Automatic welding method of electrically heated element bushing of voltage stabilizer and reducing bushing of electrically heated element bushing

A technology of electric heating element and transition sleeve, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of large deformation of electric heating element sleeve, dead angle, and time-consuming correction, etc., so as to reduce the difficulty of operation. and labor intensity, reducing the correction of post-weld deformation, and improving the first pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

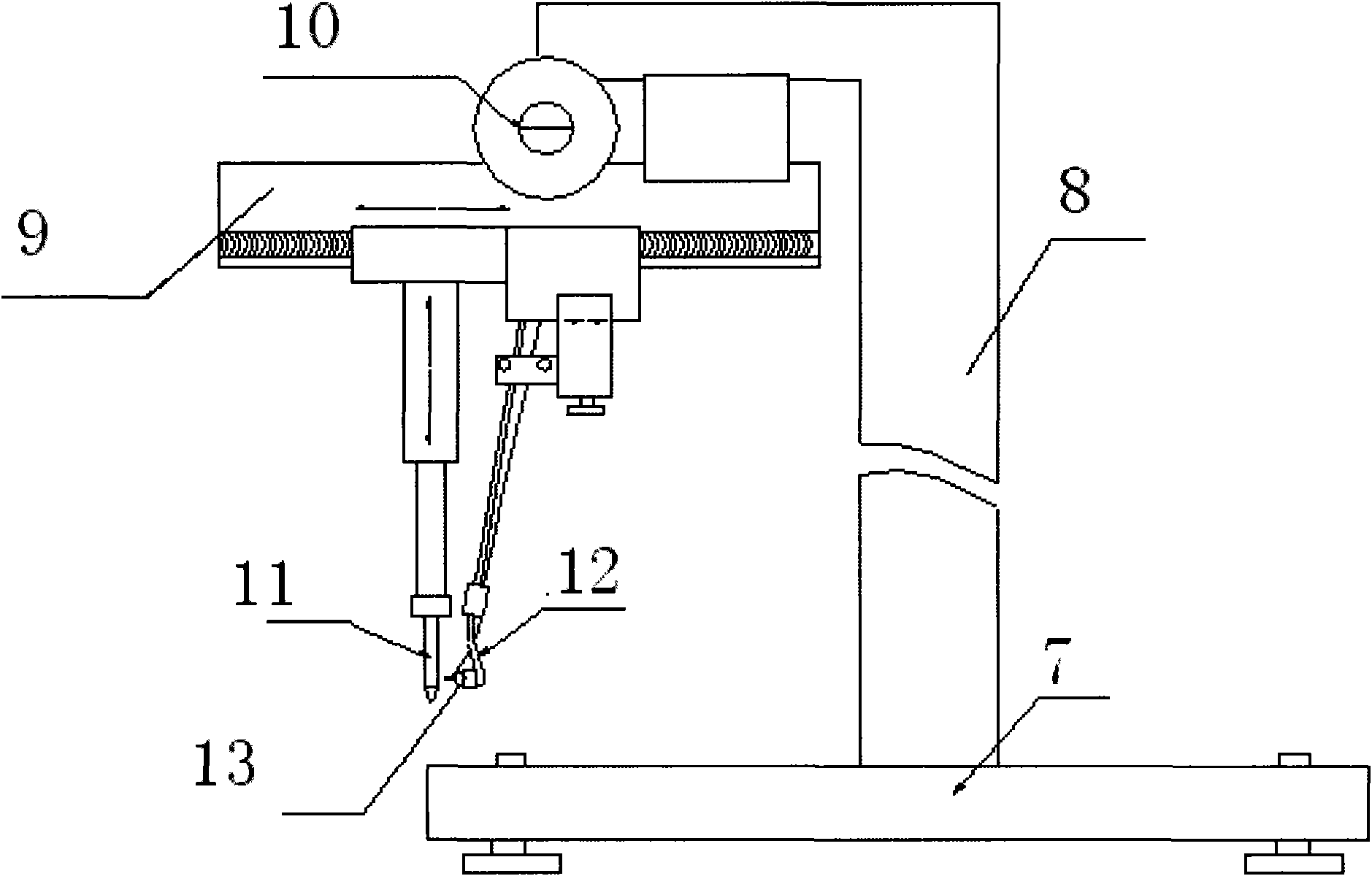

[0019] The welding torch used in the welding method in the present embodiment is as figure 2 Shown, comprise gantry 7, be provided with support 8 vertically on gantry 7, be provided with wire feeding device 10 and the rotating track 9 perpendicular with support 8 on the top of support 8, be provided with center vertically on rotating track 9 The rod 11 and the welding torch base 12 with the wire feed rod are provided with a tungsten electrode 13 at the end of the welding torch base 12 .

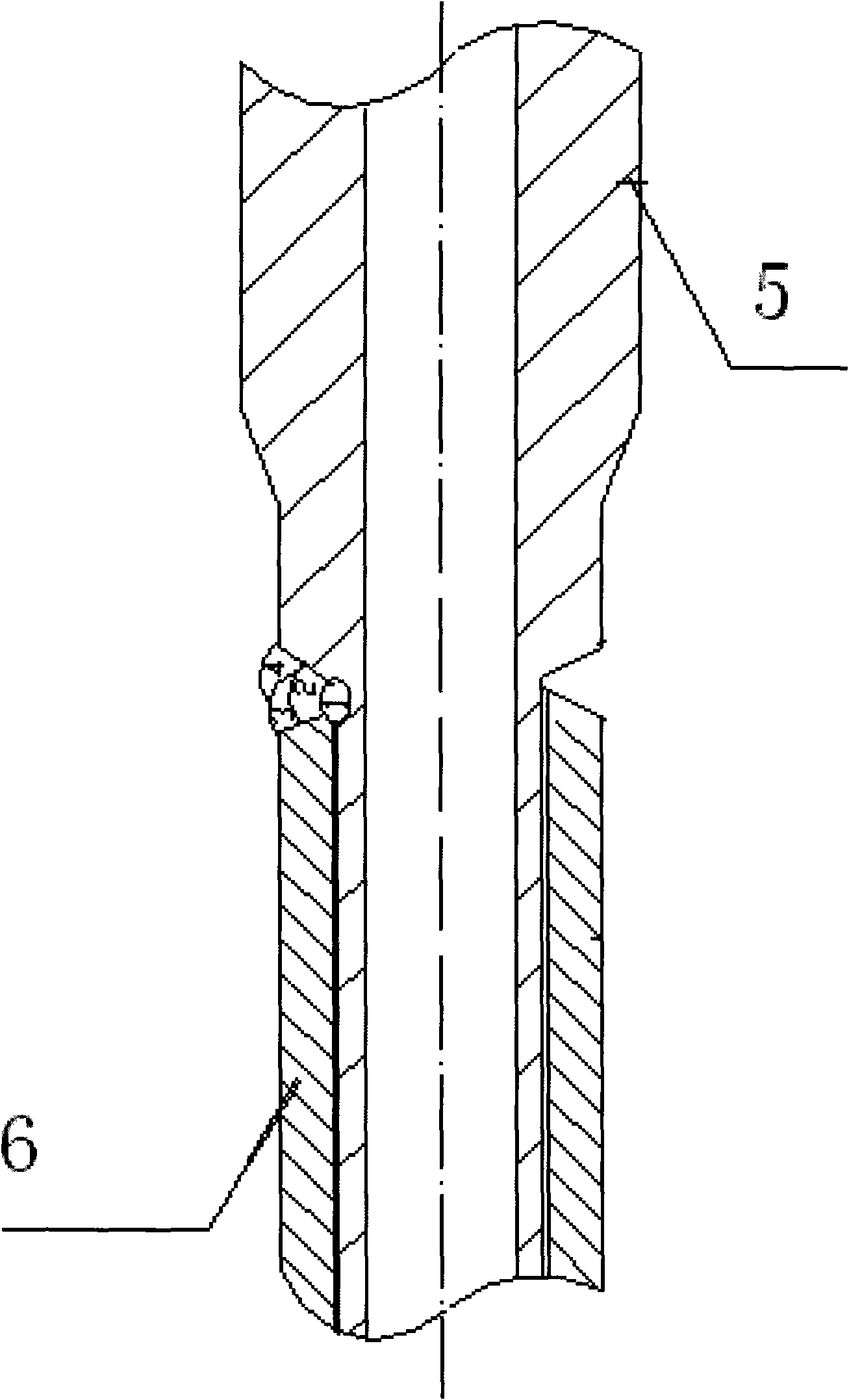

[0020] combine figure 1 and figure 2 , the specific steps of the automatic welding welding method of the voltage stabilizer electric heating element bushing and its transition bushing of the present embodiment are:

[0021] Step 1. Insert the tungsten electrode of the welding torch into the groove between the electric heating element sleeve 5 of the voltage regulator and the transition sleeve 6 and point to the root of the groove, adjust the position of the welding torch so that the axis ...

Embodiment 2

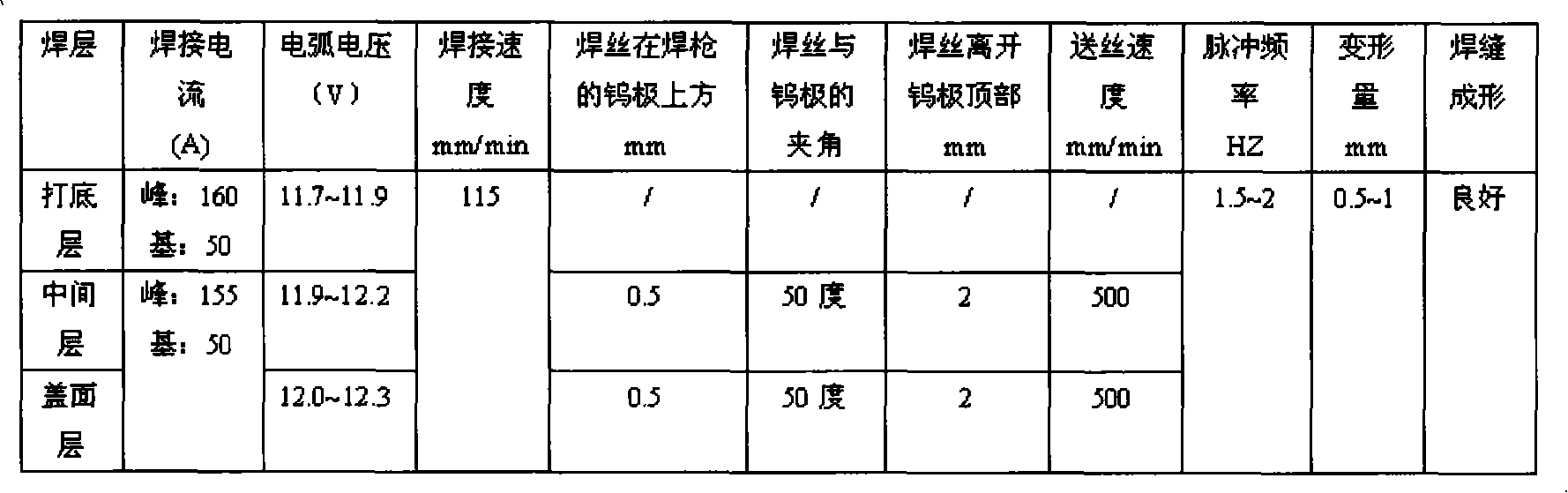

[0027] The steps of this embodiment are the same as those of Embodiment 1, except that the parameters used are different, as shown in the following table:

[0028]

Embodiment 3

[0030] The steps of this embodiment are the same as those of Embodiment 1, except that the parameters used are different, as shown in the following table:

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com