Metal plate material ring-shaped light spot laser impact forming method and device

A ring-shaped spot and laser shock technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of low efficiency and easy cracking, and achieve the advantages of preventing lamination, improving smoothness, and short production preparation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

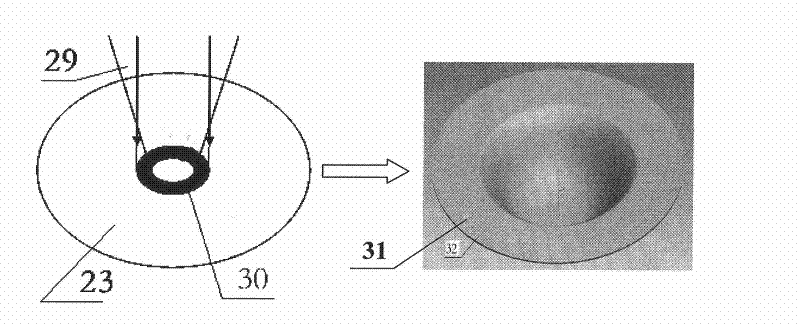

[0030] Such as figure 2 , 5 shown.

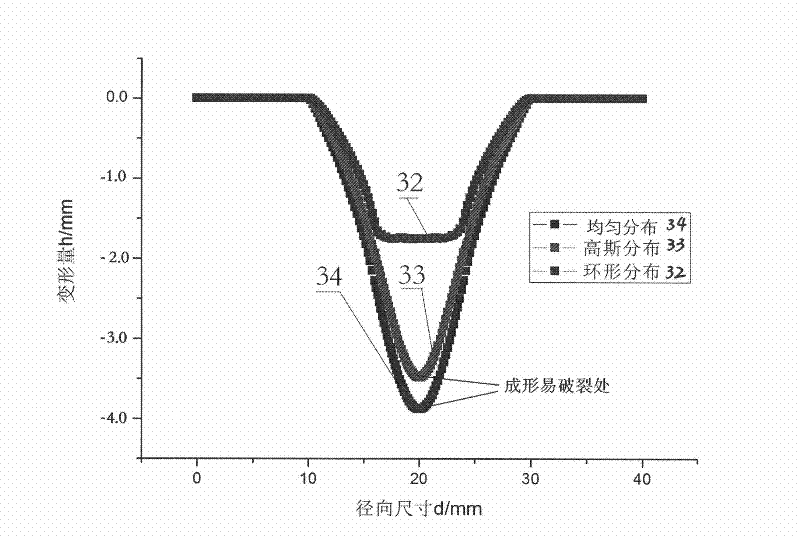

[0031] A laser shock forming method for ring-shaped spot of metal sheet, which adopts a high-power pulse laser, makes the adjustable laser beam emitted by the high-power pulse laser pass through the optical path system to form a ring-shaped laser spot, and makes the ring-shaped laser spot act on the surface of the workpiece system, The workpiece surface is subjected to laser-induced shock waves to produce rapid plastic deformation. Such as figure 2 As shown, according to the requirements of sheet shape / material / thickness and forming rules, as well as the signal of the forming detection feedback system, the central control system comprehensively adjusts the laser pulse width, laser energy, inner and outer diameter of the ring spot, and the impact position to obtain a reasonable The size and distribution of the impact force to obtain precise workpiece contours and improve forming efficiency.

[0032] During specific implementation, the ...

Embodiment 2

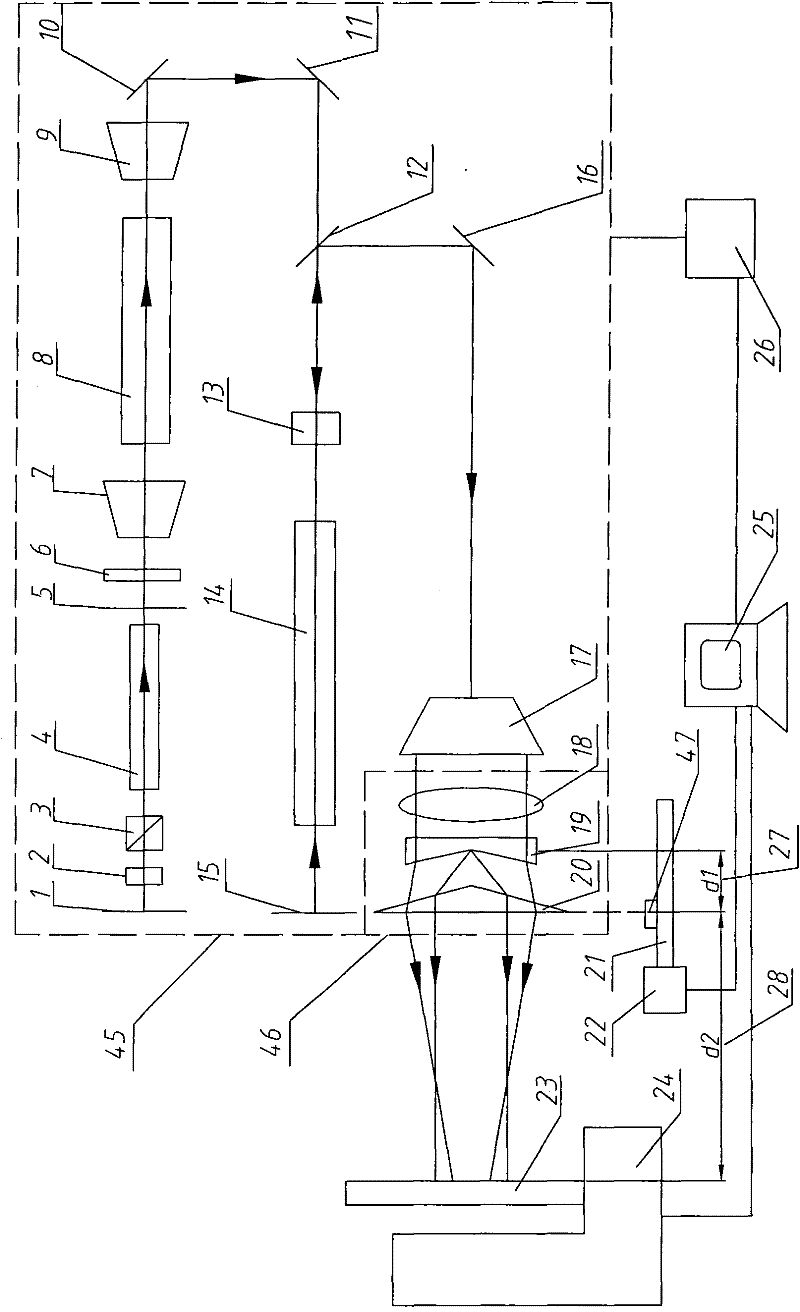

[0035] Such as Figure 1-5 shown.

[0036] A ring-shaped spot laser impact forming device for sheet metal, which includes a laser generator power supply 26, a control device 25, a machine tool 24, a stepping motor 22, a guide rail 21, a laser generating system 45, and a ring-shaped spot forming adjustment device 46, and a control device 25 It is respectively electrically connected with the laser generator power supply 26, stepper motor 22 and machine tool 24. A movable workpiece system 23 is installed on the machine tool 24. On the top, the laser generator power supply 26 passes through a laser generating system 45 and then outputs an annular light spot to act on the workpiece. System 23, the stepper motor 22 is connected to the slider 47 on the guide rail 21 through a screw mandrel, and the ring-shaped spot forming adjustment device 46 is composed of a converging lens 18, a first conical lens 19 and a second conical lens 20, and the converging lens 18 is used as a ring-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com