Patents

Literature

61results about How to "Increase flow direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

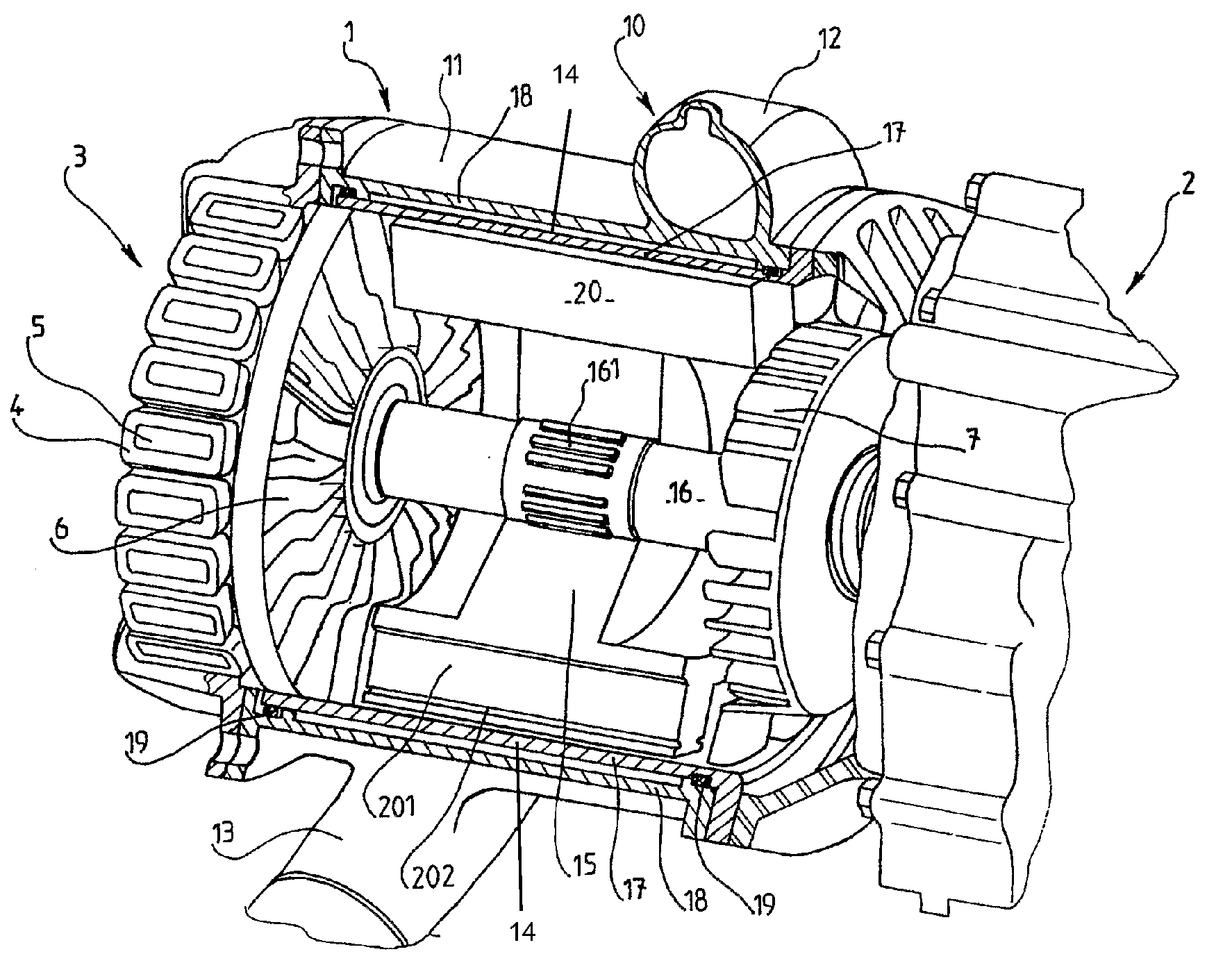

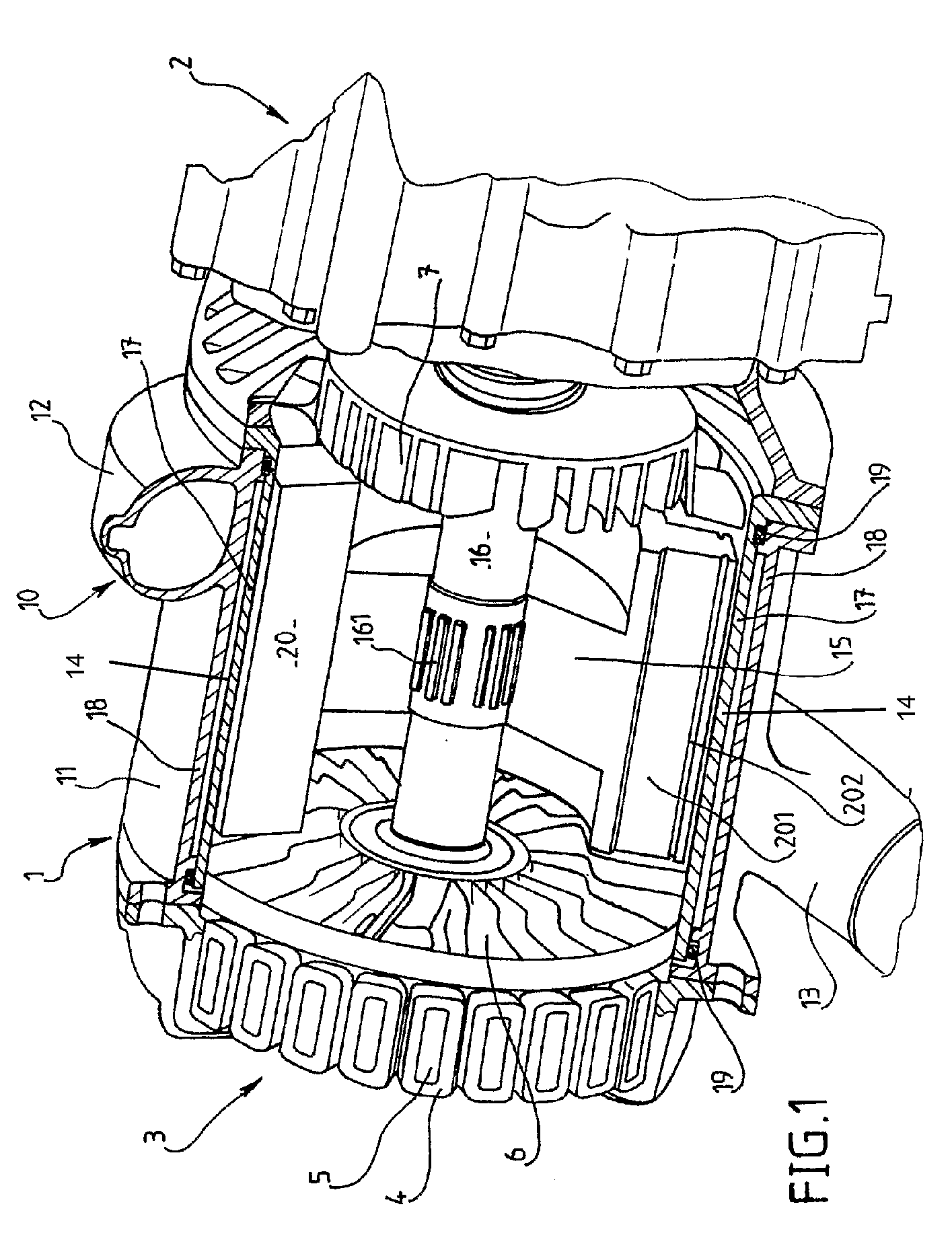

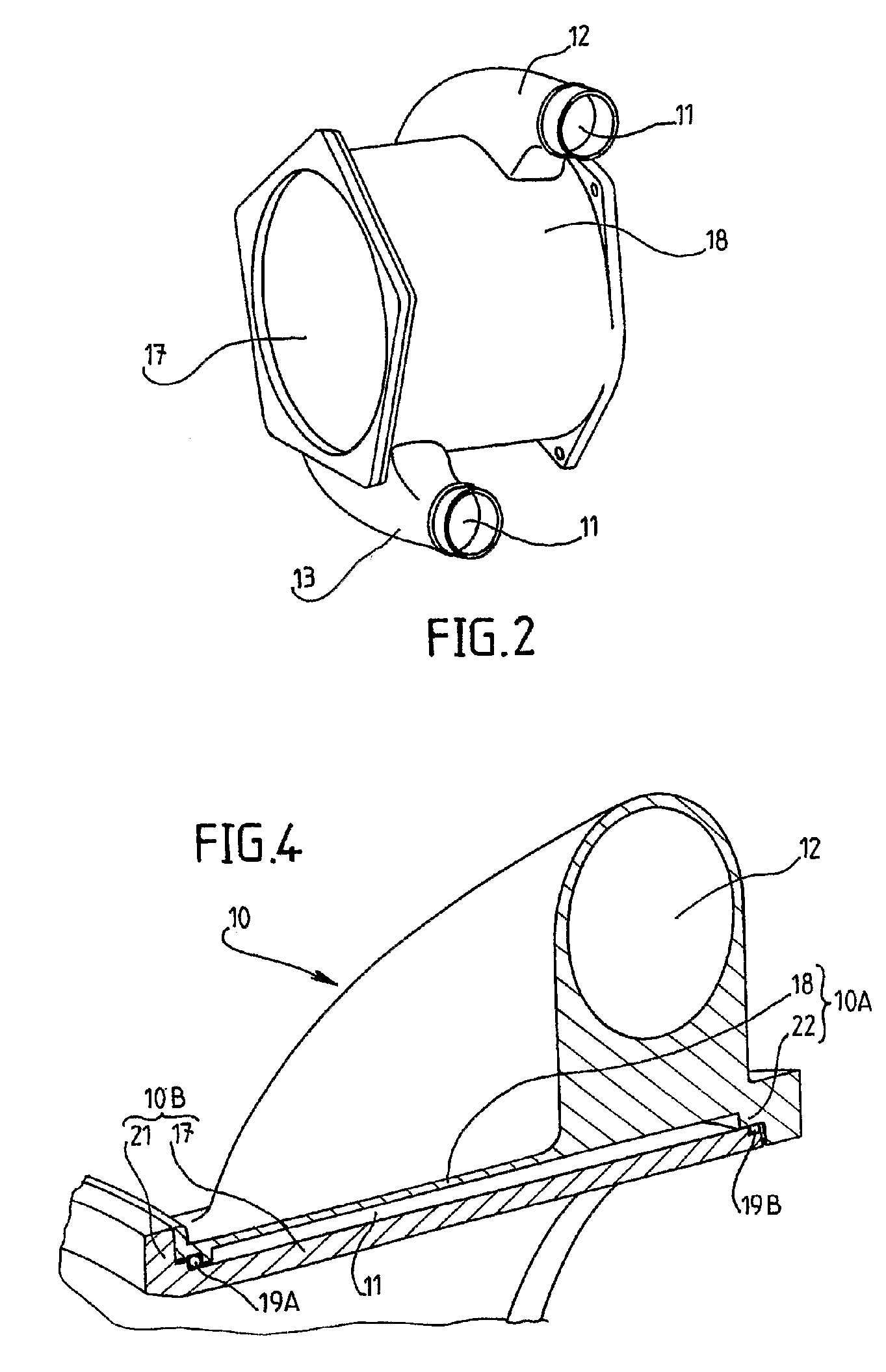

Water Jacket for a Rotary Machine and Rotary Machine Comprising Same

InactiveUS20080284263A1Reduce weightOptimises thermomechanical characteristicMagnetic circuit stationary partsAsynchronous induction clutches/brakesCouplingEngineering

The invention concerns a water jacket for a rotary machine, the water jacket comprising at least one conduit (11) designed to be in cooling contact with at least one part of the machine and having at least one inlet coupling (12) and at least one outlet coupling for a coolant between which the conduit(s) (11) extend. The water jacket comprises an inner wall (17) and an outer wall (18) made of two different materials. The invention also concerns a rotary machine equipped with such a water jacket and an electromagnetic retarder provided with such a water jacket.

Owner:TELMA

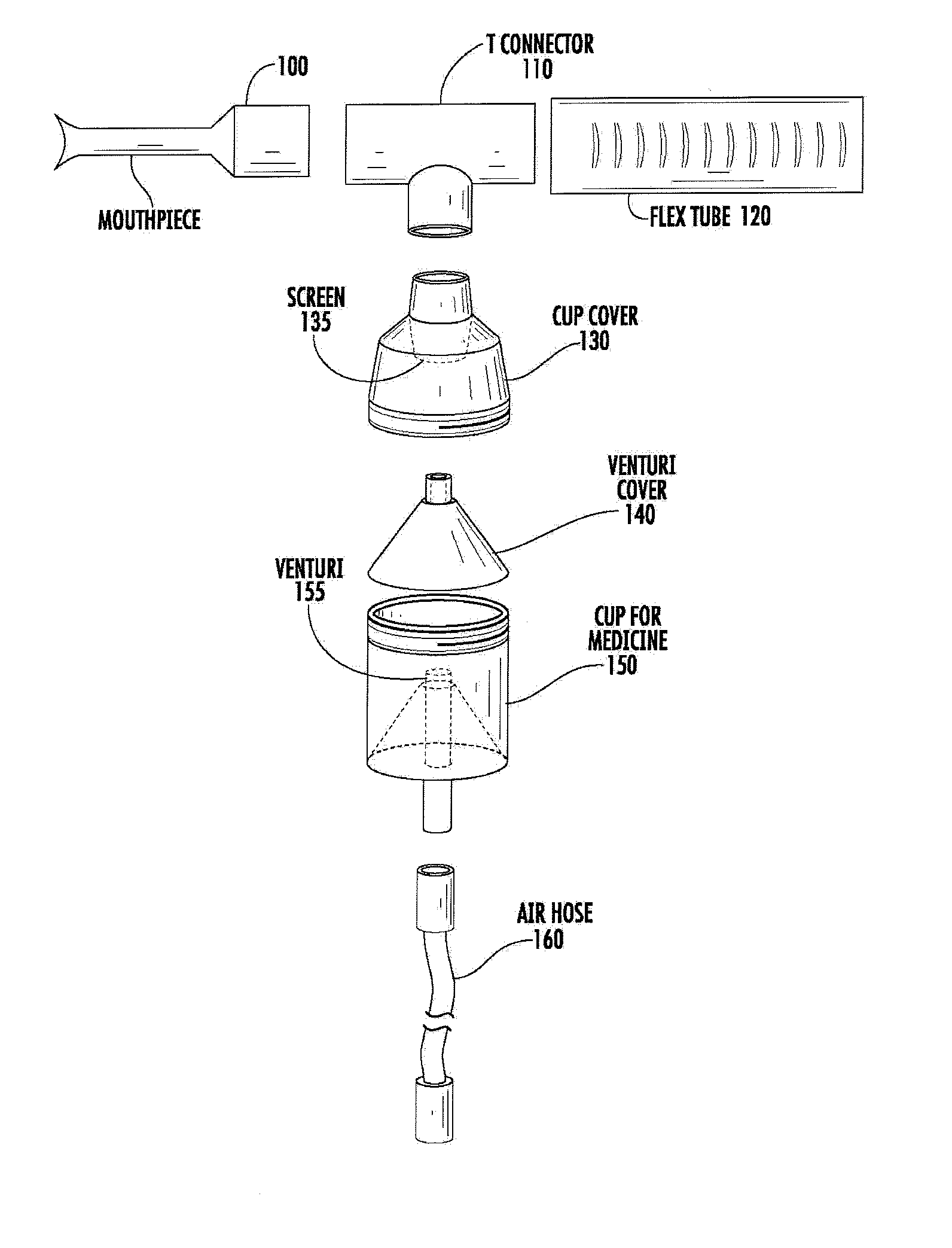

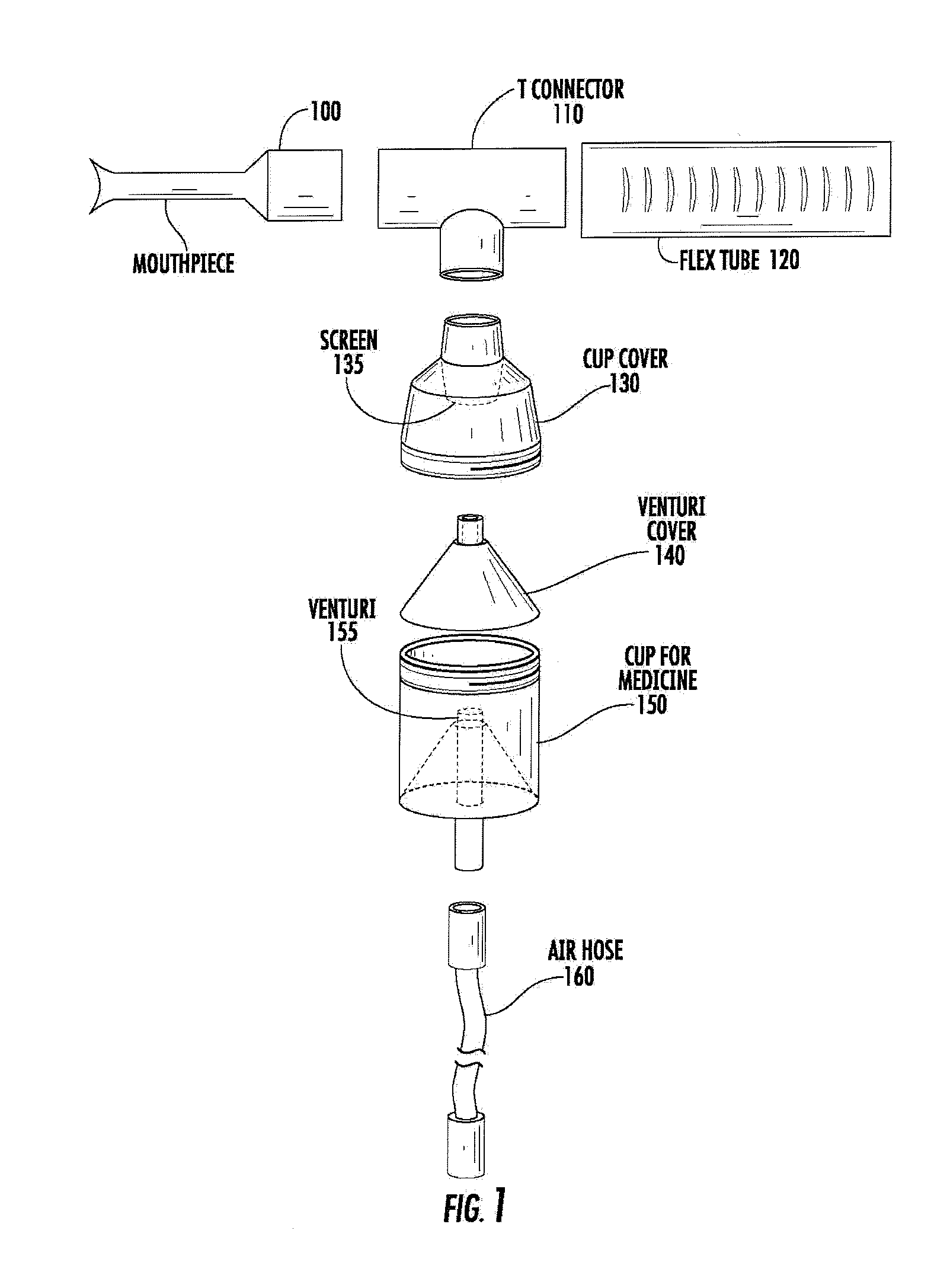

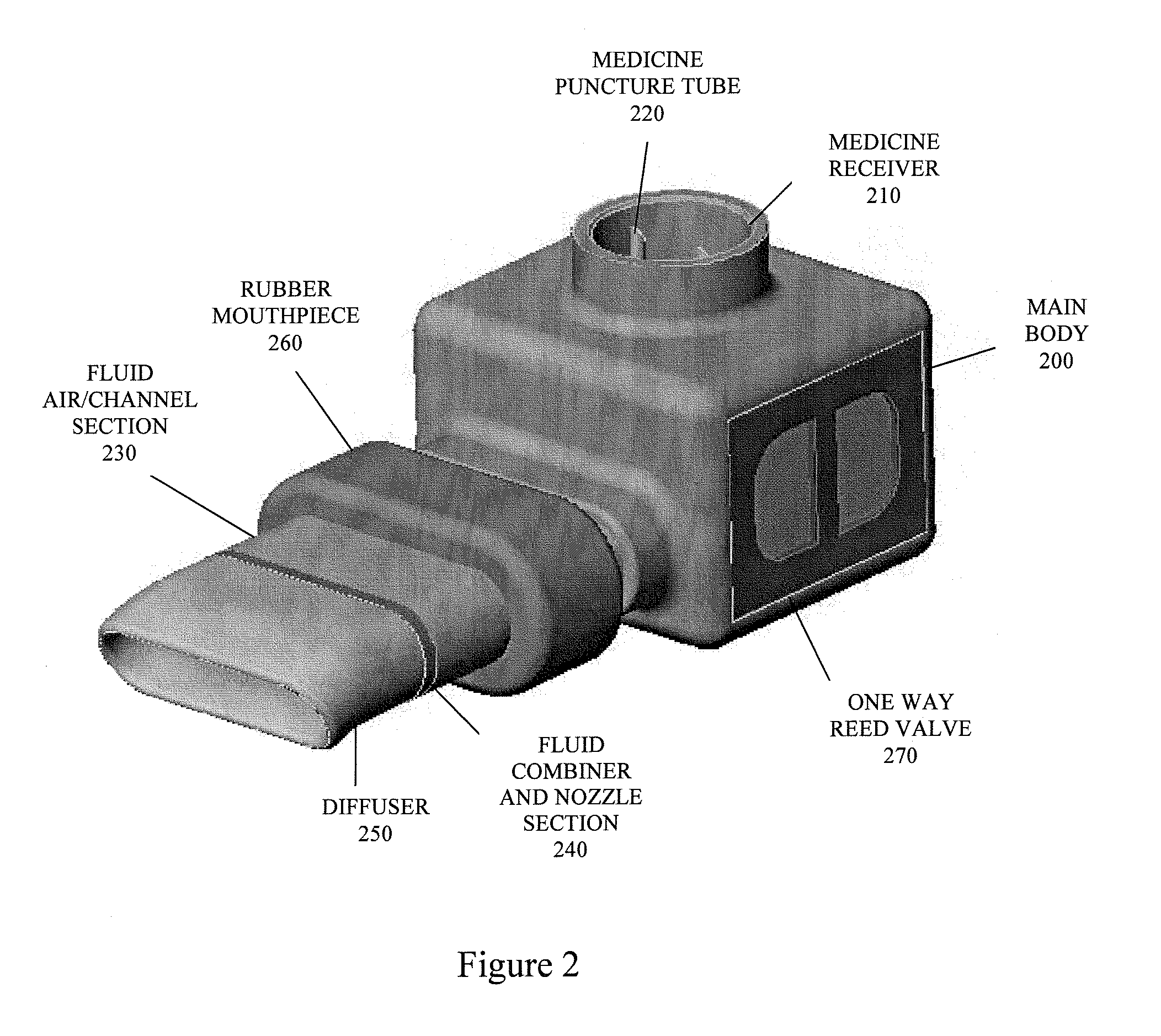

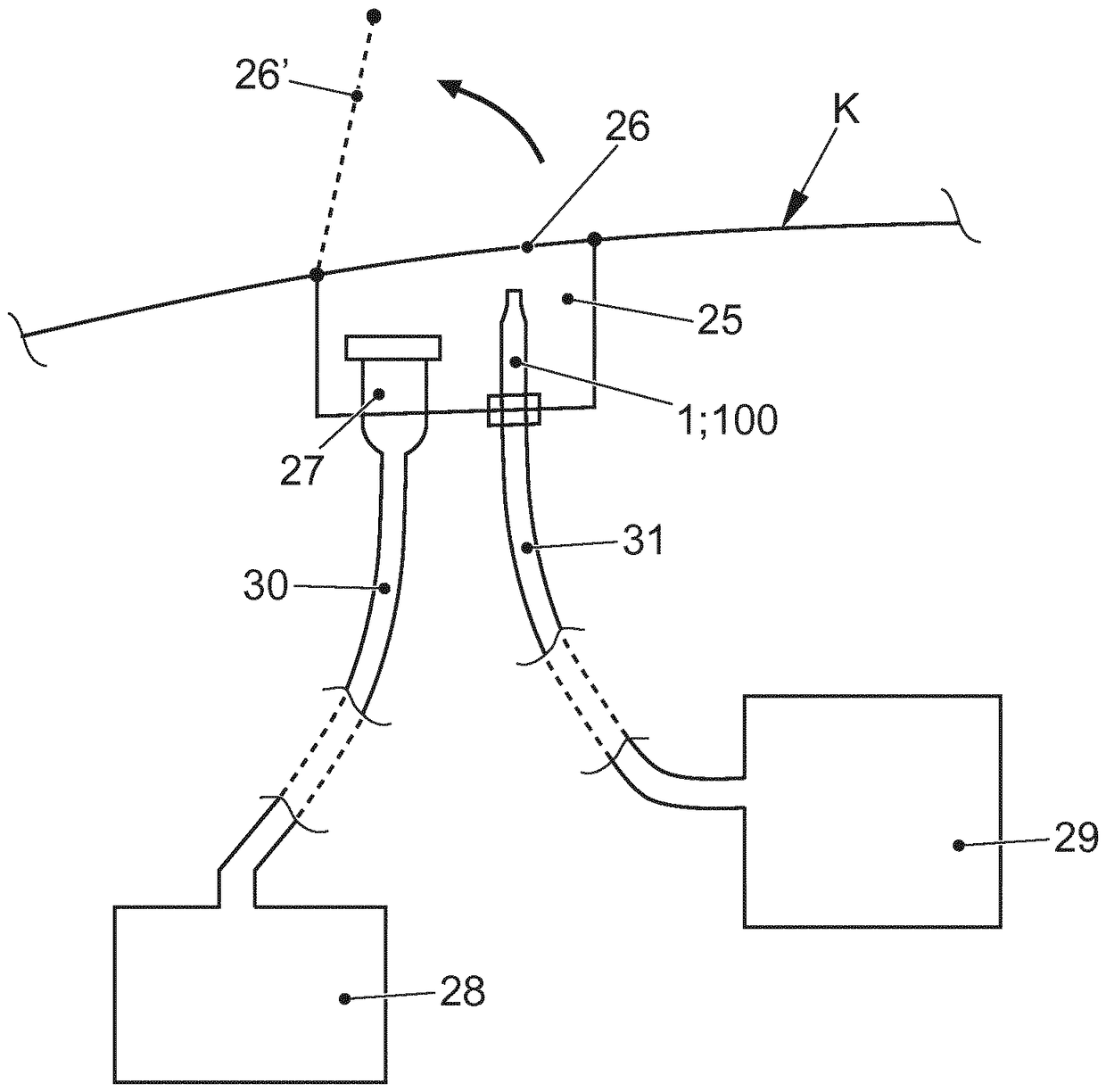

Intraoral Nebulizer Providing Air Curtains

InactiveUS20070137648A1Increase flow directionDegrade some medicationRespiratorsFire rescueNebulizerProximate

An improved nebulizer places a venturi in close proximity to or inside a patient's oral cavity. One or more medicine feed lines feeds the medicine to a location proximate to a venturi. One or more air curtain conduits may be positioned near the medicine feed line and the venturi and is fed by a source of air pressure to create a curtain of fluid flow to surround at least in part the flow path of the nebulized medication. This minimizes the amount of medication lost to the oral cavity and to the trachea and permits more medication to reach a patient's lungs. Medication contained in a patients exhalant can be filtered in an exhale conduit to prevent loss to the environment and can be recaptured for reuse.

Owner:PNEUMOFLEX SYST

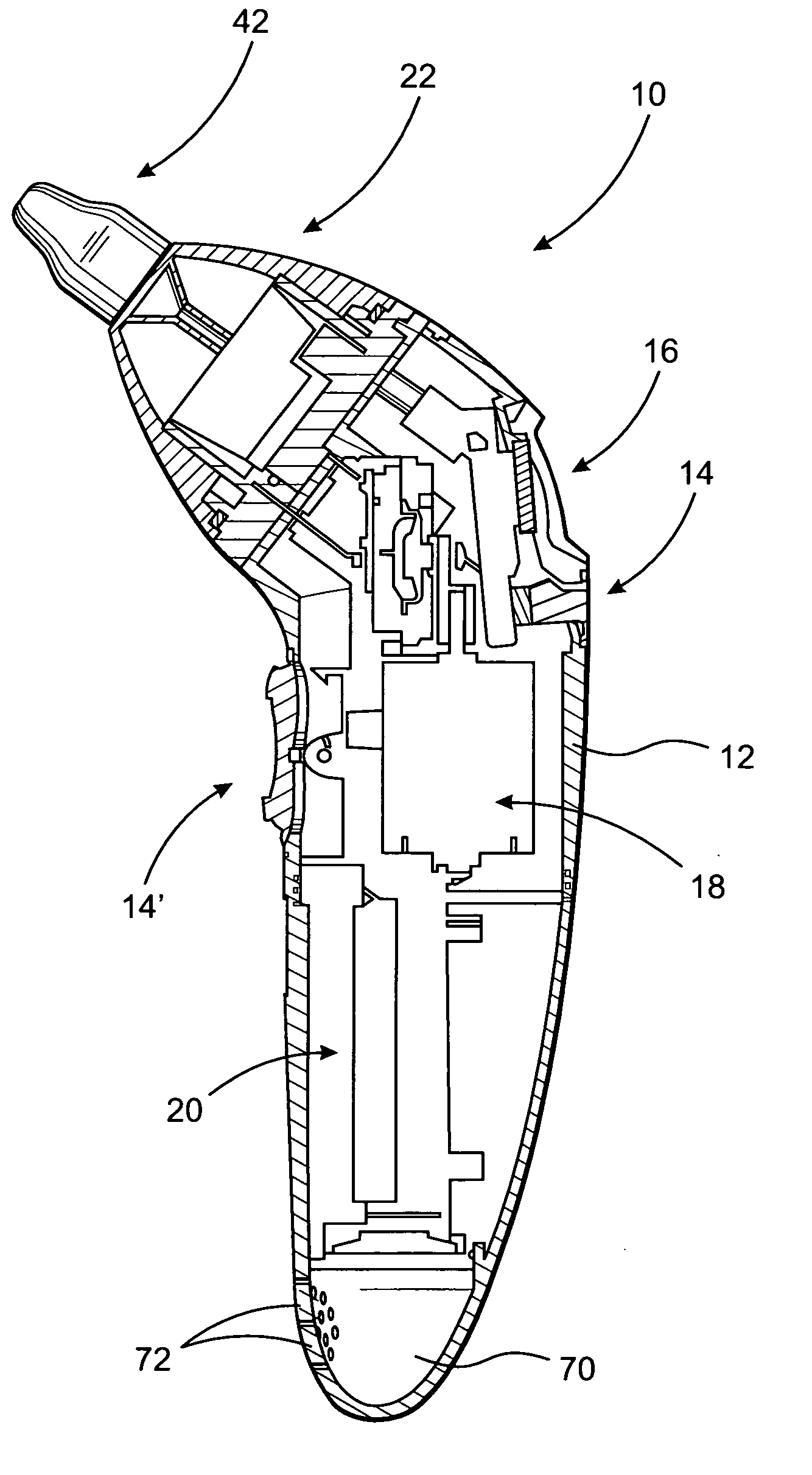

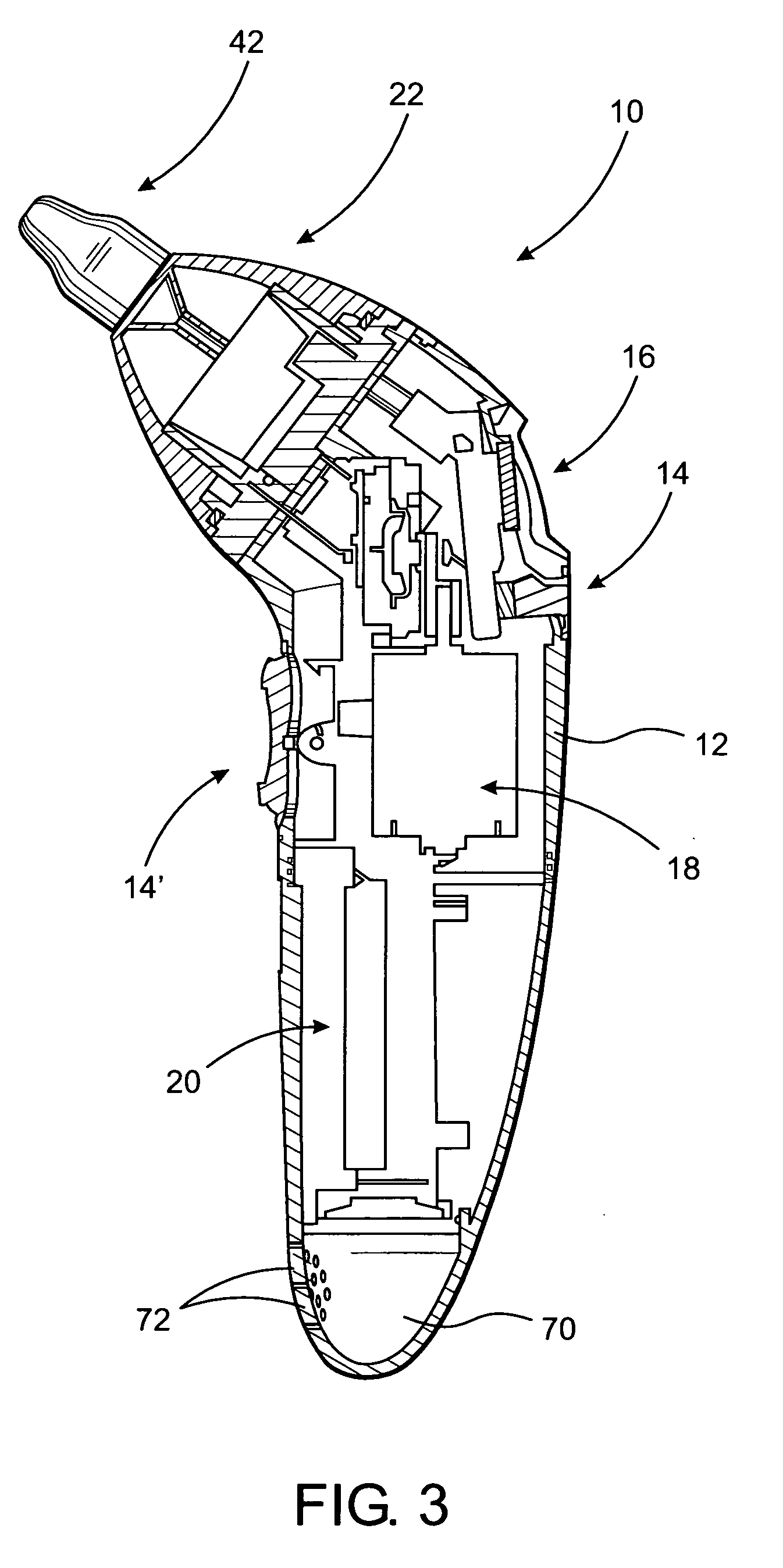

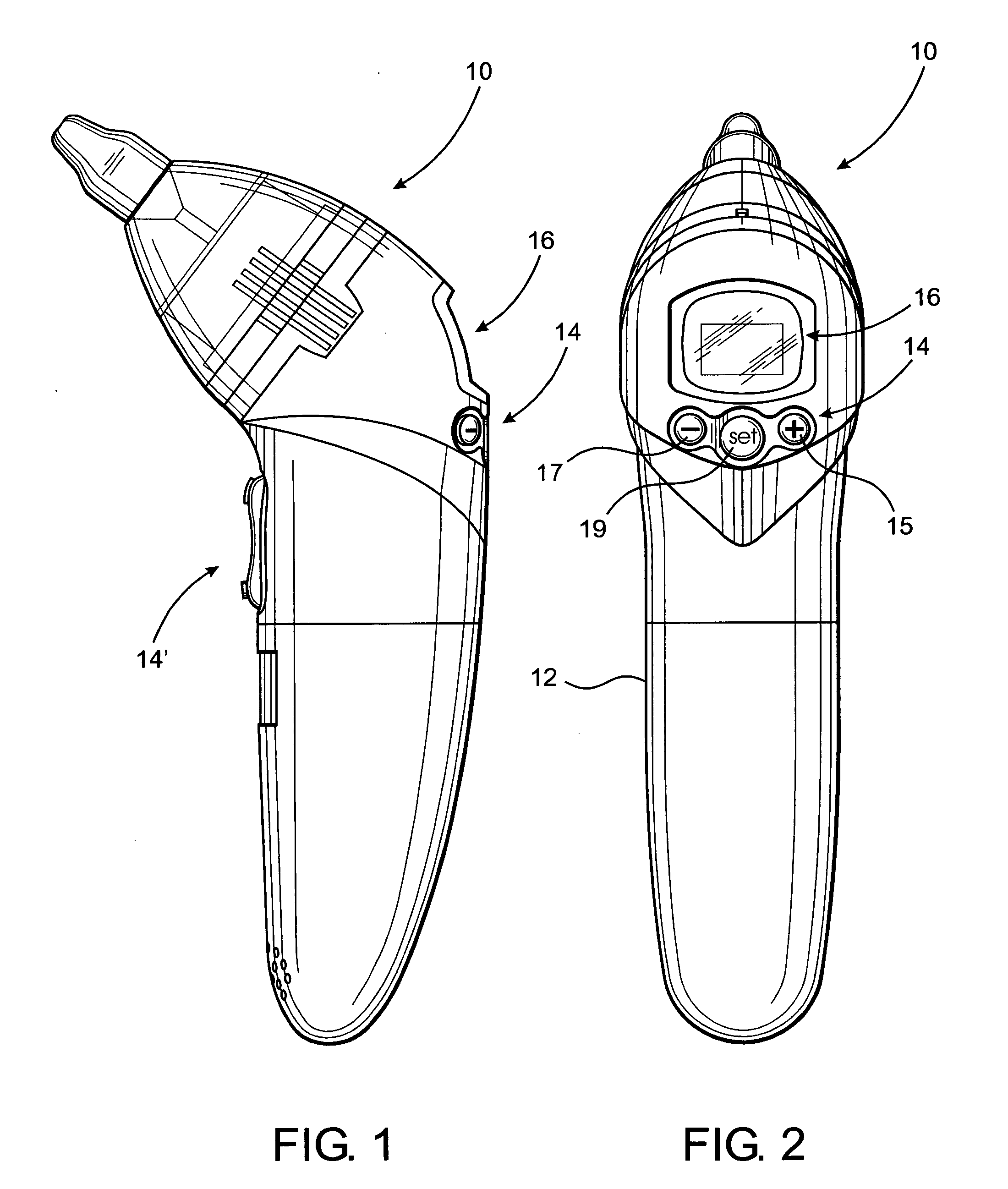

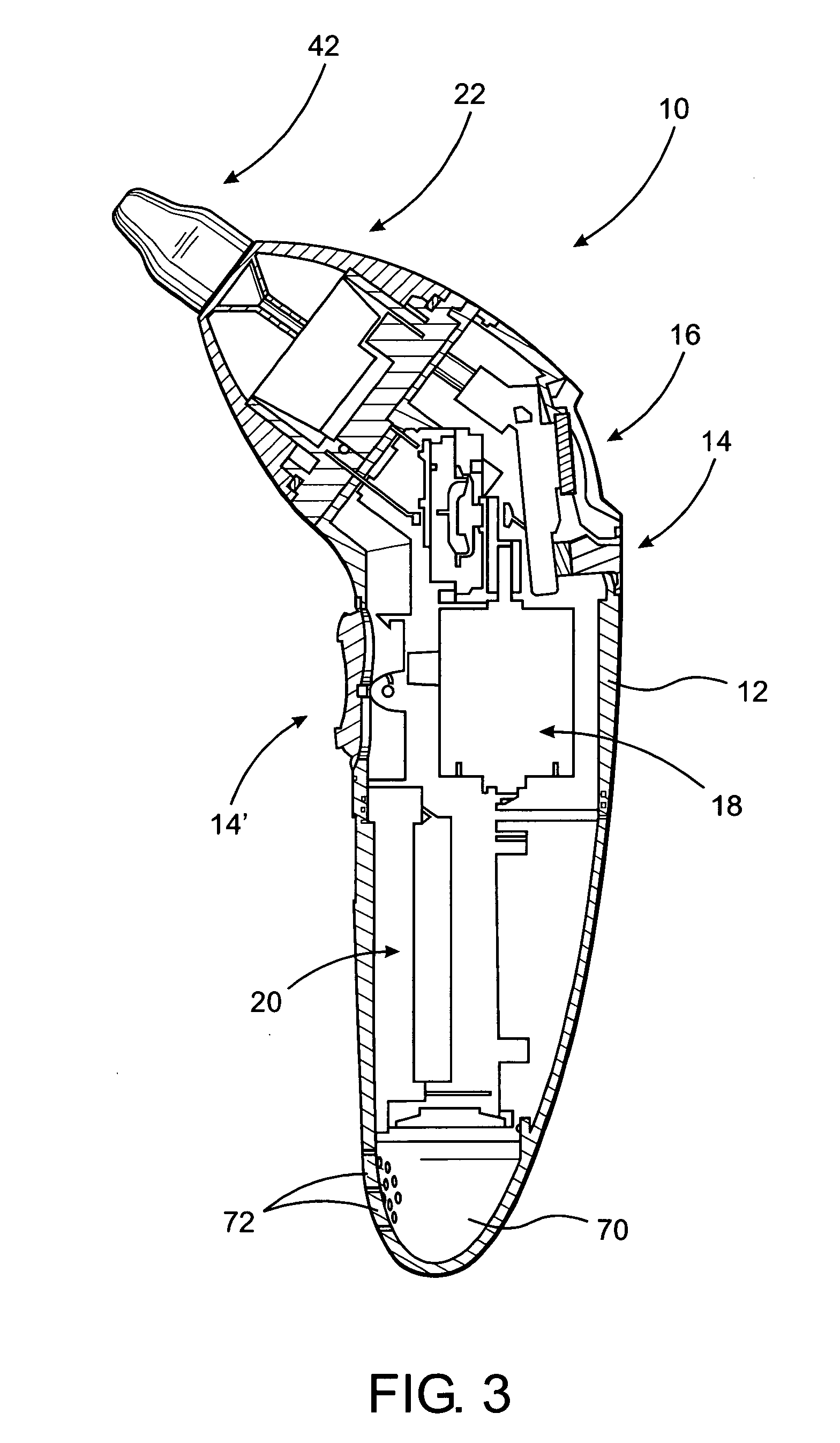

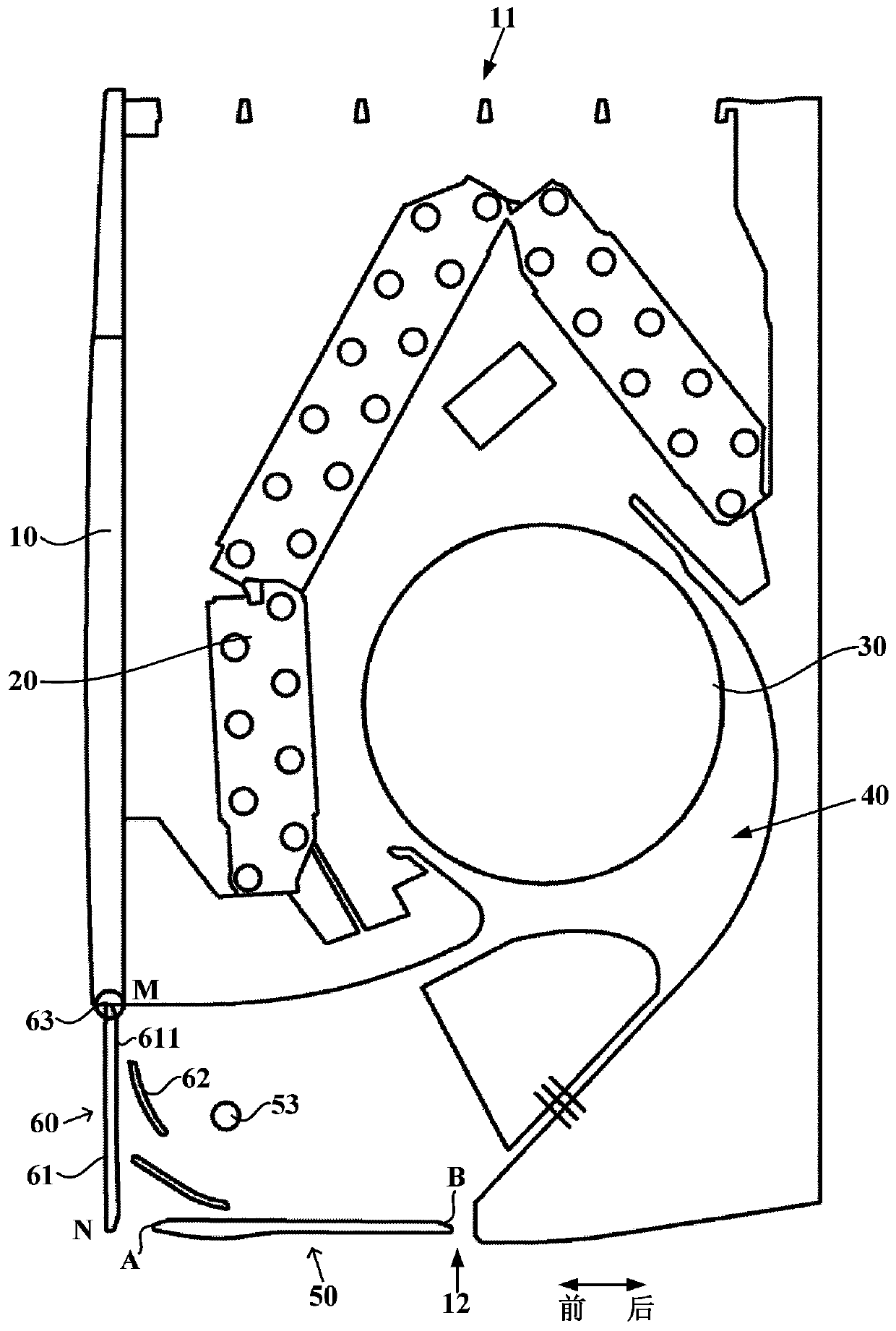

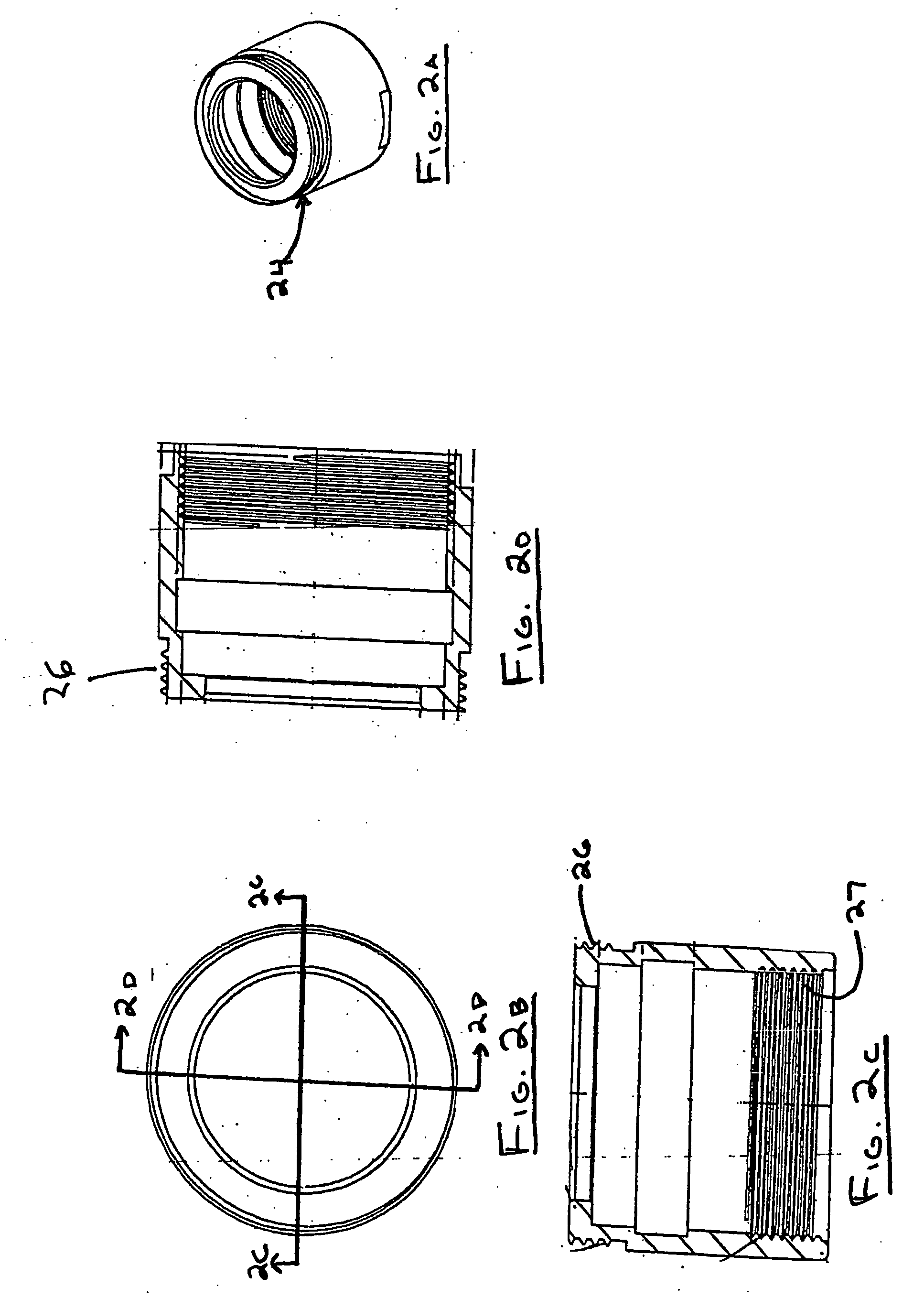

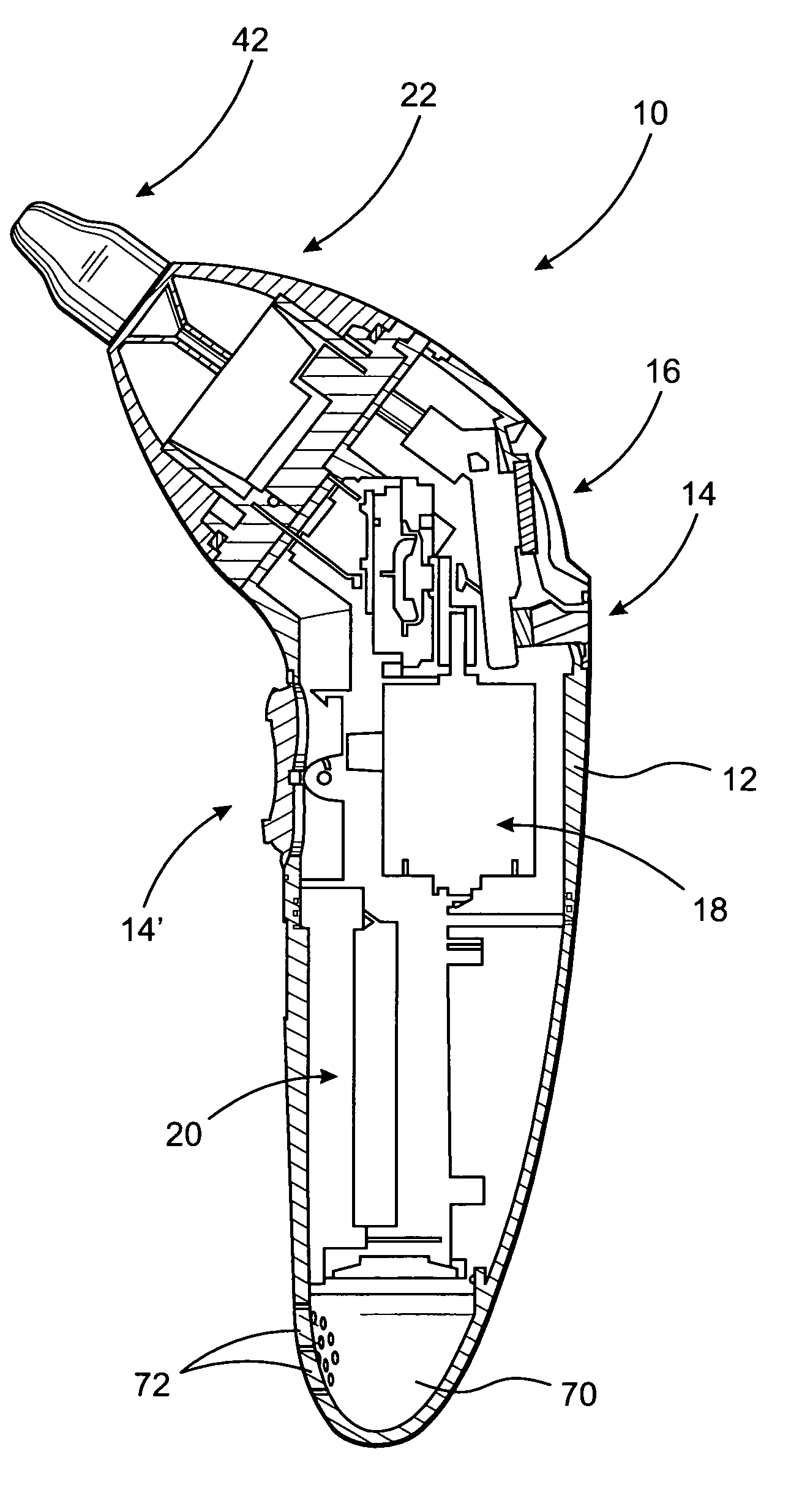

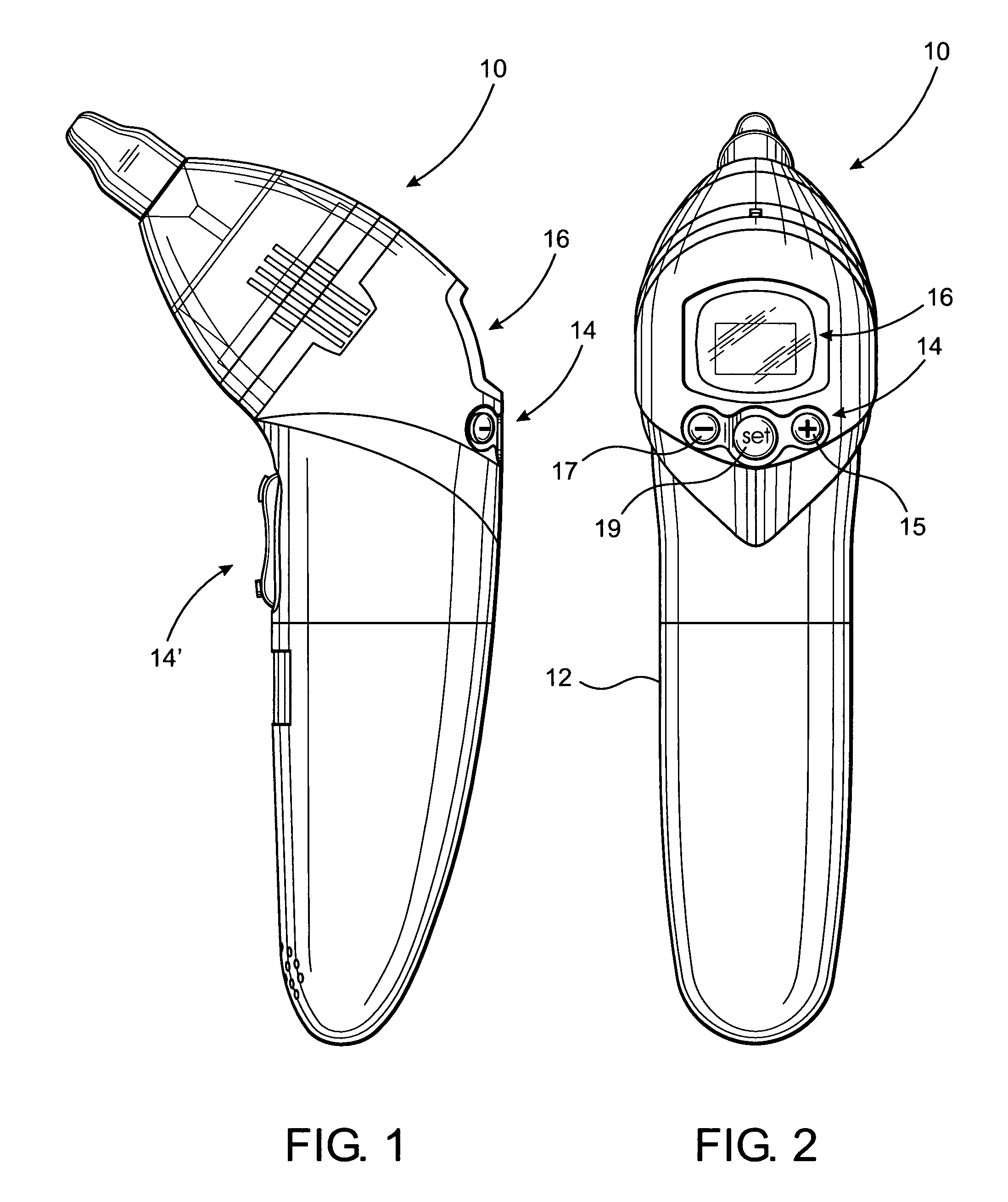

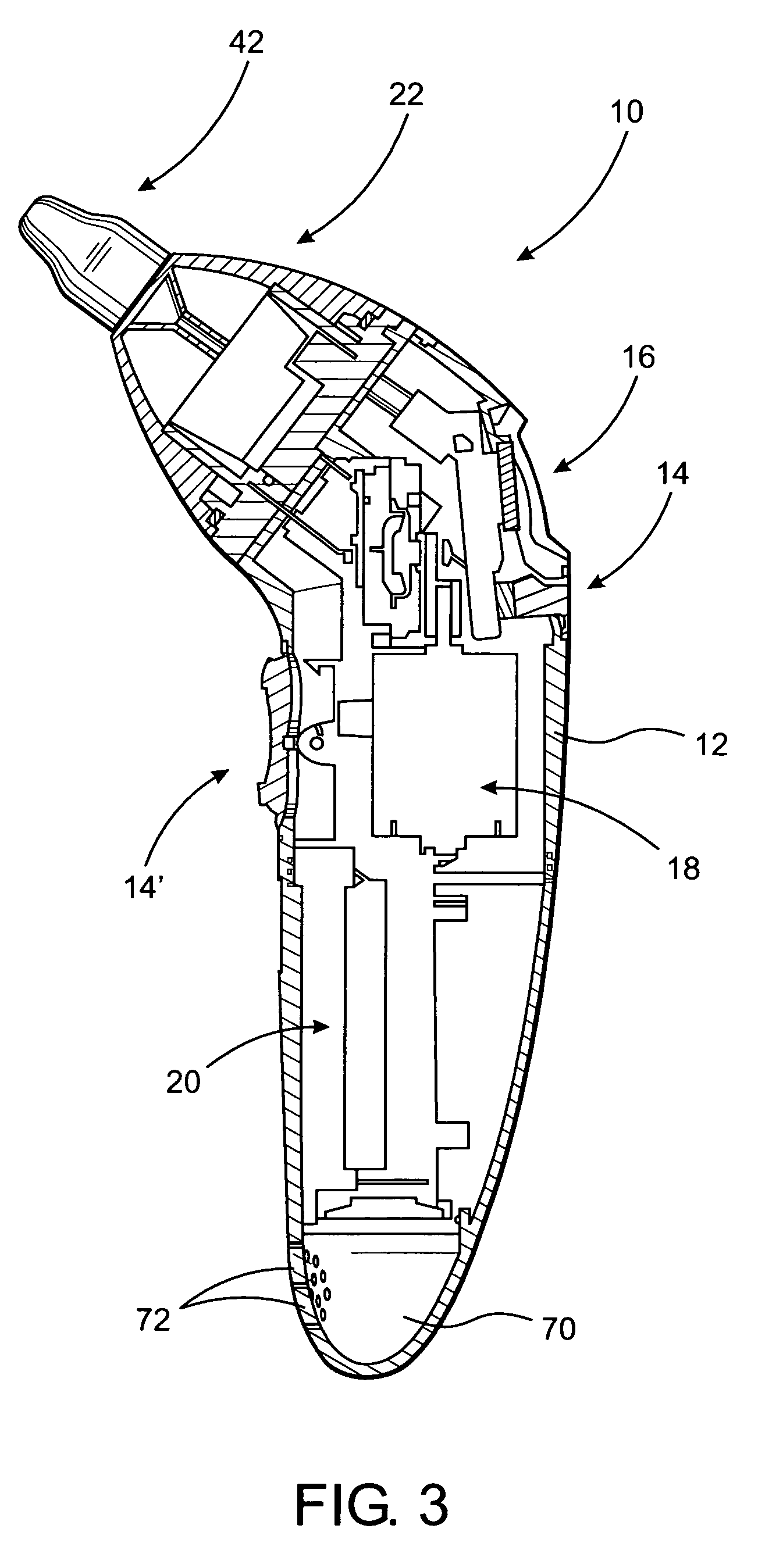

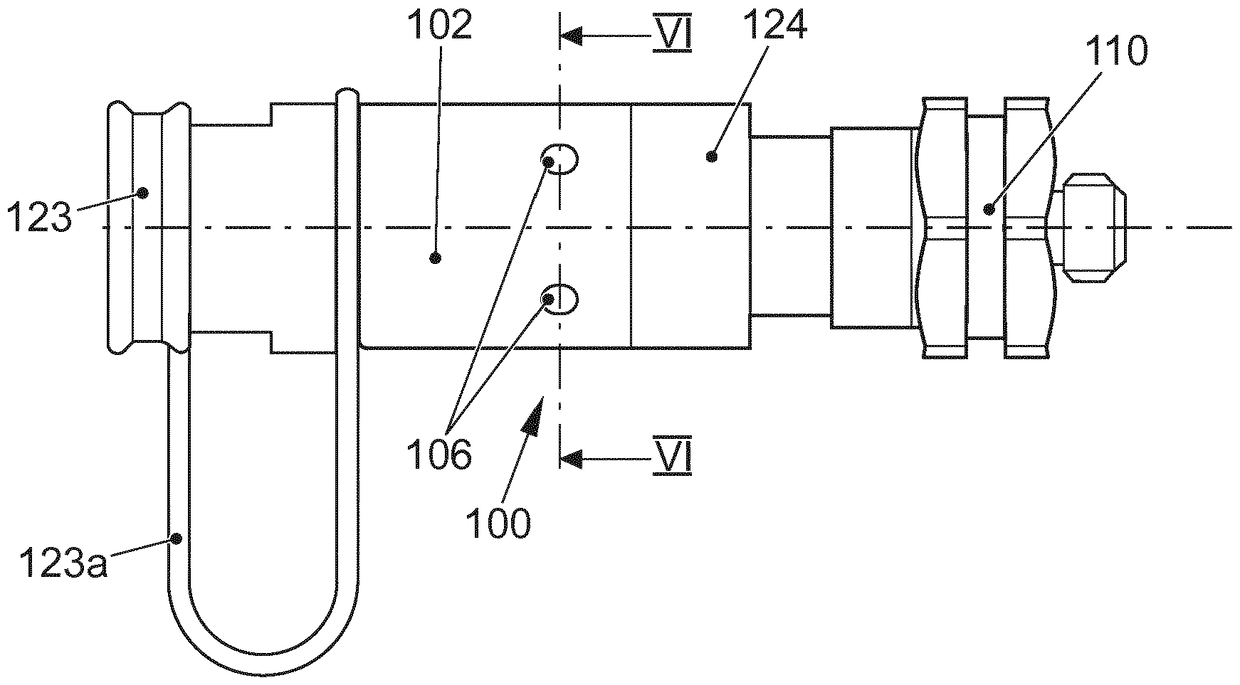

Aspirator assembly

InactiveUS20090048581A1Increase flow directionEasy to holdMedical devicesSuction drainage containersNasal cavityHand held

An assembly structured aspirate nasal cavity of individuals including, but not limited to, children. A hand held and operative casing includes a negative pressure source preferably battery operated, and a cover assembly removably connected to the casing and structured to at least partially define a receiving chamber. An inlet assembly is formed in the casing and communicates with the negative pressure source at least partially by means of a path of fluid flow. A container is removably disposed within the receiving chamber in a predetermined, operative orientation sufficient to receive and collect a predetermined portion of the aspirated fluid, such as mucus removed from the nasal cavity. The path of fluid flow is disposed, dimensioned and structured to restrict passage of the heavier, predetermined portion of the aspirated fluid thereby facilitating its collection within the container, which is disposable along with the collected aspirated fluid after use.

Owner:VISIOMED GRP SA

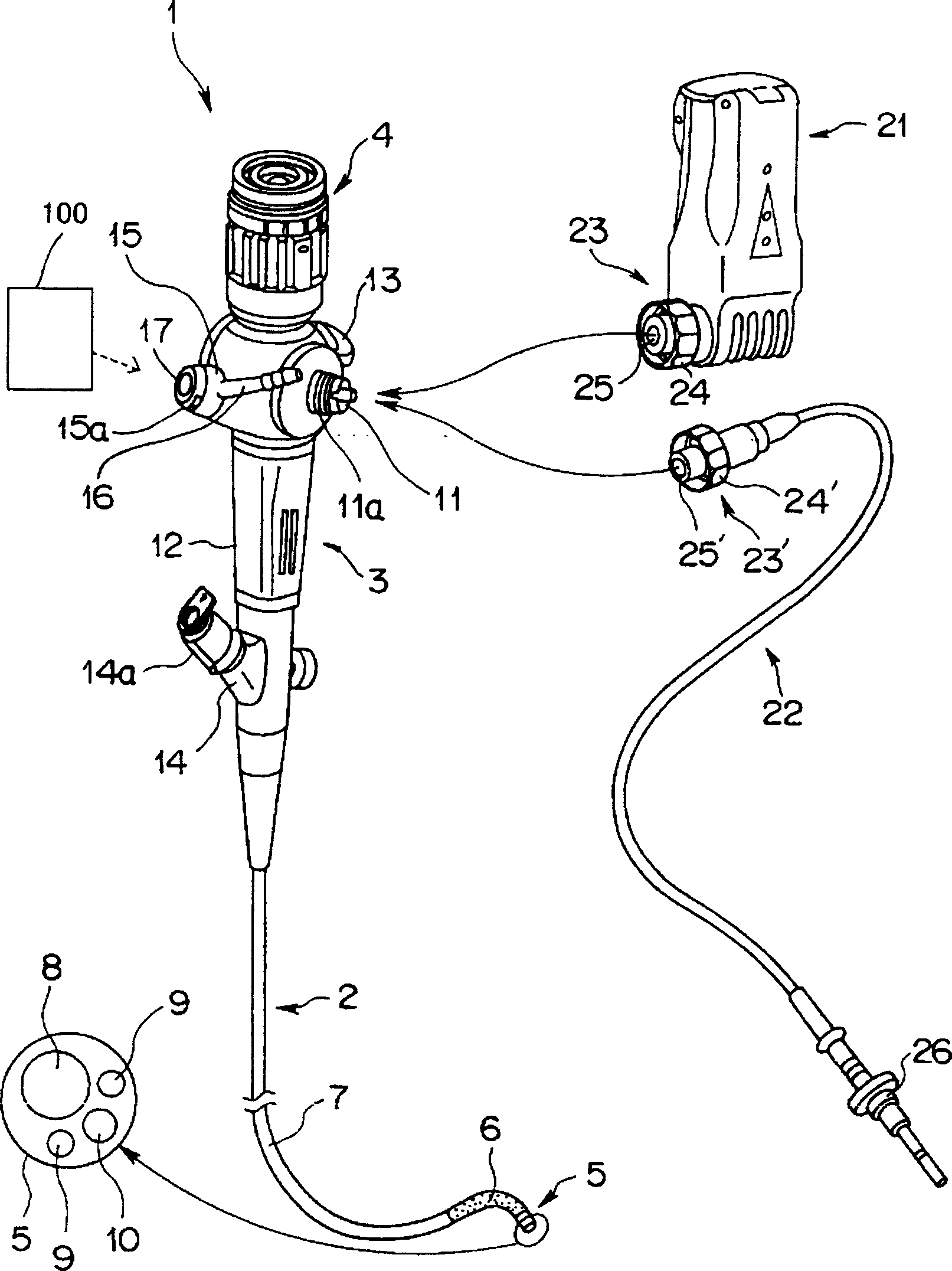

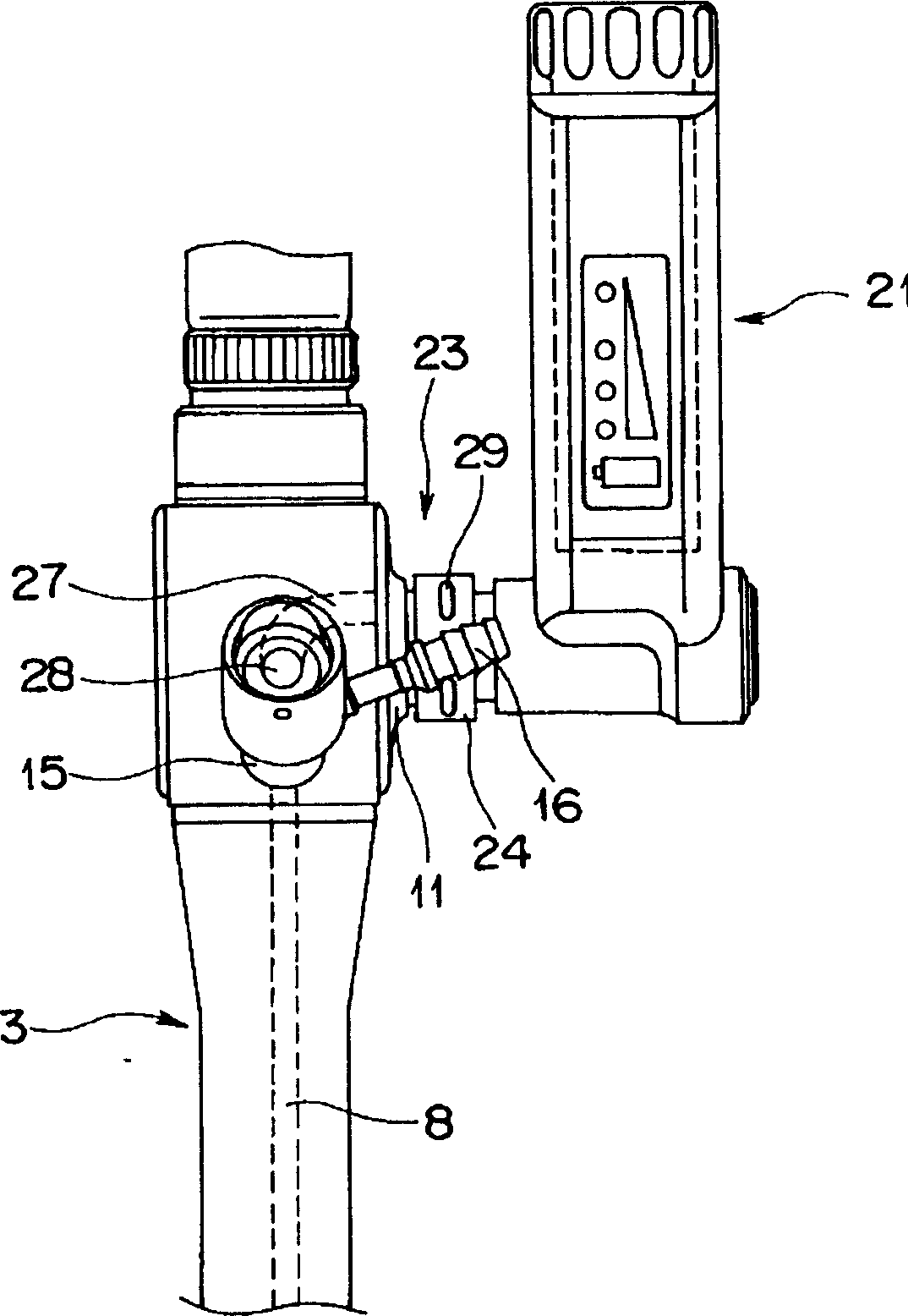

Endoscope device

InactiveCN1440721AIncrease flow directionImprove cooling efficiencySurgeryEndoscopesEndoscopeGas supply

Endoscope apparatus having a space through which a cooling fluid flows in the inside of a connection portion between the endoscope and a light source device in order to cool heat generated in the connection portion. For example, a device for performing air supply or air suction (at least either one of air supply and air suction) in the endoscope communicates with the space, and cooling is effected by the flow of air formed by the device. In a preferred example of a cooling method, when neither air supply nor air suction is needed during manipulation of the endoscope, the device and the space are connected to each other to effect cooling, and when air supply or air suction is needed, the flow of air used for cooling is intercepted, and is exclusively directed to an air channel in the endoscope.

Owner:OLYMPUS OPTICAL CO LTD

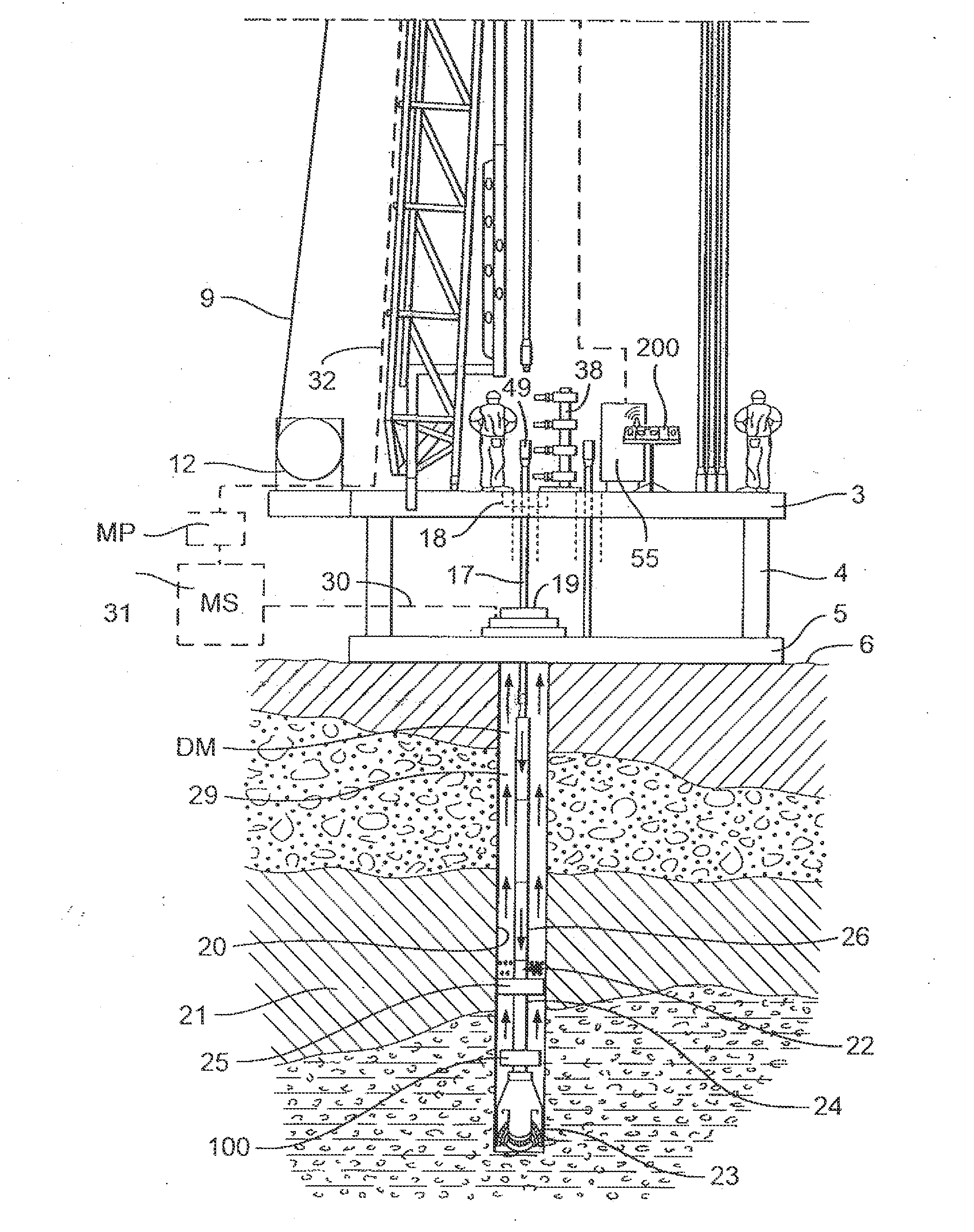

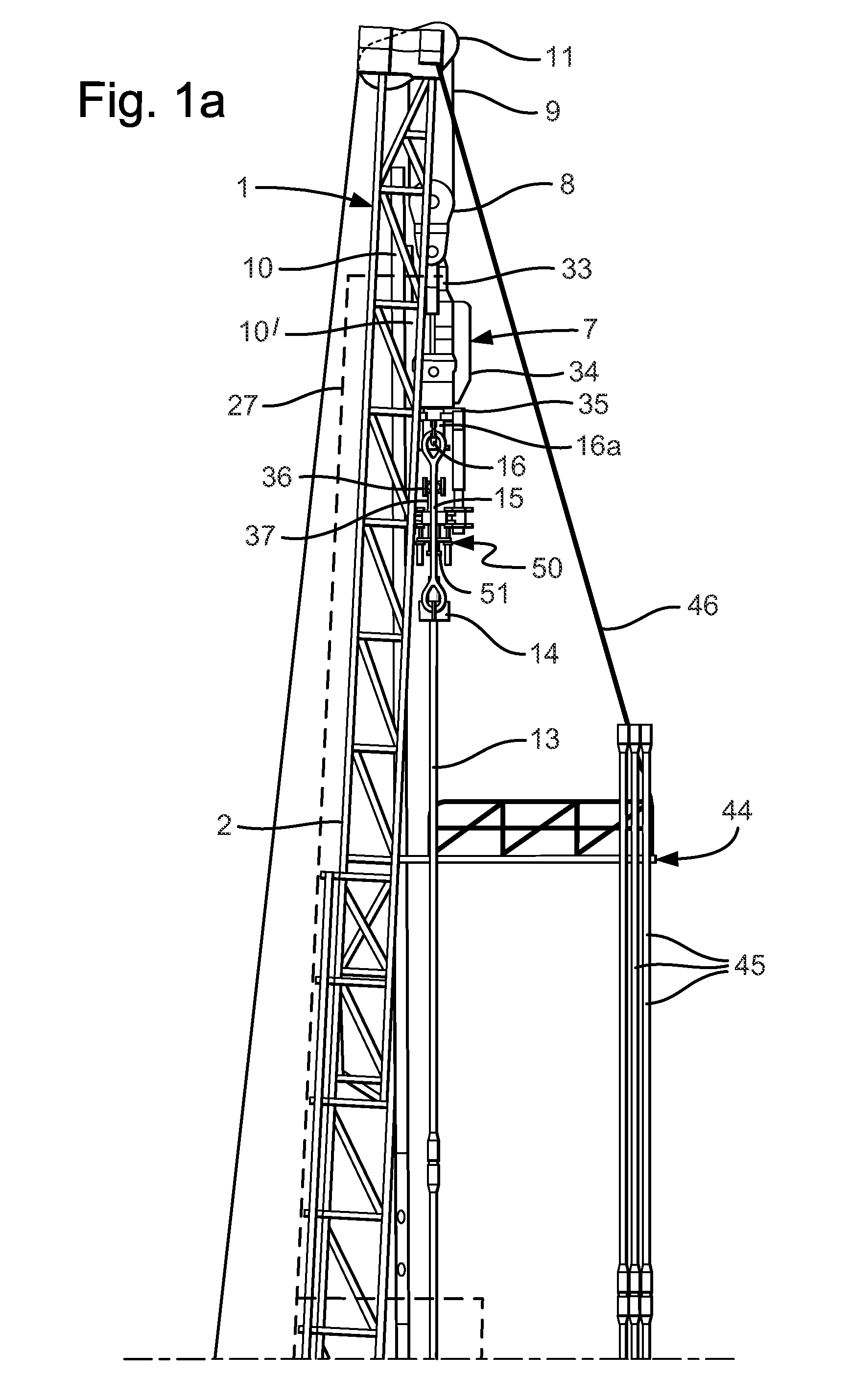

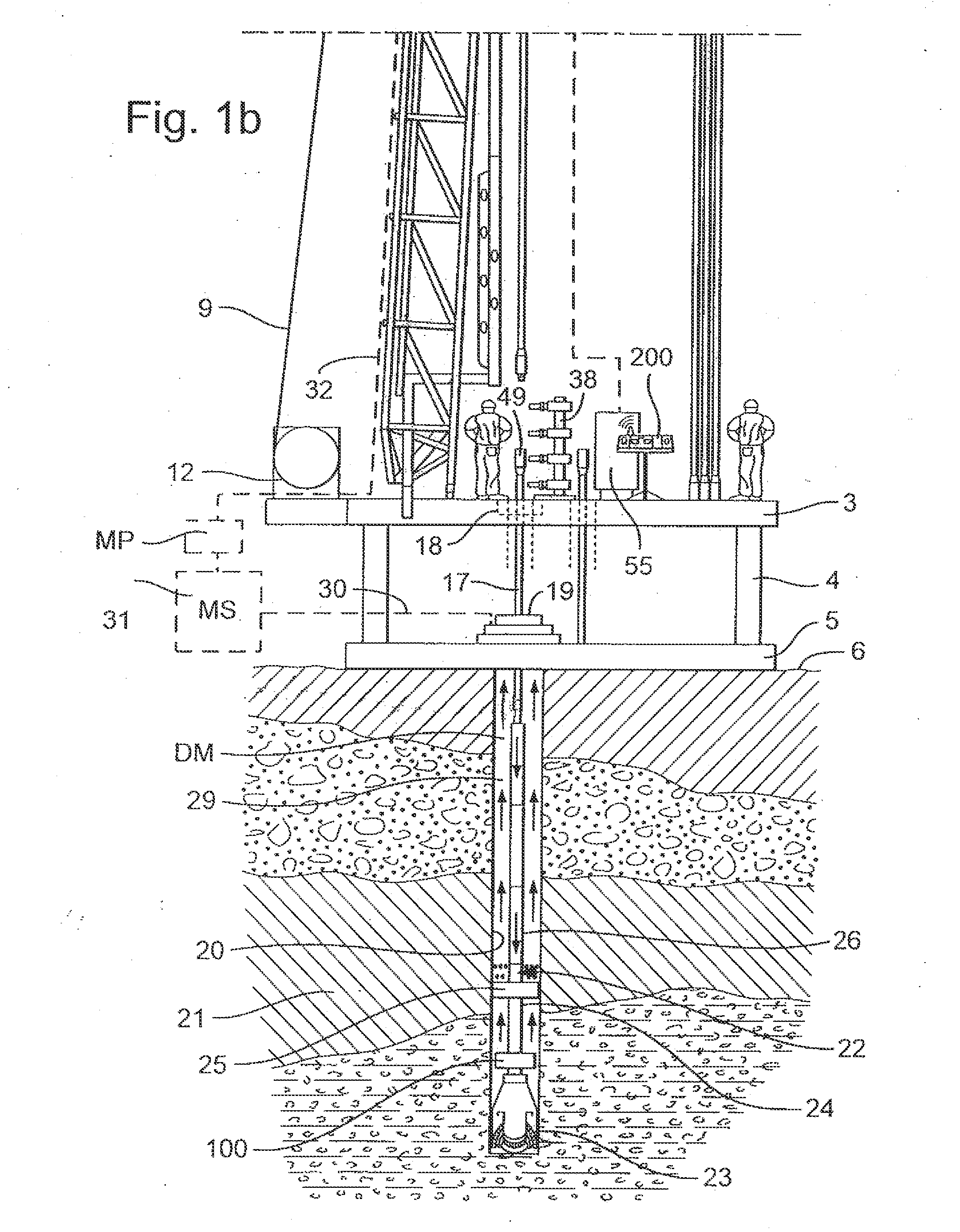

Component of bottom hole assembly having upwardly-directed fluid cleaning flow and methods of using same

InactiveUS20160290067A1Increase in sizeAvoid cakingDrilling rodsDrilling casingsEngineeringMechanical engineering

A stabilizer, drill bit, or other component of a bottom hole assembly for use in drilling a borehole includes an elongate and generally cylindrical body, a flow bore in the body, a plurality of outwardly-extending blades, with a valley disposed between adjacent blades. A ring segment that is spaced from the body and extends across at least one valley to define a flow passage through which cuttings-laden drilling mud is conveyed with an upwardly-direct trajectory. The body includes a hole or passageway for conveying drilling mud from the flow bore to between the blades. The passageway terminates in an exit directed toward the flow passage so as to provide fresh drilling mud with a trajectory such that the fluid passes through the flow passage.

Owner:NOV DOWNHOLE EURASIA LTD

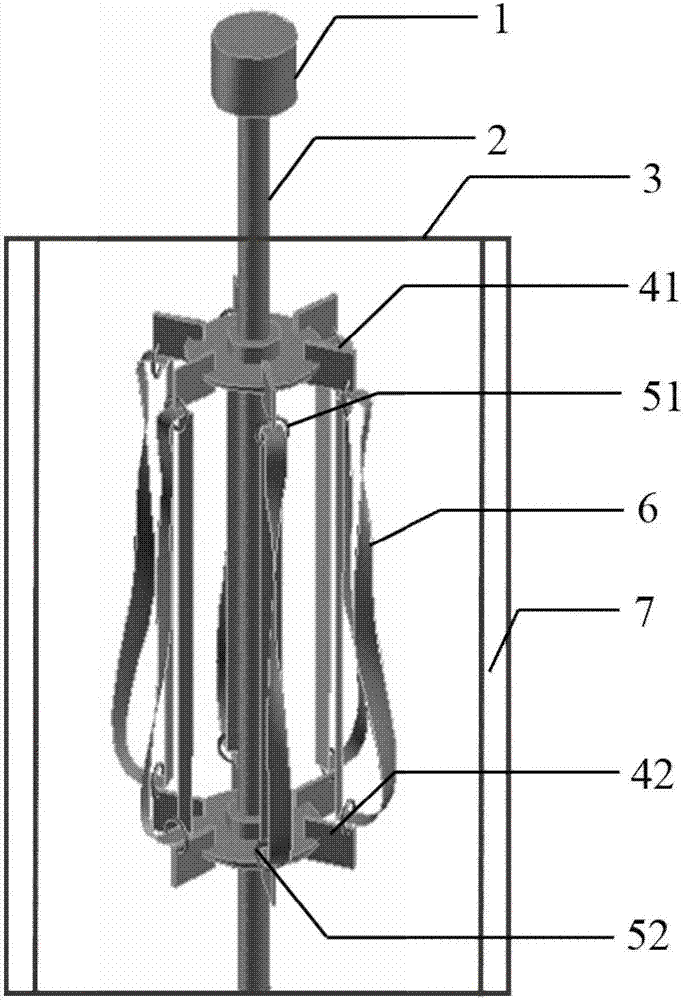

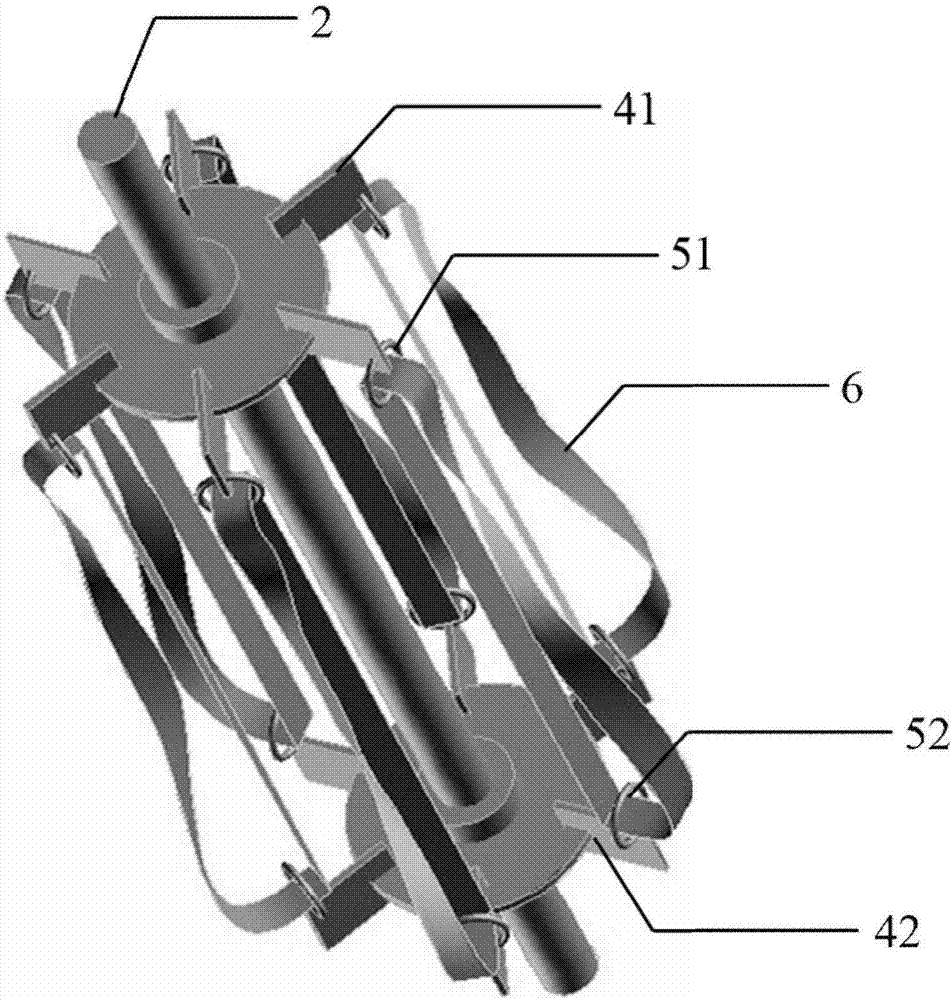

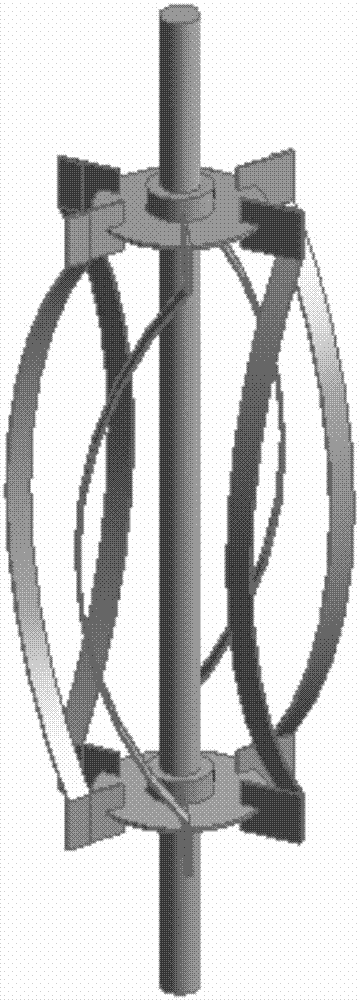

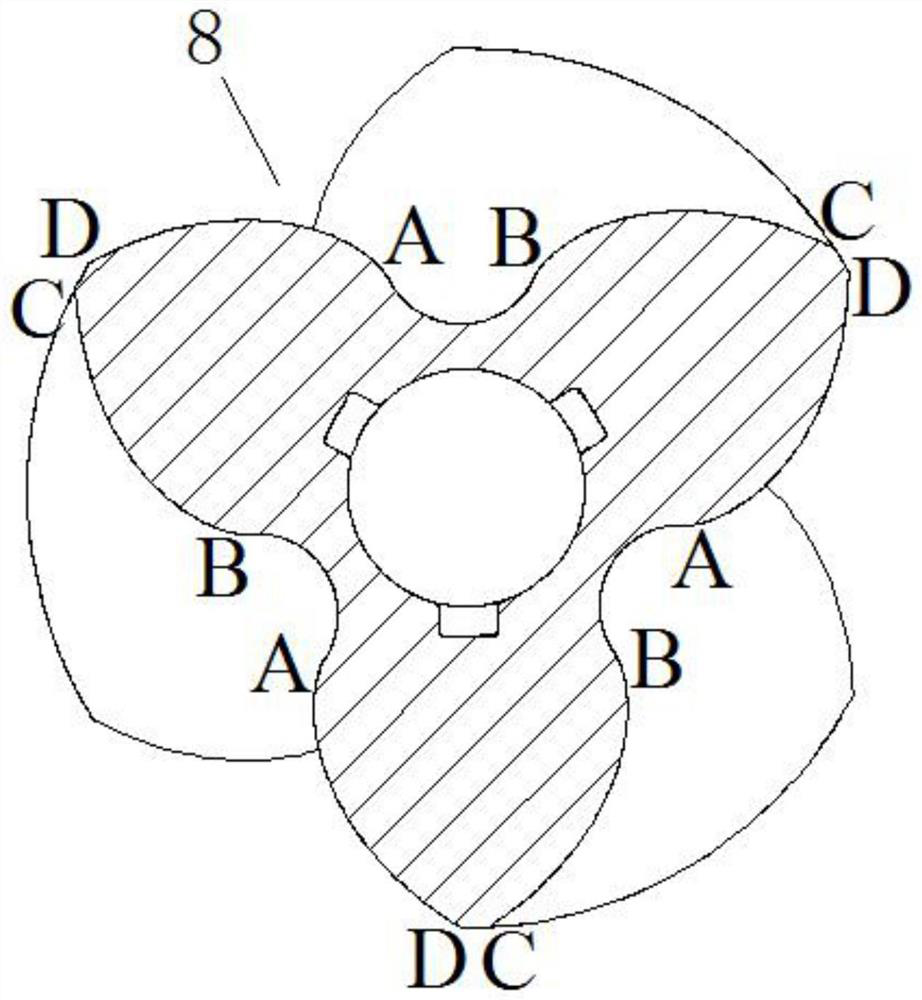

Rigid-flexible combined paddle for enhancing the fluid mixing effect

ActiveCN107278170AIncrease flow directionIncreased turbulenceRotary stirring mixersTransportation and packagingEnergy transferMechanical energy

The present invention relates to a rigid-flexible combined paddle for enhancing the fluid mixing effect, comprising a stirring shaft, a plurality of rigid stirring blades, a plurality of flexible Mobius bands and a plurality of rings. The rigid and flexible combined paddle consists of at least upper and lower layers and is mainly composed of upper and lower rigid stirring blades fixed on a stirring shaft and the flexible Mobius bands connected between the upper and lower rigid stirring blades through the ring. The rigid-flexible combined paddle is driven by the motor to rotate in a stirring tank, and mechanical energy is input to the fluid in the stirring tank to obtain the appropriate flow field of the fluid to strengthen the fluid mixing process. Compared with the prior art, the flexible Mobius strip in the rigid-flexible combined paddle according to the present invention can constantly shake or perform multi-body movement by the interaction between the stirring shaft and the fluid to continuously change the flow direction of the fluid, increase the turbulence of the fluid, enhance the energy transfer process, increase the mixing efficiency of the fluid, and save the cost of the device.

Owner:CHONGQING UNIV +1

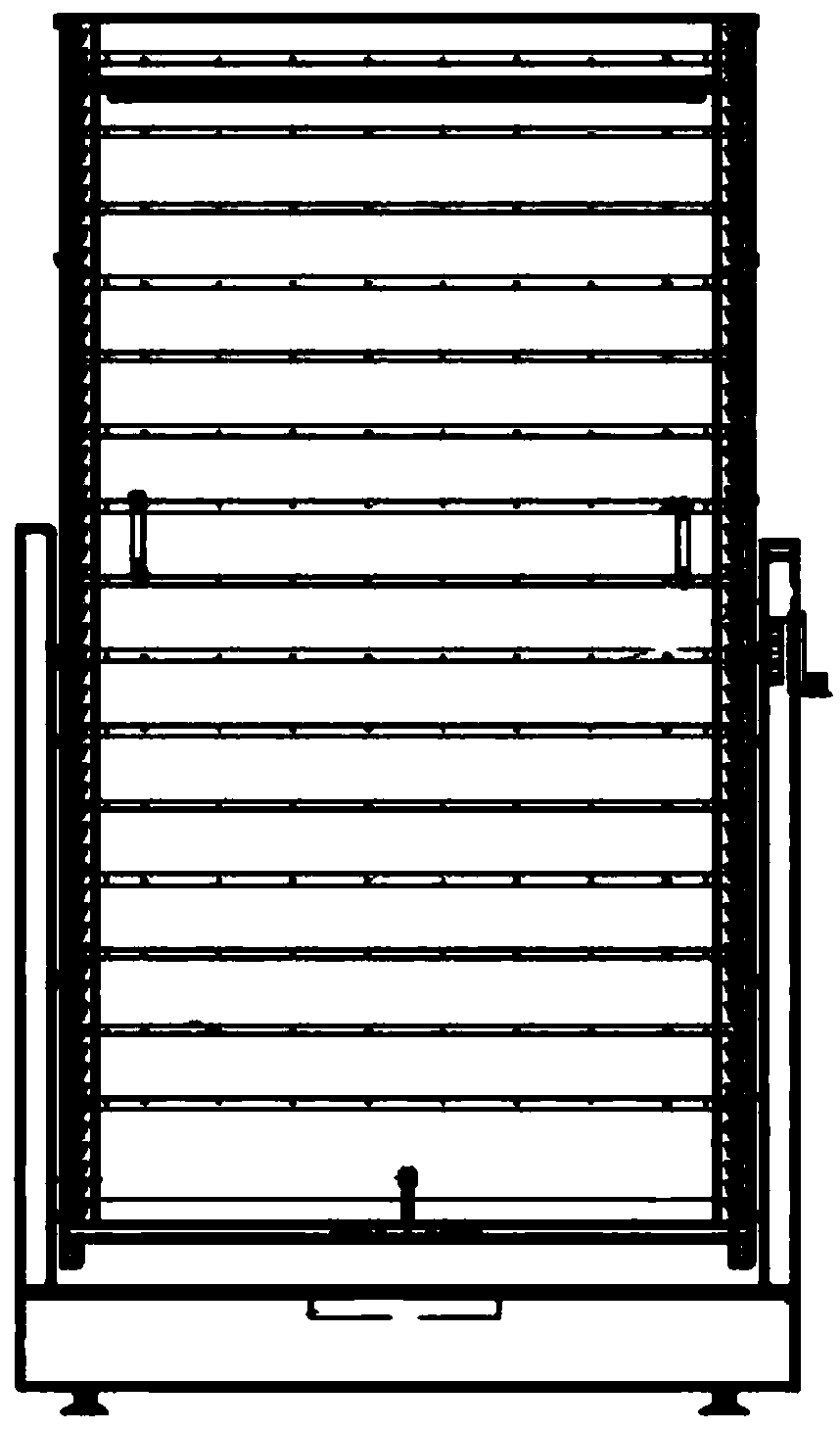

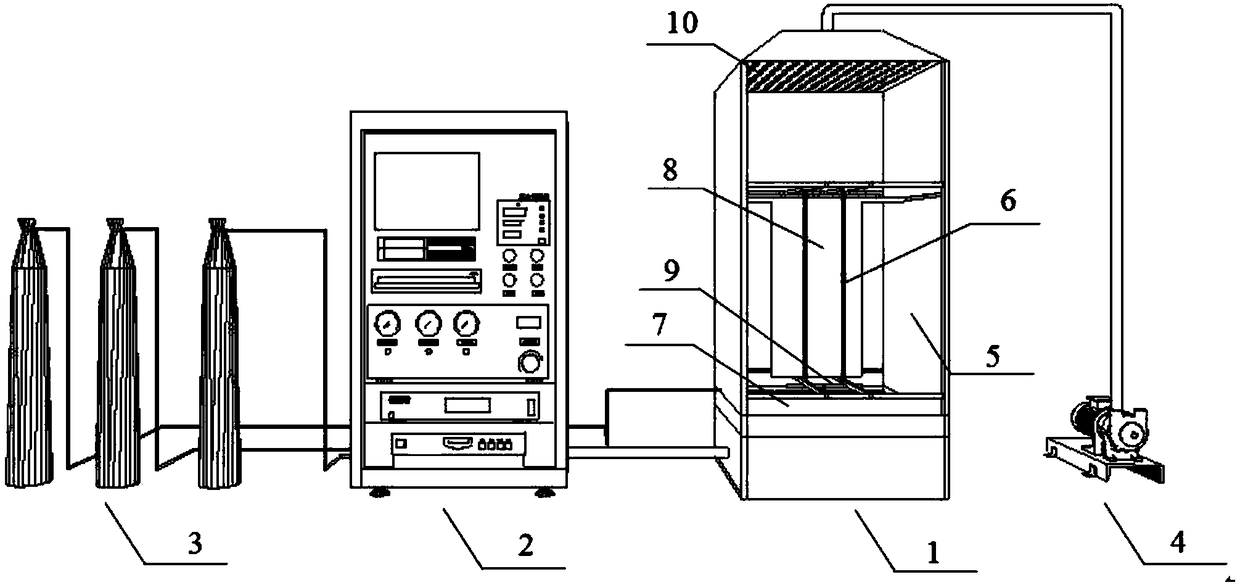

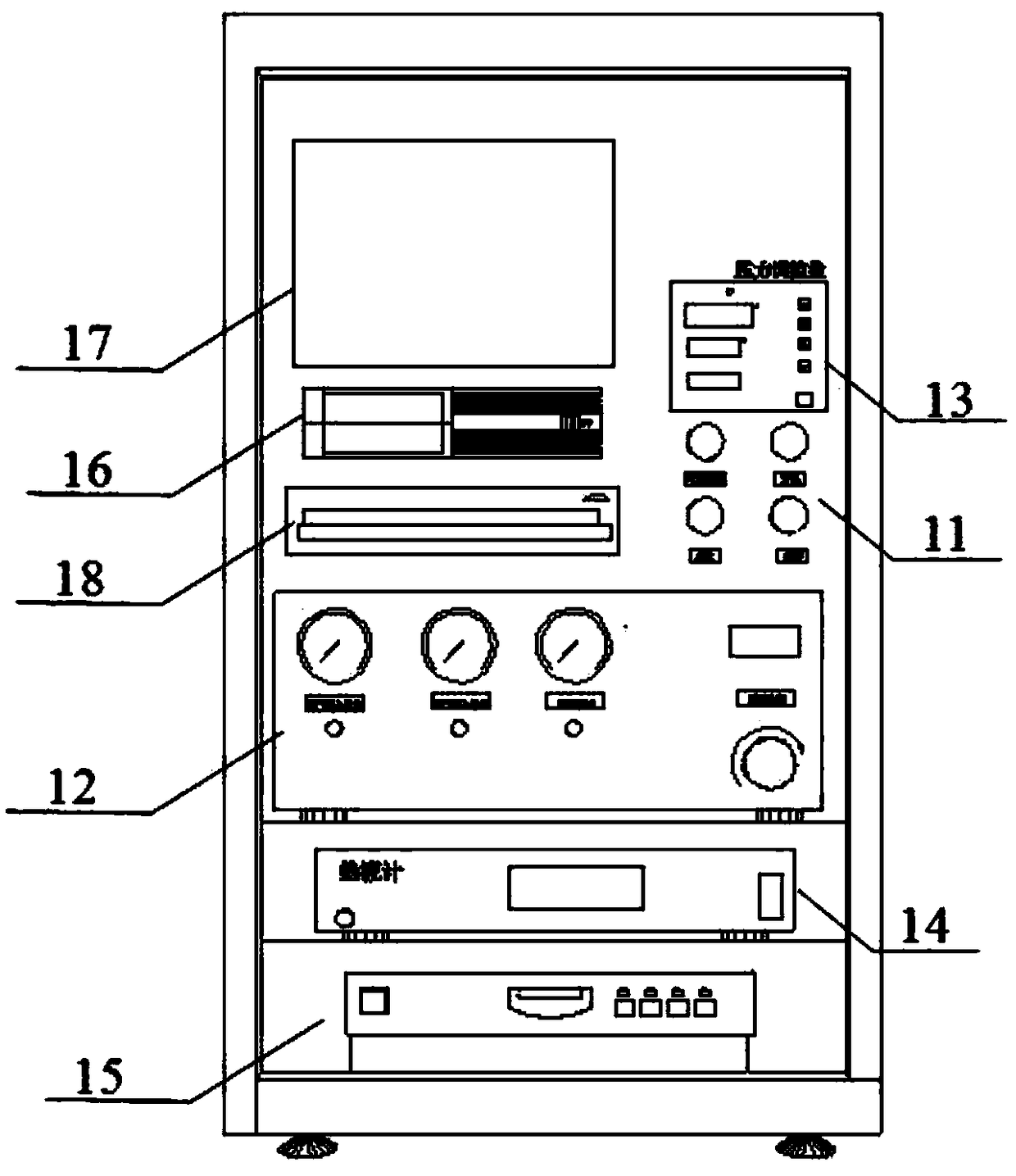

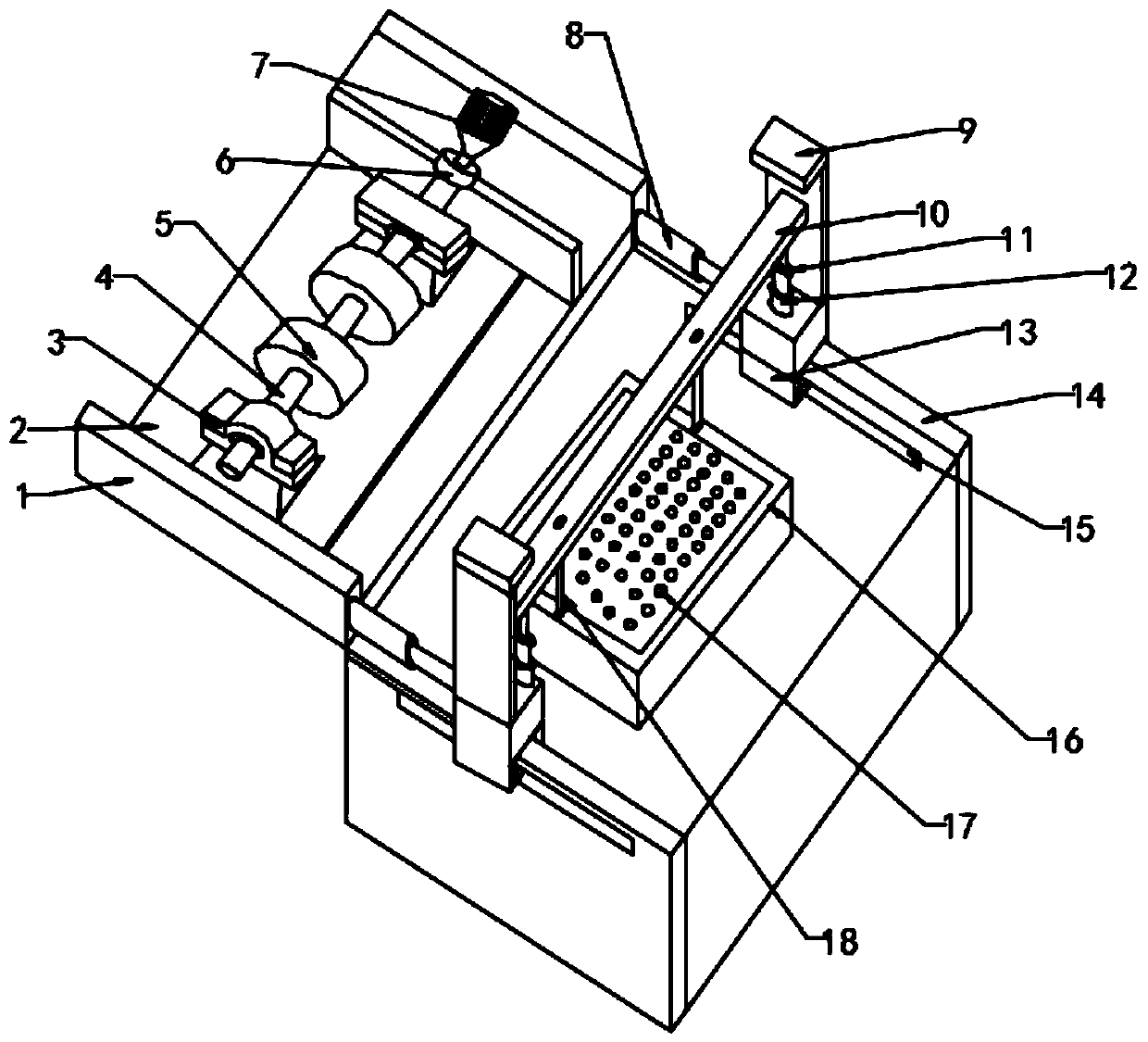

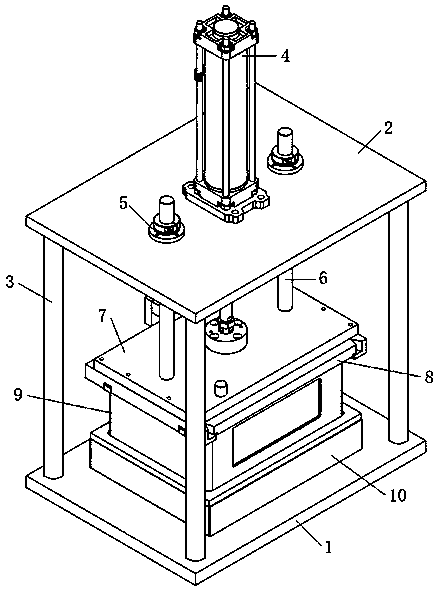

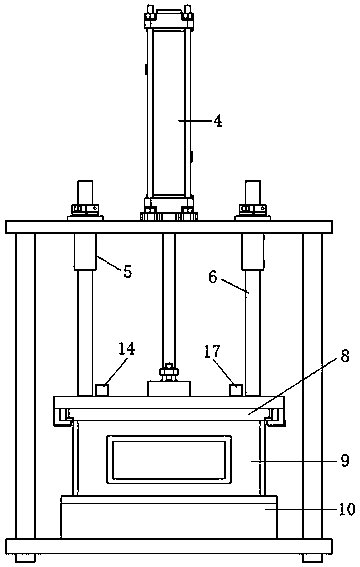

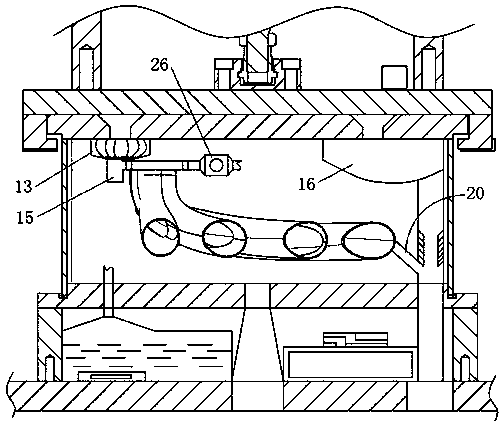

Vertical combustion characteristic experiment device capable of controlling gas environments and side wall structures

InactiveCN108169407AIncrease pressureImprove smoke extraction rateChemical analysis using combustionCombustion chamberHeat flow

The invention discloses a vertical combustion characteristic experiment device capable of controlling gas environments and side wall structures, and belongs to the technical field of experiment teaching or scientific research apparatus. The vertical combustion characteristic experiment device capable of controlling gas environments and side wall structures comprises an experiment table, an analysis control cabinet, a combustible gas bomb group, and a vacuum pump; the experimental table comprises a combustion chamber, a fixing device of variable side wall structures, a gas homogenizing device,a hot flow sensor, a linear ignition device, and a flue gas collecting device; the analysis control cabinet comprises an operation panel, a gas mixing regulating and controlling system, a gas pressureregulating and controlling system, a hot flow data acquisition device, a flue gas toxicity analysis device, a computer host, a computer display, a mouse, and a keyboard; the operation panel comprisesa power supply switch button, a sudden stop button, a measuring starting button, and an igniting button. The vertical combustion characteristic experiment device is used for measuring of characteristic parameters of vertical arranged combustible matters at different gas environments, under different side wall structure conditions, and is mainly used in fire-fighting teaching and scientific research.

Owner:CHINA UNIV OF MINING & TECH

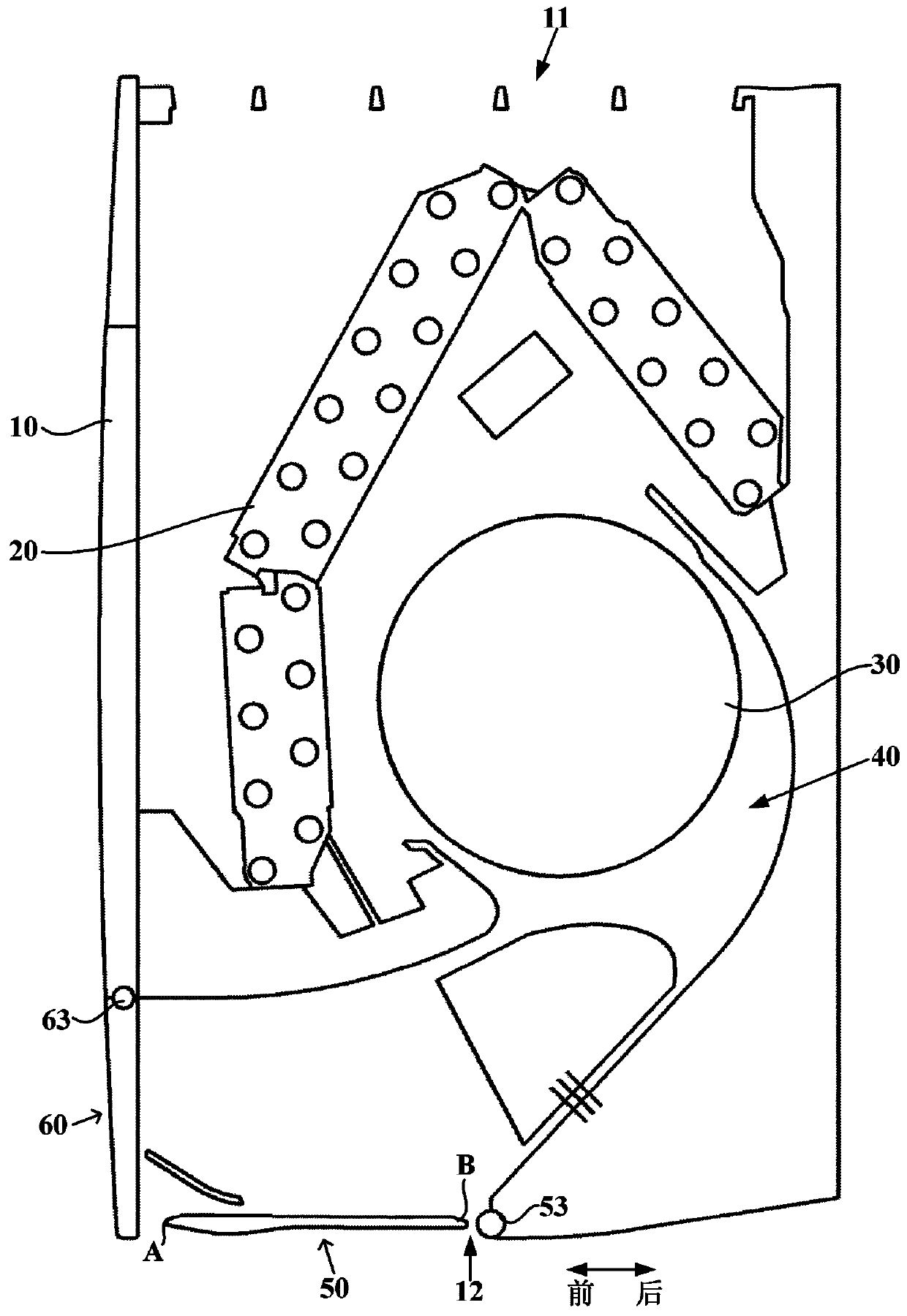

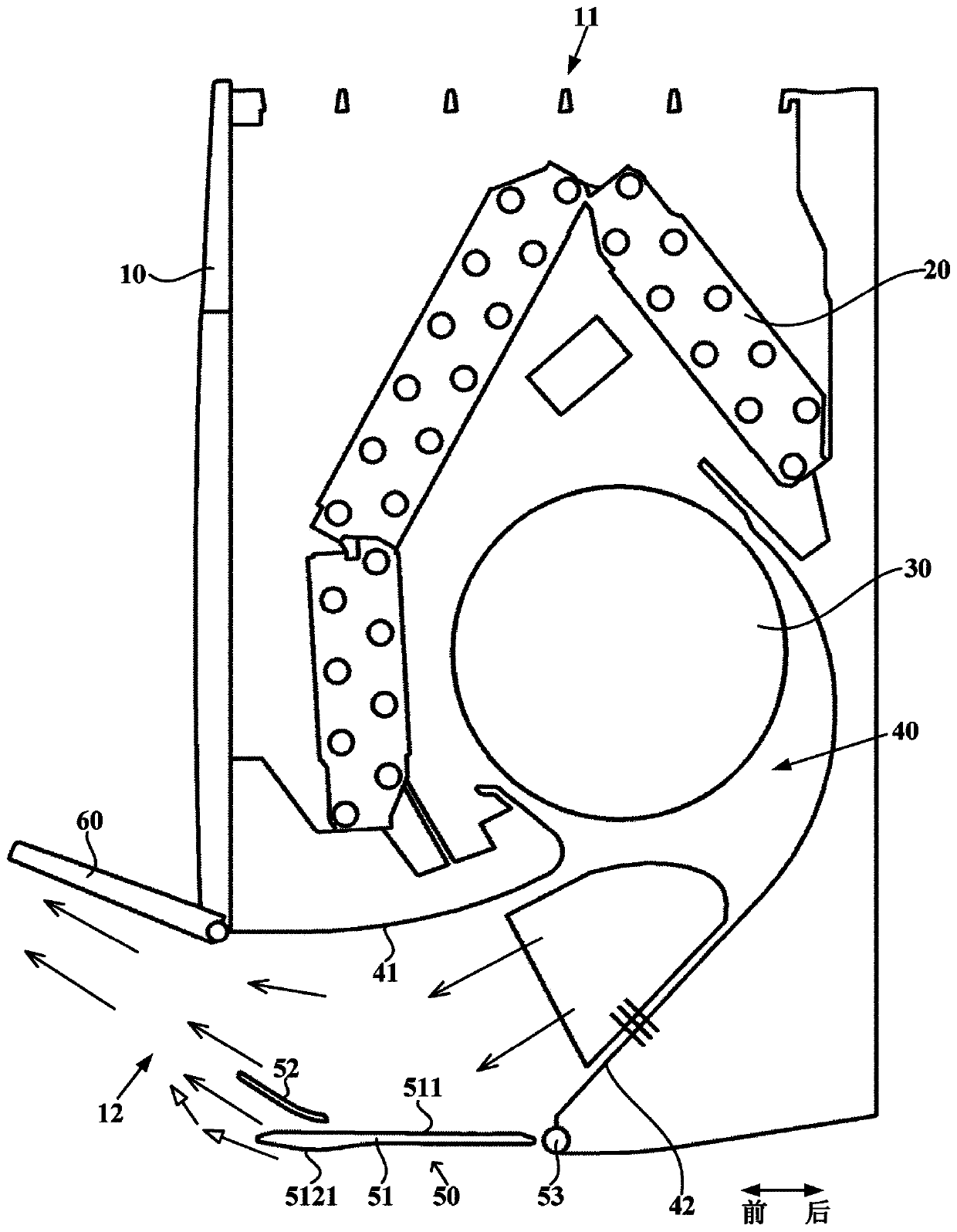

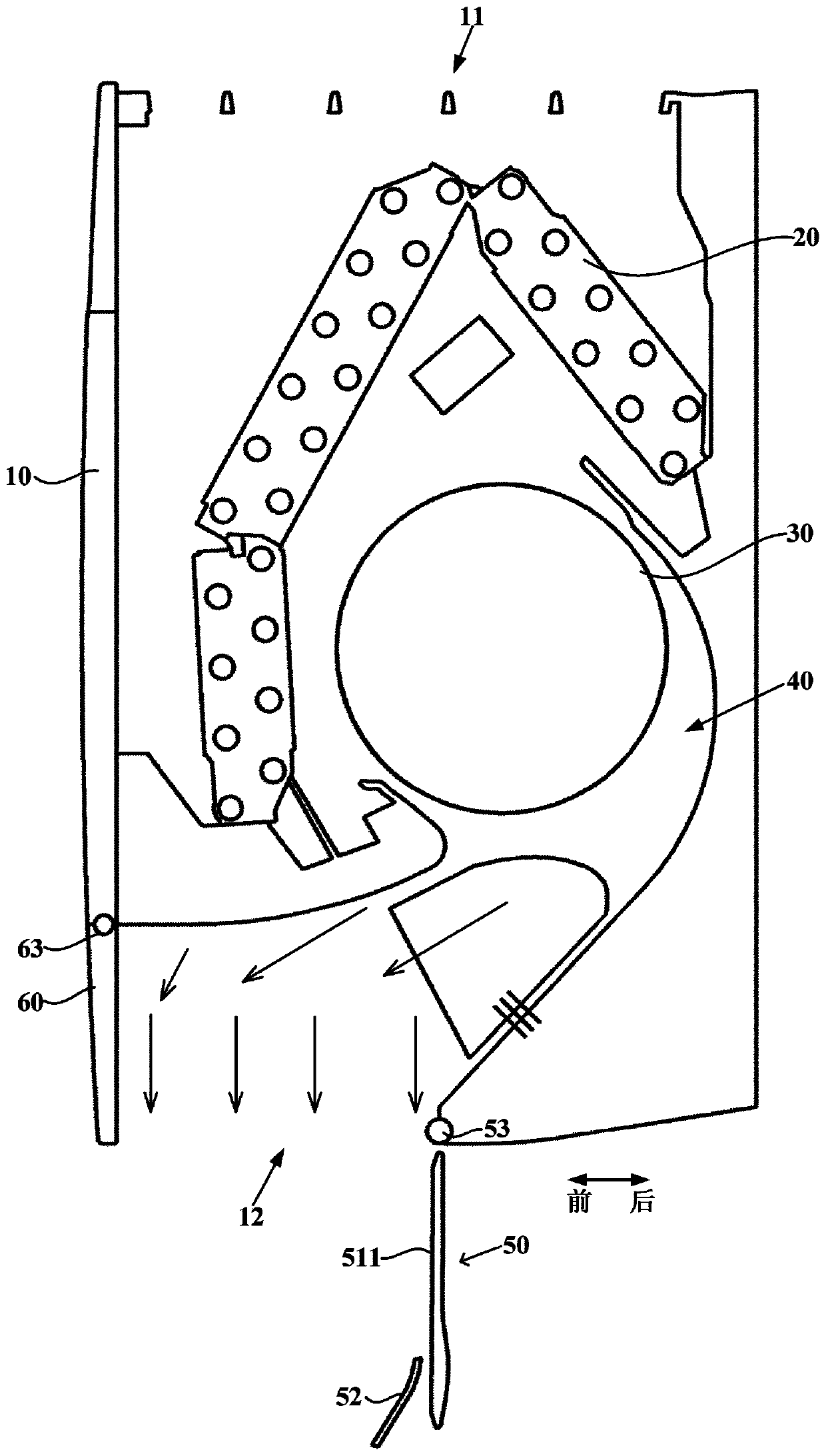

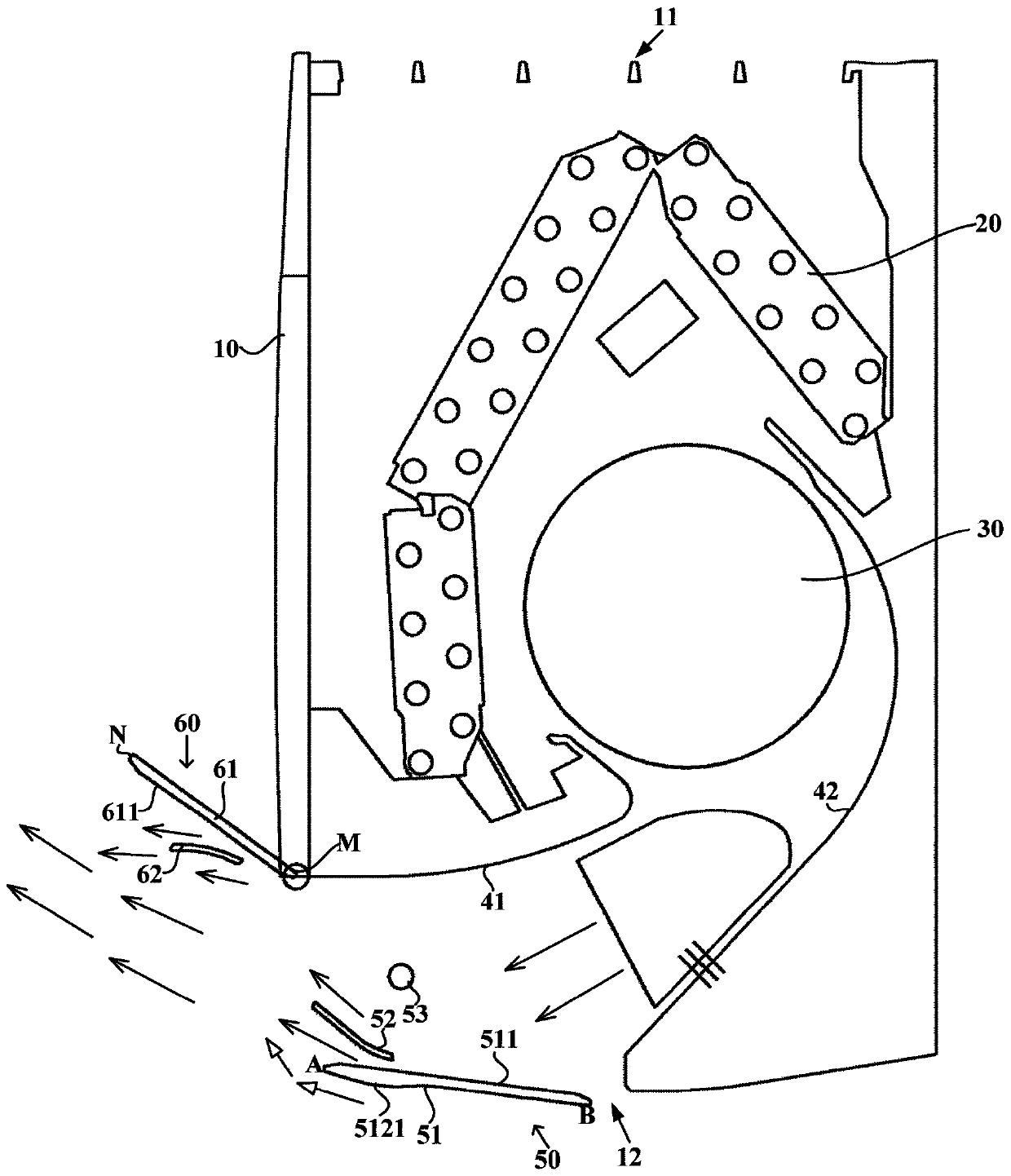

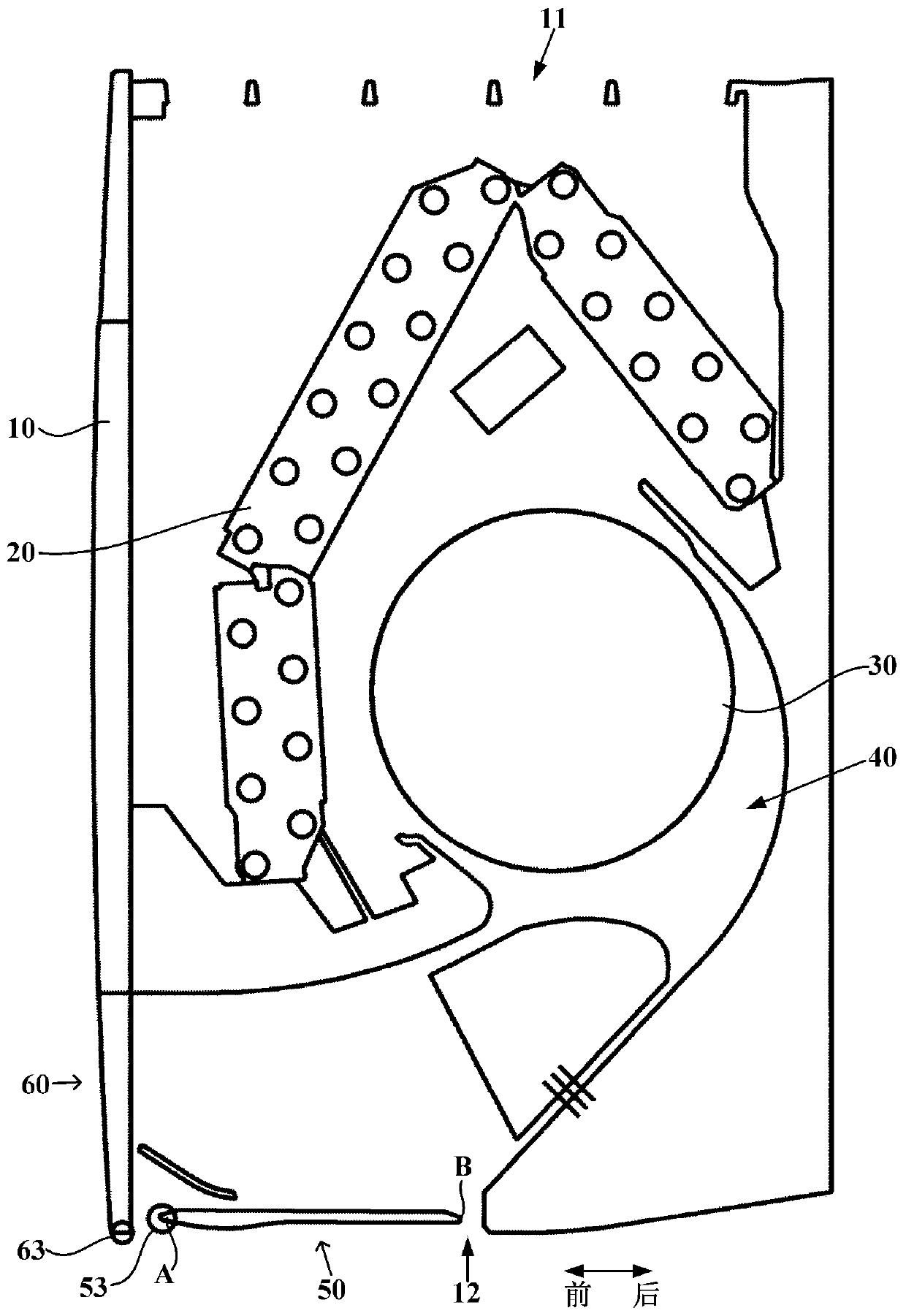

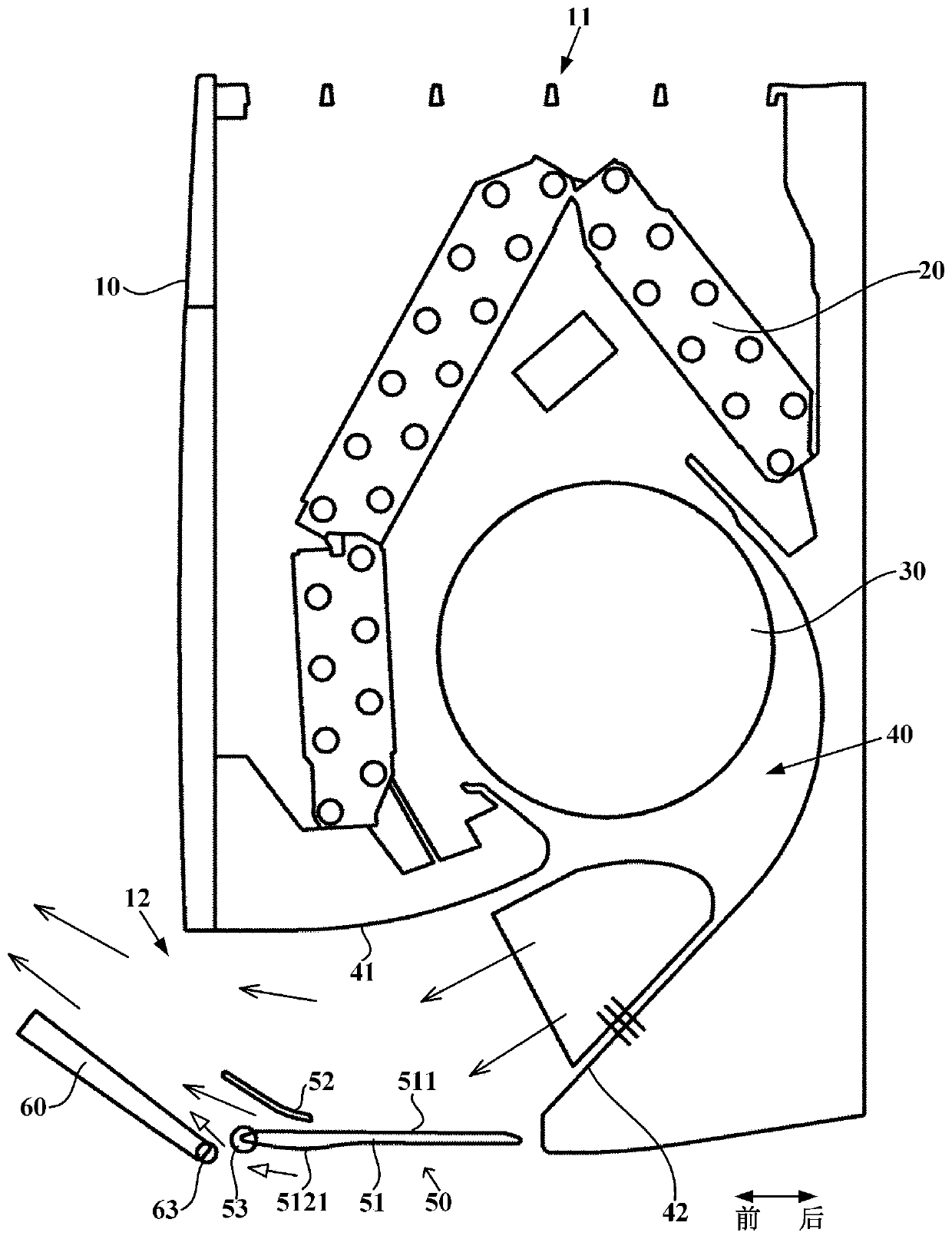

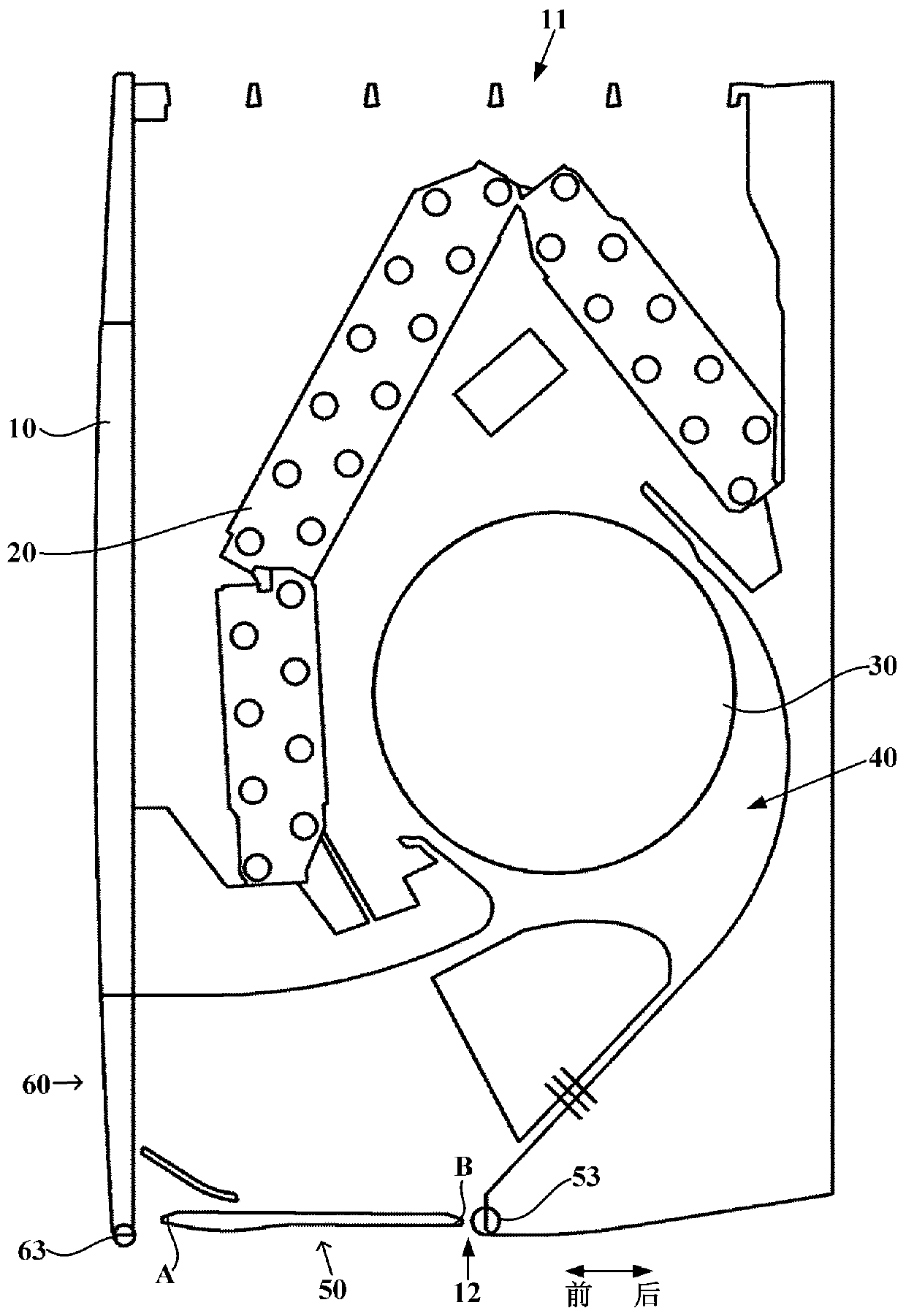

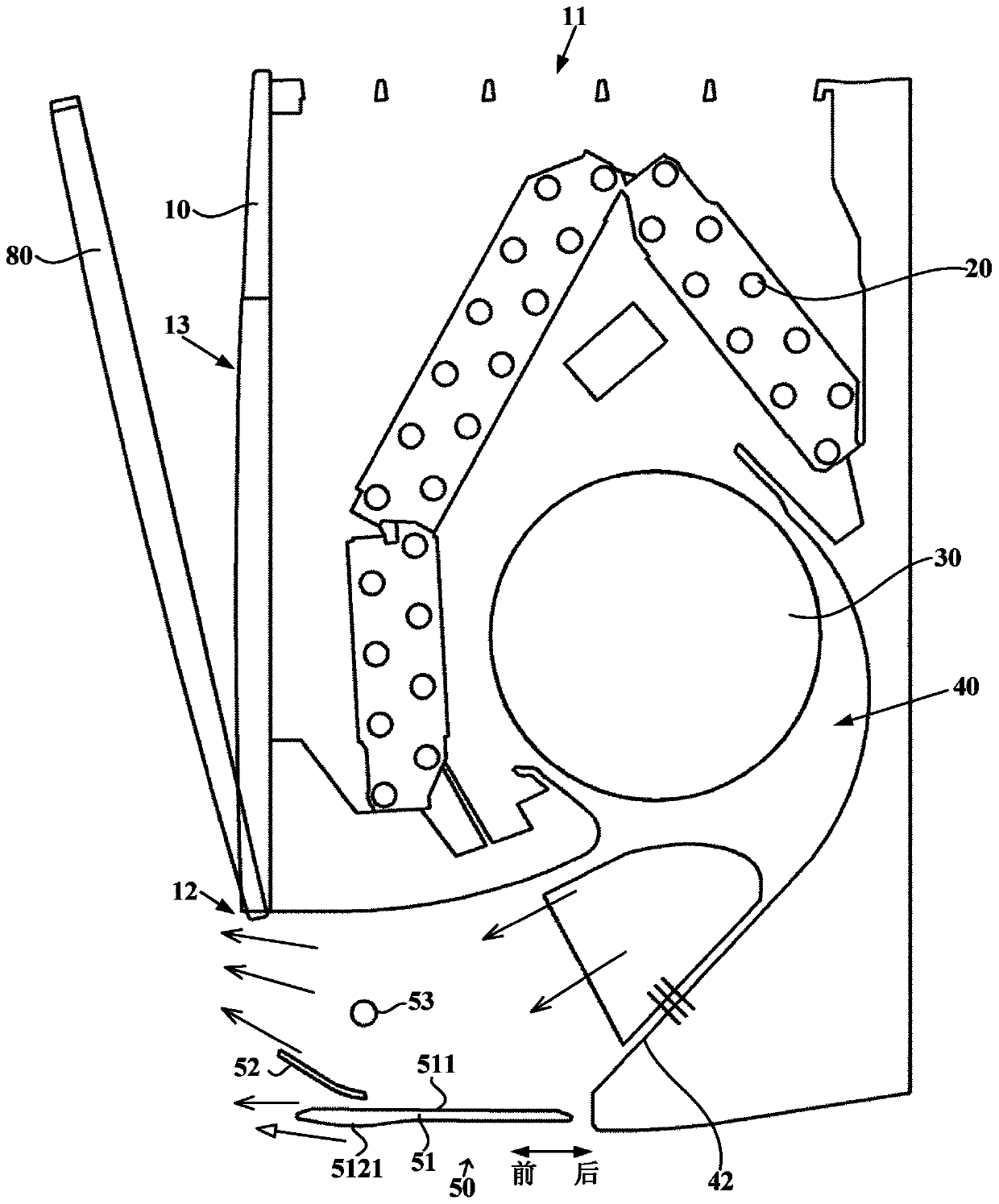

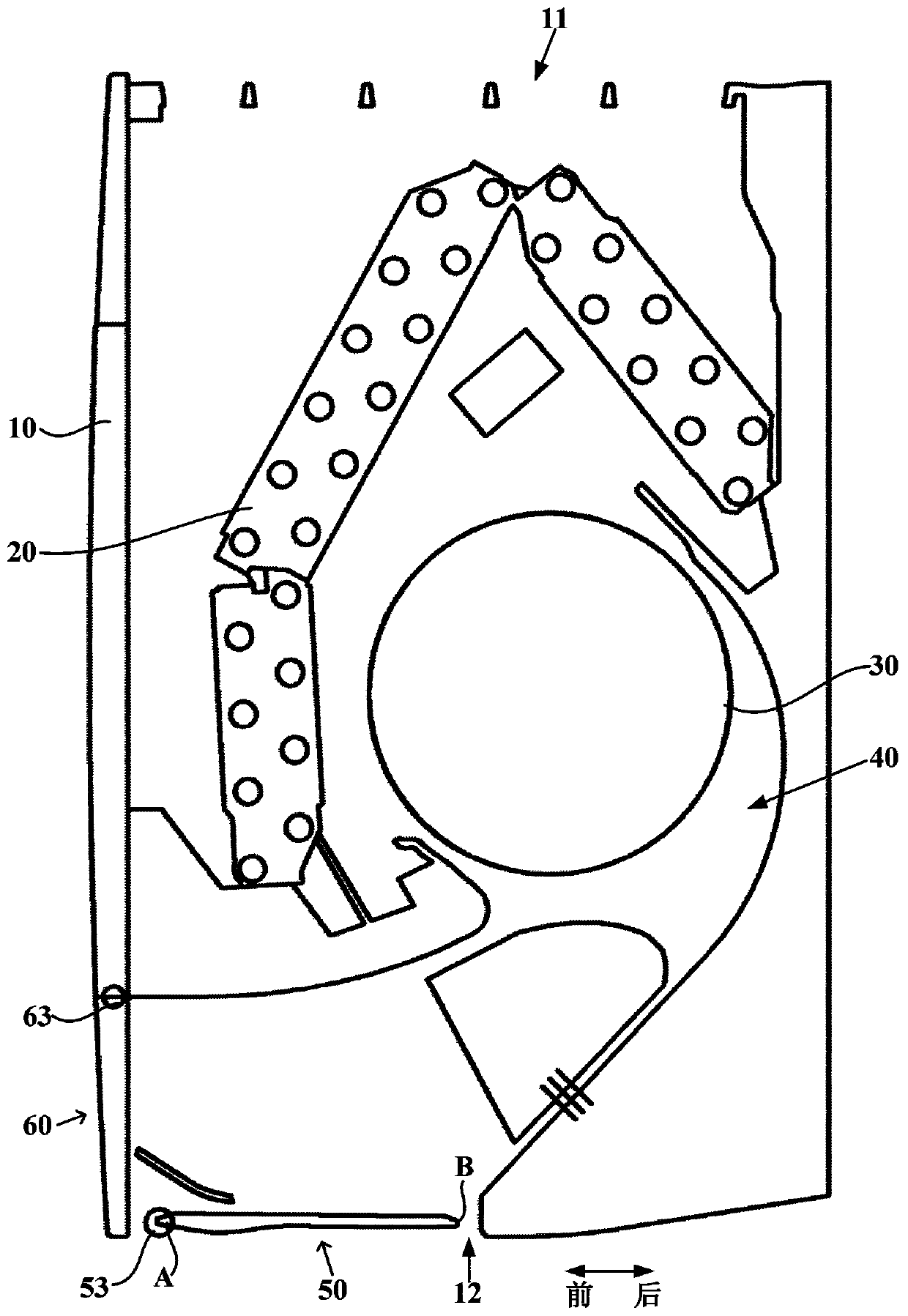

Indoor unit of air conditioner

PendingCN111351130AImprove air supply comfort experienceRealize the cooling experienceLighting and heating apparatusAir conditioning systemsCold airEngineering

The invention provides an indoor unit of an air conditioner. The indoor unit comprises a shell, a baffle plate and an air deflector, wherein the shell is provided with an air outlet facing the front lower side; the upper end of the baffle plate is rotatably mounted on the shell, and a rotating shaft of the baffle plate is located at the upper edge of the air outlet, so that the baffle plate rotates to an opened position opening the front side of the air outlet or rotates to a closed position shielding the front side of the air outlet; and the air deflector is rotatably mounted on the shell andis configured to rotate to a first position, through which an air guide surface thereof faces upward, on the lower side of the air outlet, so as to guide a blowing air flow to the front side, the front upper side or the front lower side by the air deflector when the baffle plate is located in the opened position; and the air deflector is configured to rotate to a second position, through which the air guide surface faces forward, on the back side of the air outlet, so as to guide the blowing air flow to the lower side. The indoor unit of the air conditioner can blow cold air in a rising manner and blow hot air in a sinking manner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

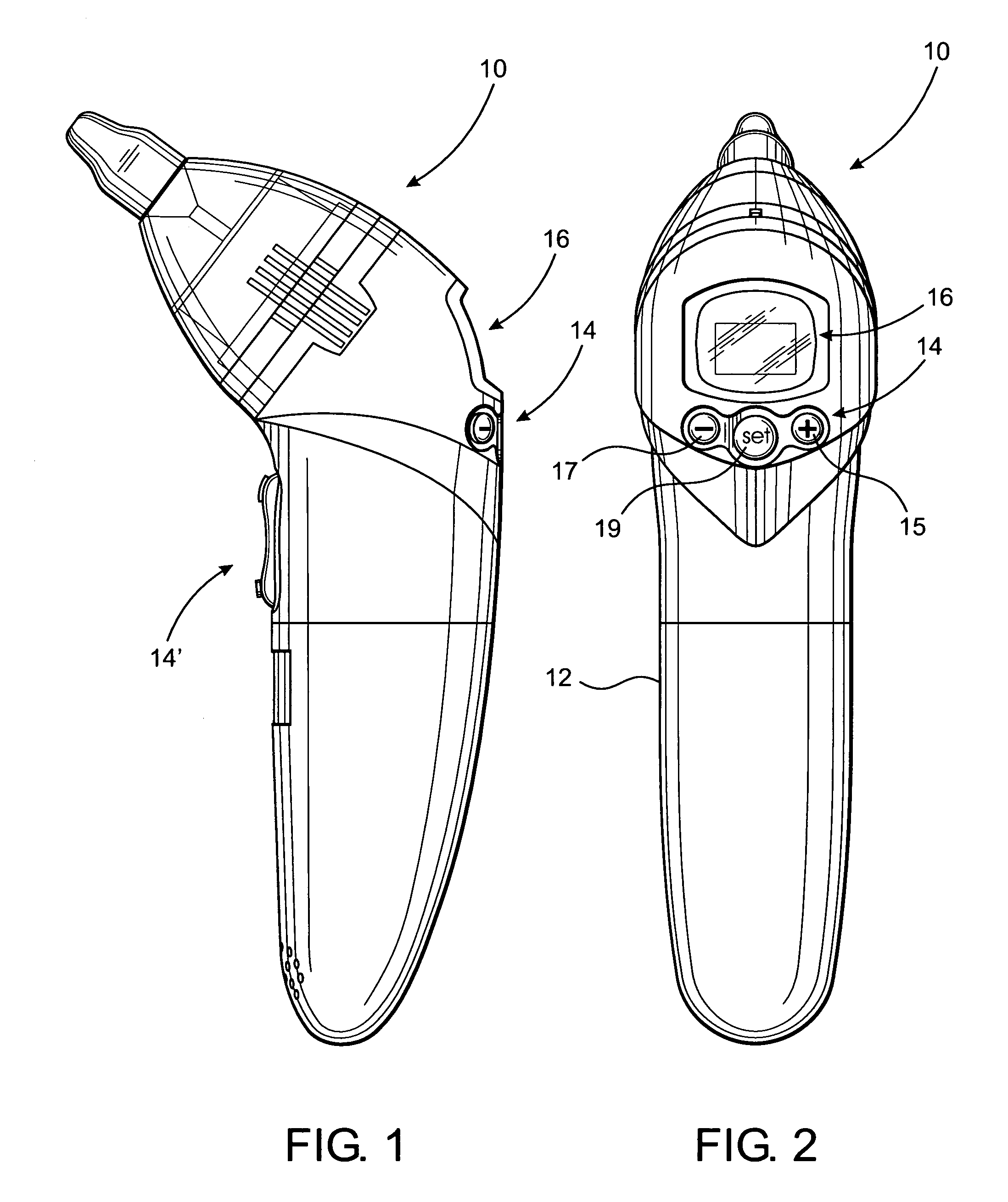

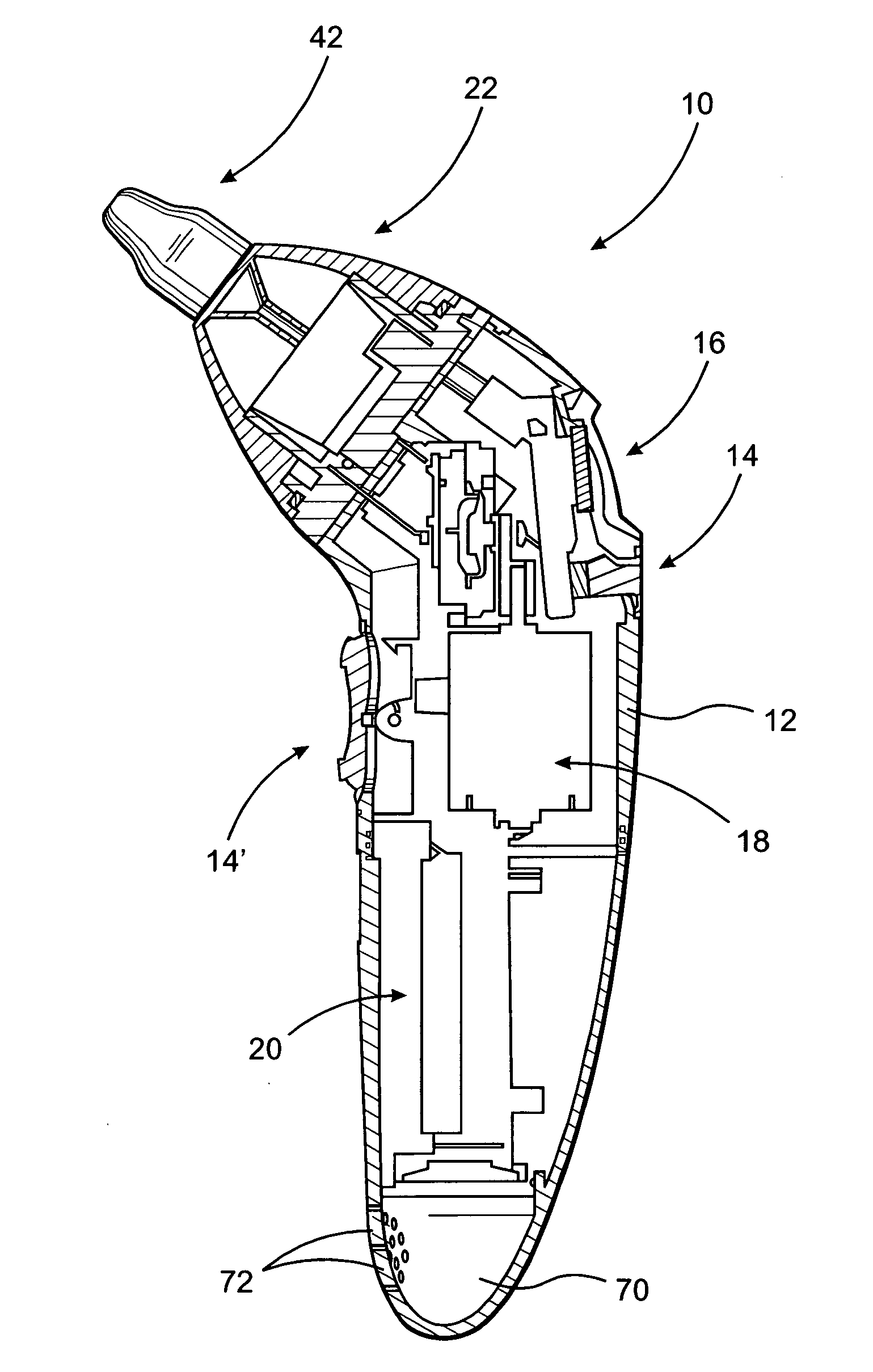

Aspirator assembly

InactiveUS20090076441A1Promote activationImprove visualizationSurgeryMedical devicesNasal cavityHand held

An assembly structured aspirate nasal cavity of individuals including, but not limited to, children. A hand held and operative casing includes a negative pressure source preferably battery operated, and a cover assembly removably connected to the casing and structured to at least partially define a receiving chamber. An inlet assembly is formed in the casing and communicates with the negative pressure source at least partially by means of a path of fluid flow. A container is removably disposed within the receiving chamber in a predetermined, operative orientation sufficient to receive and collect a predetermined portion of the aspirated fluid, such as mucus removed from the nasal cavity. The path of fluid flow is disposed, dimensioned and structured to restrict passage of the heavier, predetermined portion of the aspirated fluid thereby facilitating its collection within the container, which is disposable along with the collected aspirated fluid after use.

Owner:VISIOMED GRP SA

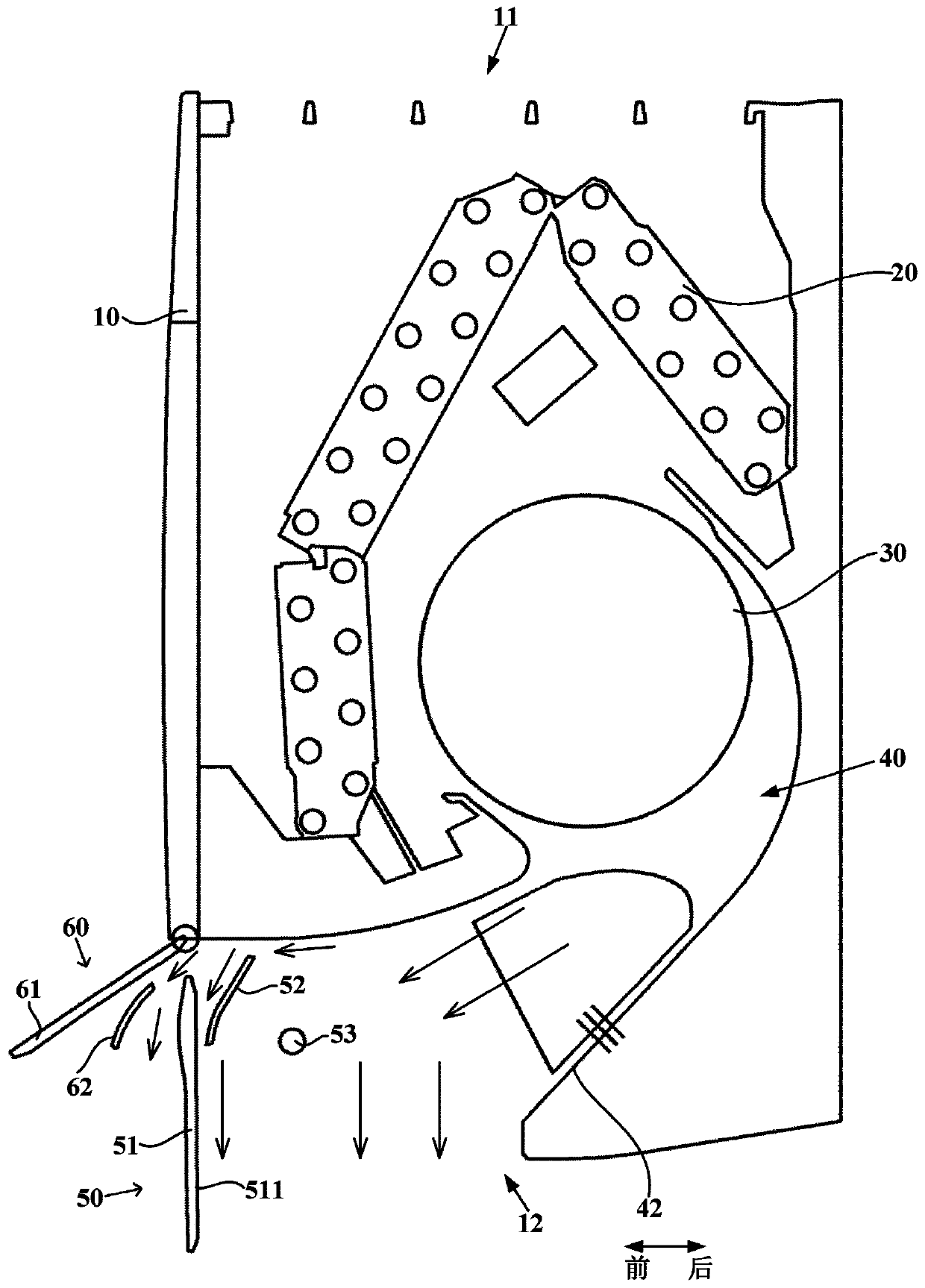

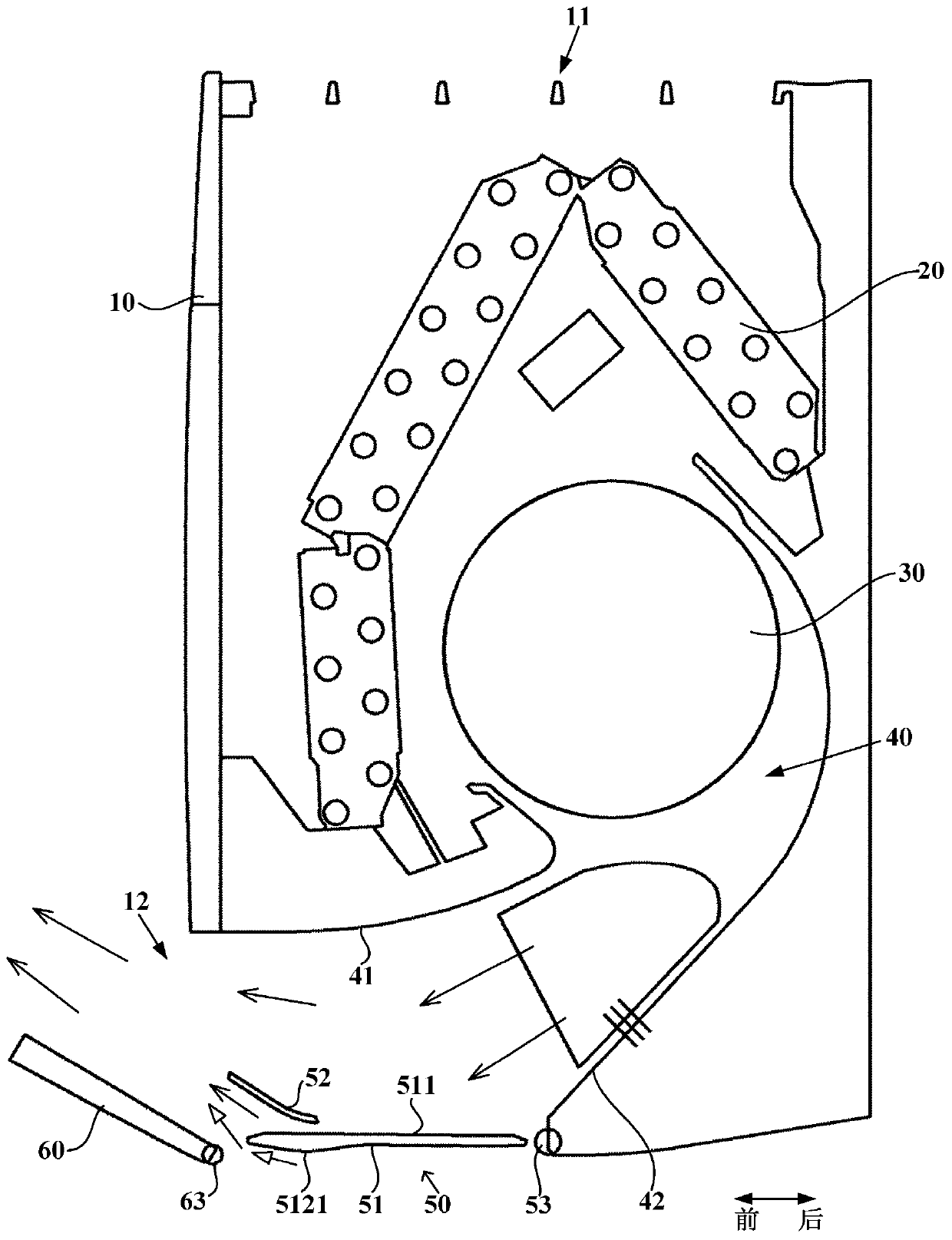

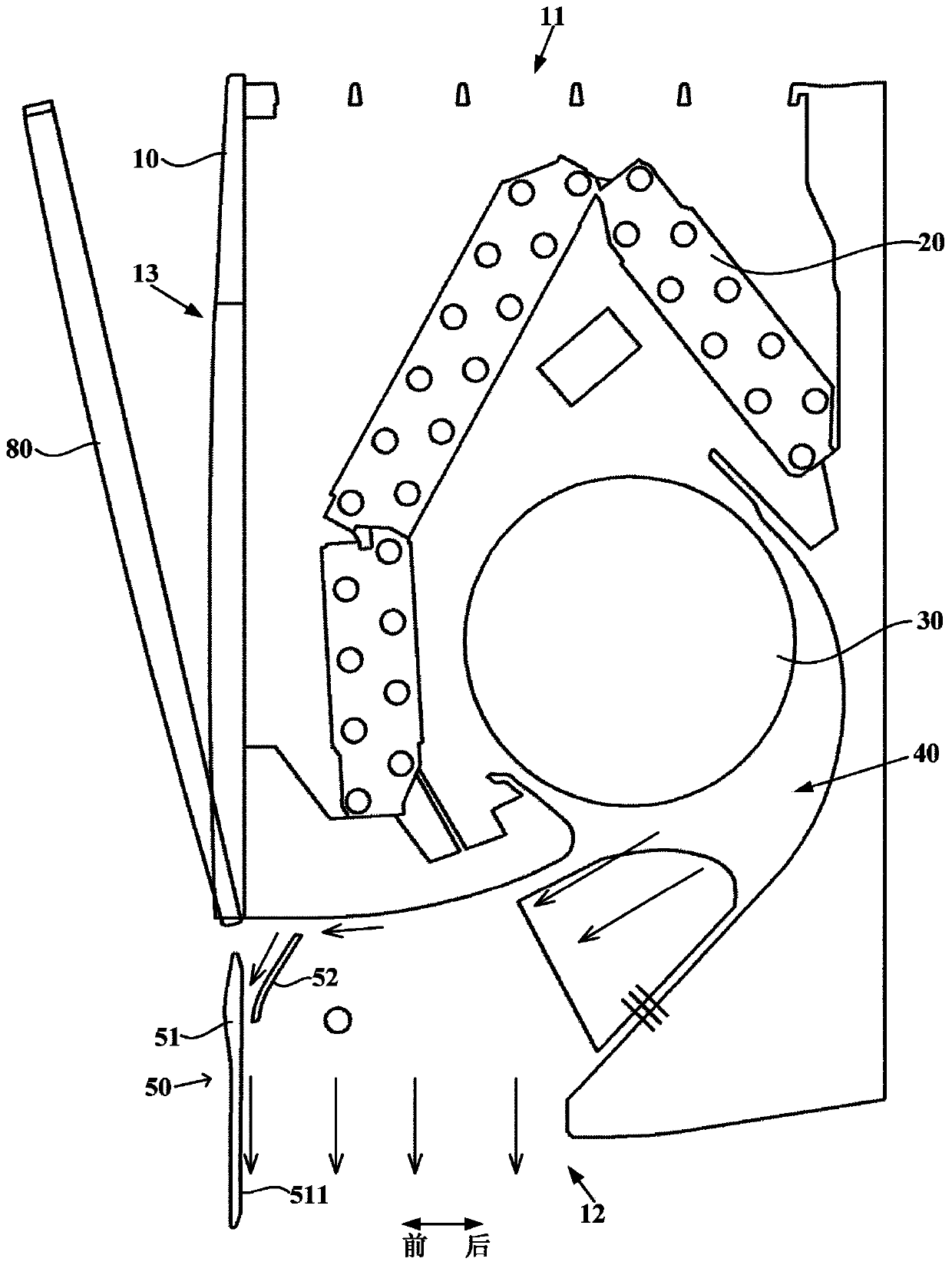

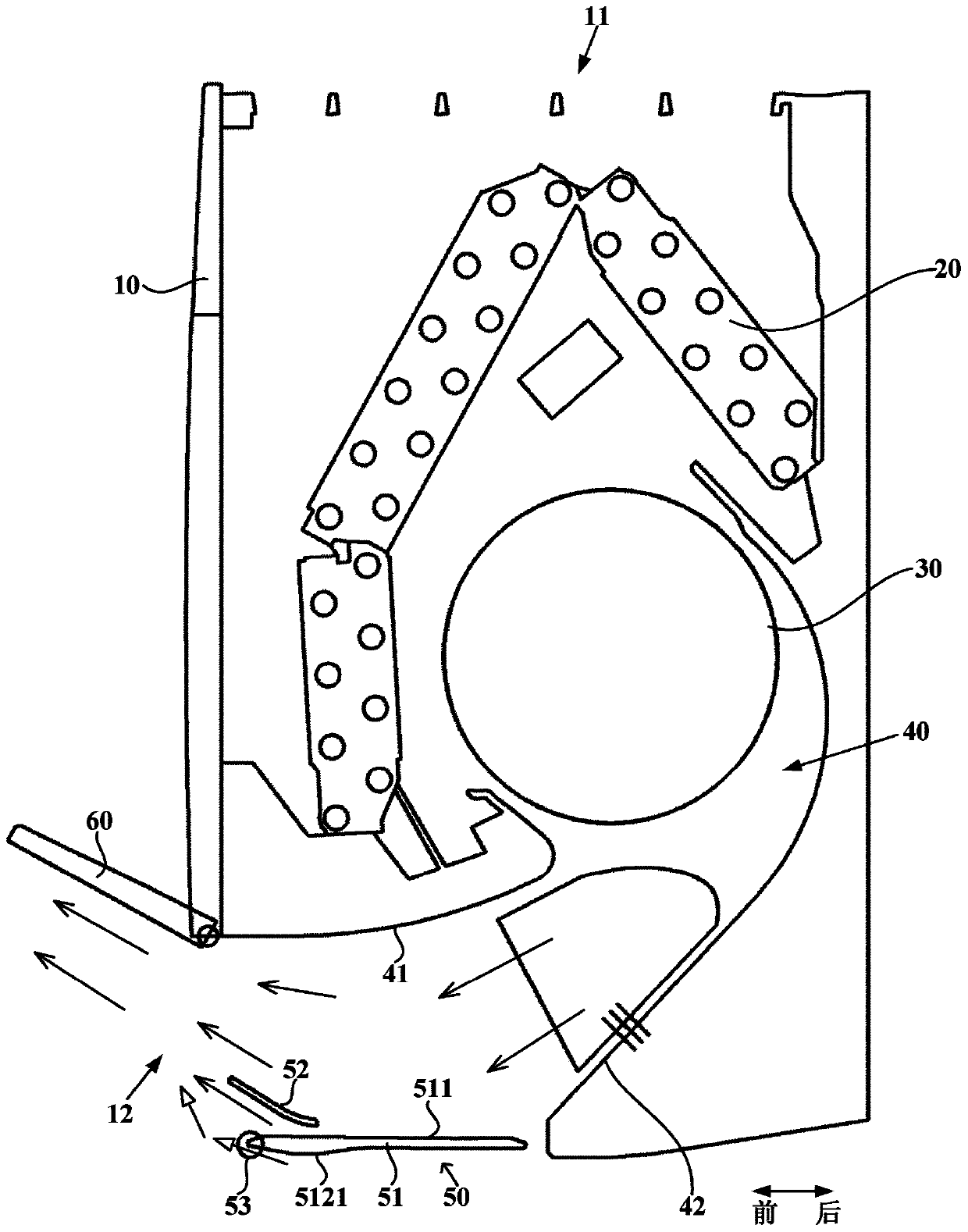

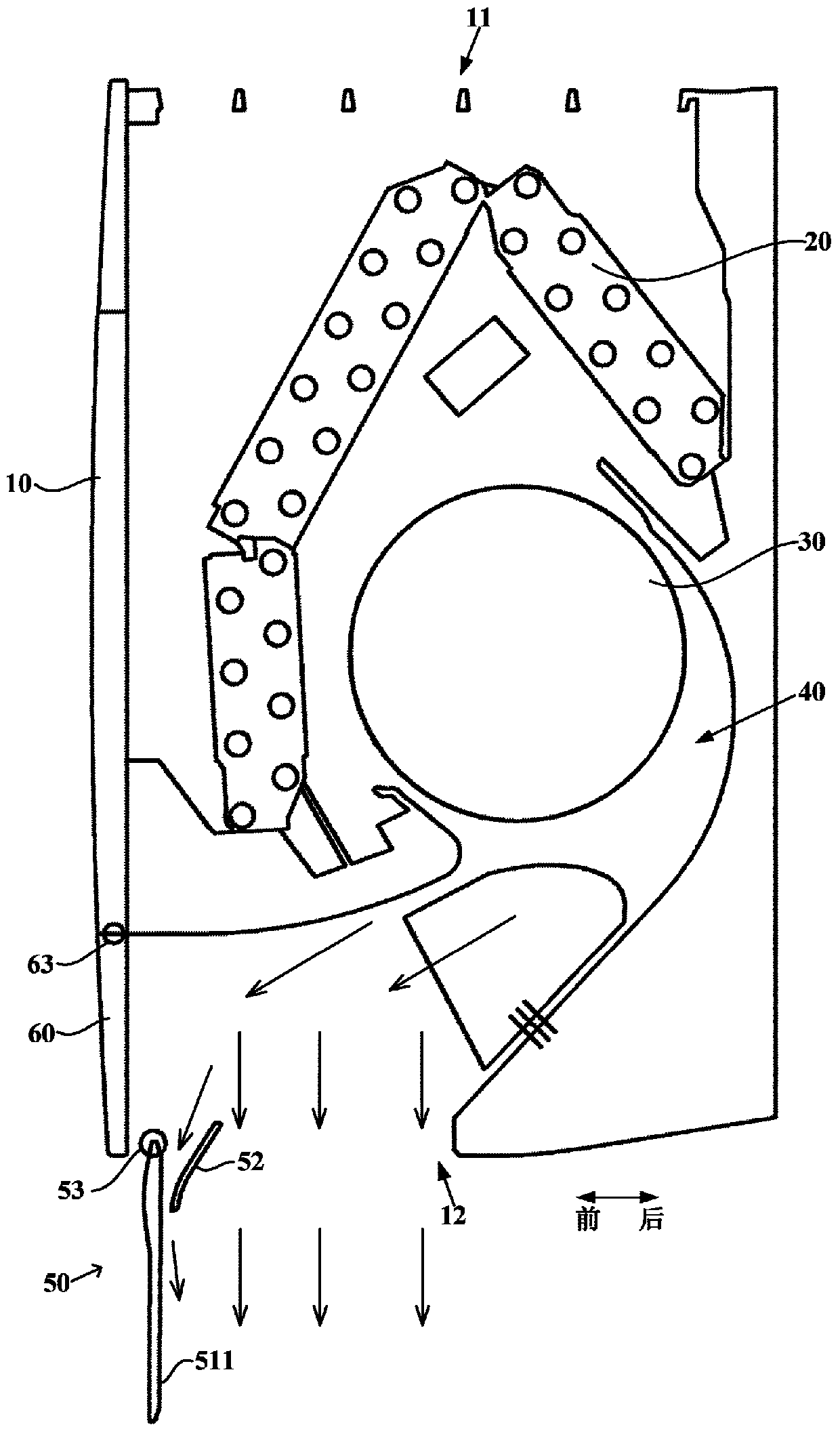

Air conditioner indoor unit

ActiveCN111351129AImprove the sinking blowing effectRealize warm foot experienceLighting and heating apparatusAir conditioning systemsCold airThermodynamics

The invention provides an air conditioner indoor unit which comprises a shell, a flow guide plate and an air guide plate. An air outlet facing forwards and downwards is formed in the shell; the flow guide plate and the air guide plate are movably arranged on the front side and the lower side of the air outlet correspondingly so as to cooperatively open and close the air outlet; the flow guide plate comprises a flow guide plate body and a flow distributing part, the flow distributing part is arranged on the flow guide surface of the flow guide plate body and is configured to guide air supply airflow flowing through the flow distributing part to gradually flow away from the flow guide plate body; and the air guide plate comprises an air guide plate body and an air lifting part, wherein the air lifting part is arranged on the air guide surface of the air guide plate body and is configured to guide air supply airflow passing through the air lifting part to gradually flow away from the airguide plate body when the air guide plate is positioned on the lower side of the air outlet and the air guide plate is in a front air guide state with the air guide surface facing upwards. According to the air conditioner indoor unit, better cold air upward blowing and hot air downward blowing effects can be achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Faucet adaptor

InactiveUS20060180681A1Increase flow directionIncrease ratingsMovable spraying apparatusSpray nozzlesExit angleEngineering

A faucet adaptor with a coaxial arrangement of an outer shell, a cover within the shell, a rotor at least partially within the cover, and a faceplate secured to the shell to secure the coaxial arrangement. A passage from the shell through the cover directs fluid from a source onto the rotor and then through the rotor and out of the adapter. The faucet adapter may enable the exiting spray of fluid to have a cone-like shape and the exit angle of the fluid may be altered depending on user-preferences.

Owner:JING MEI IND HLDG LTD

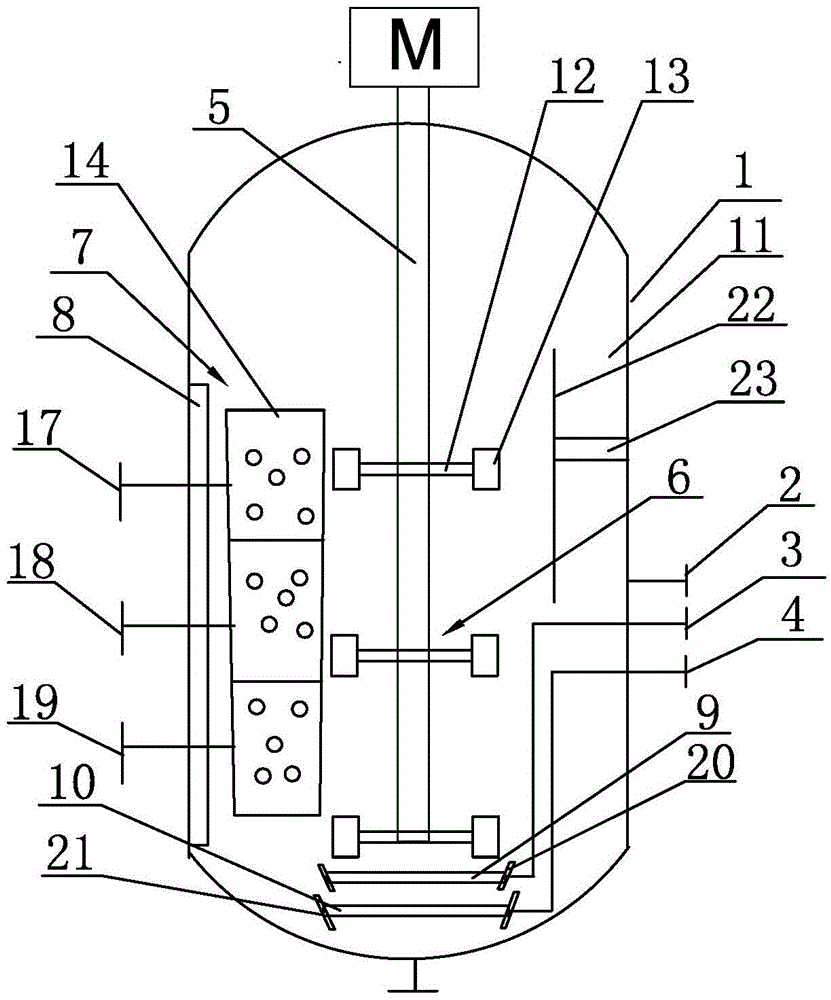

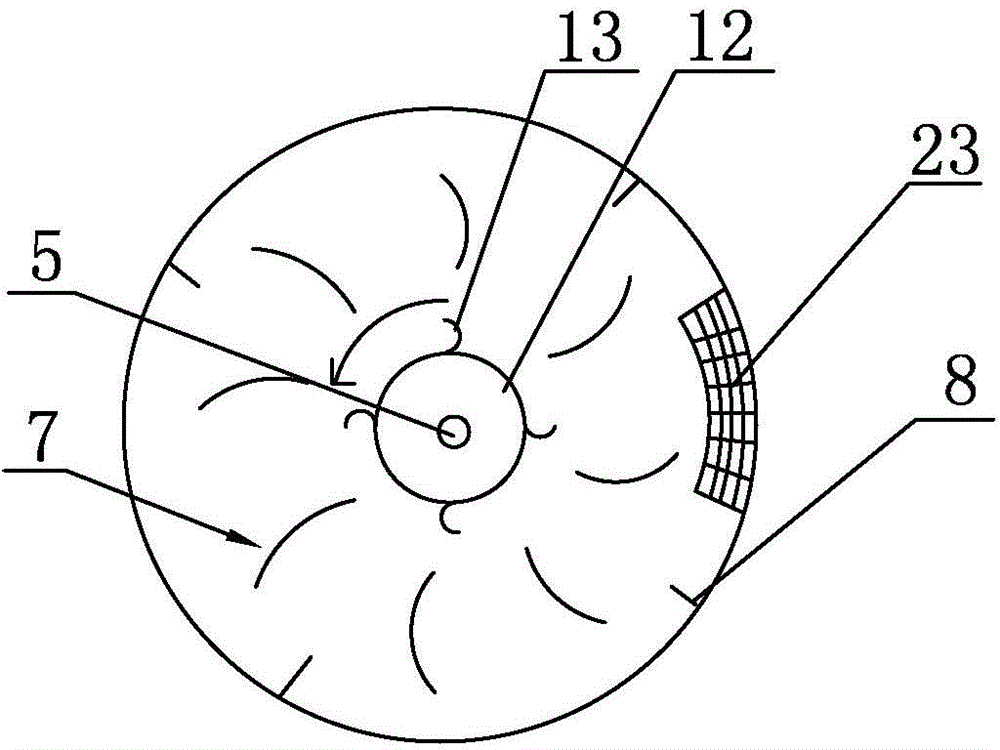

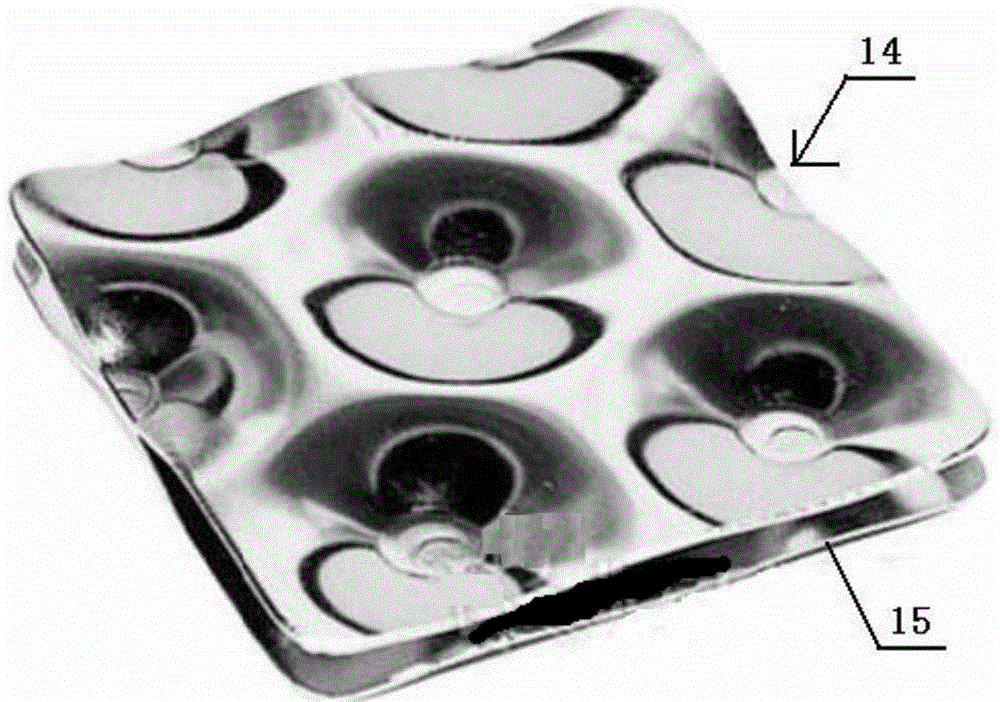

Swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle

ActiveCN104128133AIncrease contact timeIncrease contact areaHydrocarbon by hydrogenationChemical industryLiquid jetTemperature control

The invention discloses a swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle. The reaction kettle comprises a cylindrical kettle body which is arranged vertically. A discharge port, a liquid feeding port, and a gas feeding port are sequentially arranged from top to bottom on the side wall of the kettle body. A central shaft connected with an outside motor is arranged vertically in the kettle body. The reaction kettle is characterized in that three layers of vertically arranged swept-back half-pipe turbo agitators are arranged on the central shaft. 6-10 high-efficiency heat-exchange diversion rectification devices are horizontally uniformly distributed between the outer end of the swept-back half-pipe turbo agitators and the inner wall of the kettle body. 4-6 sheets of side wall diversion full baffles are uniformly distributed on the inner wall of the kettle body. A liquid jet distributor connected with the liquid feeding port and a gas jet distributor connected with the gas feeding port are arranged on the bottom of the kettle body. An overflow zone is arranged in the kettle body. Reaction products pass through the overflow zone and is collected from the discharge port. The swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle has the advantages of good multiphase system mixing effect, large heat-exchange area, and precise temperature control.

Owner:SEDIN NINGBO ENG

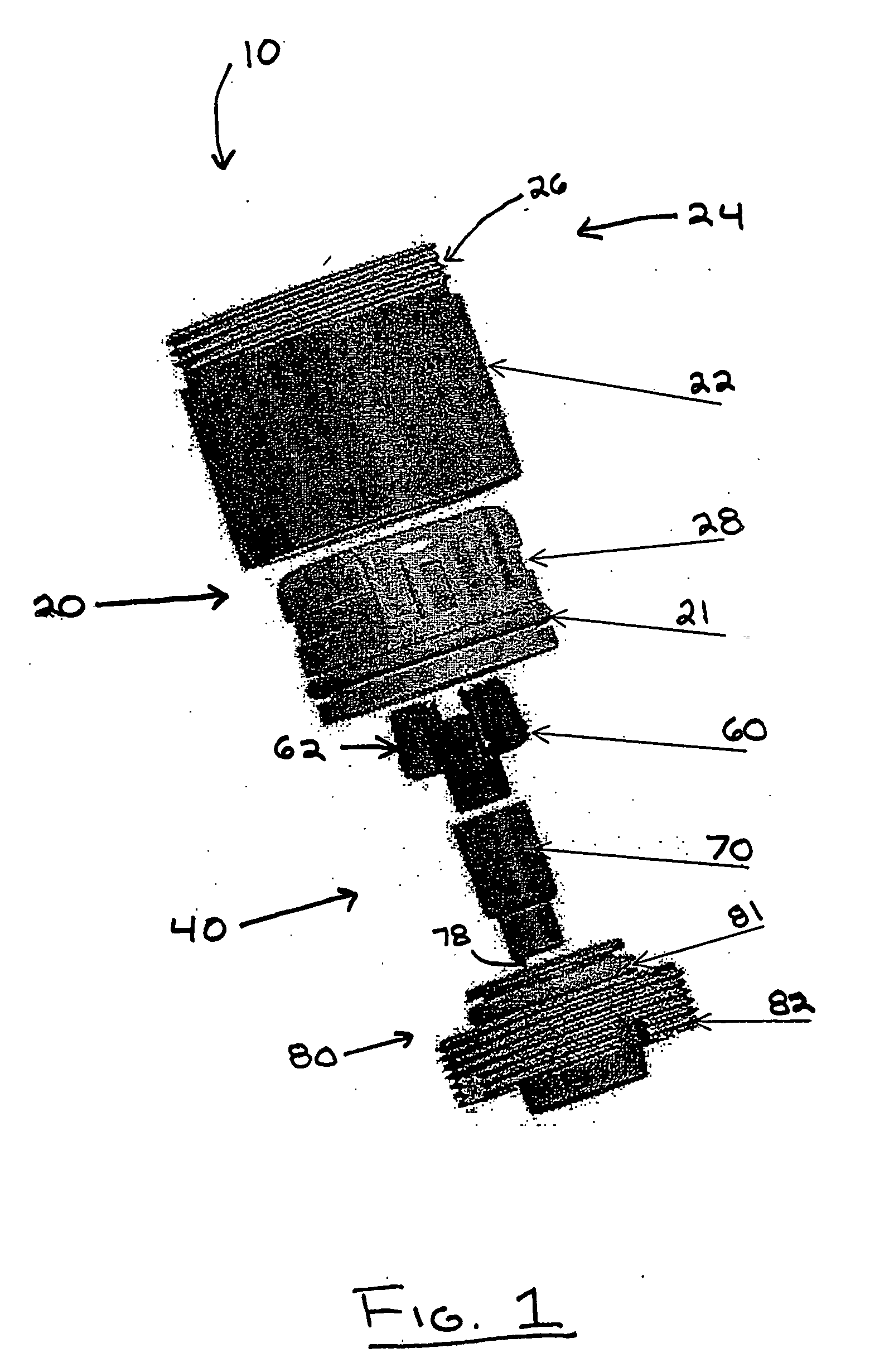

Aspirator assembly

InactiveUS8100886B2Increase flow directionEasy to holdMedical devicesSuction drainage containersNasal cavityHand held

An assembly structured to aspirate nasal cavity of individuals including, but not limited to, children. A hand held and hand operative casing includes a negative pressure source preferably battery operated, and a cover assembly removably connected to the casing and structured to at least partially define a receiving chamber. An inlet assembly is formed in the casing and communicates with the negative pressure source at least partially by means of a path of fluid flow. A container is removably disposed within the receiving chamber in a predetermined, operative orientation sufficient to receive and collect a predetermined portion or phase of the aspirated fluid, such as mucus is removed from the nasal cavity. The path of fluid flow is disposed, dimensioned and structured to restrict passage of the heavier, predetermined portion or phase of the aspirated fluid thereby facilitating its collection within the container, which is disposable along with the collected aspirated fluid after use.

Owner:VISIOMED GRP SA

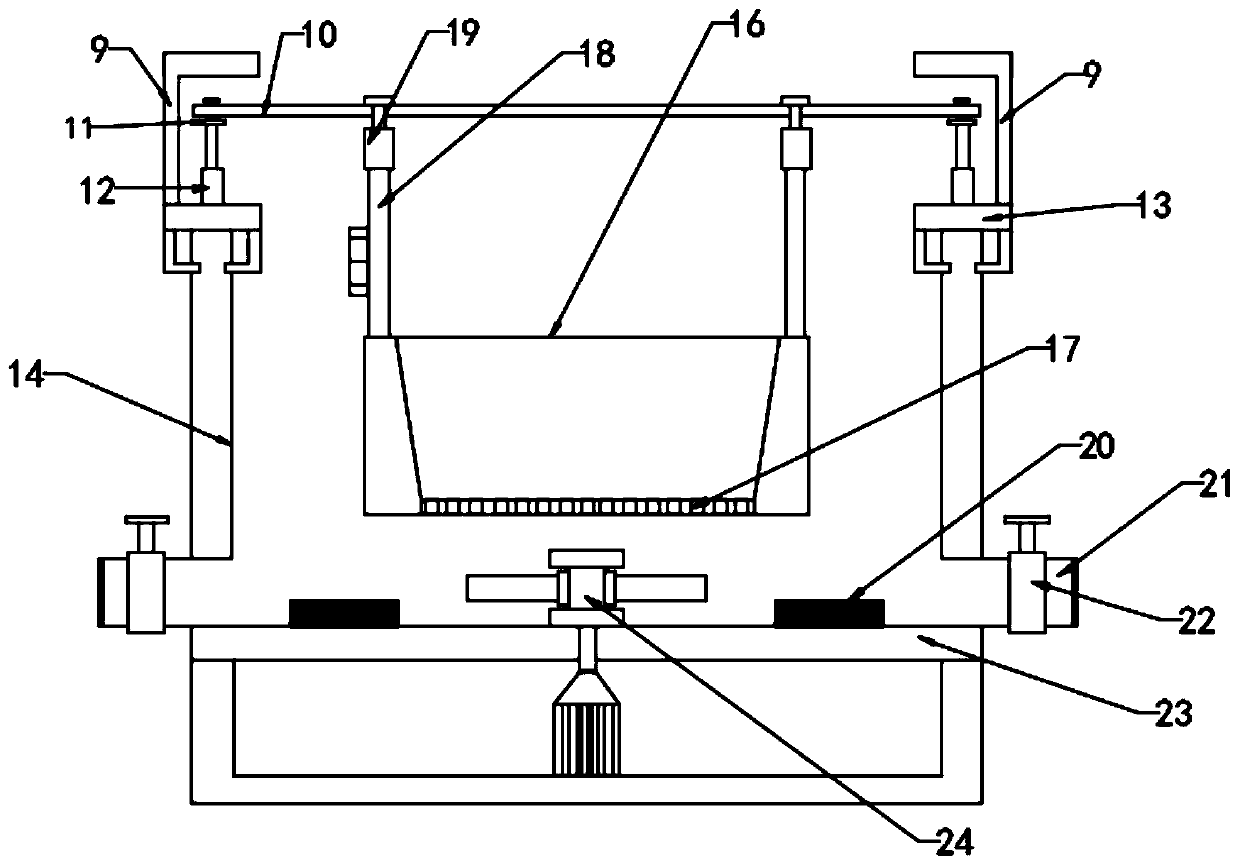

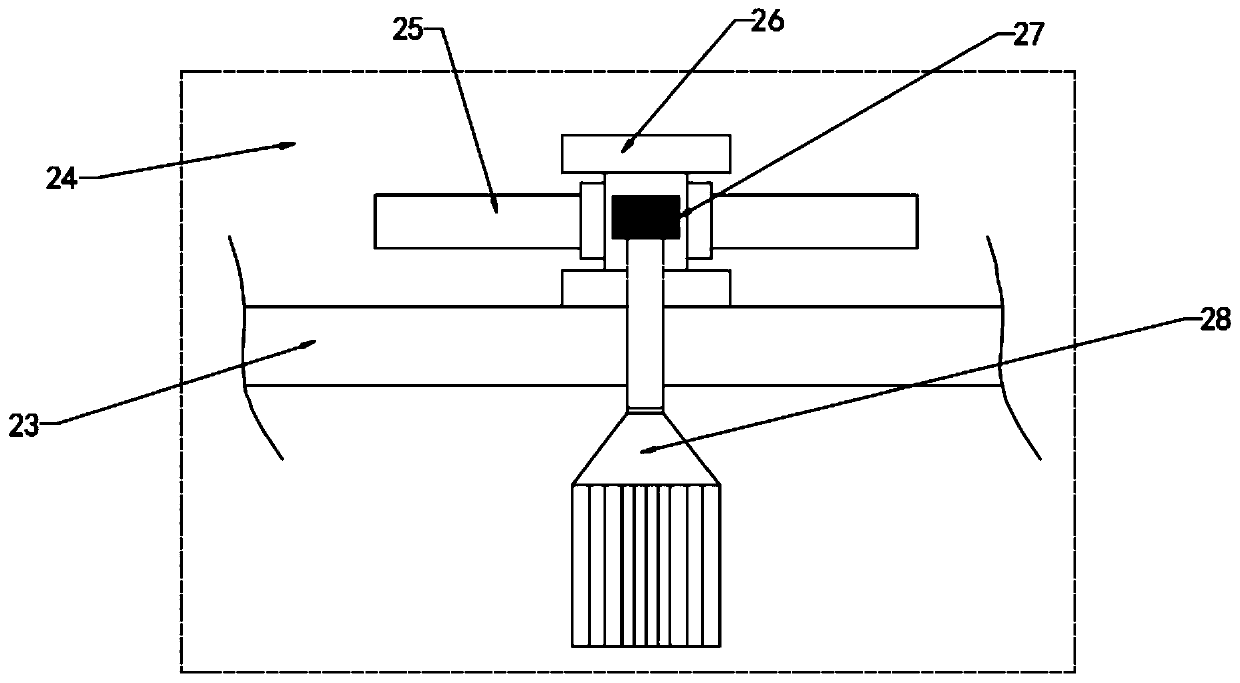

Polishing device for machining stainless steel product

InactiveCN111571412AIncrease flow directionLess likely to leakElectrolysis componentsPolishing machinesElectrolysisMachining

The invention relates to the field of stainless steel product machining equipment, in particular to a polishing device for machining a stainless steel product. The polishing device comprises a grinding table and an electrolytic tank arranged on one side of the grinding table, and a grinding assembly is installed on the grinding table; a soaking tank is arranged in the electrolytic tank, and the right and left sides of the upper end of the soaking tank are provided with electrolytic bars; the upper end of each electrolytic bar is installed in a mounting end arranged at the lower end of a movable plate; the right and left sides of each movable plate are installed on support plates, and the lower ends of the support plates are provided with second electric telescopic rods arranged on a vertical frame; the vertical frame is fixed to a sliding block installed at the upper end of the electrolytic tank slidably; and the bottom end of the electrolytic tank is a separating plate, and a stirringassembly and a negative electrode are installed on the separating plate. According to the polishing device for machining the stainless steel product, through combination of two ways, namely mechanical grinding and polishing and electrochemical polishing; and various stains sticking to the surface of the stainless steel product can be removed, and the polishing effect is improved.

Owner:SUZHOU SAISHUOLA STAINLESS STEEL PROD CO LTD

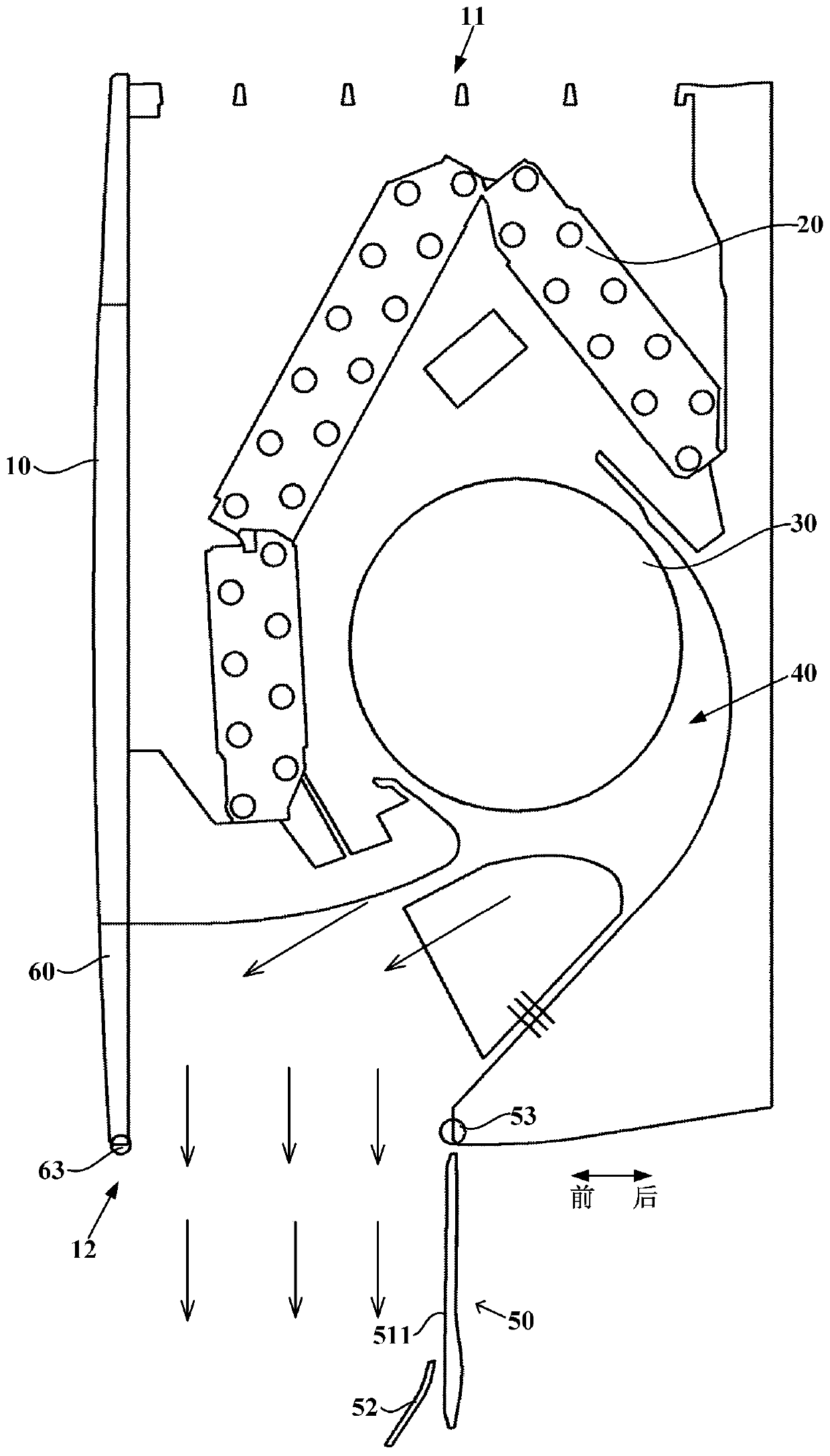

Air conditioner indoor unit

PendingCN111351133AImprove air supply comfort experienceRealize the cooling experienceLighting and heating apparatusAir conditioning systemsCold airEngineering

The invention provides an air conditioner indoor unit. The air conditioner indoor unit comprises a shell, a first air guide plate and a second air guide plate. An air outlet facing the front lower portion is formed on the shell. The first air guide plate and the second air guide plate are rotationally mounted on the front side and the lower side of the air outlet so as to open and close the air outlet cooperatively. According to the configuration of the second air guide plate, the second air guide plate can rotate to the front air guide state that the second air guide plate is located on the lower side of the air outlet and the air guide face is upward, so that the air supply airflow is guided to the front portion or the front upper portion or the front lower portion; and the second air guide plate can rotate to the downward air guide state that the second air guide plate is located below the first air guide plate and the air guide face is backward, so that the air supply airflow is guided downwards. The air conditioner indoor unit can achieve cold air rising blowing and hot air sinking blowing.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Stepped forging forming method for super-huge type titanium alloy propeller hub forged piece

InactiveCN107414001AIncreased anisotropyImprove ductilityForging hammersForging/hammering/pressing machinesStructure propertyPropeller

The invention discloses a step-by-step forging forming method for an extra-large titanium alloy propeller hub forging. The billet is forged, and the rotary table is rotated at an angle after each press down, and the second press is performed until the surface is completely formed, the forging is turned over, and the other side of the forging is formed in the same way, and then trimmed Obtain extra-large titanium alloy propeller hub forgings. This method can overcome the lack of equipment capacity, and obtain the forming of an extra-large titanium alloy propeller hub with good shape, size and structure. This method is used for the forming of extra-large titanium alloy propeller hub forgings.

Owner:GUIZHOU ANDA AVIATION FORGING

Air conditioner indoor unit

PendingCN111351127AImprove air supply comfort experienceIncrease the air outlet areaLighting and heating apparatusAir conditioning systemsHot blastEngineering

The invention provides an air conditioner indoor unit. The air conditioner indoor unit comprises a shell, a first air guide plate and a second air guide plate, wherein the shell is provided with an air outlet facing the front lower portion; and the first air guide plate and the second air guide plate are rotatably installed on the front side of the air outlet and the lower side of the air outlet correspondingly to open and close the air outlet in a coordinating manner, and the second air guide plate is configurated in a front air guide state that the second air guide plate can be rotated to belocated on the lower side of the air outlet and make an air guide face of the second air guide plate face upwards to guide air feeding airflow to the front portion, the front upper portion or the front lower portion and in a lower air guide state that the second air guide plate can be rotated to be located on the rear side of the air outlet and make the air guide face of the second air guide plate face forwards to guide the air feeding airflow to the lower portion. By means of the air conditioner indoor unit, cold air upward blowing and hot air downward blowing can be realized.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

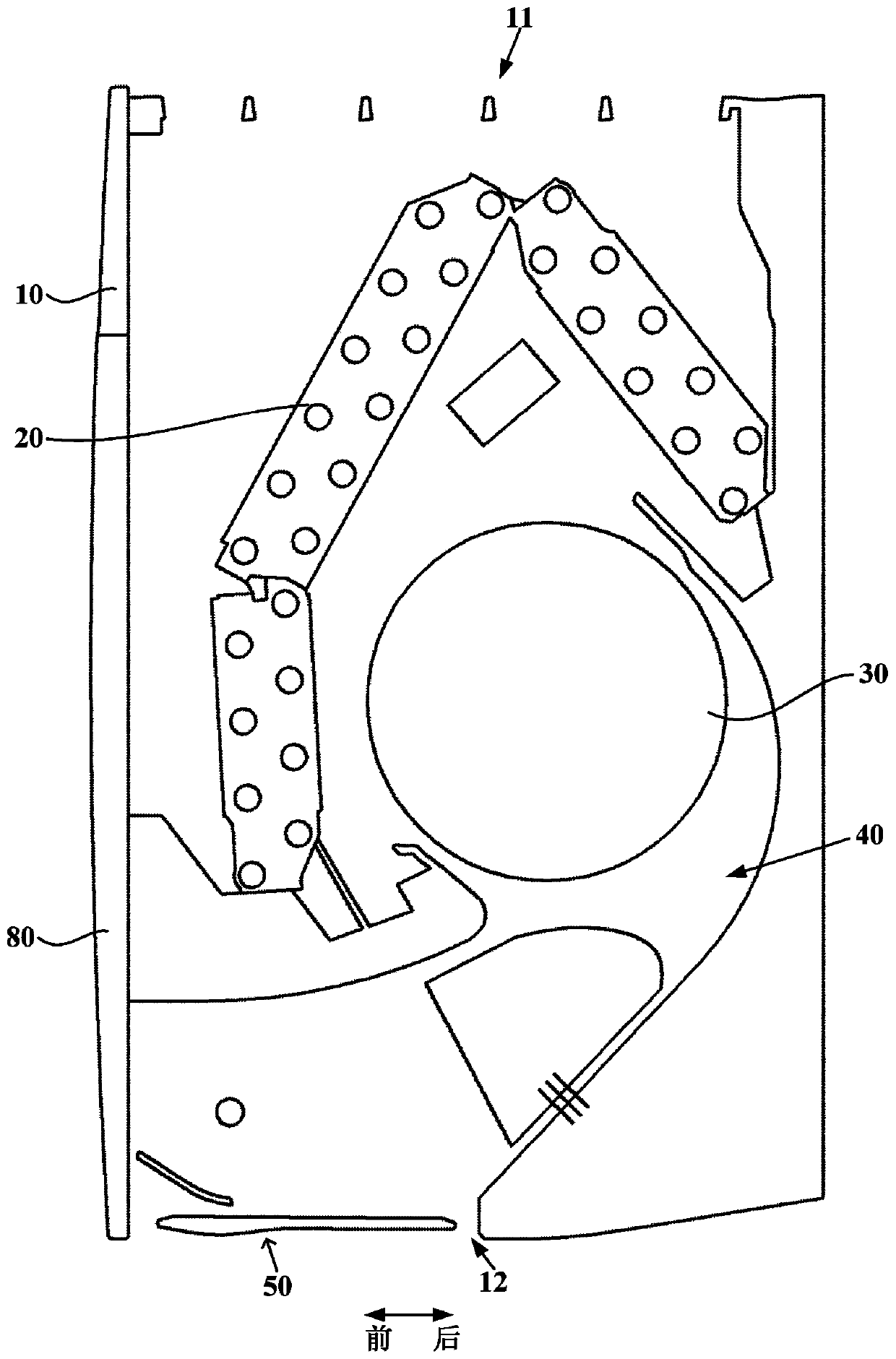

Air conditioner indoor unit

PendingCN111189111AImprove the winding effectIncrease angle of ascentLighting and heating apparatusHeating and ventilation casings/coversCold airEngineering

The invention provides an air conditioner indoor unit. The air conditioner indoor unit comprises a shell, a movable face board and an air guide plate, wherein the shell is provided with one air outletfacing the lower front portion; the movable face board is movably arranged on the shell and is configured to be capable of moving to a closing position located on the front side of the air outlet ormoving to an opening position far away from the front side of the air outlet; and the air guide plate is movably arranged on the shell and is configured to be capable of moving to a first position which is located on the lower side of the air outlet and enables the air guide face of the air guide plate to face upwards when the movable face board is located at the opening position so as to guide air supply flow to the front portion or the upper front portion or the lower front portion, or moving to a second position which is located on the front side of the air outlet to enable the air guide surface to face backwards so as to guide the air supply flow to the lower portion. The air conditioner indoor unit can achieve cold air rising blowing and hot air sinking blowing.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

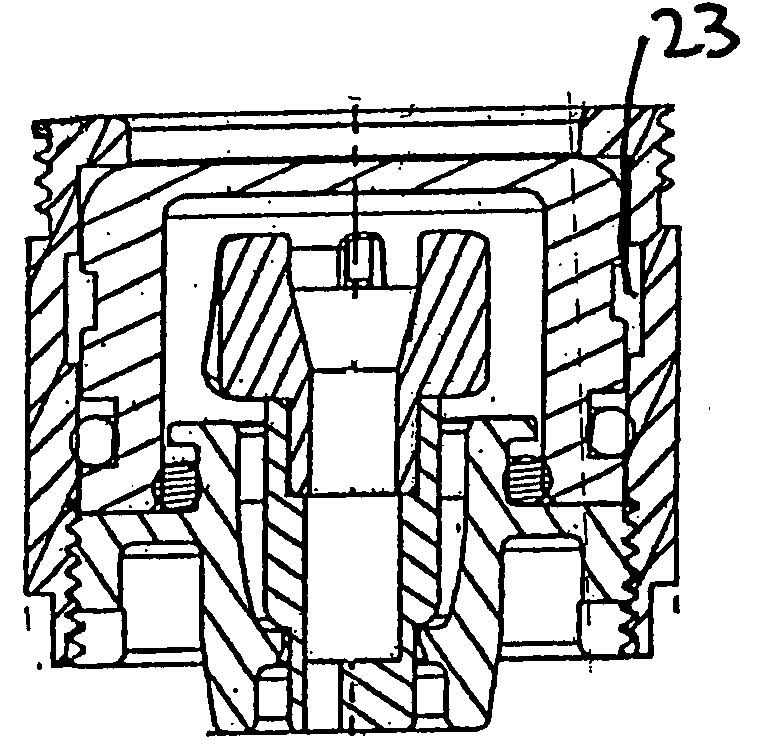

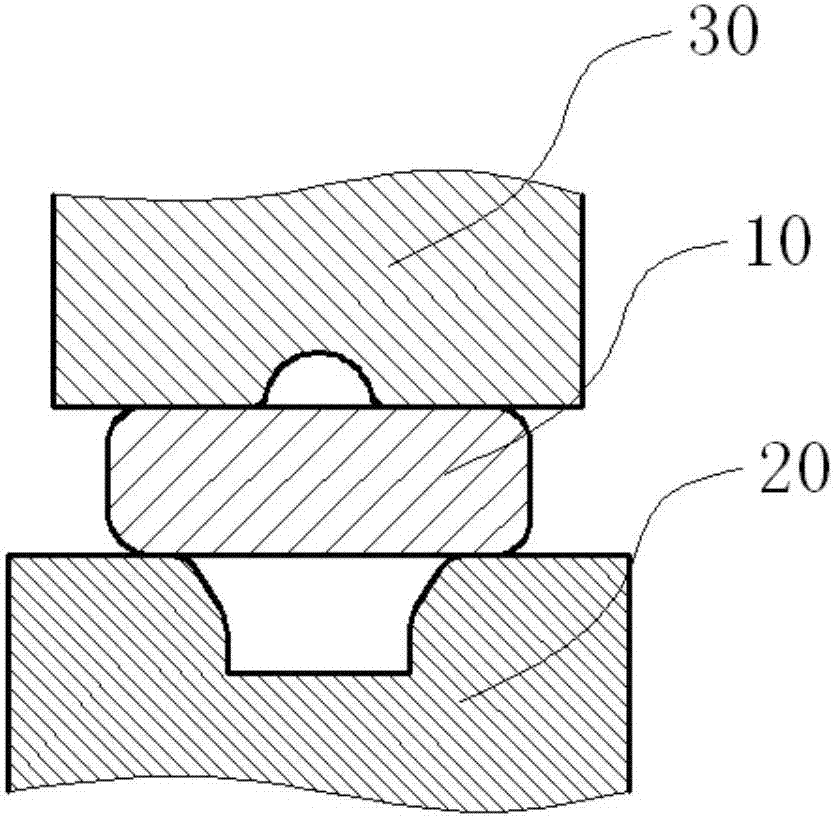

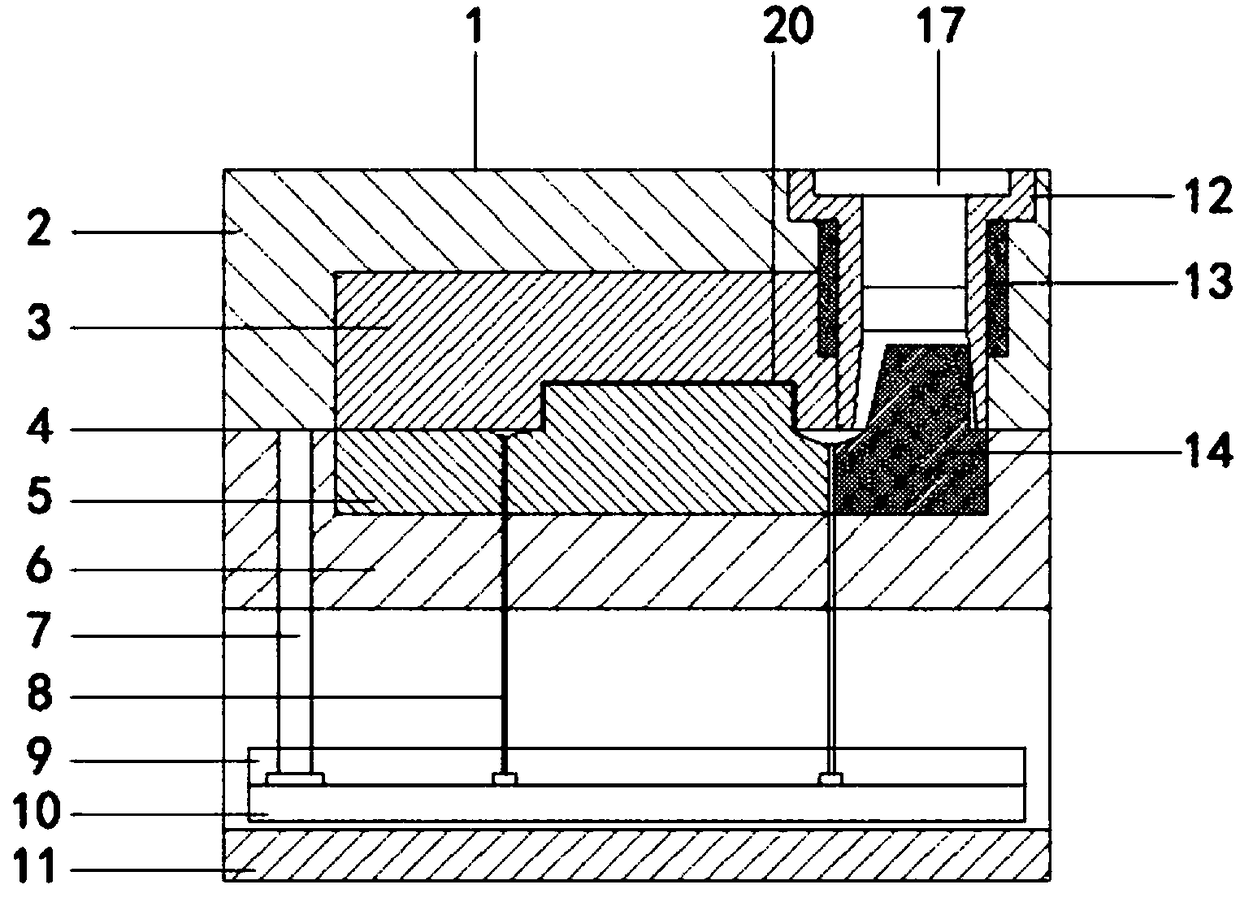

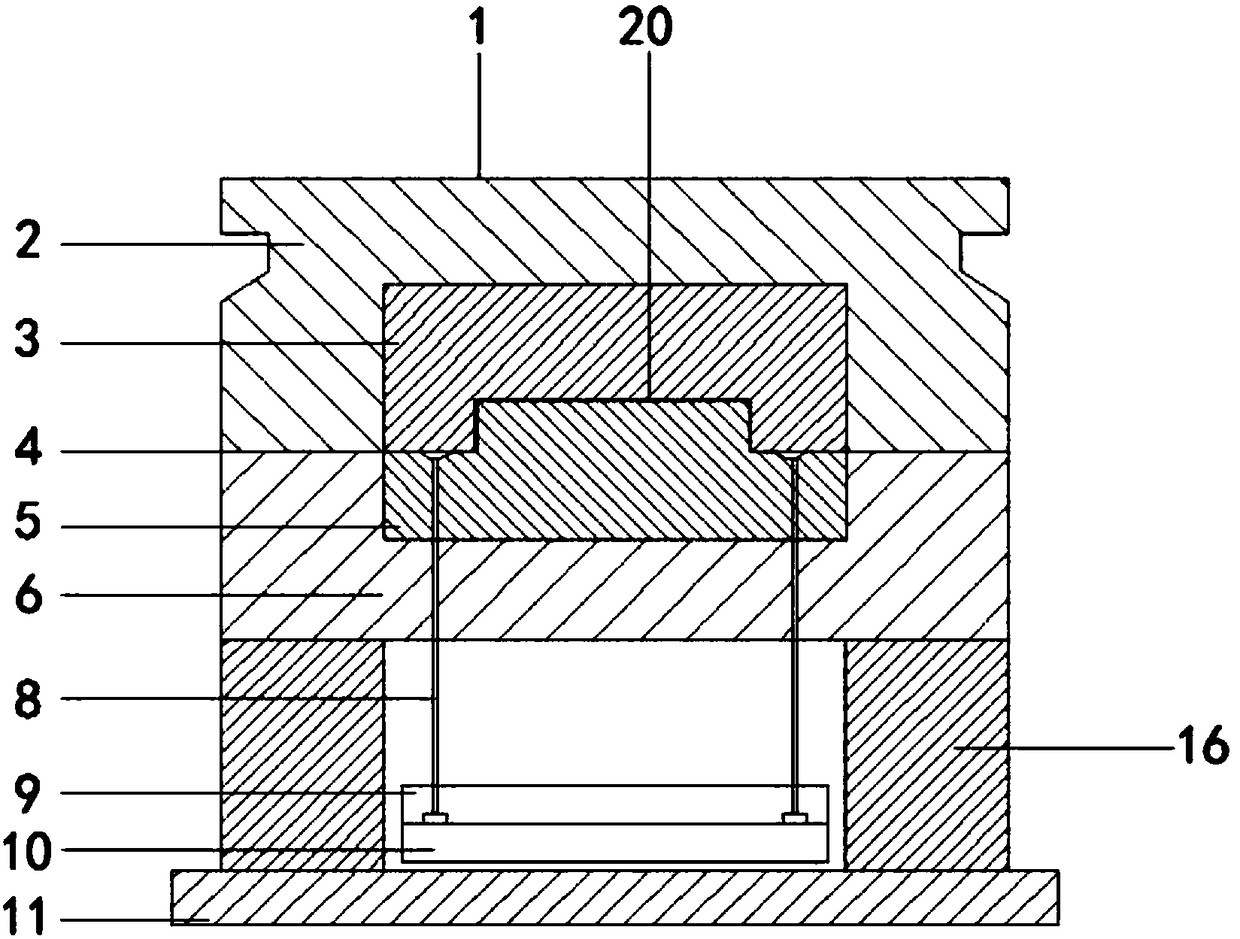

Pressure casting die

The invention provides a pressure casting die which comprises a die body, a fixed die fixing plate, a fixed die insert, a die joint, a movable die insert and a movable die fixing plate. According to the external physical characteristic, the die body is in a cuboid shape, the fixed die fixing plate is arranged at the top end of the die body, the fixed die insert is arranged inside the fixed die fixing plate, and the fixed die insert is connected with the fixed die fixing plate through a bolt manner; the movable die fixing plate is arranged below the fixed die fixing plate, and the movable die fixing plate and the fixed die fixing plate are connected through a guide column and a guide sleeve. The pressure casting die is improved, the advantages that structure design is reasonable, side pouring gate feeding is reasonably carried out for pouring a pressure casting, the size accuracy of the pressure casting is high, the surface is smooth and bright, and technological defects such as deformation, cracks, flash and the like which influence the appearance and the product performance are avoided are achieved, and the problems and shortcomings provided in the background technology are solved.

Owner:湖北昊昌汽车零部件制造有限公司

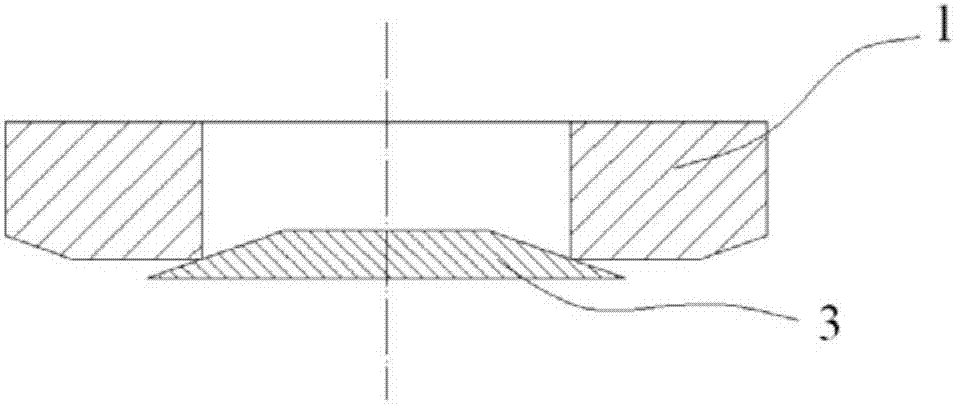

Extrusion device and extrusion method for hollow helicoid rotor profile with internal key groove

The invention discloses an extrusion device and an extrusion method for a hollow helicoid rotor profile with an inner key groove. The device comprises an upper die and a lower die, wherein one end of the upper die is provided with at least one diversion chamber, and the other end of the upper die is provided with at least two shunting holes communicating with the diversion chamber; a shunting bridge is arranged between every two adjacent shunting holes; a blocking table is arranged at the intersection of every two shunting bridges; the end, away from the diversion chamber, of the upper die is connected with a die core; the end, connected with the upper die, of the lower die is at least provided with a first-stage welding chamber, the end, far away from the upper die, of the welding chamber communicates with an orifice of the lower die, and the end, far away from the upper die, of the die core is sequentially inserted into the welding chamber and the orifice of the lower die; the diversion chamber, the shunting holes, the welding chamber and the orifice of the lower die communicate in sequence; and a transition key structure and a key structure which are connected in a matching manner are arranged on the outer wall of the die core. According to the extrusion method based on the device, light alloy is adopted for direct extrusion forming of the hollow rotor, the machining efficiency and blank utilization rate are high, and the production cost is low.

Owner:SHANDONG UNIV

Air conditioner indoor unit

PendingCN111351131AEnhanced down-drying effectIncrease the air outlet areaLighting and heating apparatusAir conditioning systemsCold airHot blast

The invention provides an air conditioner indoor unit. The air conditioner indoor unit comprises a shell body, a baffle and an air deflector. The shell body is provided with an air outlet facing the front lower portion. The upper end of the baffle is rotationally mounted on the shell body, a rotary shaft of the baffle is located at the position of the upper edge of the air outlet, and therefore the baffle can rotate to an opening position where the front side of the air outlet is opened or rotate to a closing position where the front side of the air outlet is shielded. The air deflector is rotationally mounted on the shell body and configured to be capable of rotating to a first position which is located on the lower side of the air outlet and enables an air guide surface of the air deflector to be upward, so that when the baffle is at the opening position, air supply airflow is guided to the front portion or the front upper portion or the front lower portion through the air deflector,and the air deflector can be configured to be capable of rotating to a second position which is located below the baffle and enables the air guide surface of the air deflector to be backward, so thatthe air supply airflow is guided to the lower portion. By means of the air conditioner indoor unit, cold air is blown in a rising manner, and hot air is blown in a sinking manner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

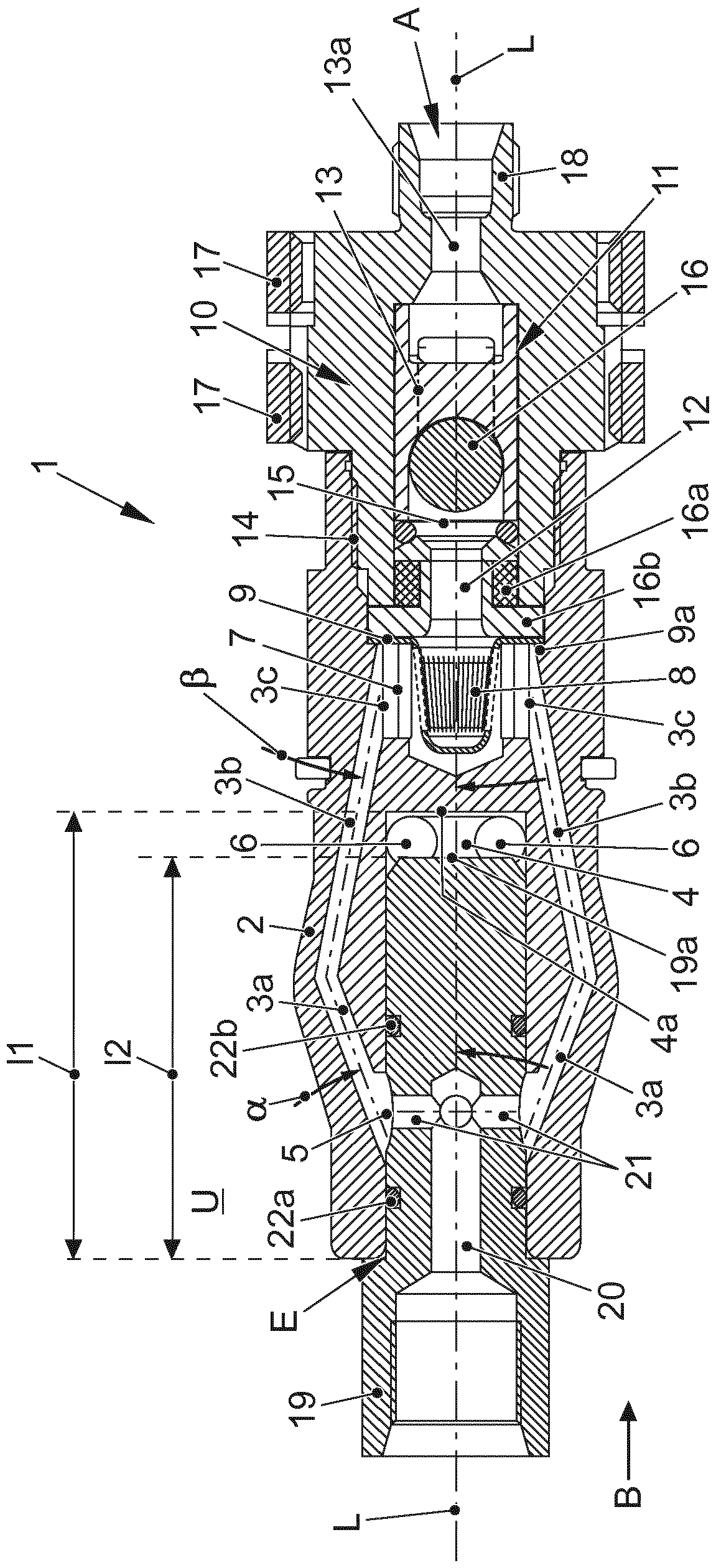

Fueling fitting for fueling a motor vehicle with a gaseous fuel

ActiveCN109311387ARelieve stressAvoid the danger of escapeVessel mounting detailsUnderstructuresEngineeringElectrical and Electronics engineering

The invention relates to a fueling fitting (1) for fueling a motor vehicle with a gaseous fuel. The fitting has a base element (2) in which a receiving chamber (4) is arranged with an input opening (E) for receiving an infrastructure-side fueling device (19). At least one channel-like connection (3a, 3b) is provided for conveying the gaseous fuel from the receiving chamber (4) toward an outlet chamber (7). According to the invention, at least one further channel-like connection (6) joins the receiving chamber (4), said further connection not serving to convey the gaseous fuel from the receiving chamber (4) toward the outlet chamber (7) but instead allowing pressure equalization between the receiving chamber (4) and the surroundings (U). In this way, proper functioning of a fueling processcan be ensured, even if the seals (22a, 22b) of the fueling device (19) are not in perfect condition.

Owner:VOLKSWAGEN AG

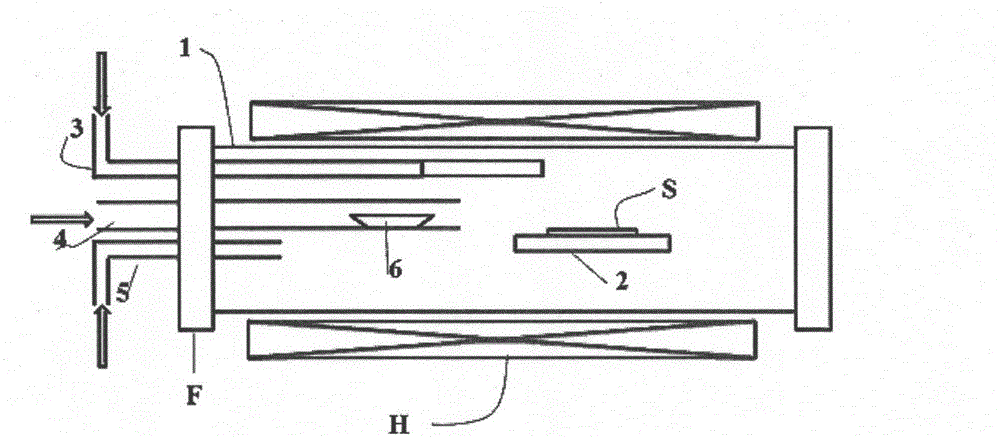

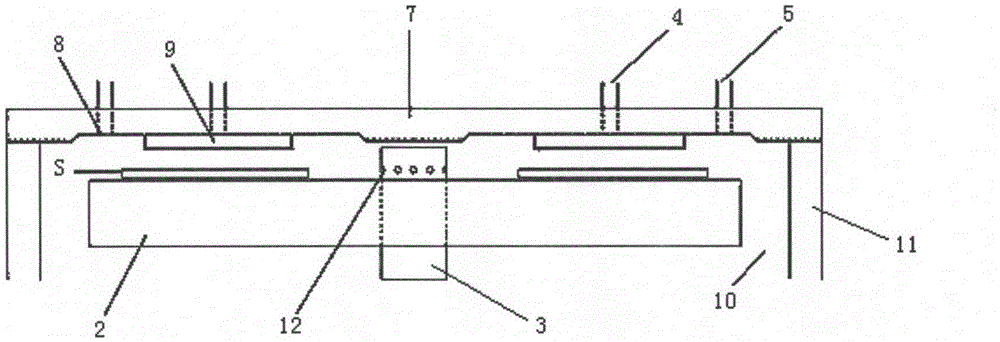

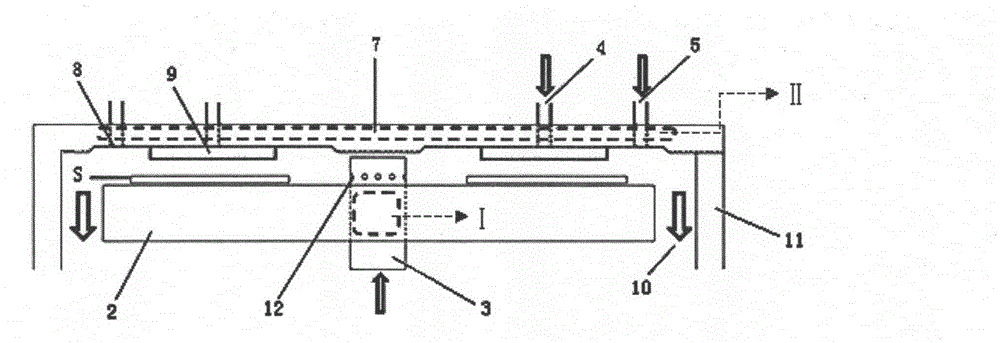

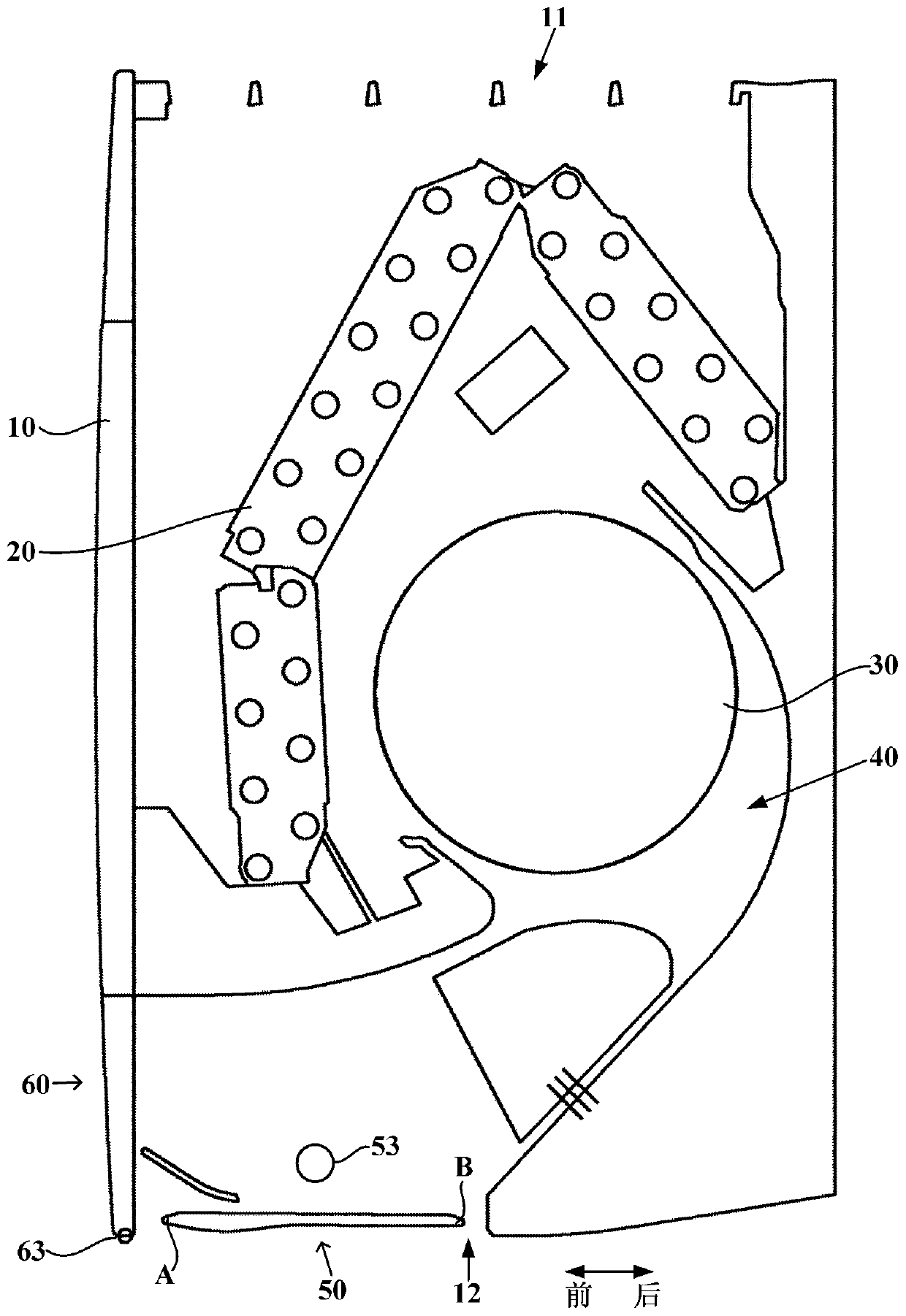

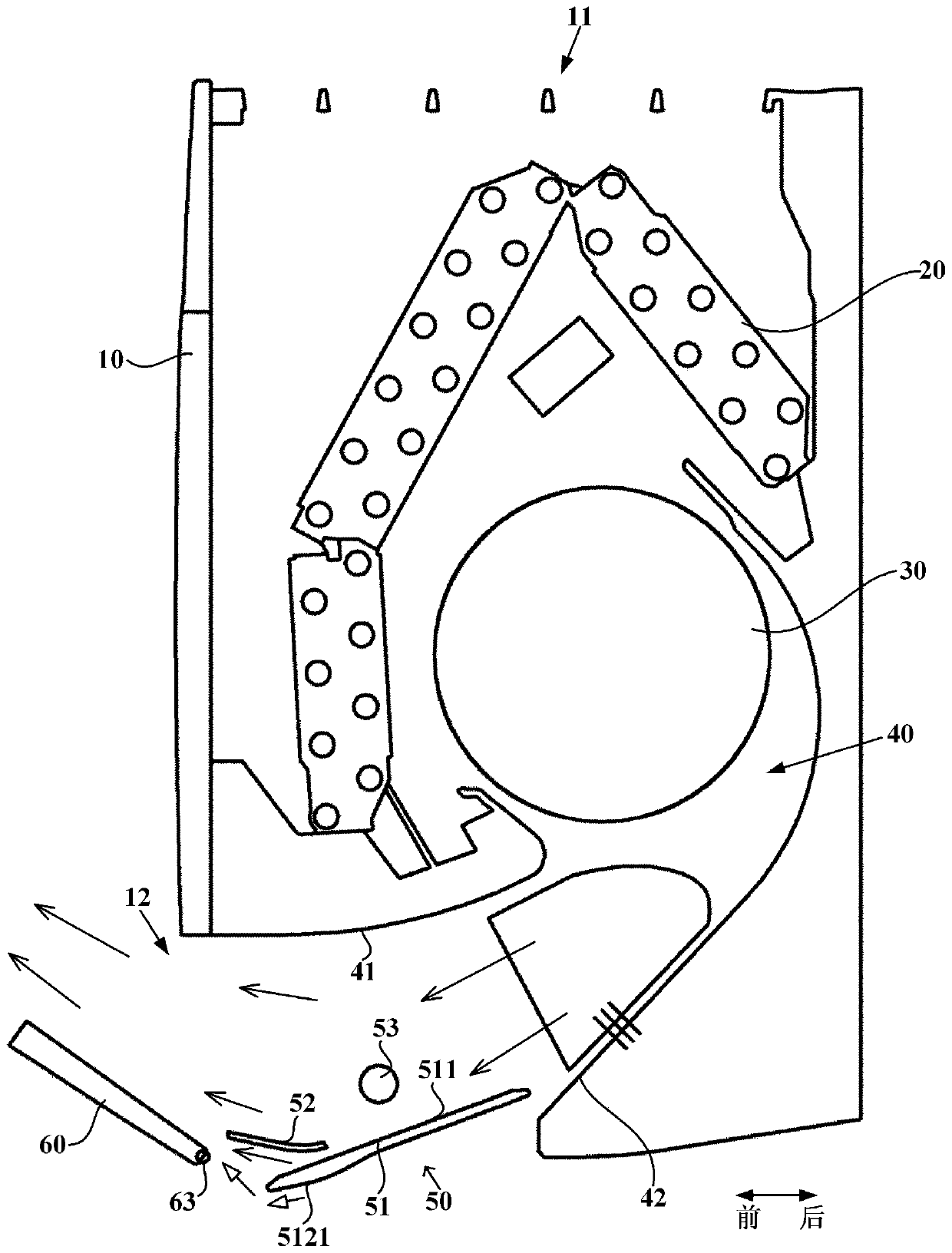

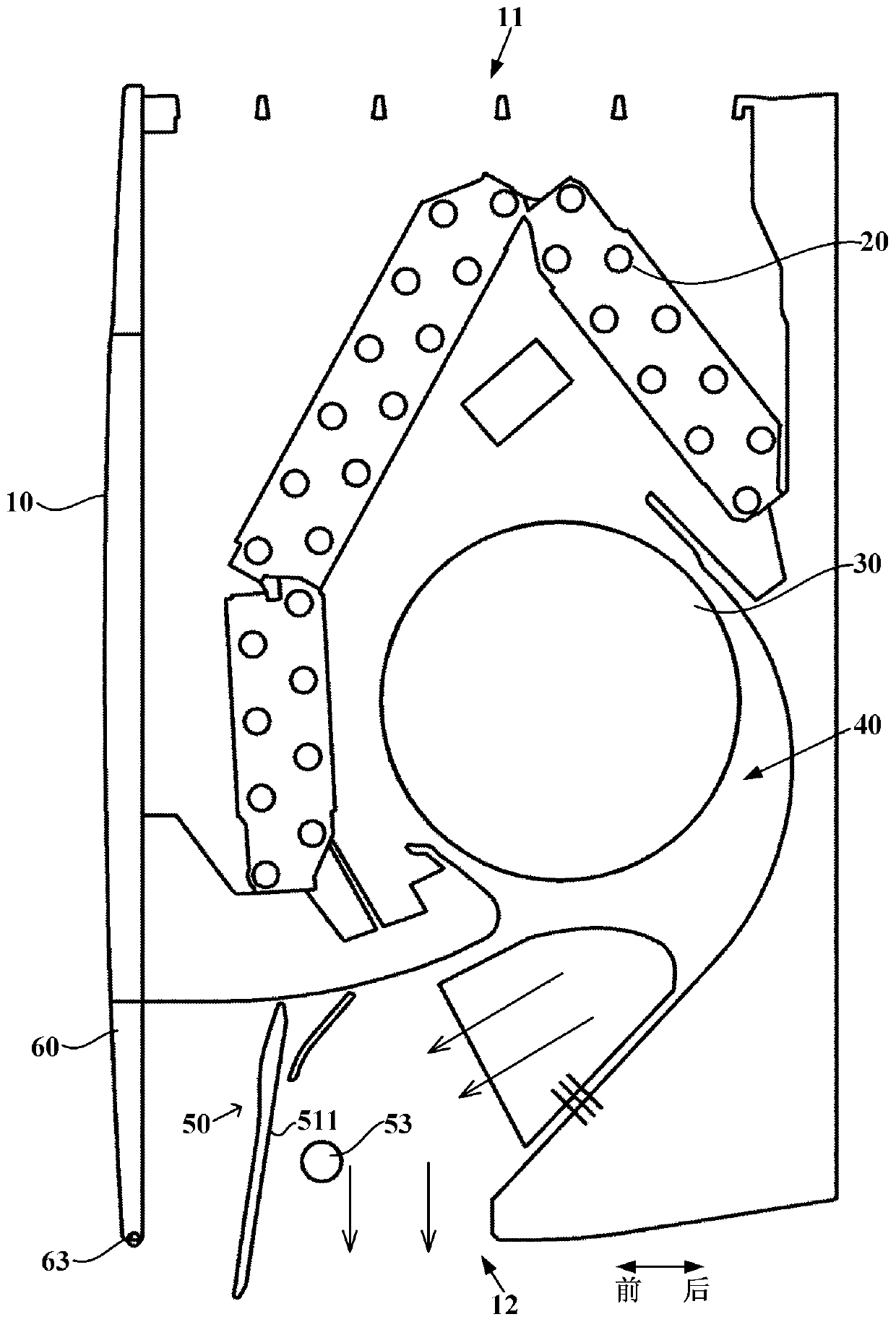

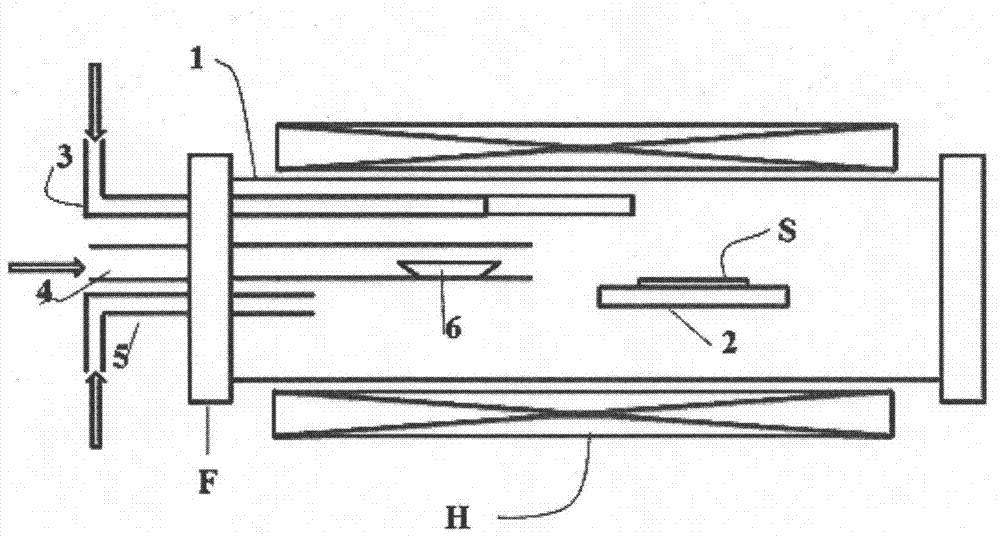

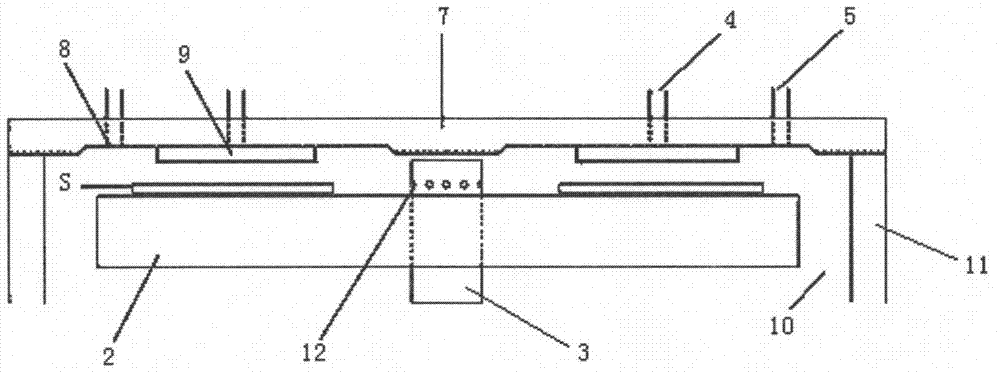

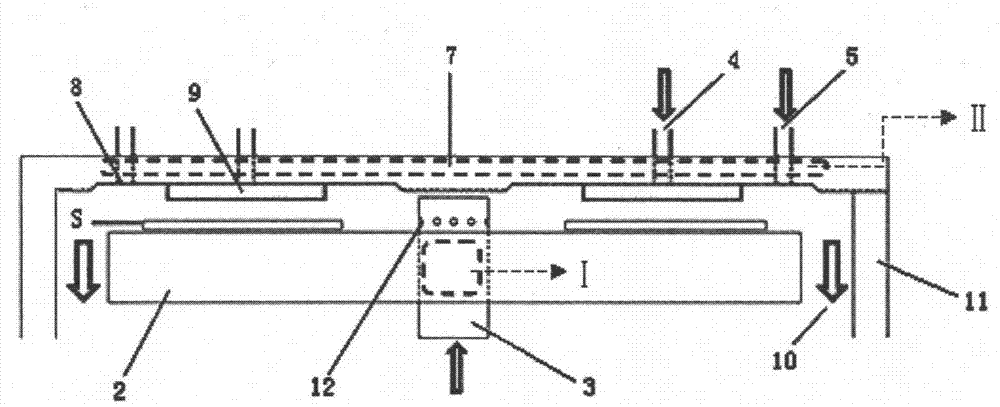

A hvpe reactor with improved substrate gas flow direction

ActiveCN104120408BIncrease flow directionRealize large-scaleChemical vapor deposition coatingEngineeringHorizontal and vertical

Owner:江苏正帆半导体设备有限公司 +1

Air conditioner indoor unit

PendingCN111351128AReduce resistanceEnhance the effect of upward guidanceLighting and heating apparatusAir conditioning systemsEnvironmental engineeringHot blast

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

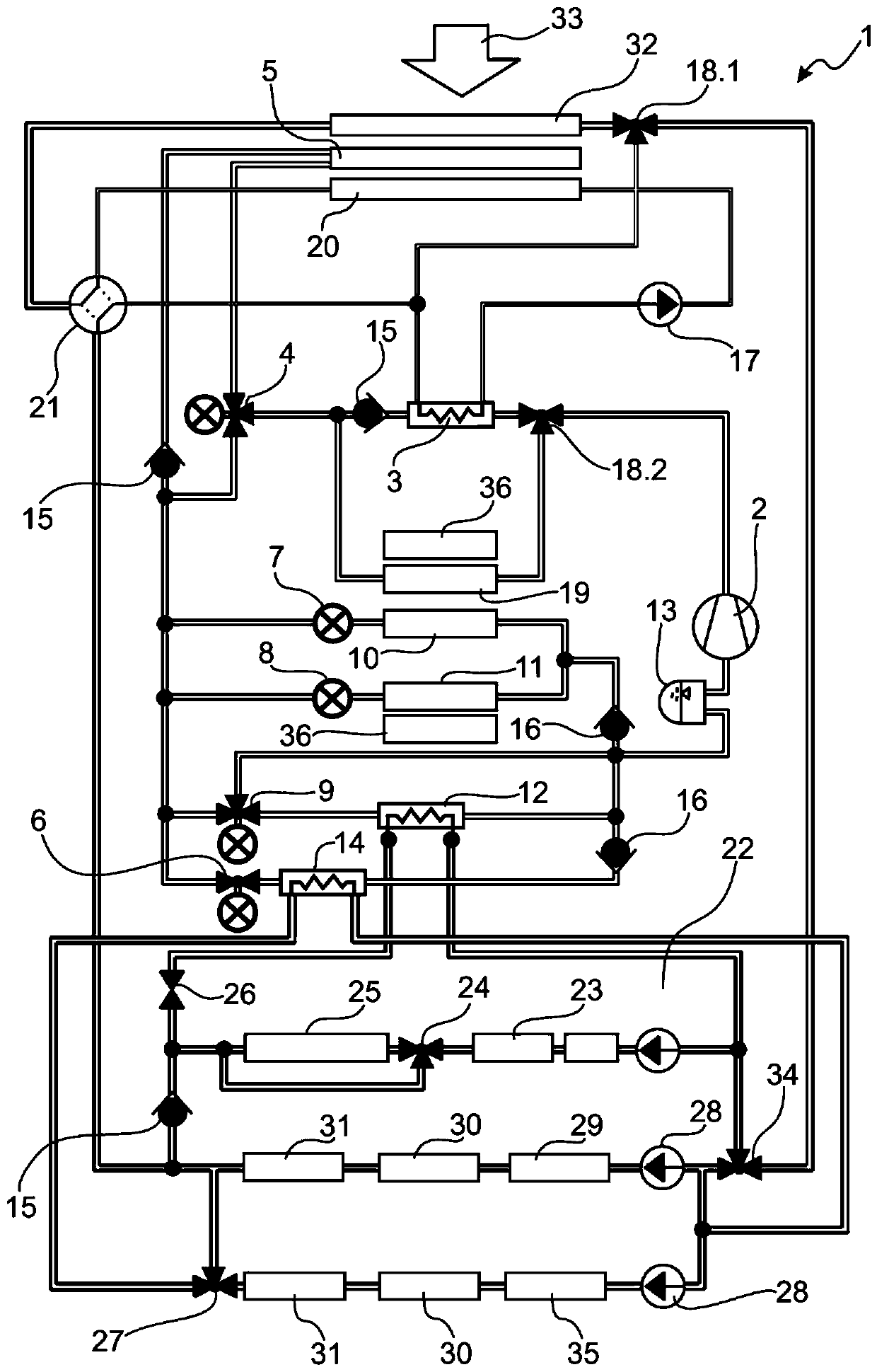

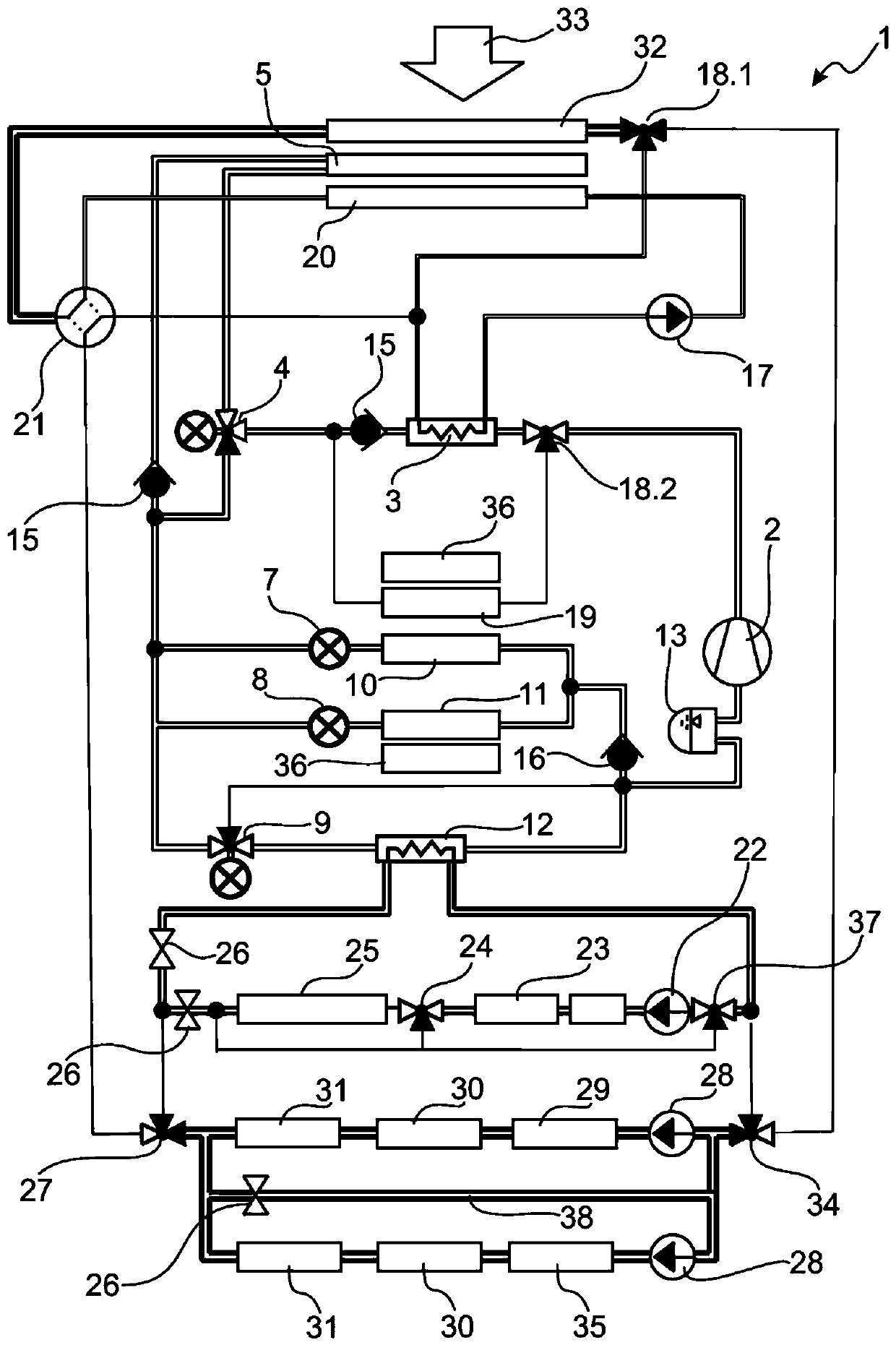

Air conditioning, battery cooling assembly, and operation method thereof

ActiveCN111532098AMaintain the homogenization functionEffective heating powerAir-treating devicesElectric propulsion mountingElectrical batteryProcess engineering

An air conditioning and battery cooling assembly with an A / C coolant circuit and an E-drive train coolant circuit as well as a refrigerant circuit, wherein the A / C coolant circuit and the E-drive train coolant circuit are coupled together across a 4 / 2-way coolant valve in such a way that the A / C coolant circuit and the E-drive train coolant circuit can be operated separately or can receive a flowin serial manner.

Owner:MAGNA STEYR FAHRZEUGTECHN

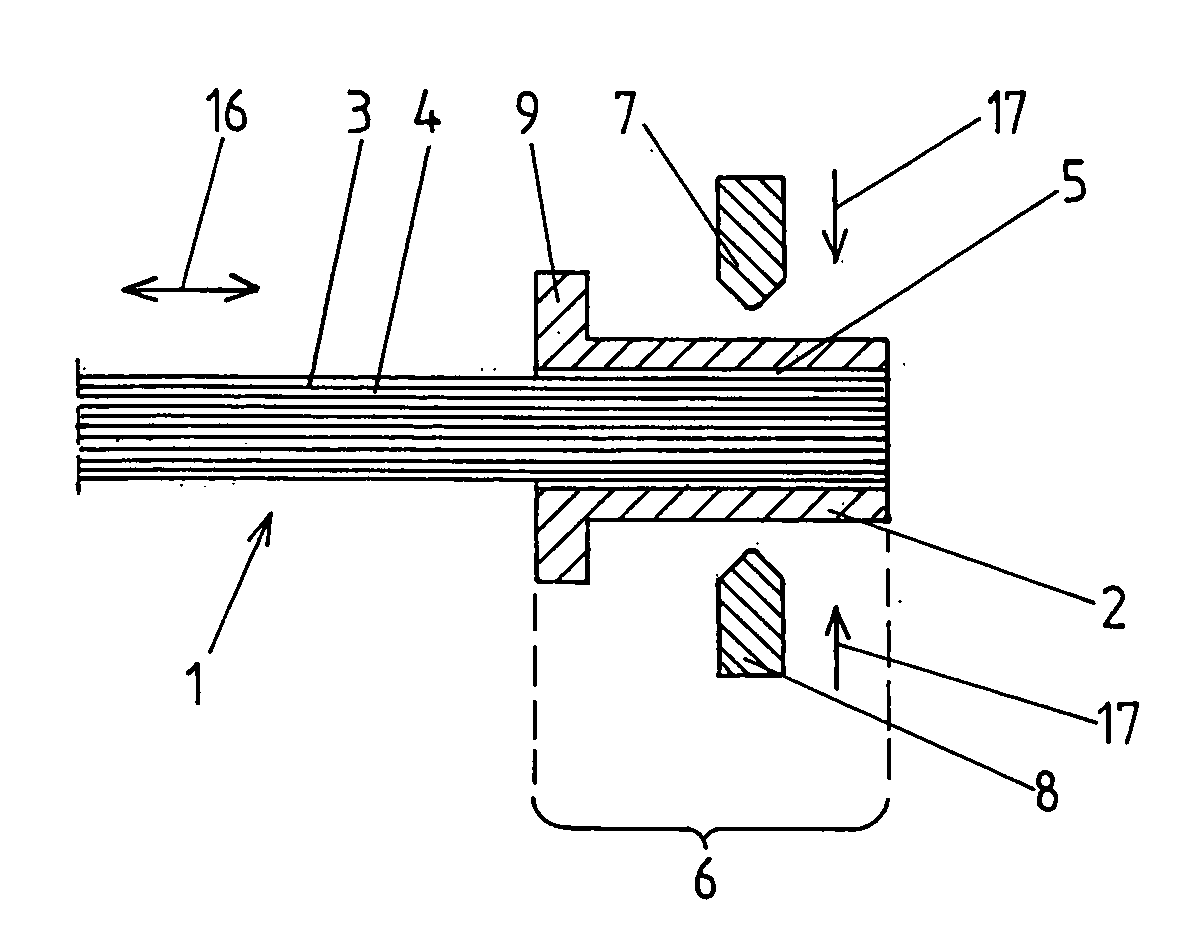

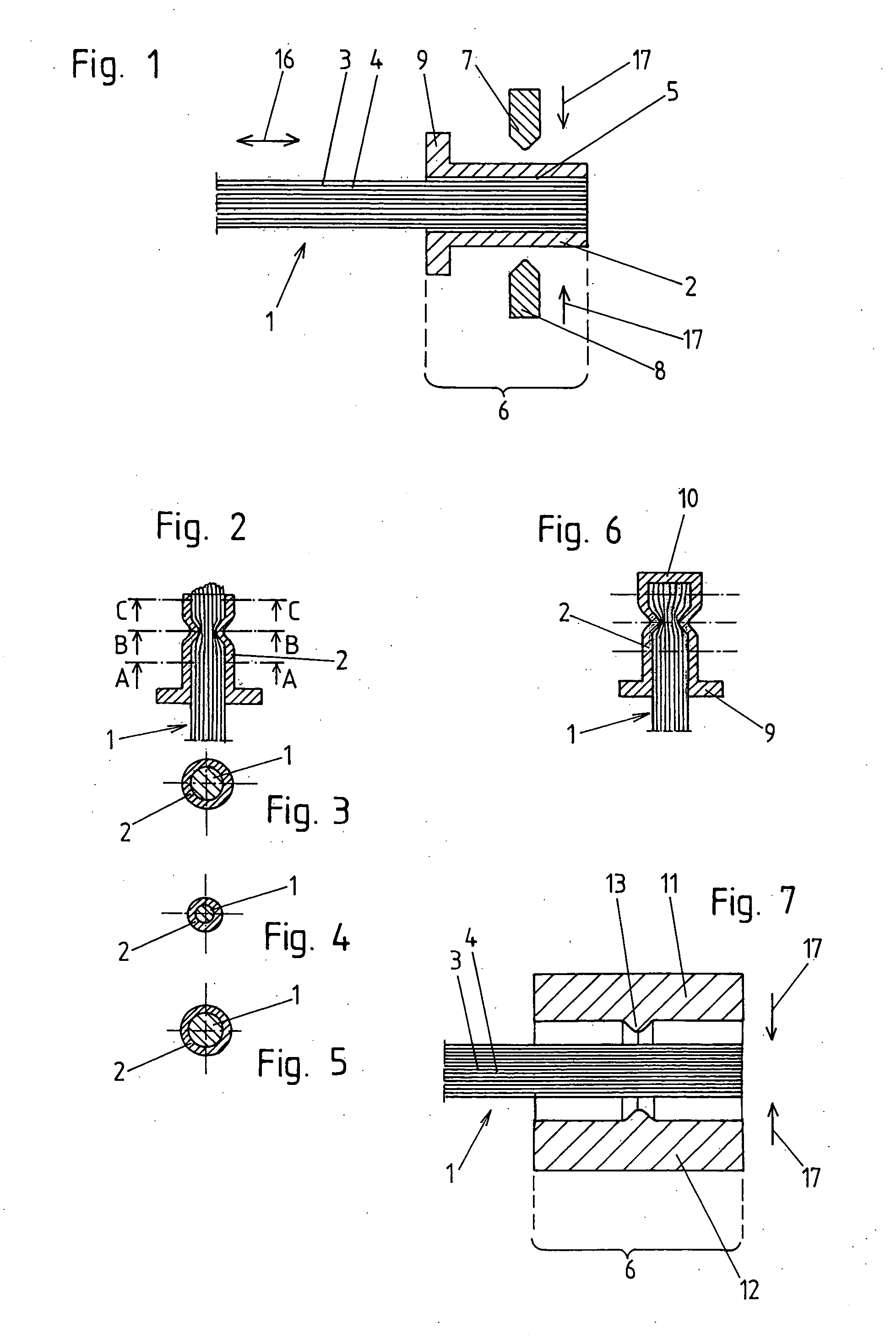

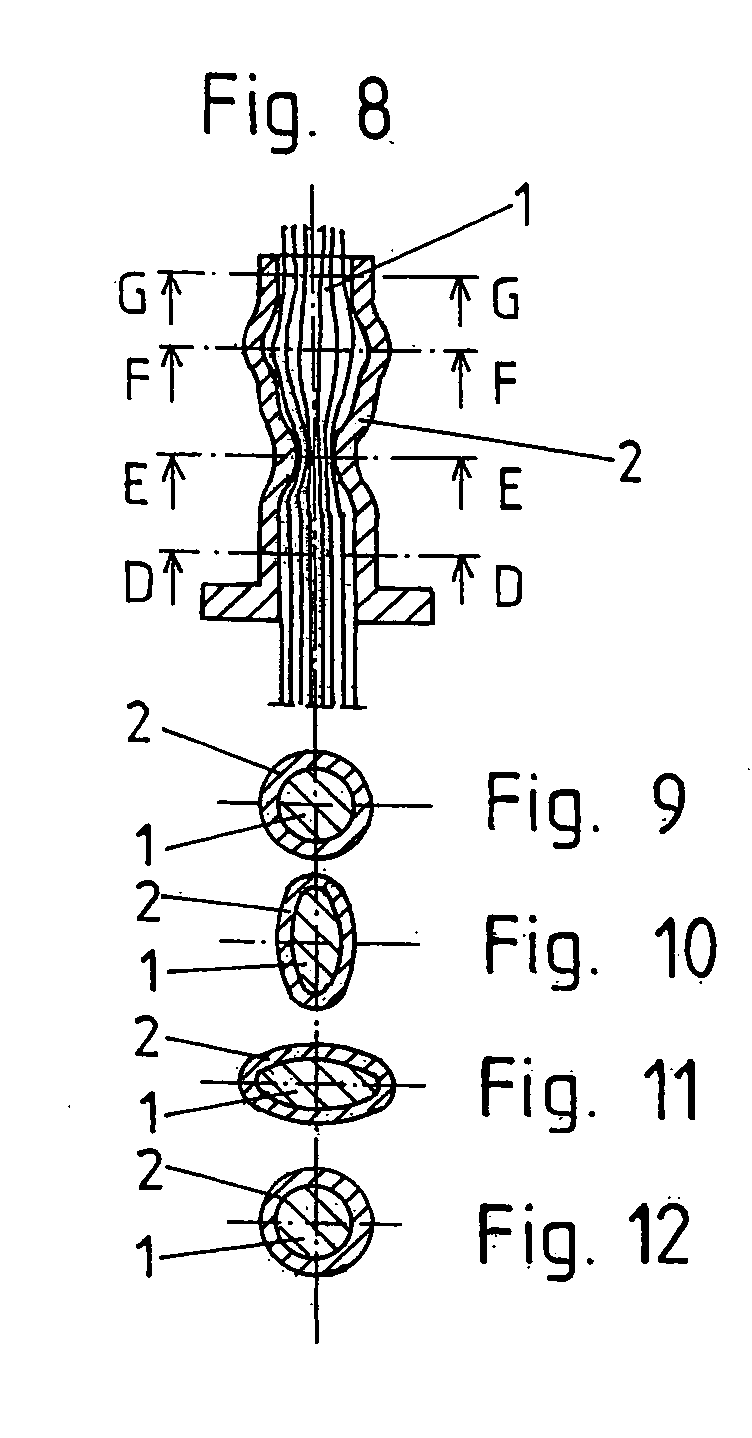

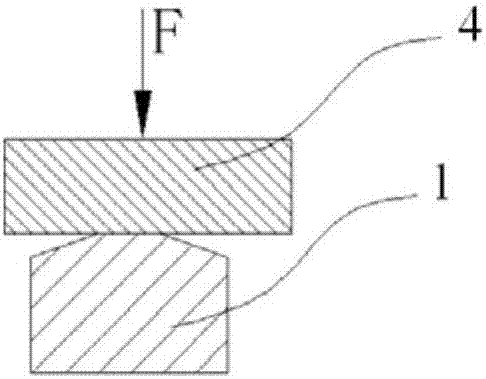

Method for forming a coupling unit on a long composite fibre section

InactiveUS20100021121A1Favorable force flow directionIncrease flow directionRopes and cables for vehicles/pulleyOptical light guidesGlass transitionThermoplastic matrix

In a method for the formation of an anchorage transmitting a longitudinal force, of an elongated composite fiber component, in particular in the form of a tension or pressure bar, which includes a thermoplastic matrix material and fibers embedded therein, on a force application element, which includes a cavity that accepts the composite fiber component over a connection section of its longitudinal extent, between the composite fiber component and the force application element a form-locking connection, acting in the longitudinal direction of the composite fiber component, is formed. For the formation of the form-locking connection the geometry of the composite fiber component, while its temperature is above the glass transition temperature of the matrix material of the composite fiber component in the connection section, is changed through a press force acting onto the external surface of the composite fiber component such that the cross sectional area of the connection section over its longitudinal extent is changed in terms of its areal enclosure. The diameter of the composite fiber component, with respect to at least one certain direction located at right angles to the longitudinal direction of the composite fiber component, is changed over the longitudinal extent of the connection section.

Owner:FAIGLE KUNSTE

Micro-nano lubricating fast drying type hydraulic mold

The invention discloses a micro-nano lubricating fast drying type hydraulic mold. The micro-nano lubricating fast drying type hydraulic mold comprises an installing framework composed of a bottom plate, a top plate and supporting columns uniformly distributed on the periphery, and a forming portion composed of an upper mold base, a casting box and a lower mold base; a hydrocyclone is arranged on one side of the upper end of the casting box; the top end of the hydrocyclone is connected with a left air inlet formed in the upper mold base in a penetrating manner; the bottom end of the hydrocyclone is provided with a containing cavity; one side of the containing cavity communicates with one side of the top end of a mold cavity; the other side of the upper end of the casting box is provided with an air guiding cavity; the top end of the air guiding cavity is connected with a right air inlet formed in the upper mold base in a penetrating manner; the lower end of the air guiding cavity is connected with a vertically arranged air conveying pipe; the air conveying pipe, a beam collecting barrel and a negative pressure injecting and sucking pipe are combined to form a negative pressure injecting and sucking system; and micro-nano lubricating and the fast dried air flowing structure design are combined, automatic lubricating and pollution discharging of pollution can be achieved easily.

Owner:江西艾特传质科技有限公司

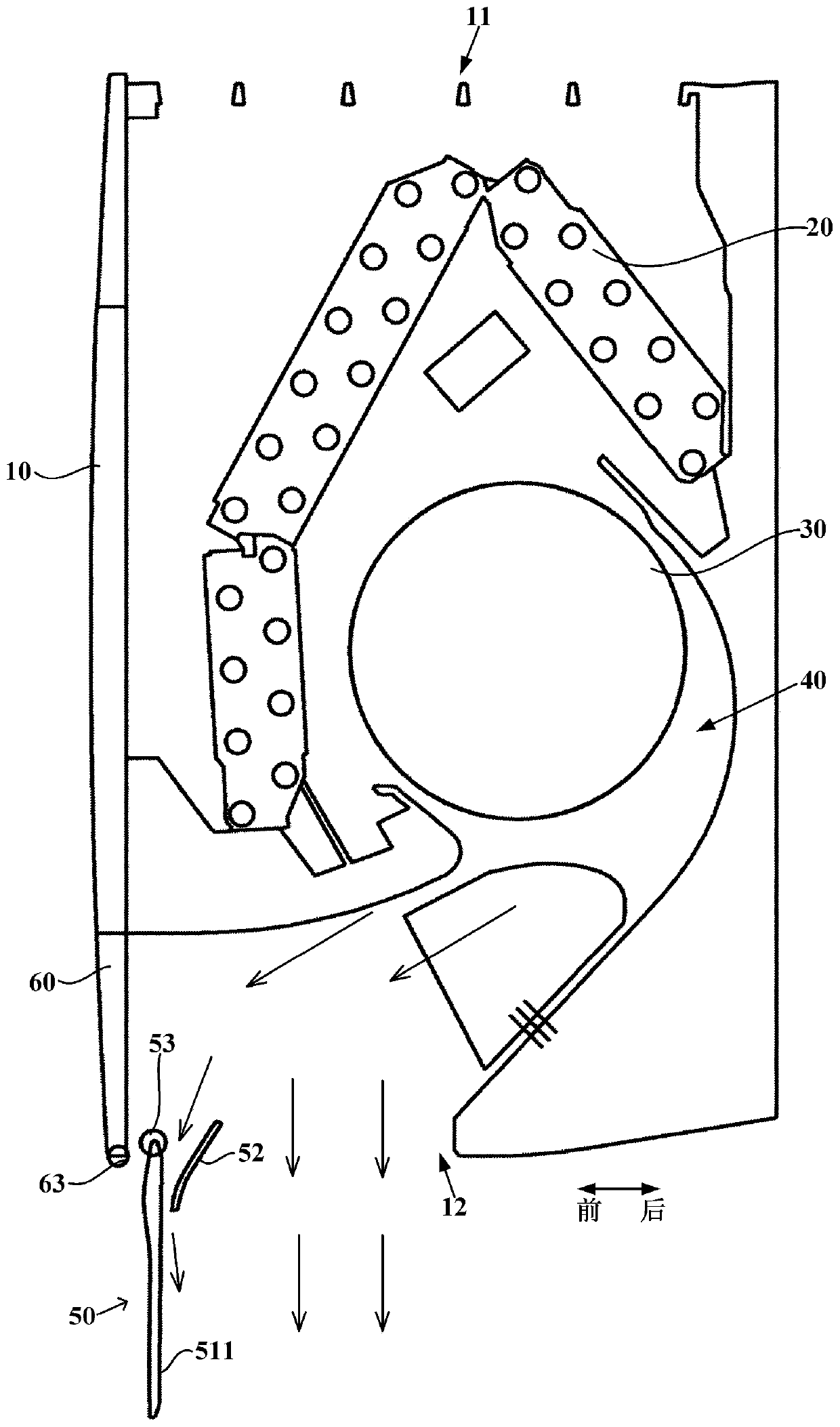

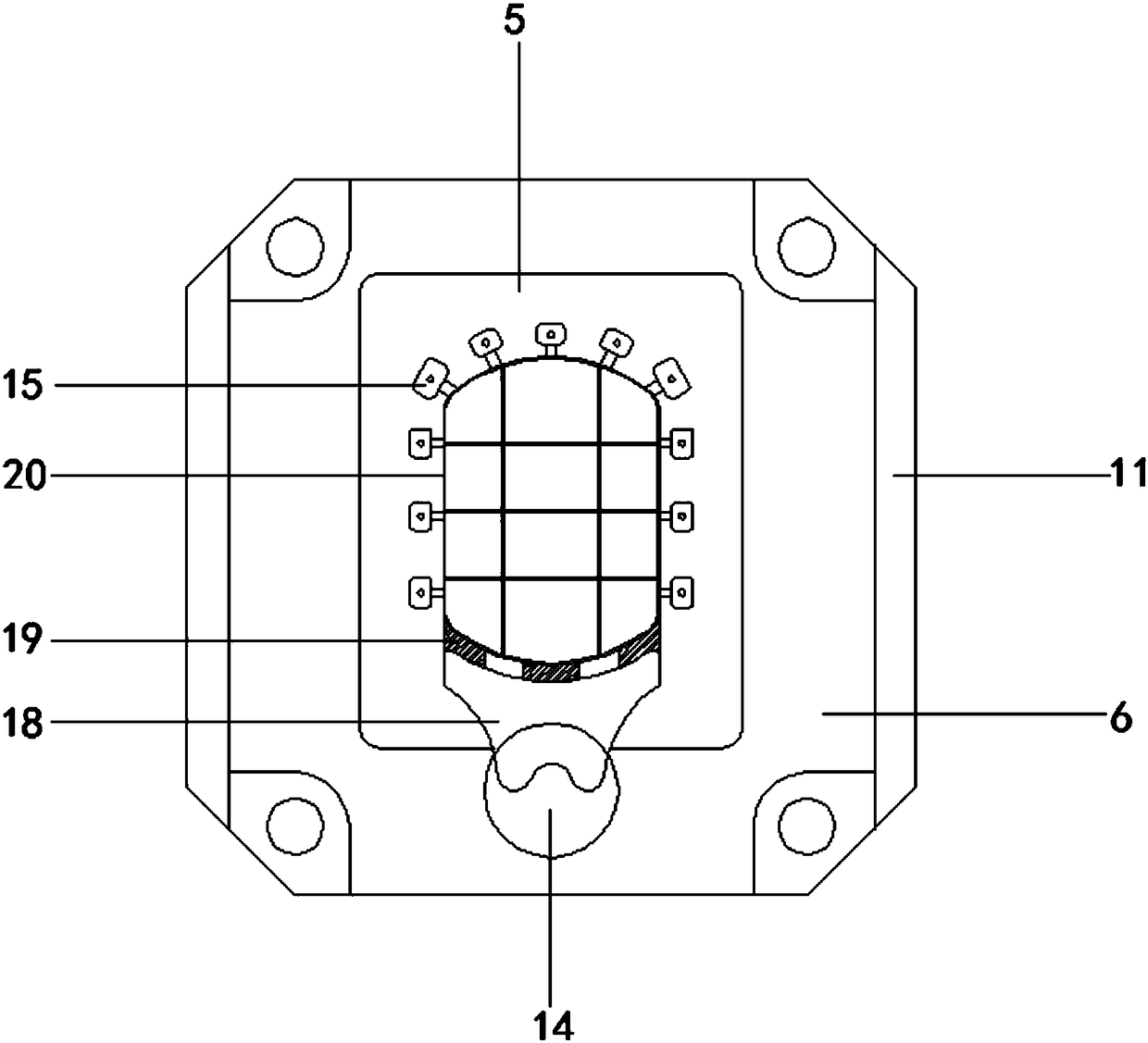

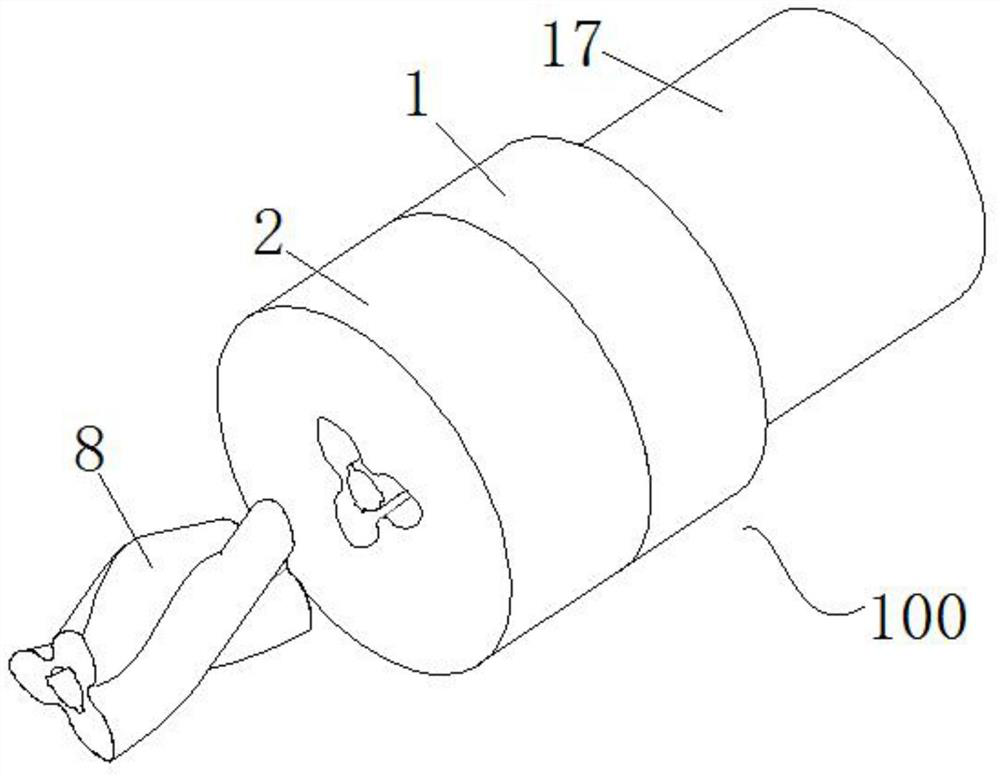

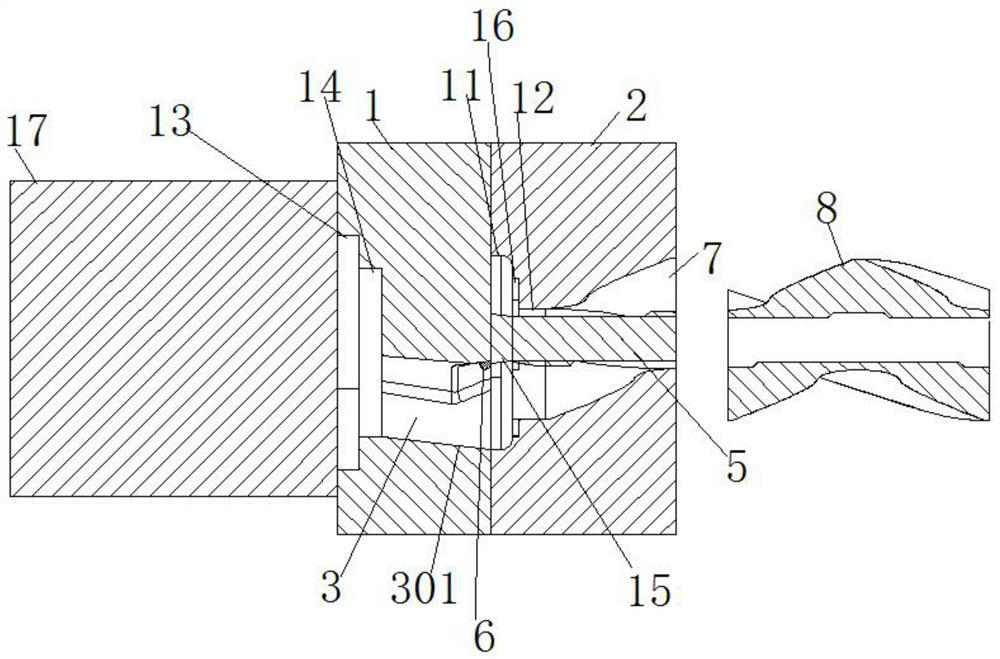

HVPE (Hydride Vapor Phase Epitaxial Growth) reactor capable of improving airflow direction of substrate

ActiveCN104120408AIncrease flow directionRealize large-scaleChemical vapor deposition coatingVapor phaseAirflow

The invention discloses an HVPE (Hydride Vapor Phase Epitaxial Growth) reactor capable of improving the airflow direction of a substrate. The HVPE reactor is characterized by comprising a shell, wherein a main body is arranged on the top of the shell; a substrate base is arranged in the shell; an injection pipe I and an injection pipe II are arranged at one side of the main body, and an air inlet pipe II and an air inlet pipe III are arranged at the other side of the main body; a pedestal is arranged on the substrate base; an air inlet pipe I is arranged in the center of the substrate base, upper and lower ends of the air inlet pipe I are exposed from the substrate base, and an injection hole is formed in the top end of the air inlet pipe I; an exhaust port is formed in a gap between the substrate base and the inner wall of the shell. When the reactor is used for production, a first reaction gas and a second reaction gas inside the reactor are mutually mixed respectively in a horizontal direction and a perpendicular direction, and a uniform film with an extensible structure can be formed on most semiconductor substrates.

Owner:江苏正帆半导体设备有限公司 +1

Local forging forming method for titanium alloy large plate type forged piece

InactiveCN107414010APromotes Elimination and RepairImprove metal flow directionWheelsForgingTitanium alloy

The invention discloses a method for local forging and forming of titanium alloy large-scale disk-like forgings. The steps are as follows: firstly, an inner gasket and an outer gasket for local forming are manufactured, and the inner wall of the outer gasket and the outer wall of the inner gasket are in an α-angle with a horizontal workbench. Then put the upsetting, punching, and pre-rolled rectangular thick-walled intermediate blank on the outer gasket and inner gasket for partial forging respectively, and then flatten the intermediate blank to complete the first partial forging; then follow the same steps for The other end face of the intermediate billet is subjected to a second partial forging, and so on, and finally a titanium alloy large disc forging is obtained. The method can overcome the lack of equipment capacity, and obtain a titanium alloy large disc forging with good shape, size, structure and performance. This method is used for forming large disk forgings.

Owner:GUIZHOU ANDA AVIATION FORGING

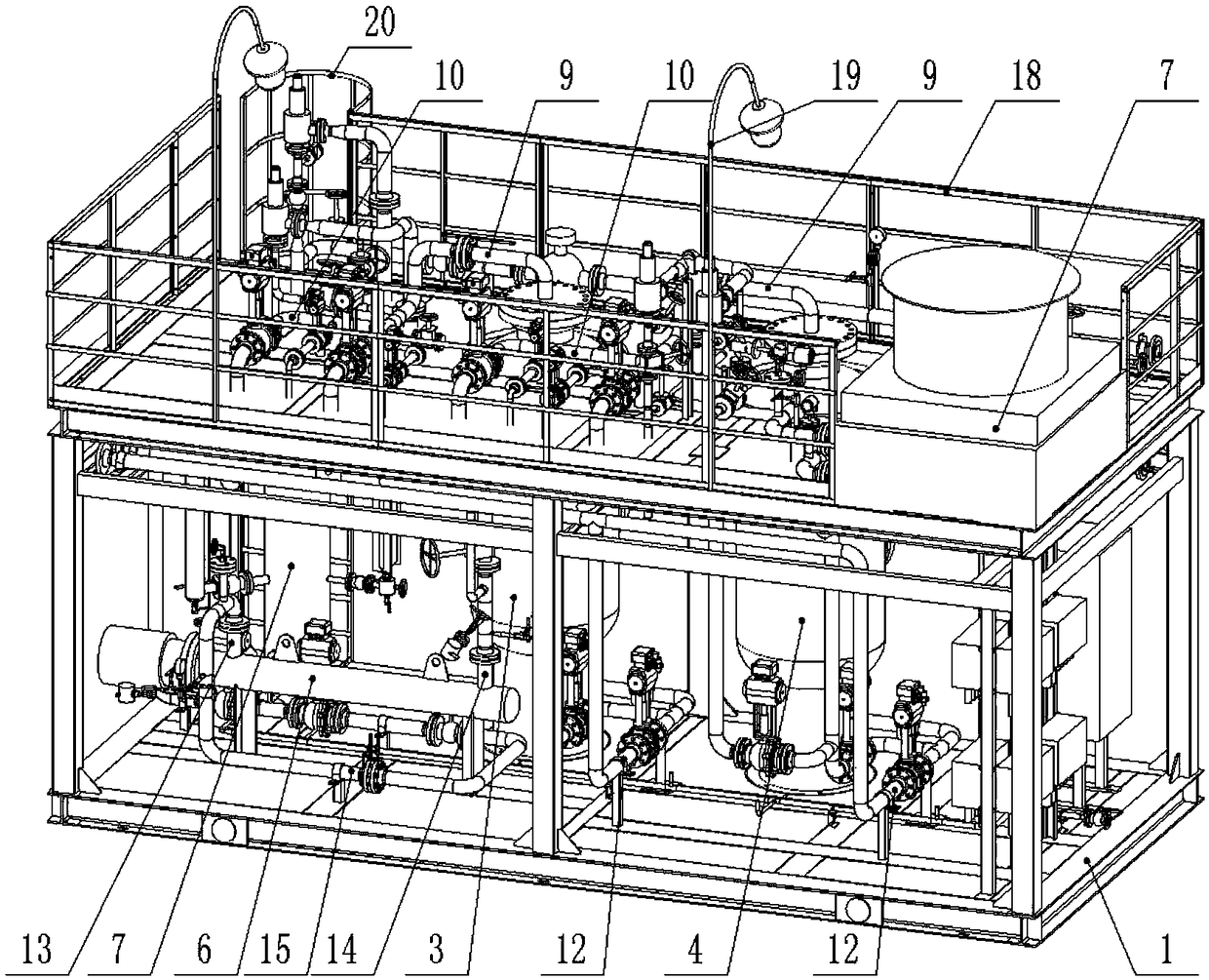

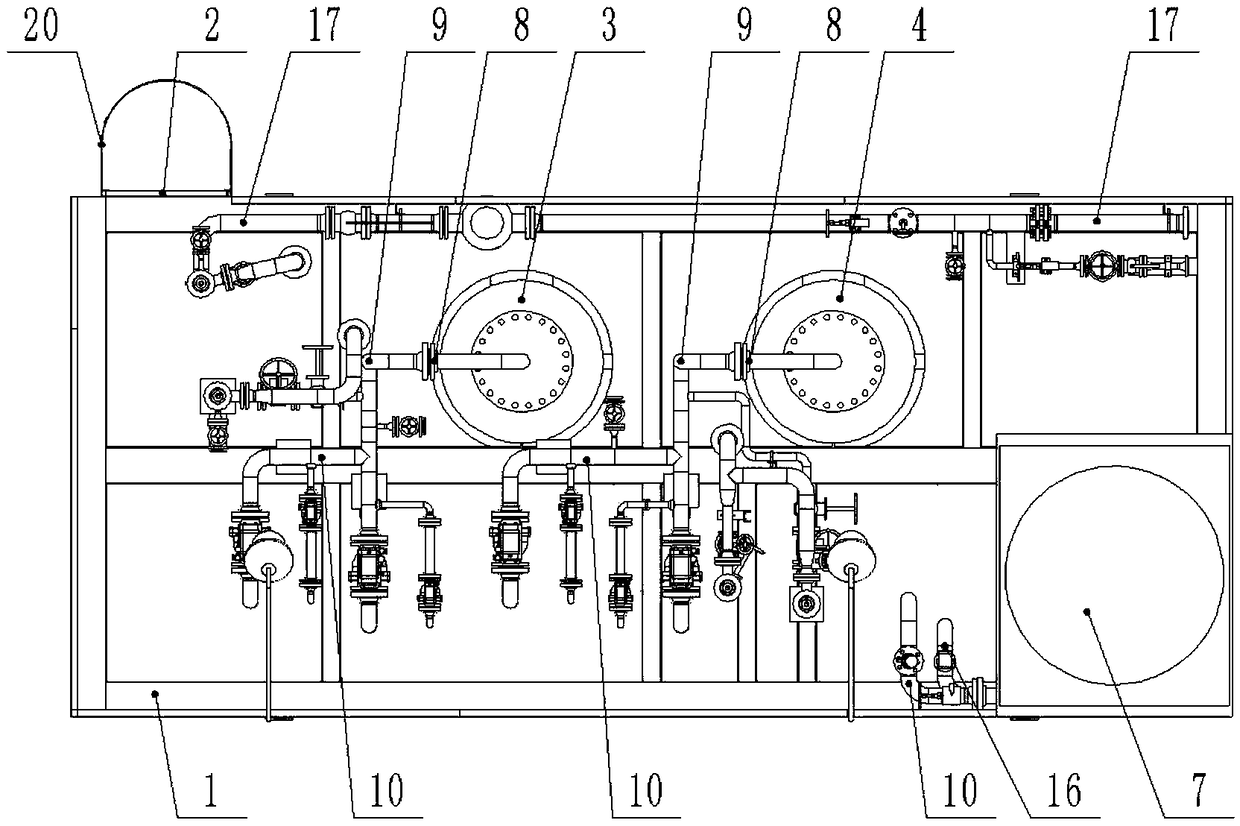

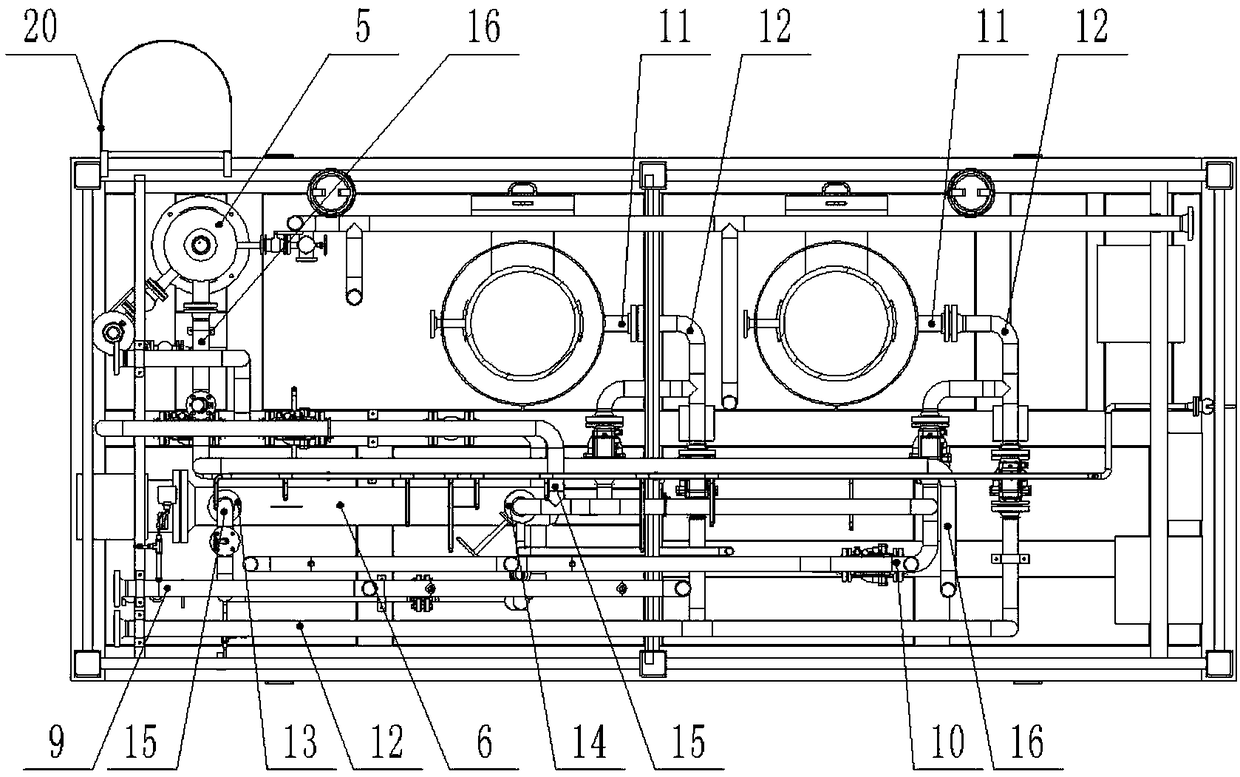

Skid-mounted device for removing heavy hydrocarbon components in natural gas

The invention discloses a skid-mounted device for removing heavy hydrocarbon components in natural gas. The skid-mounted device comprises a skid-mounted frame which comprises an upper-layer frame anda lower-layer frame, a first hydrocarbon removing tower, a second hydrocarbon removing tower, a hydrocarbon removing regeneration separator and a hydrocarbon removing regeneration heater are arrangedon the lower-layer frame, and a hydrocarbon removing regeneration gas air cooler is arranged on the upper-layer frame; the tops of the first hydrocarbon removing tower and the second hydrocarbon removing tower are connected with a natural gas incoming pipeline, a branched pipeline is arranged on the natural gas incoming pipeline and connected with the hydrocarbon removing regeneration gas air cooler, the bottoms of the first hydrocarbon removing tower and the second hydrocarbon removing tower are connected with a natural gas outgoing pipeline, and an inlet and an outlet on the hydrocarbon removing regeneration heater are connected with a regeneration cold-blowing pipeline which is connected with the natural gas outgoing pipeline; a communication pipeline is arranged between an inlet of thehydrocarbon removing regeneration separator and an outlet of the hydrocarbon removing regeneration gas air cooler, and an outlet of the hydrocarbon removing regeneration separator is connected with an outer pipeline. The skid-mounted device is of an integrated skid-mounted structure and is small in size, stable in structure and convenient for manufacturing and transporting.

Owner:天津市振津石油天然气工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com