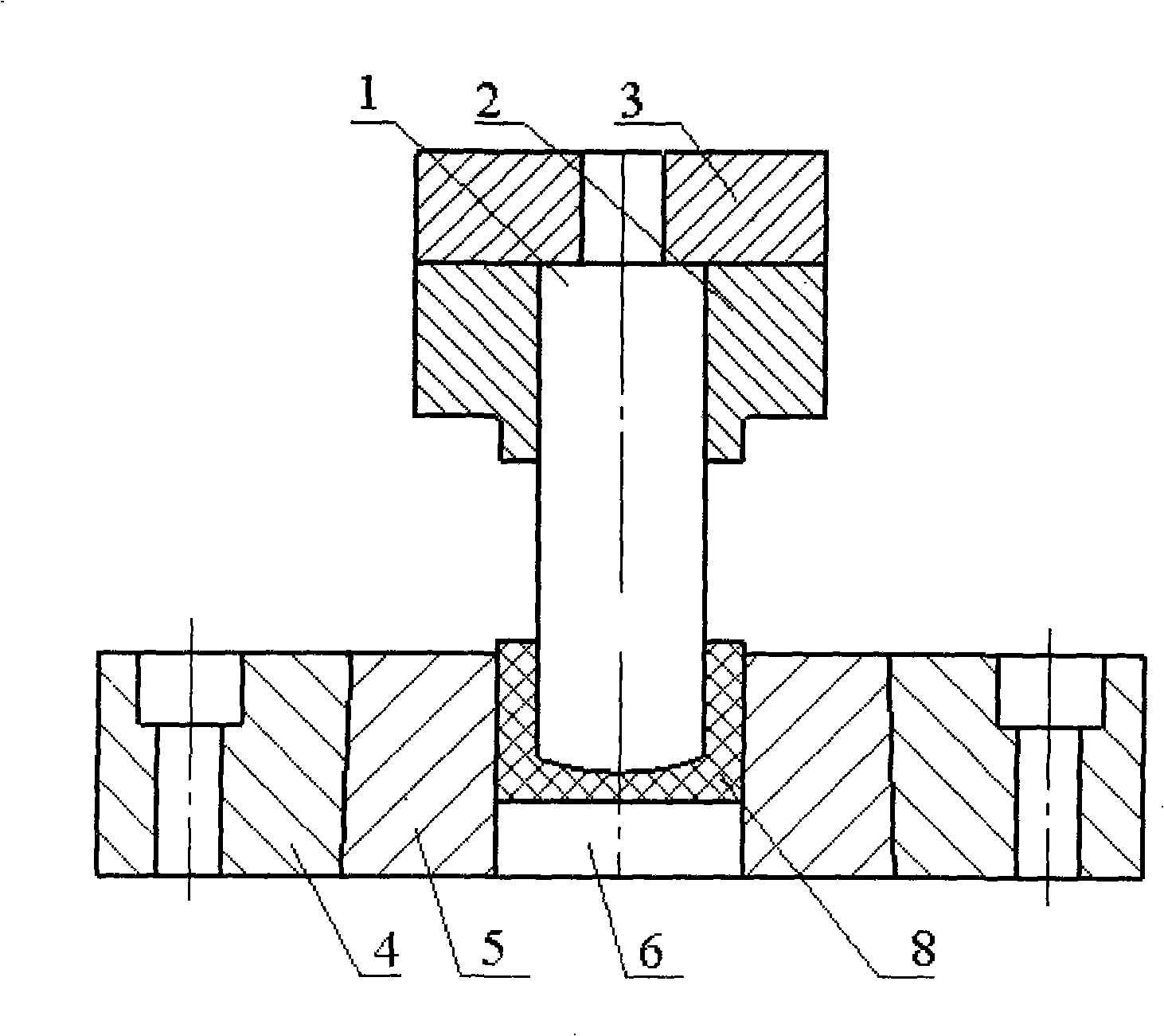

Special-shaped curved surface stator precise compound plasticity shaping process and die

A special-shaped curved surface and plastic forming technology, applied in the field of forging, can solve the problems of high production cost, unsatisfactory, poor wear resistance, etc., and achieve the effect of low cost, solving forming problems, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

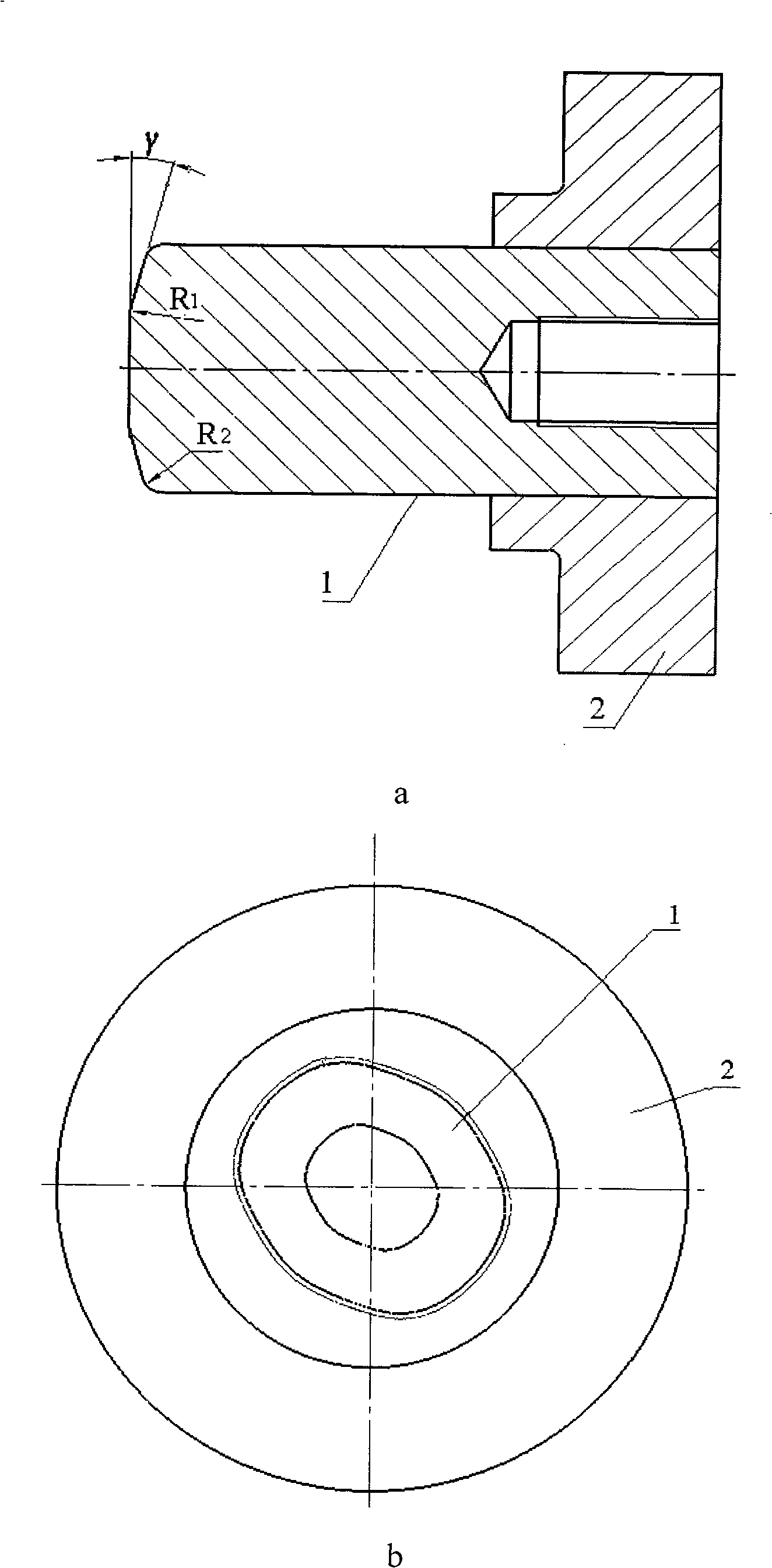

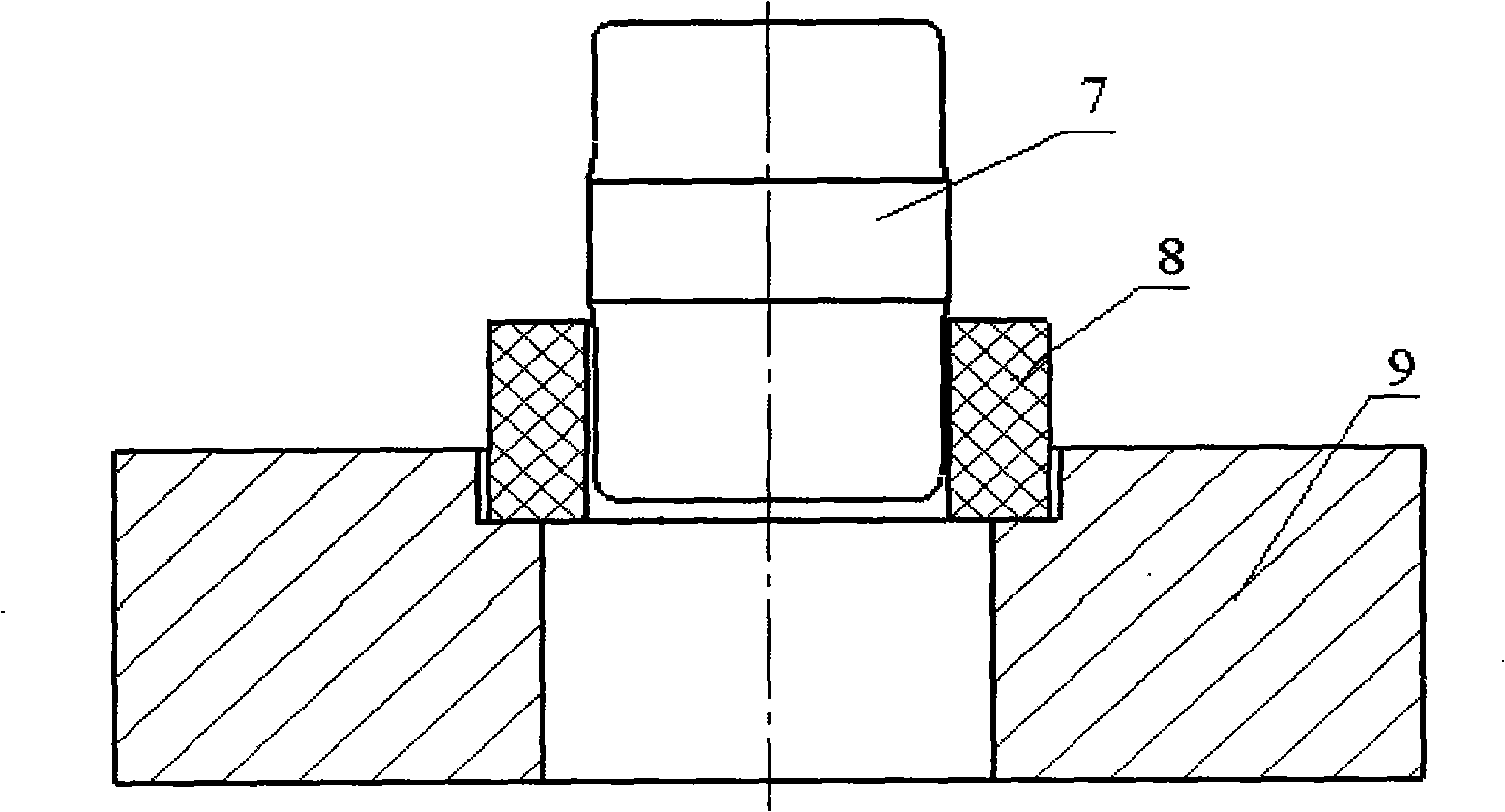

Method used

Image

Examples

Embodiment 1

[0074] Select a bar material with a material of 20CrMnTi and a diameter of Φ65mm, and cut it to obtain an original billet with a length of 26mm. The original billet is heated in a box-type resistance furnace at a heating temperature of 950±10°C and kept for 1 hour; The thermoplastic reverse extrusion mold is preheated, the mold preheating temperature is 200°C, and then the lubricant formed by mixing graphite and gun oil is applied to the working part of the mold to lubricate the mold; the heated billet is placed in the thermoplastic The stator blank is formed by extruding in the reverse extrusion die, and the unilateral machining allowance of the inner cavity surface size of the blank is ≤0.4mm; using the forging waste heat of the blank in a 30KW box-type resistance furnace, the temperature of the stator blank after forging is Under the condition of 730℃~660℃, cooling at a cooling rate of ≤20℃ / h can eliminate residual stress during hot extrusion deformation and reduce material ...

Embodiment 2

[0077]According to the calculation results, select a bar material with a material of GCr15 and a diameter of Φ65mm for blanking to obtain an original billet with a length of 26mm, and place the original billet in a 45KW box-type resistance furnace for heating at a heating temperature of 990±10°C , the holding time is 1 hour; the thermoplastic reverse extrusion mold is preheated, and the mold preheating temperature is 300 ° C, and then the lubricant formed by mixing graphite and gun oil is applied to the working part of the mold to lubricate the mold. The heated billet is extruded in a thermoplastic back-extrusion die to form a stator blank. The unilateral machining allowance of the inner cavity surface size of the blank is ≤0.4mm; the blank is processed in a 30KW box-type resistance furnace by using the forging waste heat Spheroidizing annealing, the annealing temperature is 860±10°C, and the holding time is 3 hours. When the temperature drops to 500°C, it is air-cooled to elim...

Embodiment 3

[0079] According to the calculation results, a bar material with a material of 38CrMoAl and a diameter of Φ65mm was selected for blanking to obtain an original billet with a length of 26mm. The original billet was heated in a 45KW box-type resistance furnace at a heating temperature of 990±10°C , the holding time is 1 hour; the thermoplastic reverse extrusion mold is preheated, and the mold preheating temperature is 400 ° C, and then the mixture of graphite (20%) and gun oil (80%) is painted on the mold; the heated The blank is extruded in a thermoplastic reverse extrusion die to form a stator blank. The machining allowance on one side of the inner cavity surface size of the blank is ≤0.4mm; the blank is quenched and tempered in a 30KW box-type resistance furnace using forging waste heat Treatment, the quenching temperature of this process is 930 ° C ~ 970 ° C, the actual heating temperature is 940 ± 10 ° C, the holding time is 2 hours, after the furnace is air-oil cooled, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Heart hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com