Sensor module

a technology of sensor arrays and modules, applied in the field of sensors, can solve the problems of difficult production and maintenance of such sensor arrays, and achieve the effects of convenient separation, easy combination with each other, and effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

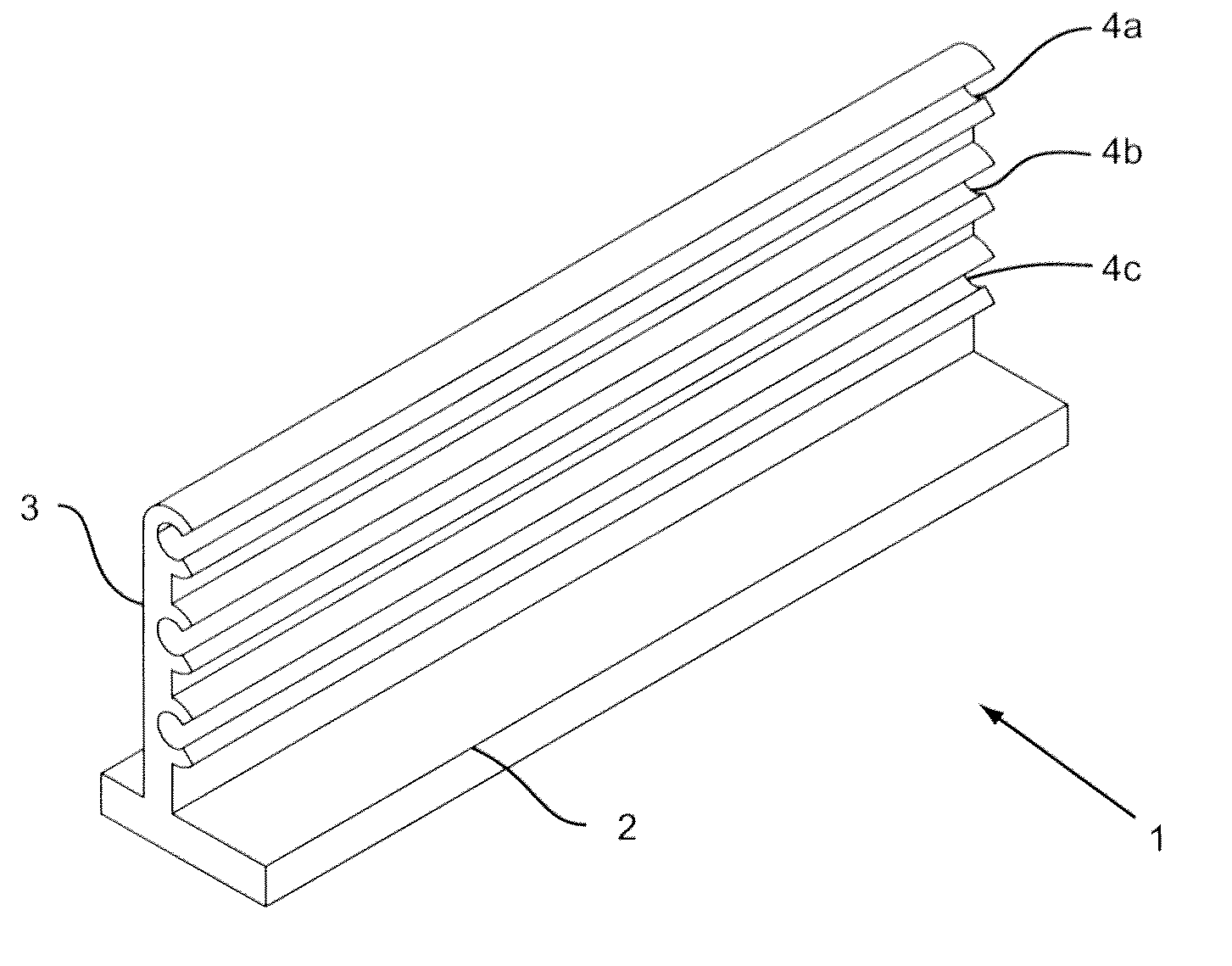

[0029]FIG. 1 shows a carrier 1 which possesses a fastening segment 2 and a mount segment 3. The mount segment 3 contains recesses 4A, 4B, 4C which serve to receive the electrodes. The carrier 1 is formed as an extrusion body out of plastic. The recesses 4A, 4B, 4C each possess circular empty spaces within their cross-sections, which are opened along a circular segment. Cables or wires can be pressed in through these openings to be held within the recesses.

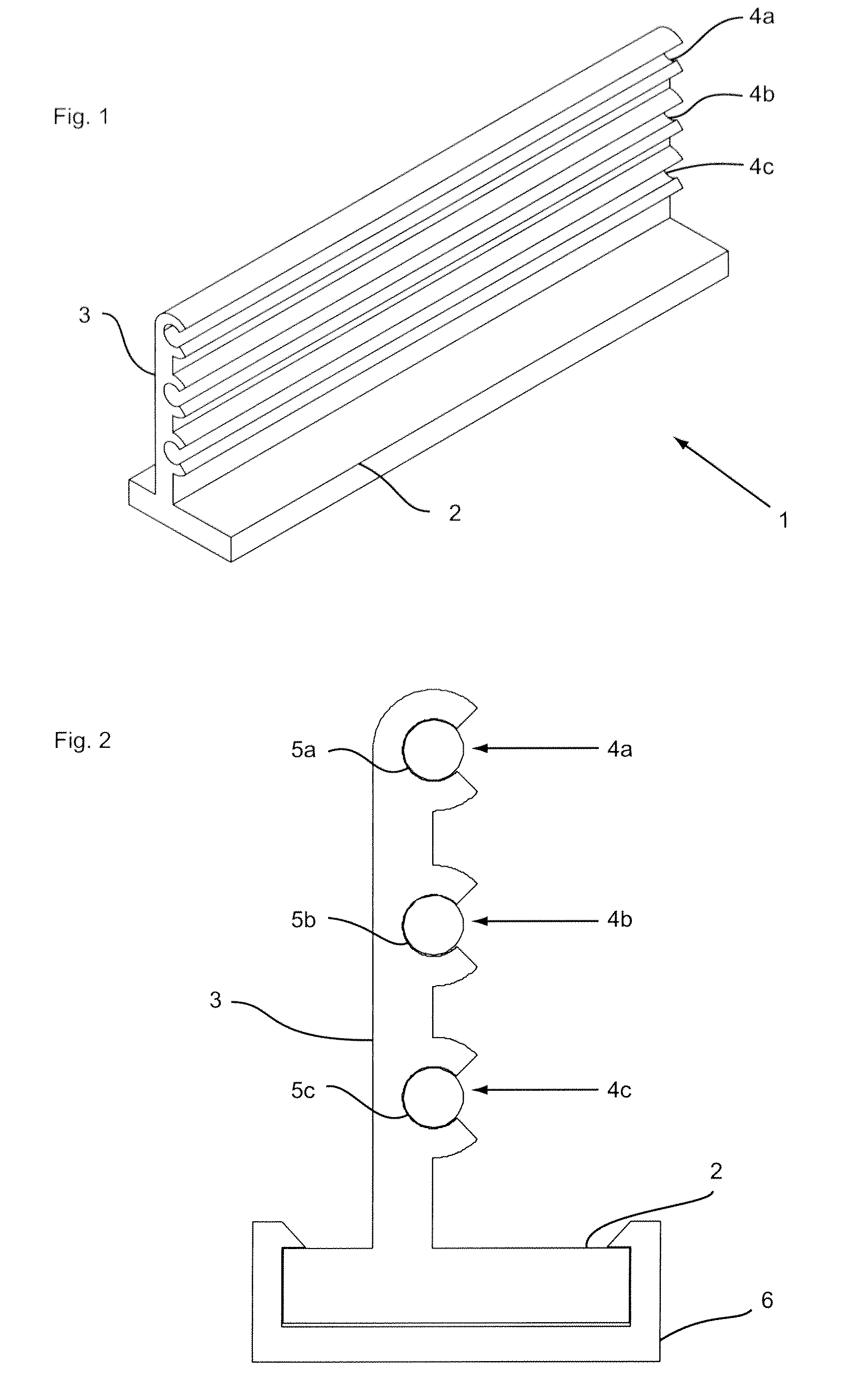

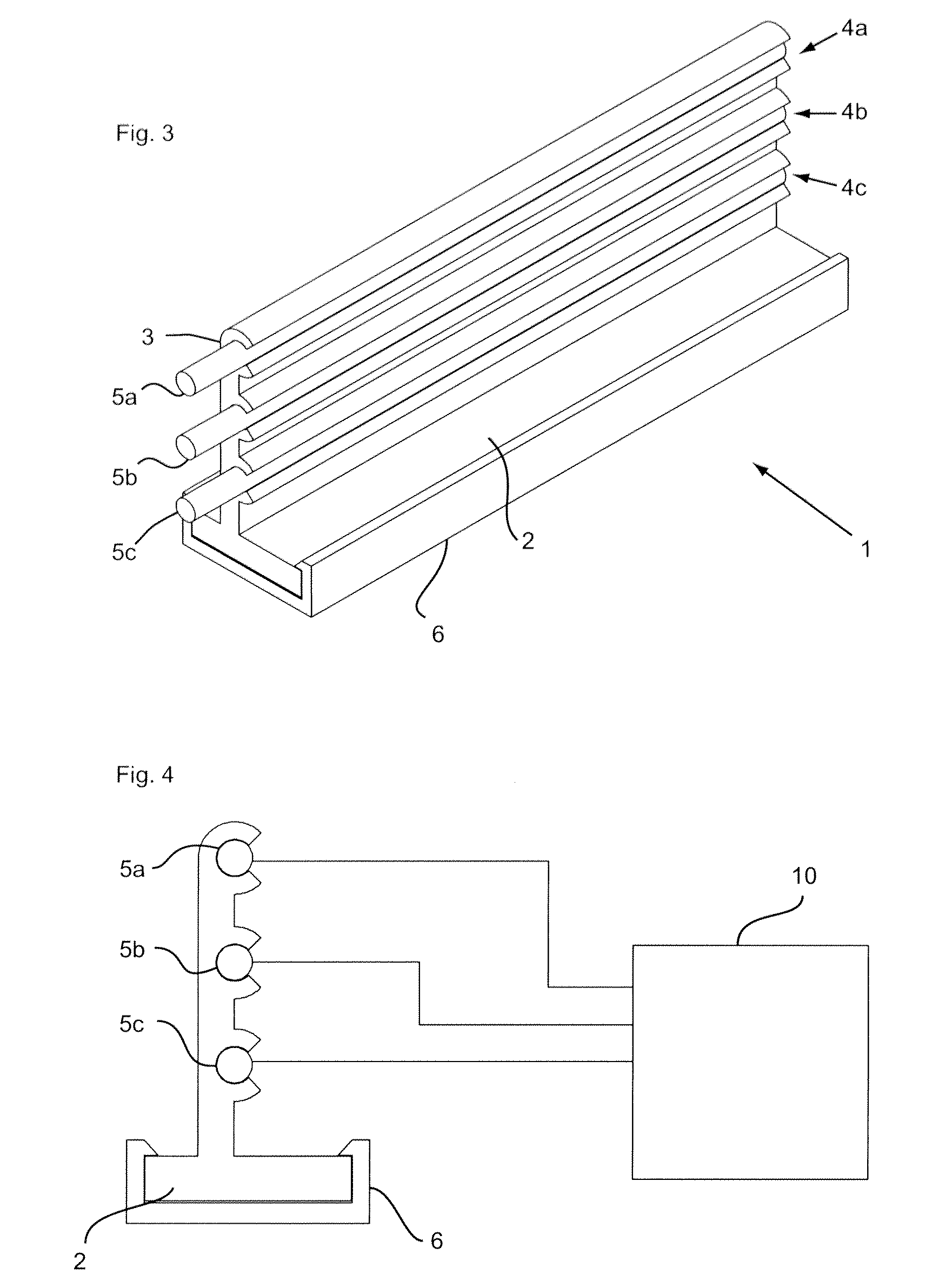

[0030]FIG. 2 shows the carrier with inserted electrodes 5A, 5B and 5C as well as a fastening clip 6.

[0031]The electrode 5A is placed in the recess 4A, the electrode 5B in the recess 4B, and the electrode 5C in the recess 4C.

[0032]The clip grasps around the fastening segment 2, fixing it firmly in place. The clip 6 has suitable elasticity and angled receiving edges in order to allow easy insertion of the fastening segment 2 into the clip 6.

[0033]This view shows that the wires or cables 5A, 5B, 5C are held in their respective inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com