Cryogenic forming method for large-size aluminum alloy tailored blank component

A technology of aluminum alloy and tailor-welded blanks, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as high cost, high risk, cracking, etc., to reduce forming force, reduce friction resistance, reduce equipment tonnage and The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

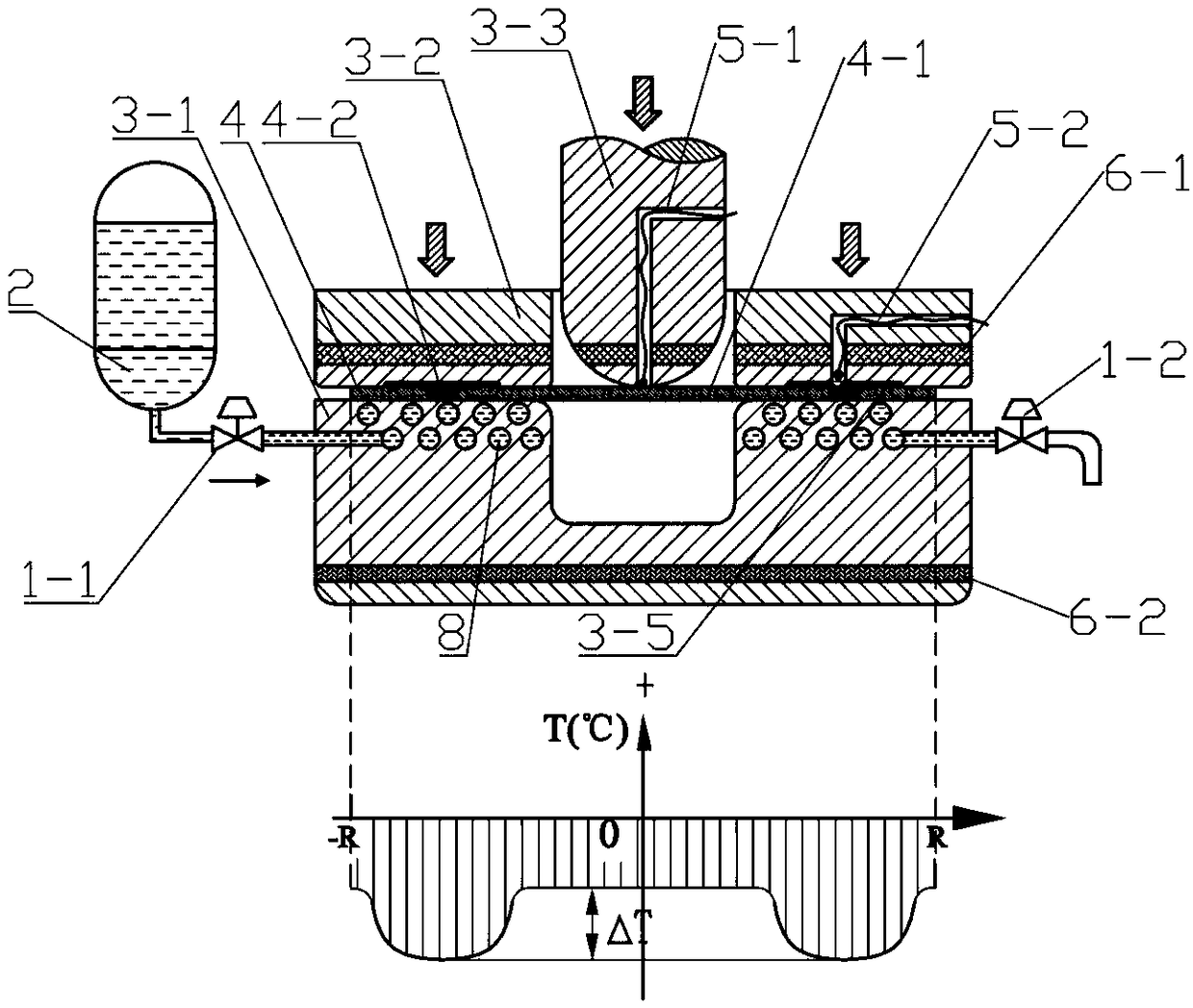

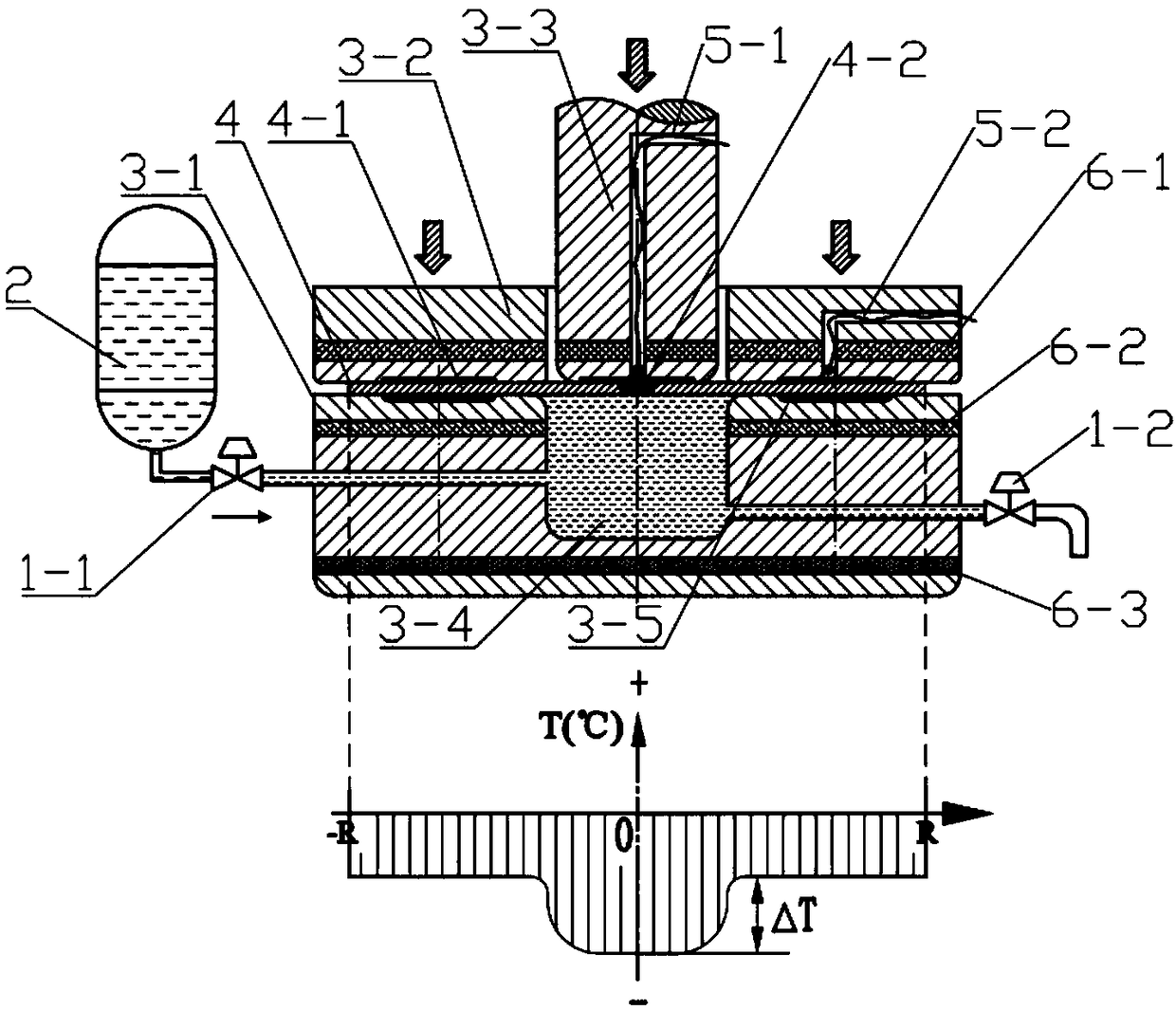

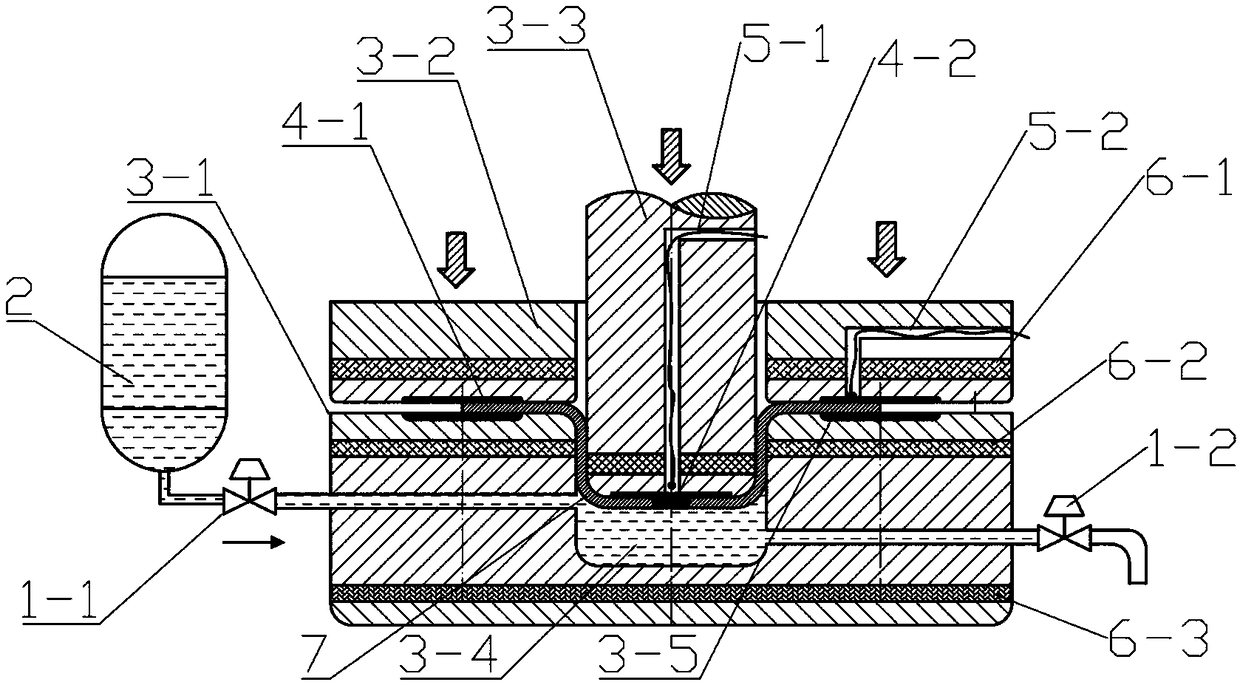

[0046] See figure 2 , image 3 and Figure 4 as shown,

[0047] figure 2 Schematic diagram of the initial state of the aluminum alloy FSW tailor welded blank in the present embodiment, the freeze-formed flat-bottomed cylindrical part;

[0048] image 3 It is a schematic diagram of the end state of the freeze-formed flat-bottomed cylindrical part of the aluminum alloy FSW tailor-welded blank in this embodiment;

[0049] Figure 4 It is a structural diagram of a flat-bottomed cylindrical part of an aluminum alloy FSW tailor welded blank freeze-formed in this embodiment.

[0050] This embodiment provides a method for freeze forming a flat-bottomed cylindrical member of a large-sized aluminum alloy FSW tailored welded blank, wherein the aluminum alloy plate is an Al-Cu-Mn alloy, and the specific material is an annealed 2219 aluminum alloy plate with a thickness of 6mm. The friction stir welding parameters are as follows: the welding forward speed is 300mm / min, the welding...

Embodiment 2

[0058] This example provides a method for freeze-forming an aluminum alloy FSW tailor-welded blank flat-bottomed cylindrical member. The difference from Example 1 is that the aluminum alloy plate is an Al-Cu-Mg alloy, and the specific material is annealed 2024 aluminum Alloy plate with a thickness of 7mm. The friction stir welding parameters are as follows: the welding forward speed is 200mm / min, the welding rotation speed is 1000rpm; the diameter of the circular slab is 2700mm, and one weld is located on the symmetric axis of the slab. A flat-bottomed cylindrical rigid mold with a diameter of 2250 mm is used, and the mold includes a punch 3-3, a die 3-1, and a blank holder 3-2, wherein a cooling chamber 3-4 is preset in the die 3-1. Specific steps are as follows:

[0059] The first step: placing the 2024 aluminum alloy tailor welded blank 4 on the mold so that the weld zone 4-2 is located above the die cooling chamber 3-4;

[0060] The second step: filling the concave mold ...

Embodiment 3

[0066] See Figure 5 , Figure 6 and Figure 7 as shown,

[0067] Figure 5 Schematic diagram of the initial state of the freeze-formed hemispherical part of aluminum alloy FSW tailor-welded blank in Example 4 of the present invention;

[0068] Figure 6 It is a schematic diagram of the end state of the freeze-formed hemispherical part of aluminum alloy FSW tailor welded blank in Example 4 of the present invention;

[0069] Figure 7 It is the structural diagram of the hemispherical part freeze-formed by aluminum alloy FSW tailor welded blank in Example 4 of the present invention.

[0070] This embodiment provides a method for freeze forming an aluminum alloy FSW tailored welded blank hemispherical component, wherein the aluminum alloy plate is an Al-Cu-Mn alloy, and the specific material is an annealed 2219 aluminum alloy plate with a thickness of 8 mm. The parameters of the friction stir welding are: the welding forward speed is 300mm / min, and the welding rotation spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com