Ball-spinning device and method of integrated outer ring typed self-lubricating spherical plain bearing

A joint bearing and integral outer ring technology, which is applied in the field of joint bearing processing and manufacturing, can solve the problems of low product yield, low reliability of self-lubricating layer, crush damage, etc., and achieve small impact, bearing life and reliability Good effect of improvement and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

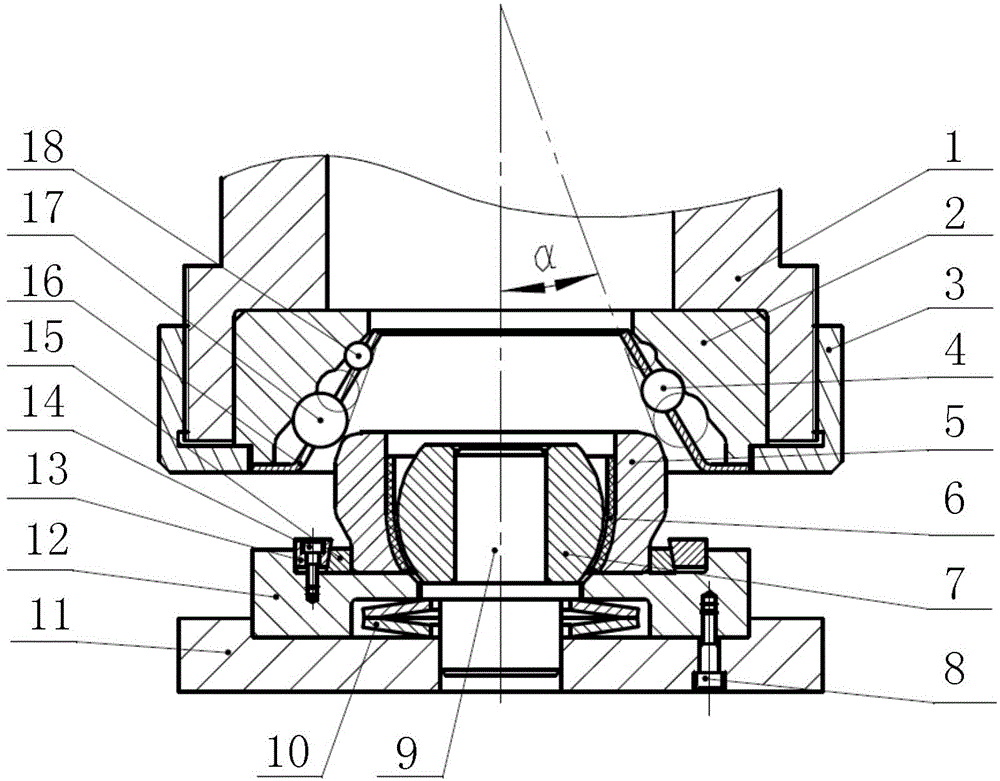

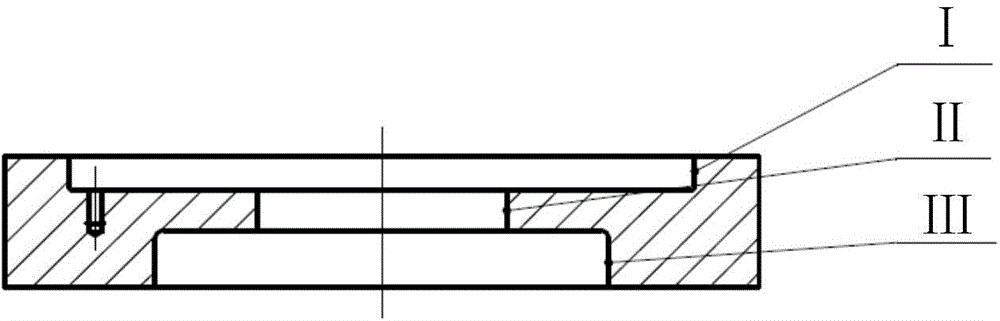

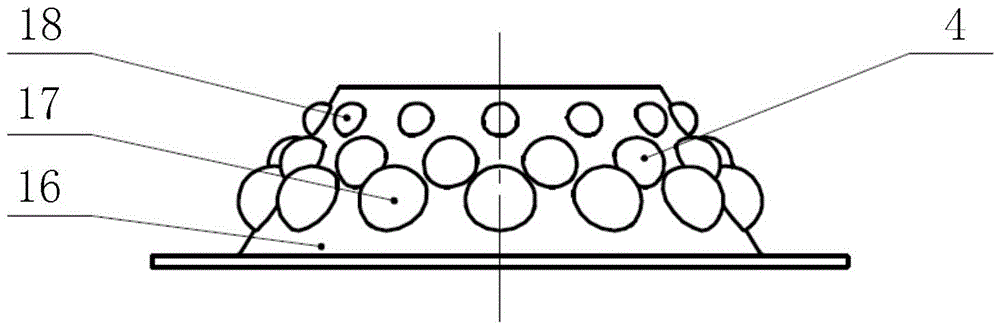

[0025] attached Figure 1-3 Disclosed is a ball spinning forming device for an integral outer ring type self-lubricating joint bearing. The forming device includes an upper mold base 1, a lock nut 3, a bottom plate 11, a driving device and a workbench. The upper part of the upper die base 1 is connected with the driving equipment, and the inner tapered surface ring 2 in the installed upper die base 1 is processed with three groups of roller tables that are respectively matched with the large, medium and small groups of balls. The cage 16 is installed on the inner cone ring 2 to constrain the three groups of large, medium and small balls in their corresponding roller tables, and the lock nut 3 fixes the inner cone ring 2 on the upper die base 1 . Mandrel 9 is housed in the center counterbore of base plate 11, and base plate 11 is connected with lower mold 12 by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com