Pressure casting die

A die-casting and mold technology, applied in the field of molds, can solve problems such as poor welding of aluminum alloys, poor surface quality of castings, poor filling of aluminum liquid, etc., achieve smooth surface, reasonable structure design, and improve the effect of liquid flow direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

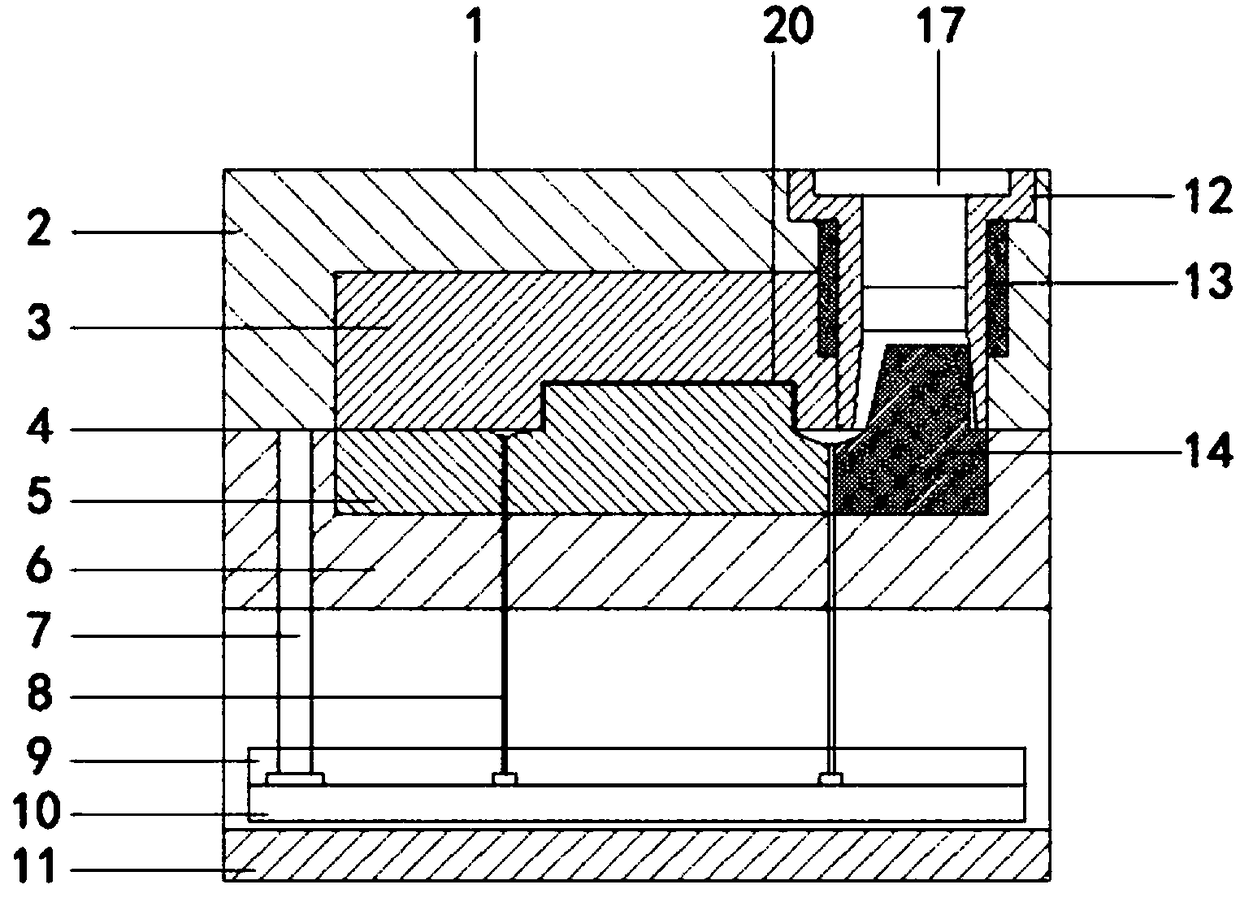

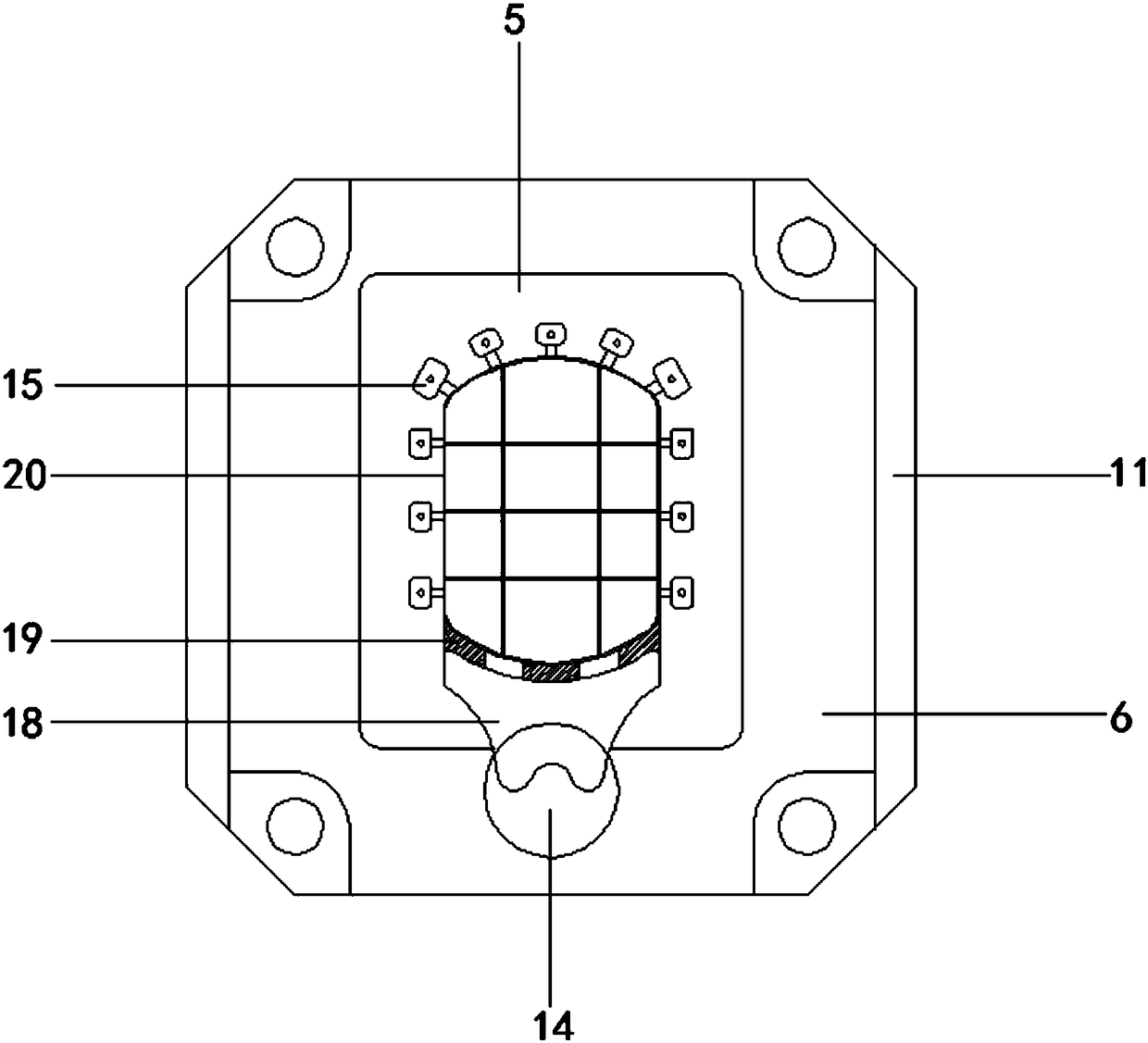

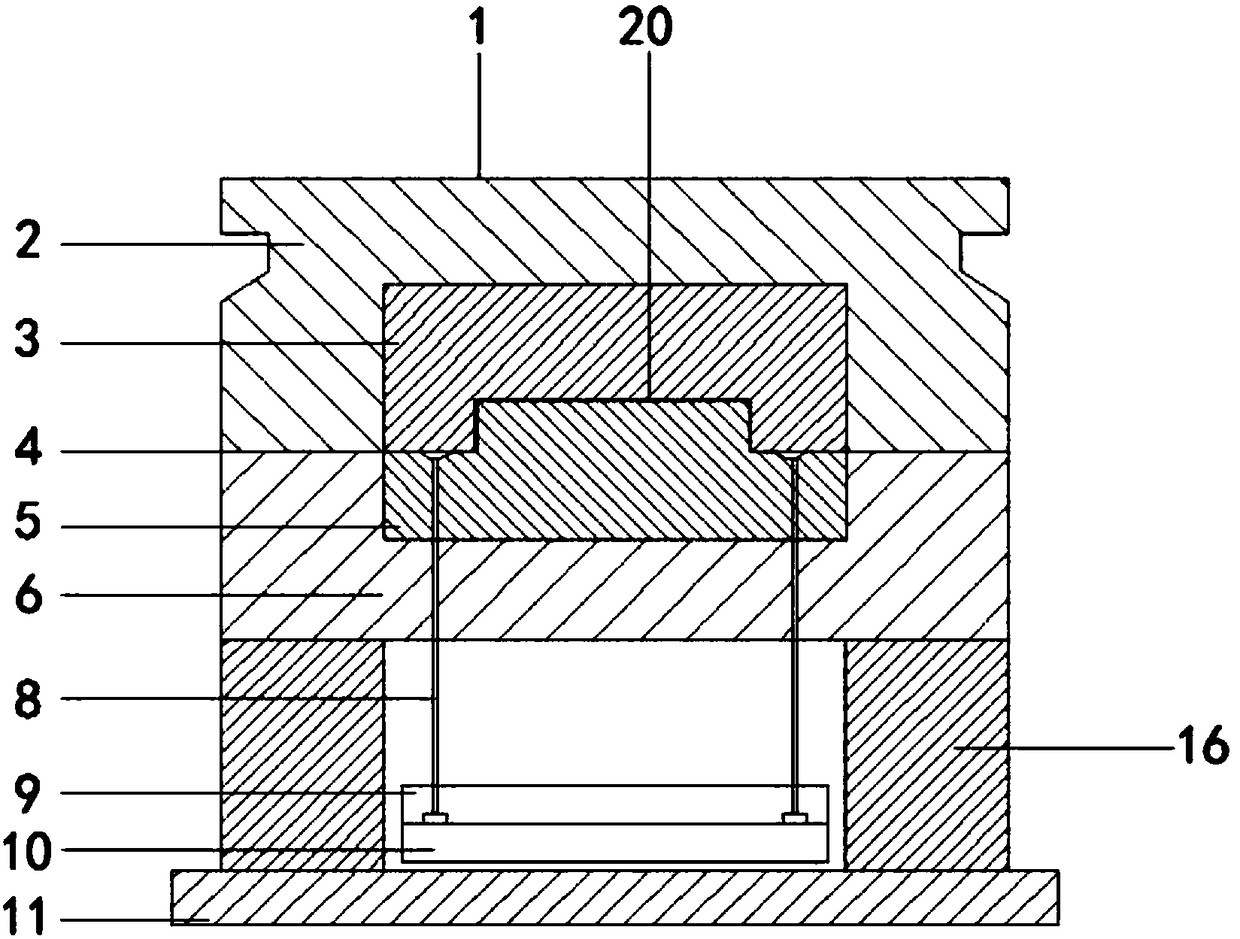

[0029] Die casting mold, including: mold body 1, fixed mold fixed plate 2, fixed mold insert 3, parting surface 4, movable mold insert 5, movable mold fixed plate 6, reset rod 7, ejector rod 8, upper backing plate 9. Lower backing plate 10, bottom plate 11, sprue sleeve 12, sprue bushing 13, diverter cone 14, square iron 15, overflow groove 16, sprue 17, runner 18, side sprue 19, die-casting Part 20; the shape of the mold body 1 is cuboid, and the top of the mold body 1 is provided with a fixed mold fixed plate 2; the fixed mold fixed plate 2 is provided with a fixed mold insert 3, and the fixed mold insert 3 and the fixed mold insert The fixed mold plate 2 is connected by bolts; the movable mold fixed plate 6 is arranged under the fixed mold fixed plate 2, and the movable mold fixed plate 6 is connected with the fixed mold fixed plate 2 through guide pillars and guide sleeves; the movable mold fixed plate The inside of 6 is provided with a movable mold insert 5, and the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com