Rigid-flexible combined paddle for enhancing the fluid mixing effect

A fluid mixing and stirring paddle technology, applied in the field of stirring paddles, can solve the problems of insufficient mixing of the flow field structure and low fluid mixing efficiency, and achieve the effects of improving energy utilization, improving fluid mixing effect, and strengthening the fluid mixing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

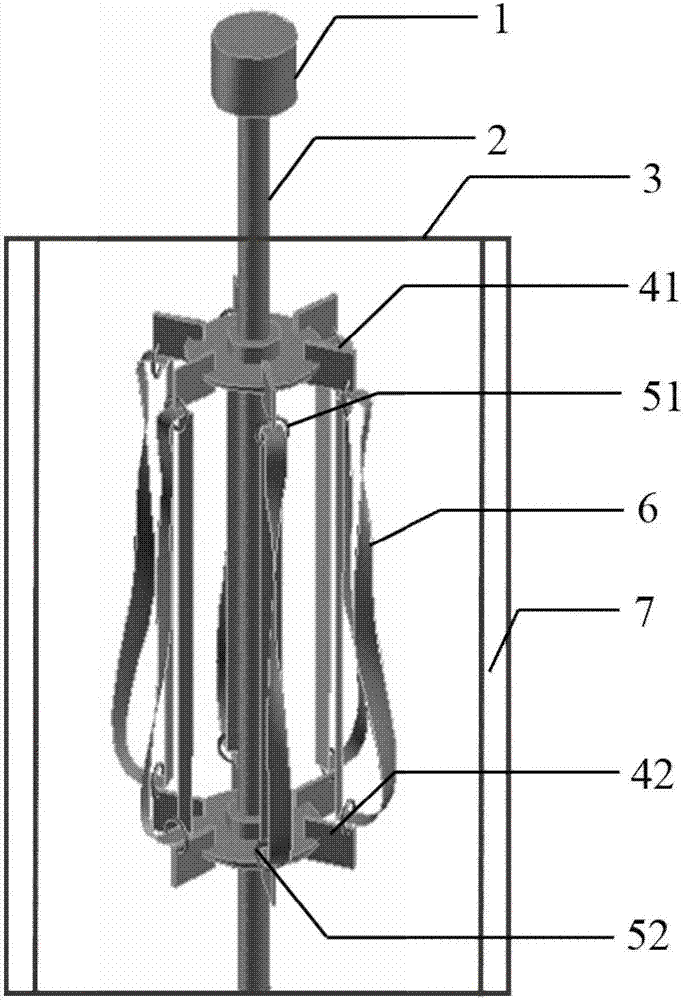

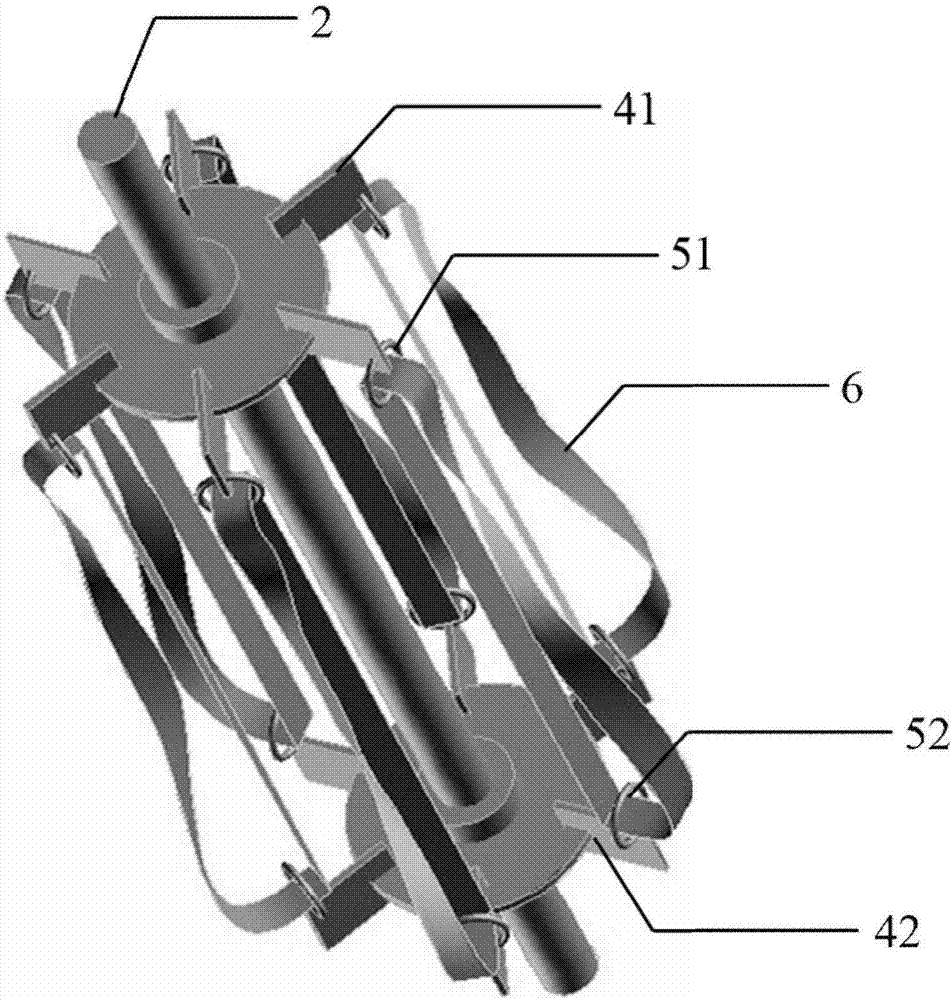

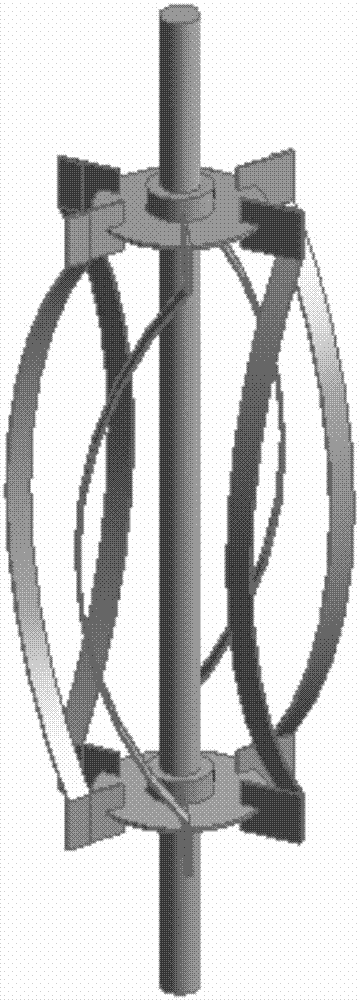

[0037] A rigid-flexible combined stirring paddle that improves fluid mixing effect, is characterized in that: comprise stirring shaft 2, and rigid paddle I41, rigid paddle II42, several rings I51, several rings II52, several flexible Mobius strips 6 . The number of blades of the rigid stirring paddle I41 and the rigid stirring paddle II42 is equal.

[0038] The node on the stirring shaft 2 with fixed rigid stirring paddle I41 is marked as node A, and the node on the stirring shaft 2 with fixed rigid stirring paddle II42 is marked as node B.

[0039] The node A is fixed with a disc body A, and one end of several rigid paddles is fixed around the disc body A. That is, a number of rigid paddles are radially distributed on node A of the stirring shaft 2 . In the embodiment, several rigid paddles are evenly distributed around the stirring shaft 2 .

[0040] The node B is fixed with a disc body B, and one end of several rigid paddles is fixed around the disc body B. That is, a n...

Embodiment 2

[0044] The main structure of this embodiment is the same as embodiment 1, further:

[0045] The diameter of rigid stirring paddle I41 and rigid stirring paddle II42 is equal. That is, the diameter of the rigid stirring blade I41 is D, and the diameter of the rigid stirring blade II42 is also D. The paddle of rigid paddle I41 is the same size as the paddle of rigid paddle II42.

[0046]It is found through research that when the width of the flexible Mobius strip 6 is too narrow, it is beneficial for the flexible Mobius strip 6 to twist or vibrate, but the ability to transfer energy is poor; when the width of the flexible Mobius strip 6 is too large Wide, it is not conducive to twisting or shaking of the flexible Möbius strip 6, but the ability to transmit energy is strong. The width of the flexible Möbius strip 6 is d, and when d is 1 / 40-1 / 10 of D, the system can obtain a better mixing effect.

[0047] The distance between the blade lower edge of the rigid paddle I41 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com