Micro-nano lubricating fast drying type hydraulic mold

A micro-nano, quick-drying technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of extensive automatic supply of lubricating oil, unsatisfactory supply and cleaning, and short maintenance and filling cycles. Speed and Sensitivity, Relief of Elastic Elements, Effects of Fast Air Flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0035]It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

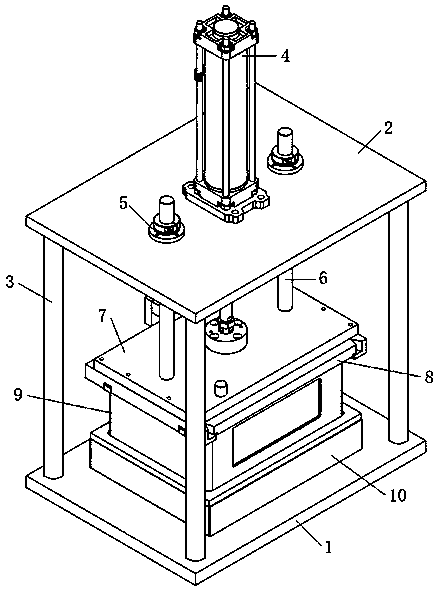

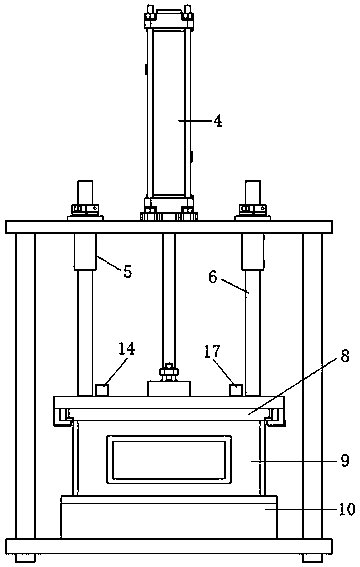

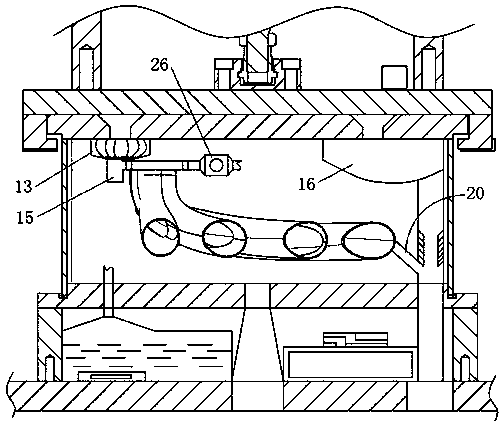

[0036] according to Figure 1-7 As shown, the present invention provides a quick-dry hydraulic mold with micro-nano lubrication, and the technical scheme is as follows:

[0037] The installation frame is composed of the bottom plate 1, the top plate 2 and the support columns 3 evenly distributed around it. The installation frame is used as the base of the whole structure. The middle part of the top plate 2 is vertically installed with the driving hydraulic cylinder 4 vertically to the top plate 2. The driving hydraulic cylinder 4 provides the up and down The push-pull force of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com