Hydraulic cylinder test bench load simulation device and control method thereof

A technology of load simulation and hydraulic cylinder, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems of low test standard, low degree of intelligence, low degree of automation, etc. The effect of spare power and interference, improving detection accuracy, and avoiding errors caused by human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

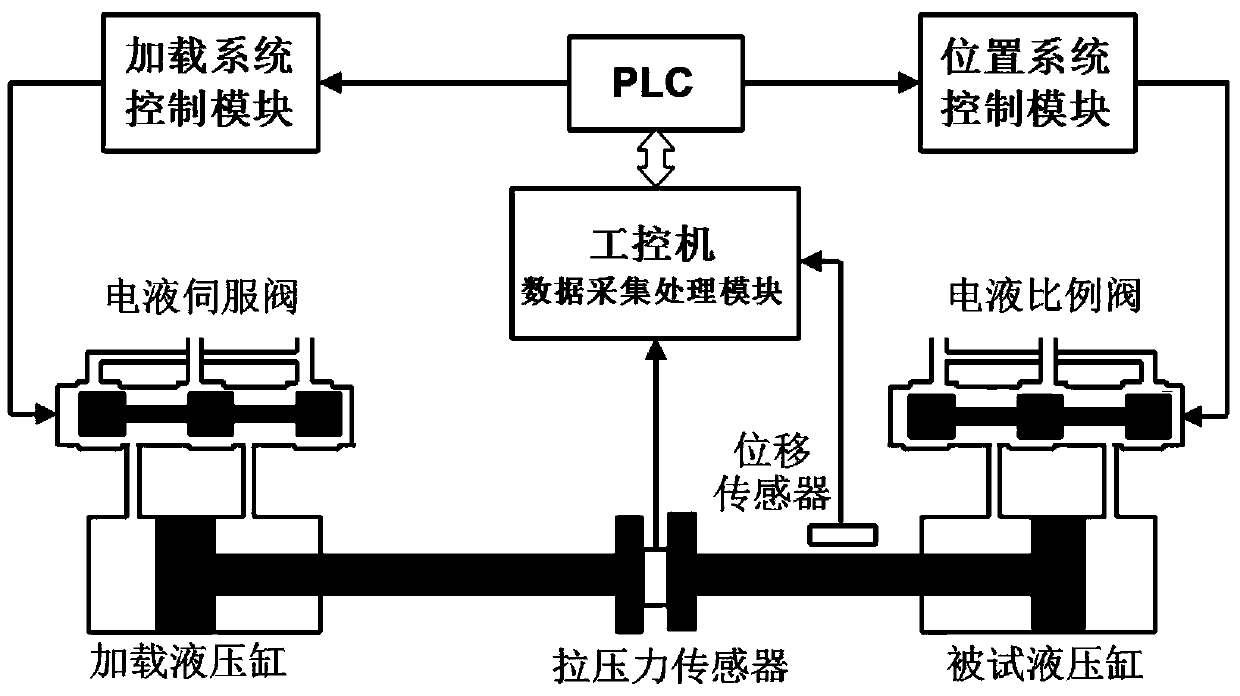

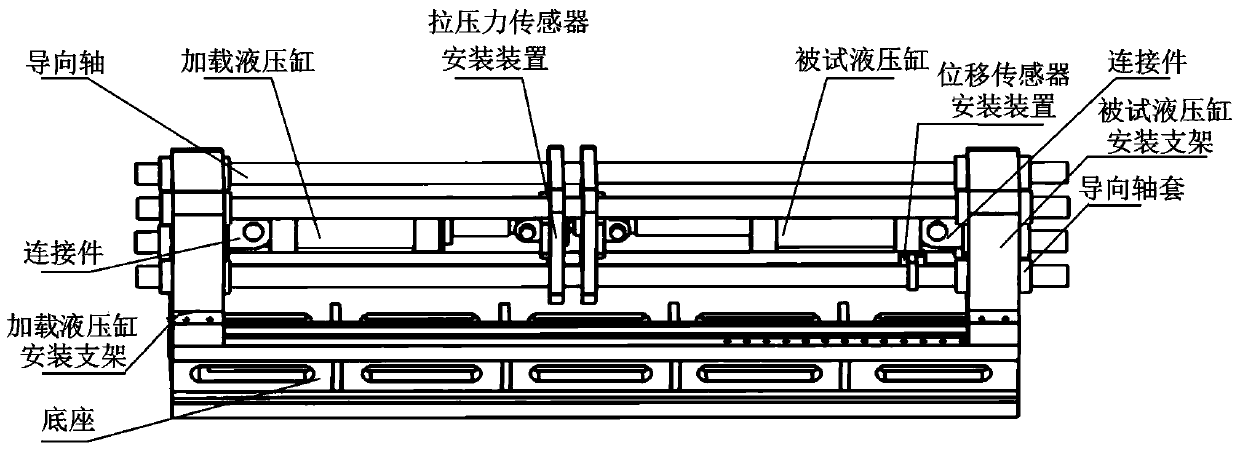

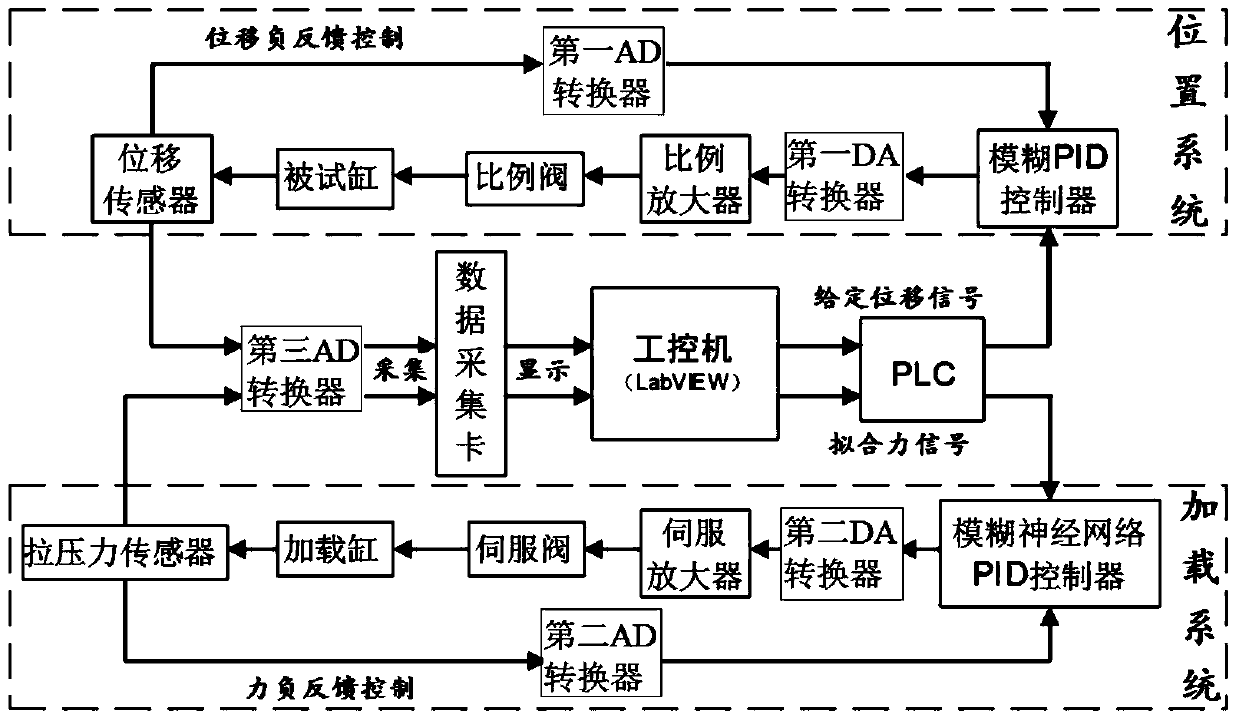

[0023] The principle of the hydraulic cylinder test bench load simulation device of the present invention is as follows: on the hydraulic cylinder test bench, the loading hydraulic cylinder loads the tested hydraulic cylinder to the top, and the fuzzy neural network PID controller is used to eliminate the excess force generated by passive loading; PLC joint monitoring can meet the needs of different hydraulic cylinder ranges. The unique design of the tension and pressure sensor installation device and the displacement sensor installation device can meet the precise detection of the tension pressure and displacement data of this test bench. The electro-hydraulic servo control system of the hydraulic cylinder test bench of the present invention adopts the fuzzy PID control scheme based on the neural network. Through the organic combination of the two, it can fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com