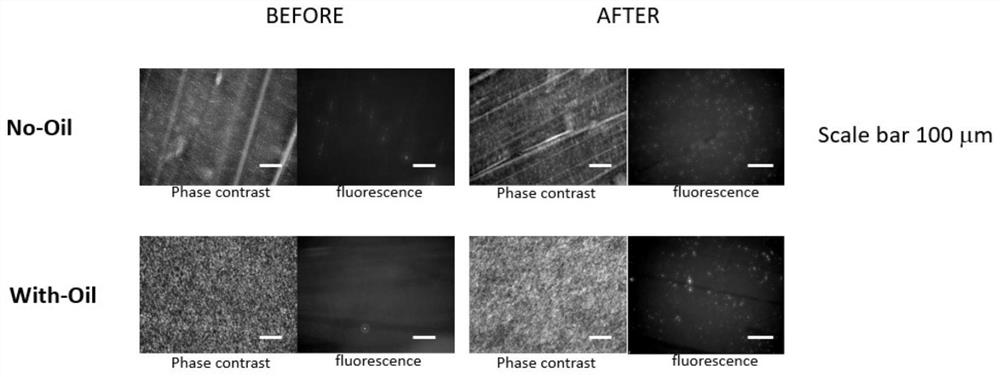

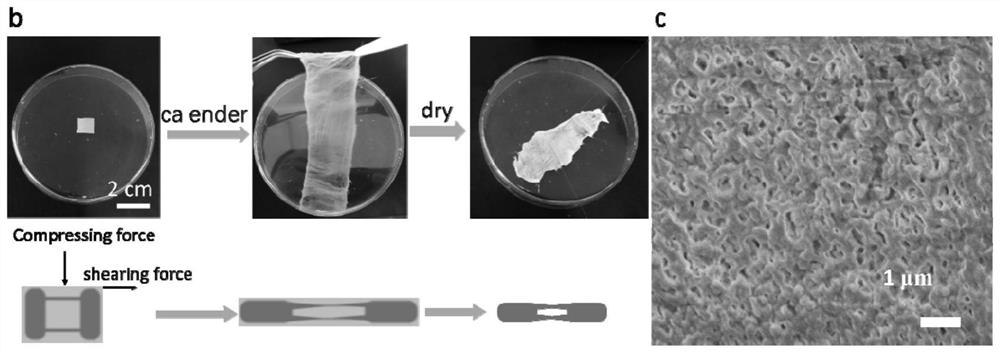

[0035] Sieve the polytetrafluoroethylene dispersed resin, remove the agglomerates and oversized particles, then weigh 600g, add naphtha as a propellant, mix in a round jar, seal the bottle mouth and roll and stir Mix for 15 minutes, place the mixed resin to mature for 8 hours, and the curing temperature is 45°C; preform on the press, and make a cylindrical resin mass on the press to remove air and reduce volume, and the preform pressure is 1.5MPa , the holding time is 1 minute, push into a rod with a pusher, the pushing compression ratio is 25, the pushing temperature is 50°C, and the pushing speed is 1 m / min; calendering film: the diameter of the roller of the calender is 20 cm, the width of the strip is 20 cm, the distance between the rollers is 0.05 mm, the temperature of the rollers is 40 ° C, and the calendering speed is 15 m / min; finally stretching and setting, the prepared film is stretched under heating conditions, After one-way stretching parallel to the film calender...

Embodiment 2

[0038]Sieve the polytetrafluoroethylene dispersion resin, remove the agglomerates and oversized particles, then weigh 600g, add 140g perfluorooctane to mix, mix in a round jar, seal the bottle mouth and roll and mix After 15 minutes, the mixed resin was left to mature for 10 hours, and the curing temperature was 50°C. Preform on a press, and make a cylindrical resin mass on the press to remove air and reduce volume. The preform pressure is 1.5MPa, and the holding time is 1 minute. Push it into a rod with a pusher, push it The compression ratio is 80, the pushing temperature is 60°C, and the pushing speed is 3 m / min; calendering film formation: the diameter of the calender roll is 28 cm, the width of the strip is 70 cm, and the distance between the rolls is 0.2 mm. The temperature is 70°C, and the calendering speed is 15 m / min; the final stretching and setting, under heating conditions, the prepared film is stretched, and after stretching in one direction perpendicular to the f...

Embodiment 3

[0041] Sieve the polytetrafluoroethylene dispersed resin, remove the agglomerates and oversized particles, then weigh 600g, add 90g of perfluoro-n-heptane to mix, mix in a round jar, seal the bottle mouth and roll and stir Mix for 15 minutes, place the mixed resin to mature for 5 hours, the curing temperature is 50°C; preform on the press, make a cylindrical resin mass on the press to remove air, reduce the volume, and the preform pressure is 1.5MPa , the holding time is 1 minute, push into a rod with a pusher, the pushing compression ratio is 60, the pushing temperature is 70°C, and the pushing speed is 2 m / min; calendering film: the diameter of the roller of the calender is 24 cm, the strip width is 40 cm, the distance between the rollers is 0.12 mm, the temperature of the rollers is 50 ° C, and the calendering speed is 15 m / min; finally stretching and setting, the prepared film is stretched under heating conditions, After biaxial stretching (it is stretching in one directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com