Hot reverse-extrusion forming mold for large cup shell

A technology of hot back extrusion and forming die, applied in the direction of metal extrusion die, etc., can solve the problems of reducing the forming force of the generator guard ring hot forging ring blank, reducing the hot back extrusion forming force, low production efficiency, etc. , to achieve obvious labor-saving effect, reduce the back extrusion molding force, and improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

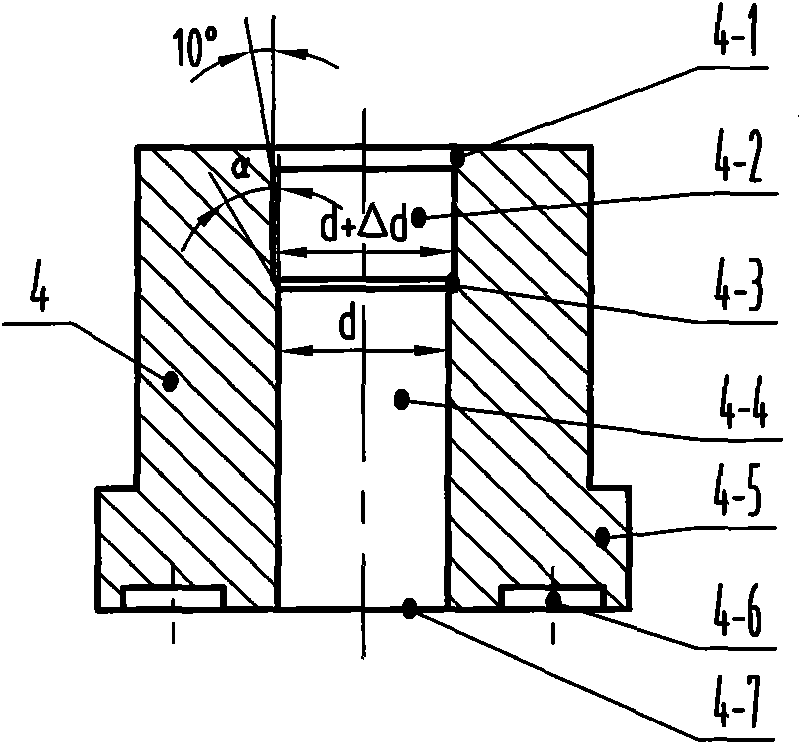

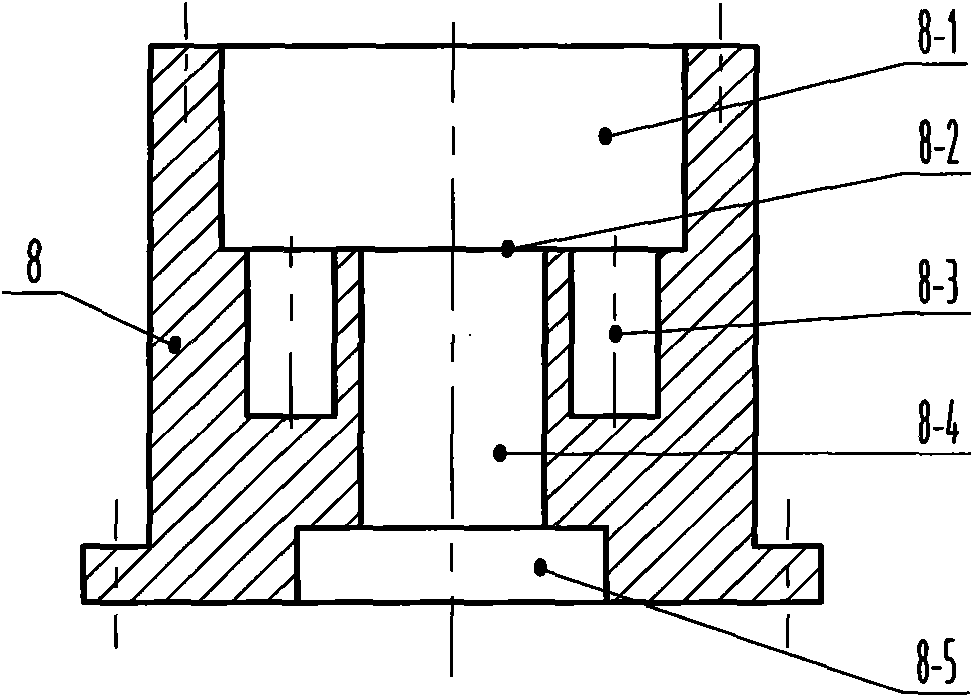

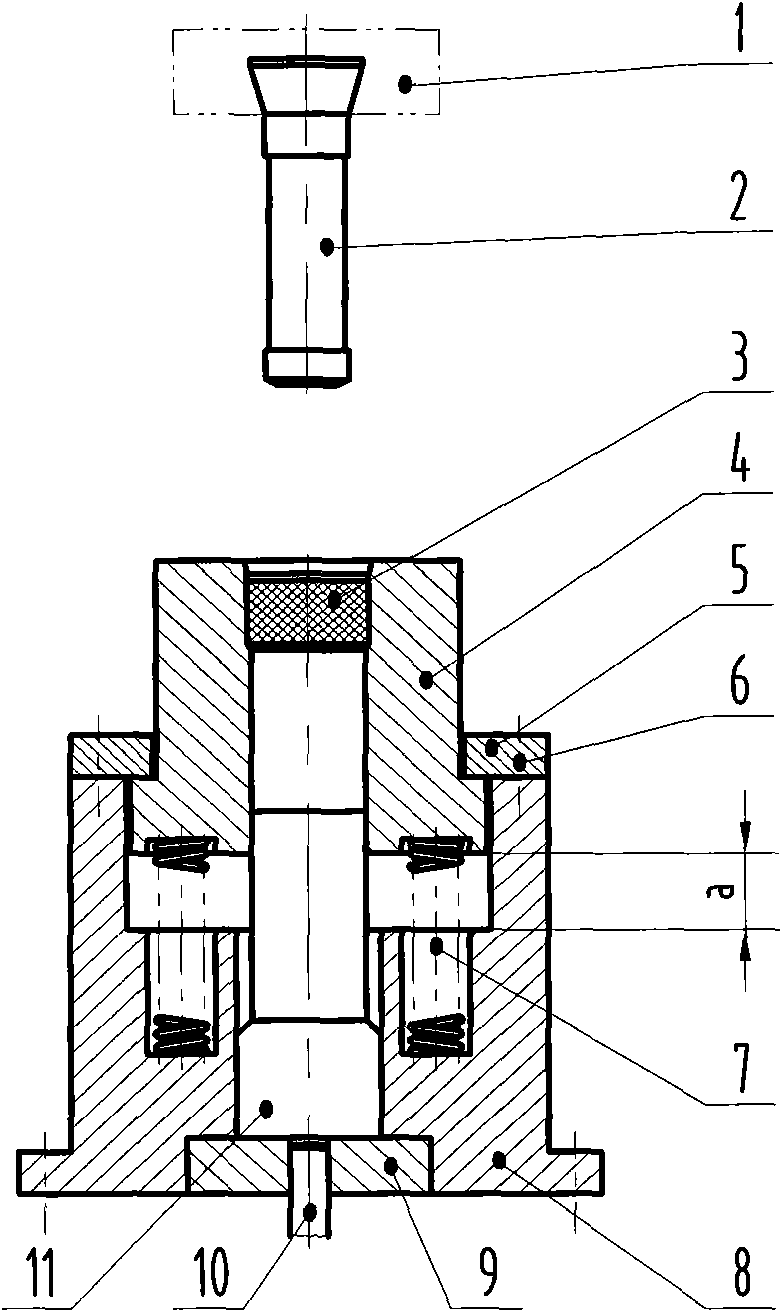

[0029] Such as Figure 1 to Figure 9 As shown, a hot reverse extrusion molding die for large cup-shaped parts includes: reverse extrusion punch 2, reverse extrusion cylinder 4, flange 5, bolt 6, cylindrical helical compression spring 7, base 8, pressure bearing Backing plate 9, ejector rod 11; the back-extrusion punch 2 is assembled on the press head 1; the inner cavity of the back-extrusion cylinder 4 is composed of two concentric cylinders with different inner diameters, and the upper part is The material holding chamber 4-2, the lower part is the back extrusion chamber 4-4, the inner diameter (d+Δd) of the said material holding chamber 4-2 is larger than the inner diameter d of the back extrusion chamber 4-4 by Δd, so There is a transition step 4-3 with an angle of α between the material holding chamber 4-2 and the reverse extrusion chamber 4-4, where α=10°~45°; the lower end of the reverse extrusion cylinder 4 has a Limiting steps 4-5; the lower end of the anti-extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com