Sapphire (Al2O3 single crystal) growing technology

A sapphire and single crystal technology, applied in the field of sapphire growth technology, can solve the problems of low yield, low crystal quality, affecting the quality and yield of sapphire single crystal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

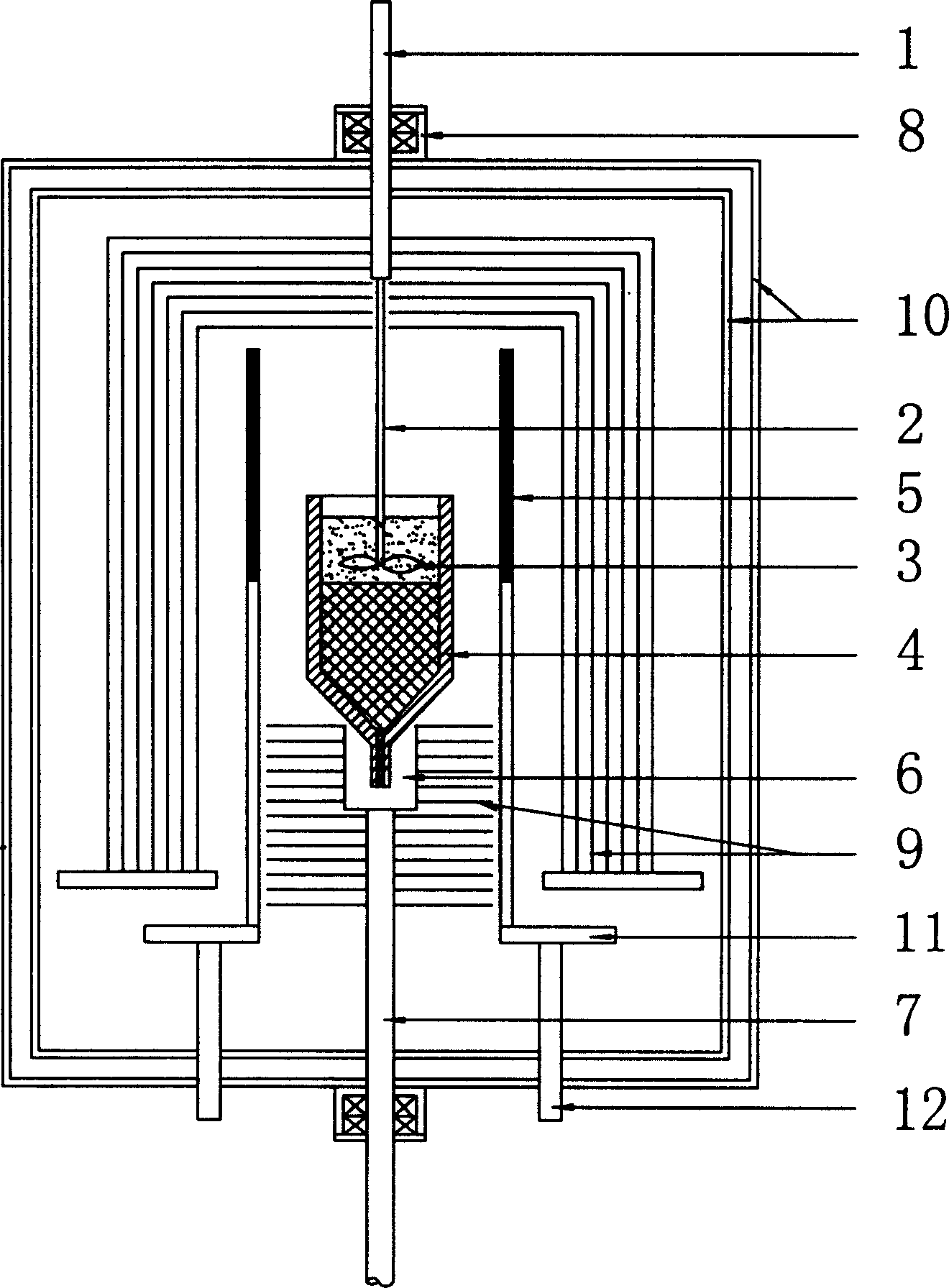

Embodiment Construction

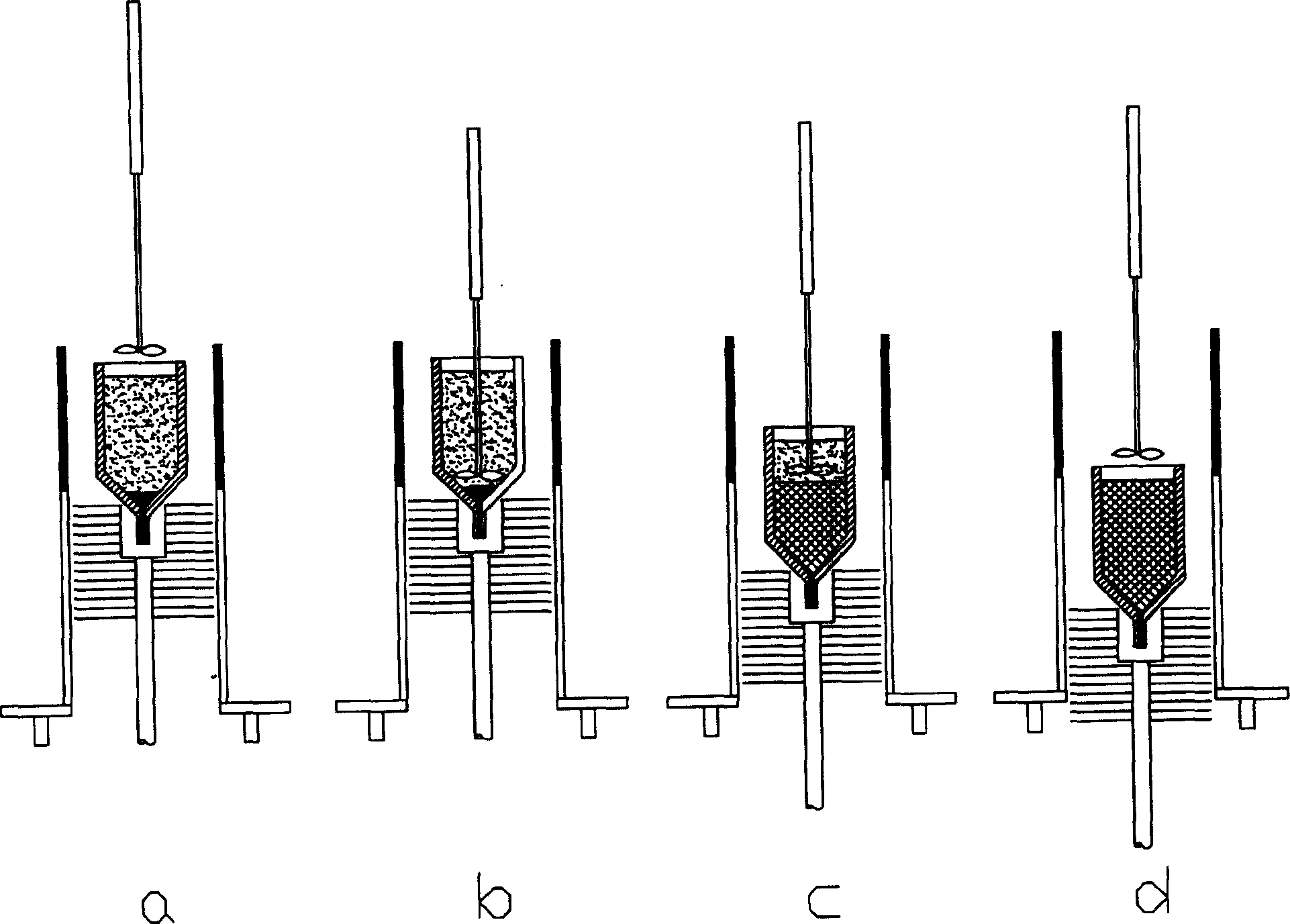

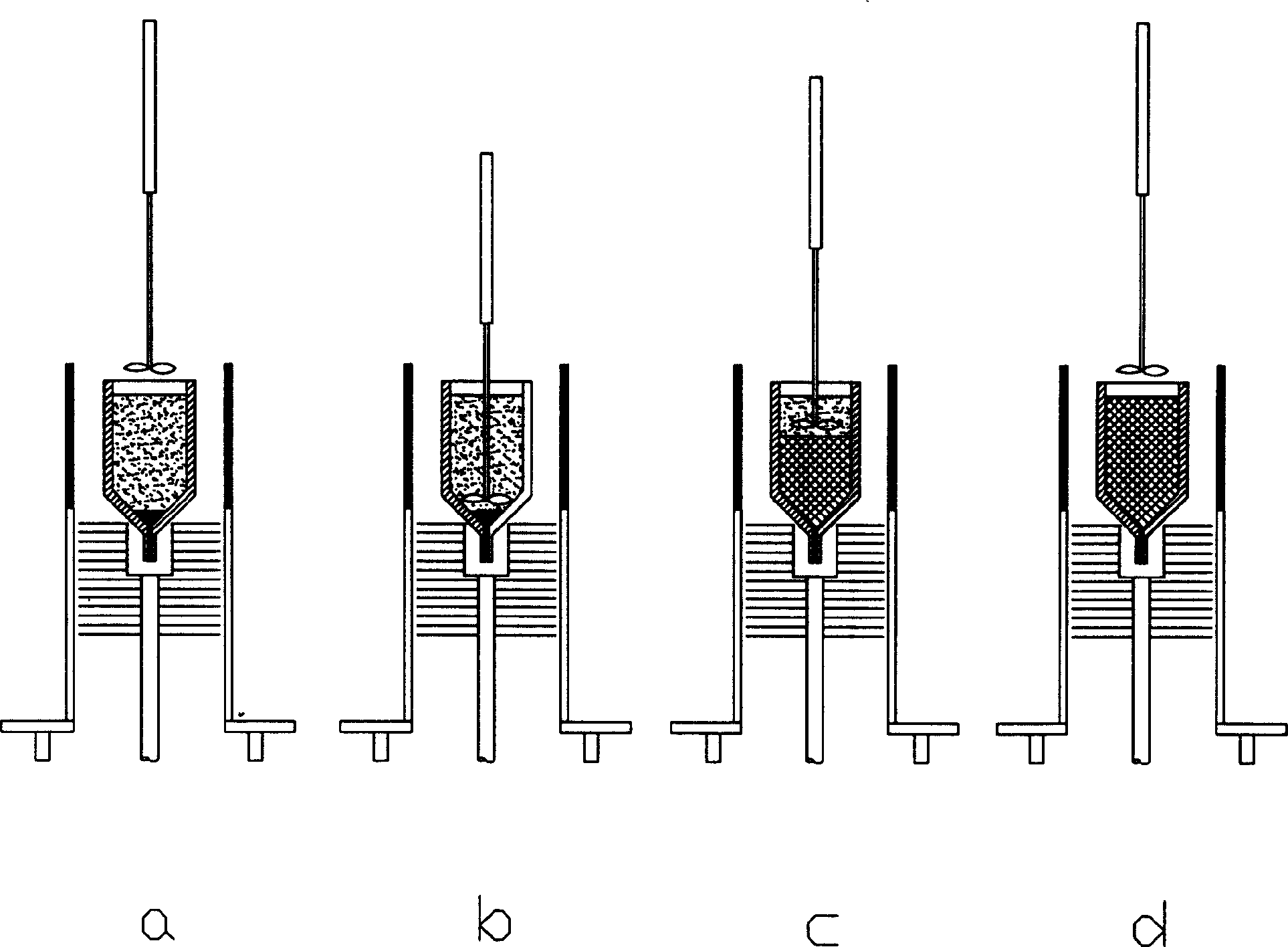

[0016] For the descent method:

[0017] ① if figure 2 As shown in (a), the stirrer is first placed above the crucible. Put the seed crystal in the round tube at the conical bottom of the crucible, and fill the crucible with Al 2 o 3 The raw materials are placed on the crucible holder on the crucible rod, and the whole system is evacuated and then filled with protective gas. Heating the Al in the crucible 2 o 3 The raw materials are all melted and the seed crystals at the bottom remain crystalline.

[0018] ② if figure 2 As shown in (b), after a "solid-liquid" interface is formed between the seed crystal and the melt, move the stirrer down until the stirring blade enters the melt to a position above the "solid-liquid" interface.

[0019] ③ if figure 2 As shown in (c), turn the stirrer, move down the crucible rod and the crucible into the heat preservation zone, as the crucible enters the heat preservation zone, the melt in the crucible will slowly crystallize from bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com