Component of bottom hole assembly having upwardly-directed fluid cleaning flow and methods of using same

a fluid cleaning and bottom hole technology, applied in the direction of drilling rods, drilling pipes, drilling casings, etc., to achieve the effect of increasing the size of the clump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

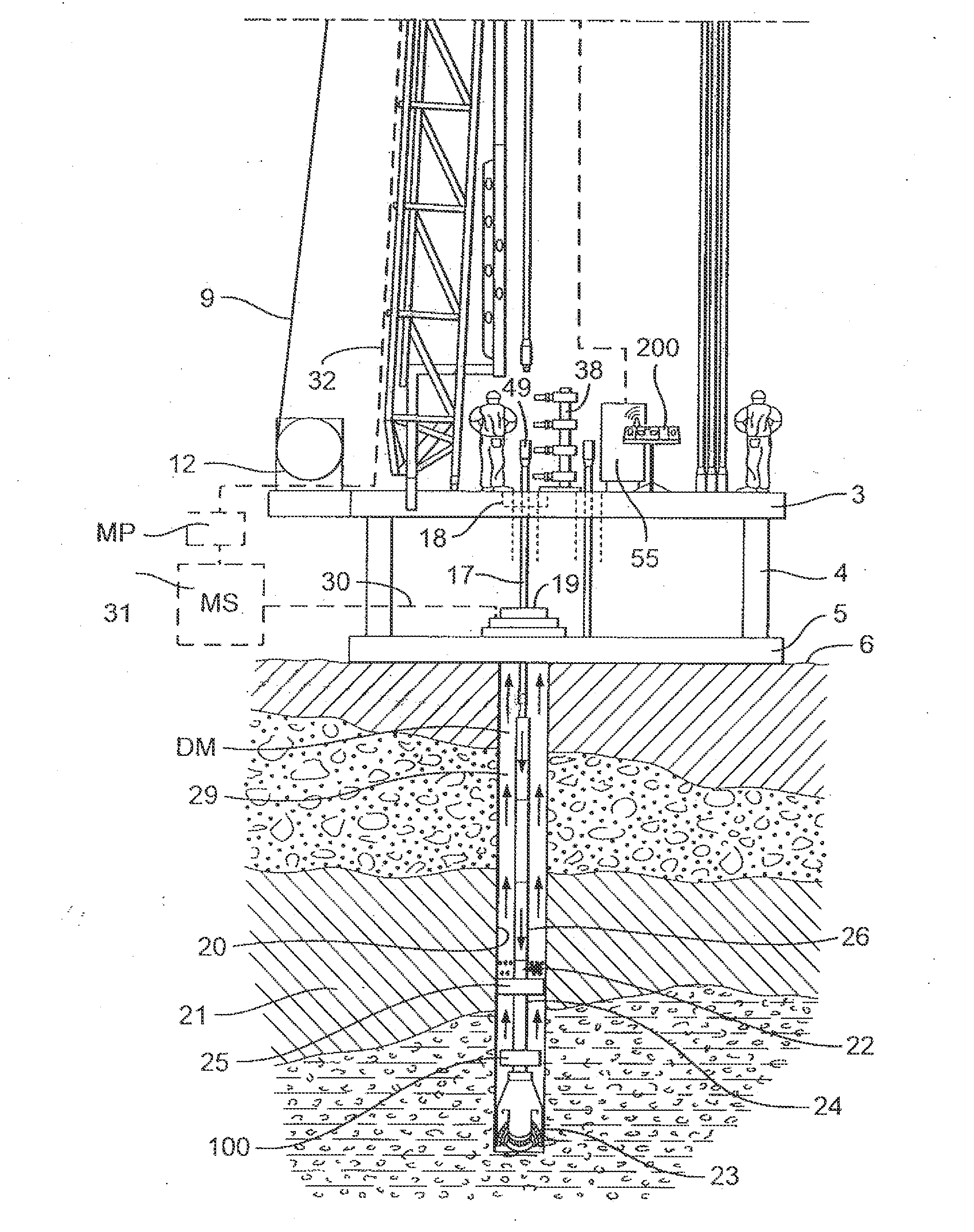

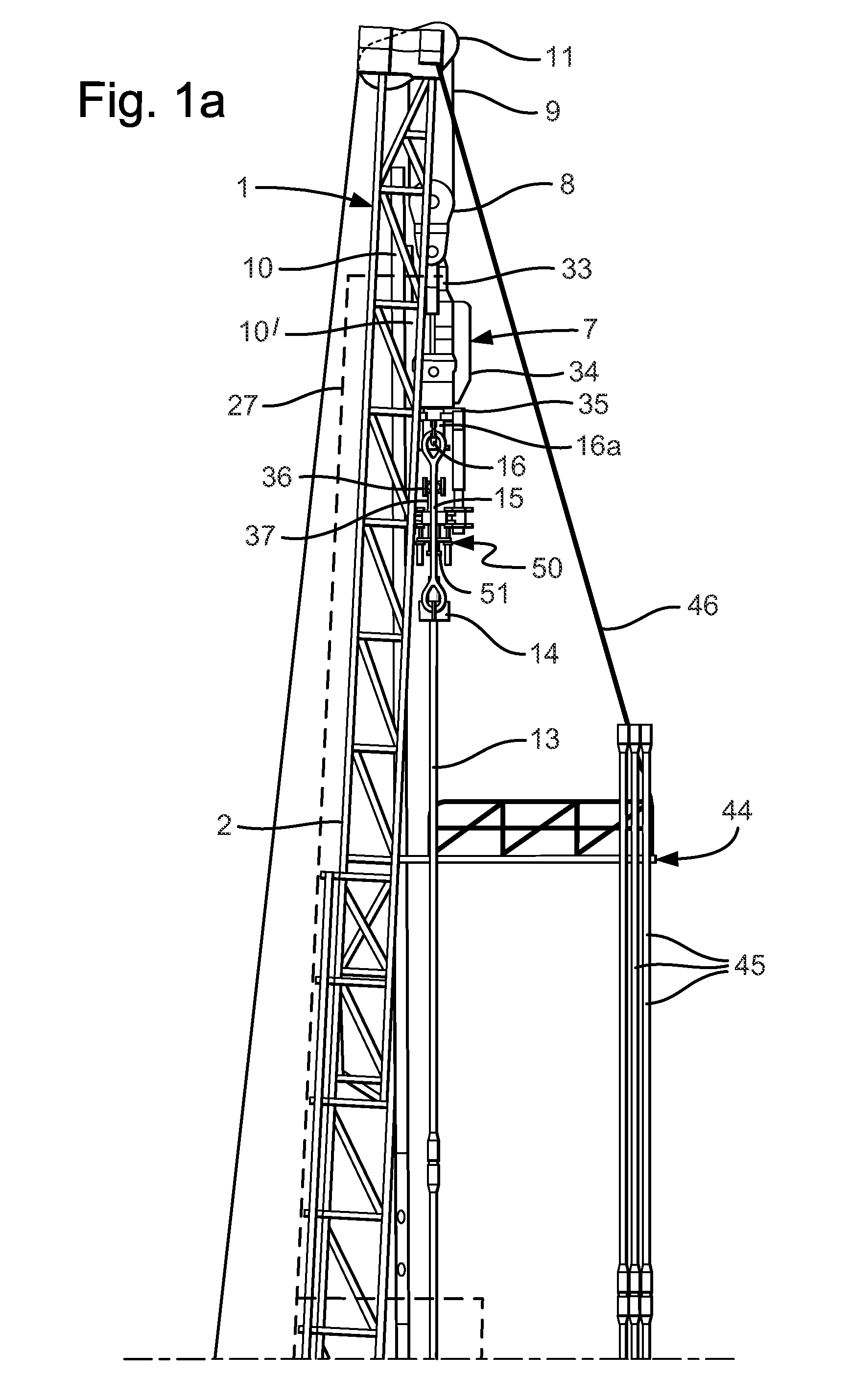

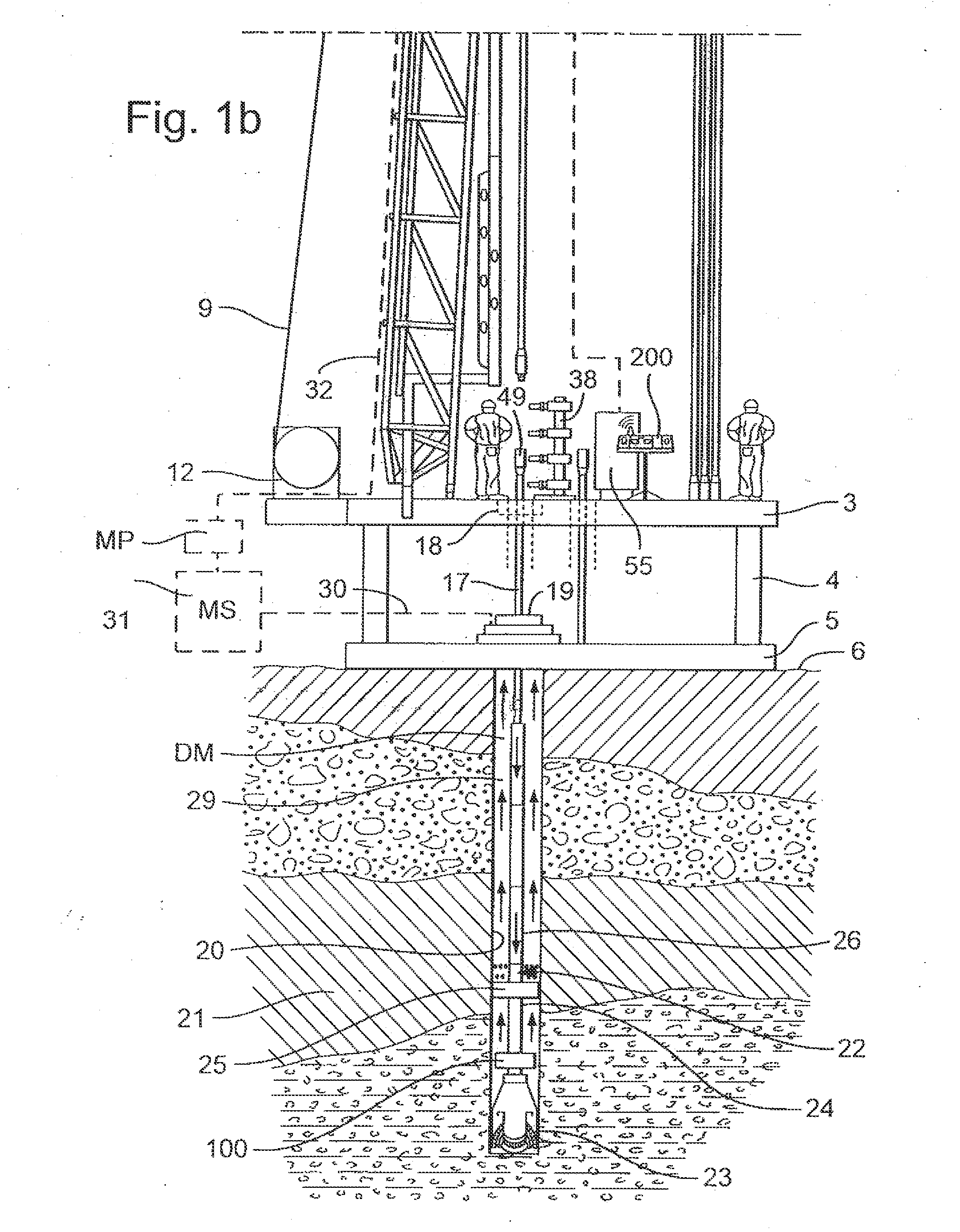

[0054]Referring to FIGS. 1a and 1b there is shown a drilling rig generally identified by reference numeral 1. The drilling rig 1 has a derrick 2 arranged on a drill floor 3 supported on legs 4. The legs 4 are seated on a substructure 5 on ground 6.

[0055]A top drive apparatus 7 is arranged on a carriage 10′ raised and lowered with a travelling block 8 on line 9 along a vertical track 10. The line 9 passes over a crown block 11 located at a top of the derrick 2 and down to a drawworks 12 on the rig floor 3 for reeling the line 9 in and out. A stand of drill pipe 13 depends from an elevator 14. The elevator 14 depends from links 15 which are looped over ears 16 of a swivel 16a of the top drive apparatus 7.

[0056]A drill string 17 passes through a spider 18 in the drill floor 3, through a wellhead 19 into a borehole 20 in formation 21. A bottom hole assembly 22 is arranged on a lower end of the drill string 17. The bottom hole assembly 22 comprises a drill bit 23 connected to a stabilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com