Pipeline hot melting butt joint technology and hot melting butt joint equipment

A hot-melt butt joint and pipeline technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problem of not being able to directly form pipelines, and achieve the effect of reducing pipeline correction and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

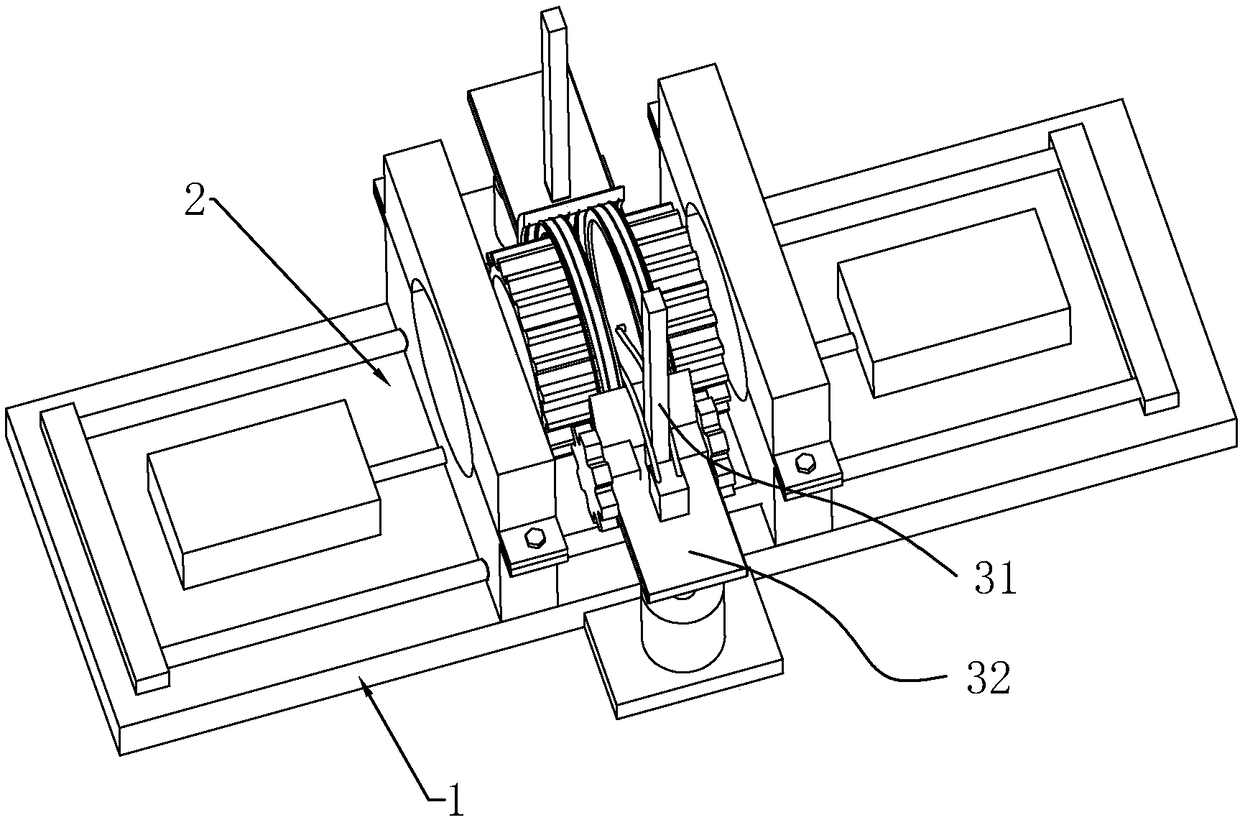

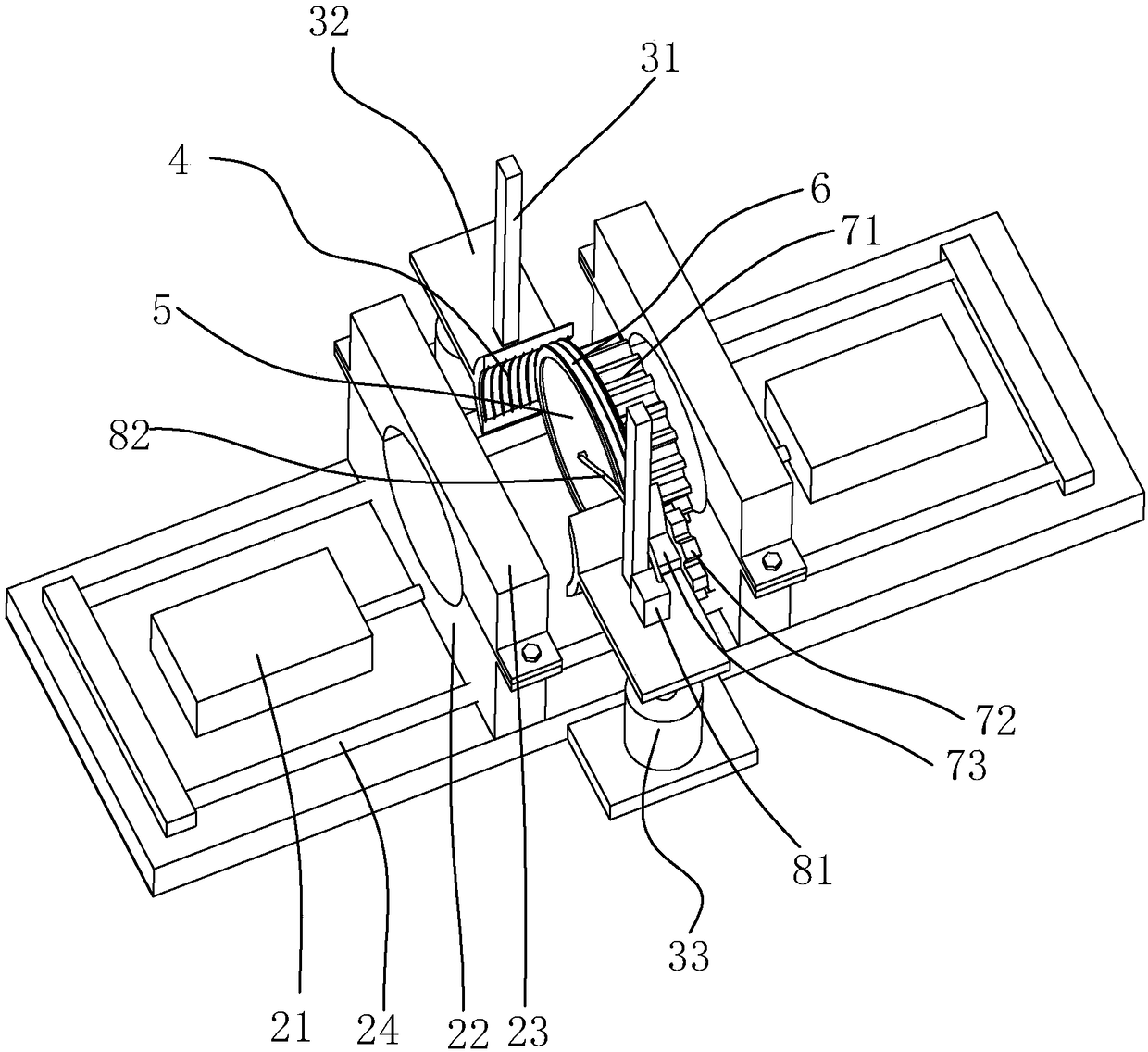

[0039] Embodiment 1: a kind of hot-melt butt joint equipment, such as Figure 1-2 , including a base 1, two pipe clamps 2 symmetrically installed on the base 1, and a driving member 21 for pushing the pipe clamps 2 to move.

[0040] The pipe clamp 2 is composed of a lower seat 22 and an upper seat 23. A semicircular hole is opened on each of the upper seat 23 and the lower seat 22. The bolt passes through the upper seat 23 and the lower seat 22 and connects a nut so that the upper seat 23 and the lower seat 22 are connected to form A circular hole through which a pipe passes. The driving part 21 is a cylinder, and the piston rod of the cylinder is connected with the lower seat 22. In order to make the pipe clamp 2 move smoothly, two guide posts 24 passing through the lower seat 22 are fixed on the base 1, and the lower seat 22 can move relative to the guide posts 24. .

[0041] A guide rail 31 is fixed on the base 1, and the guide rail 31 is located in the middle of the two ...

Embodiment 2

[0043] Embodiment 2: A pipeline hot-melt butt joint process, comprising the following steps:

[0044] 1) Preparation: use a grinder to smooth and clean the end faces of the pipes to be connected, put the two pipes into the pipe fixture respectively and the pipes protrude out of the pipe fixture, and rotate the motor so that the two heating plates are in contact with the adjacent pipes respectively. The two heating plates are set at intervals.

[0045] 2) Heating: heating the heating plate to melt the part of the pipe contacting the heating plate; the heating temperature of the heating plate is 210±10°C.

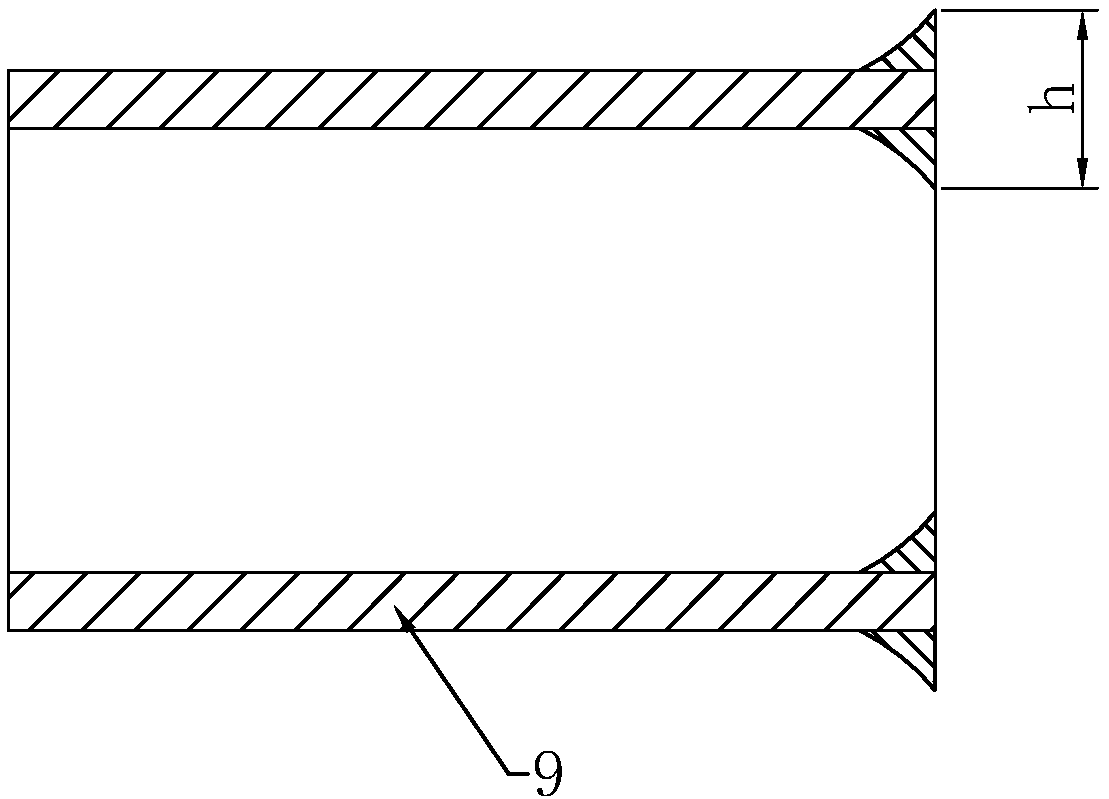

[0046] 3) Crimping: push the pipe to the heating plate so that the part of the pipe and the heating plate is deformed into a crimp; when the wall thickness of the pipe is 2-6.9mm, the height of the beading is 0.5mm; when the wall thickness of the pipe is 7-11.4mm , the curling height is 1mm; when the pipe wall thickness is 11.5-32.3mm, the middle curling height is 1.5mm.

...

Embodiment 3

[0050] Embodiment 3: A pipe hot-melt butt joint process, the difference from Embodiment 2 is that a polytetrafluoroethylene film is adhered to the end surface where the heating plate abuts with the pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com