Progressive forging forming method for large cake forged pieces

A progressive, forging technology, applied in the direction of vehicle parts, transportation and packaging, wheels, etc., can solve the problems of inability to ensure uniformity of forming, anisotropy of mechanical properties, lack of continuity, etc., to improve the direction of metal flow and promote the elimination of And the effect of repairing and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

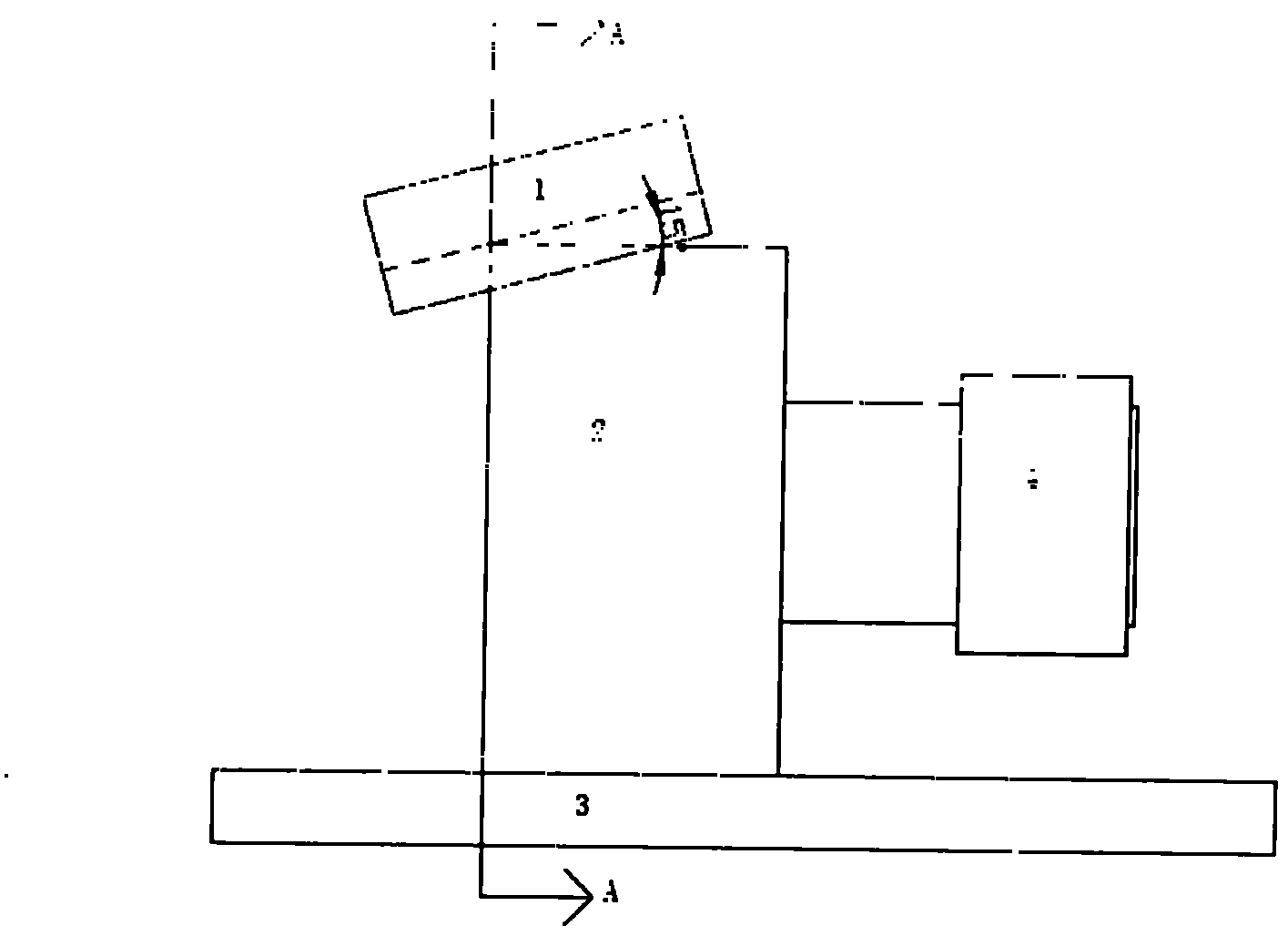

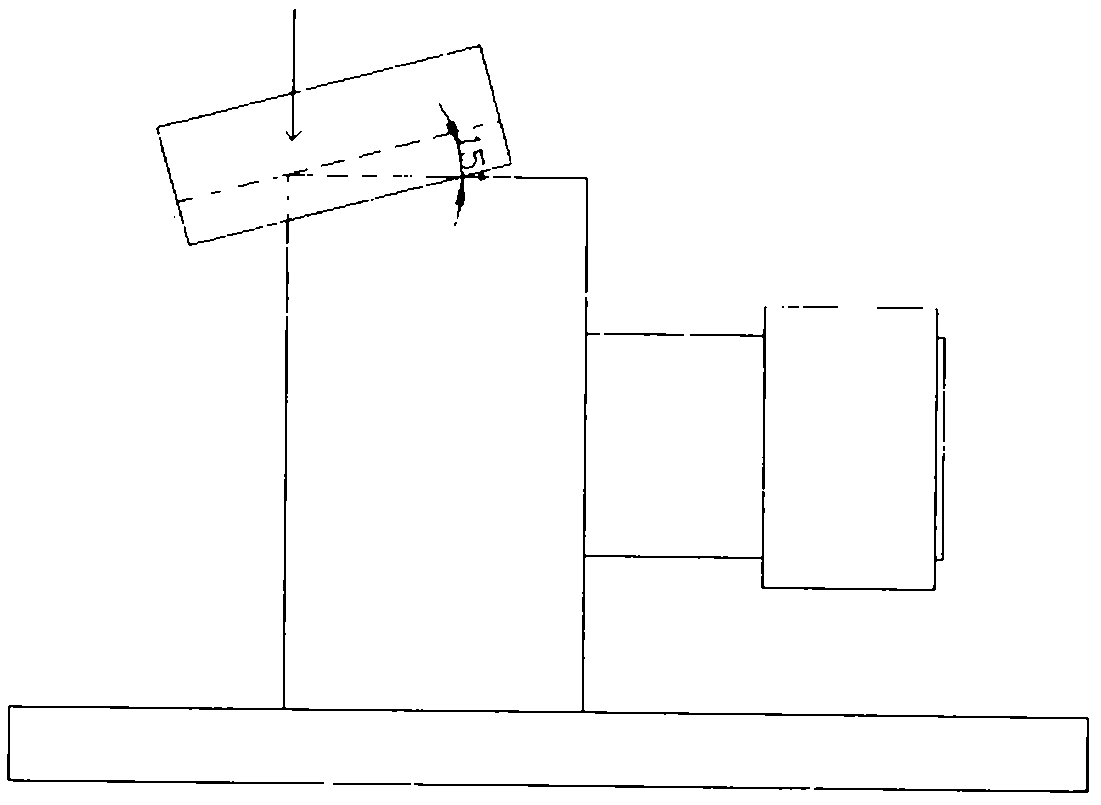

[0020] This example is a progressive forging of a large press cylinder bottom part. The forging process is completed on a 160MN press. The blank is a cast steel cylindrical billet 2 of Φ3500mm×1800mm, and the upper anvil is a V-shaped anvil with an angle of 135°. Anvil 1 (eg image 3 Shown), the lower anvil is a large platform 3, and the ring sleeve 4 plays a role in positioning and clamping. 1) Installation and adjustment: place the cylindrical billet 2 with an average temperature of 1200°C and a size of Φ3500mm×1800mm on the large platform 3, and fix it with the ring sleeve 4, so that the anvil surface of the upper anvil 1 and the axis of the billet 2 form an included angle of 15° (Such as figure 1 shown), and adjust the position of the blank to ensure that the forming process starts from the riser end of the blank. In this way, the anvil can properly improve the metal flow direction, and the metal flow at the anvil joint can be smooth, which can increase the axial ductili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com