Material fluidity control method for metal plate forming

A metal sheet and control method technology, which is applied in the field of metal forming and manufacturing, can solve the problems of limited increase of forming depth, insignificant processing effect of large drawing ratio, and inability to achieve flexible control of the fluidity of sheet metal materials. Achieve the effect of increasing the ultimate drawing coefficient and suppressing wrinkling and tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

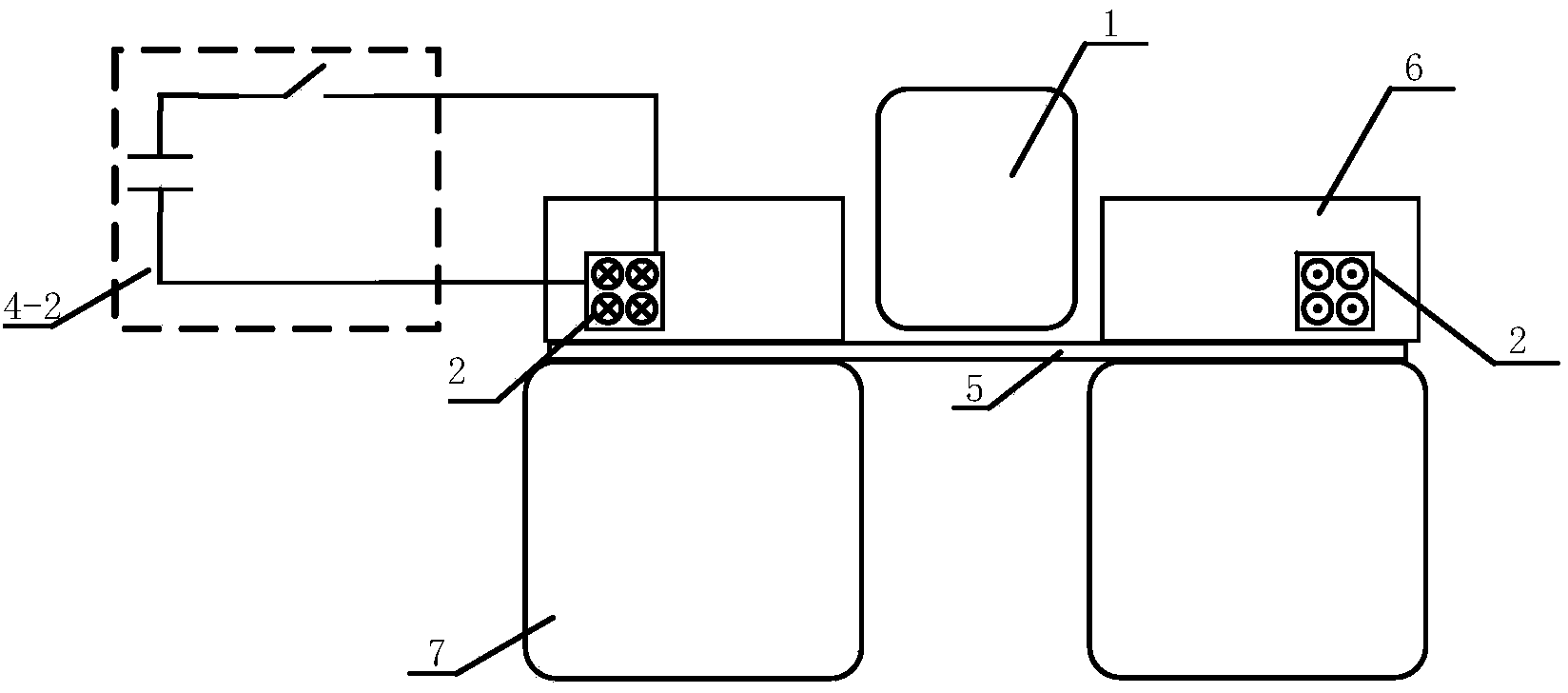

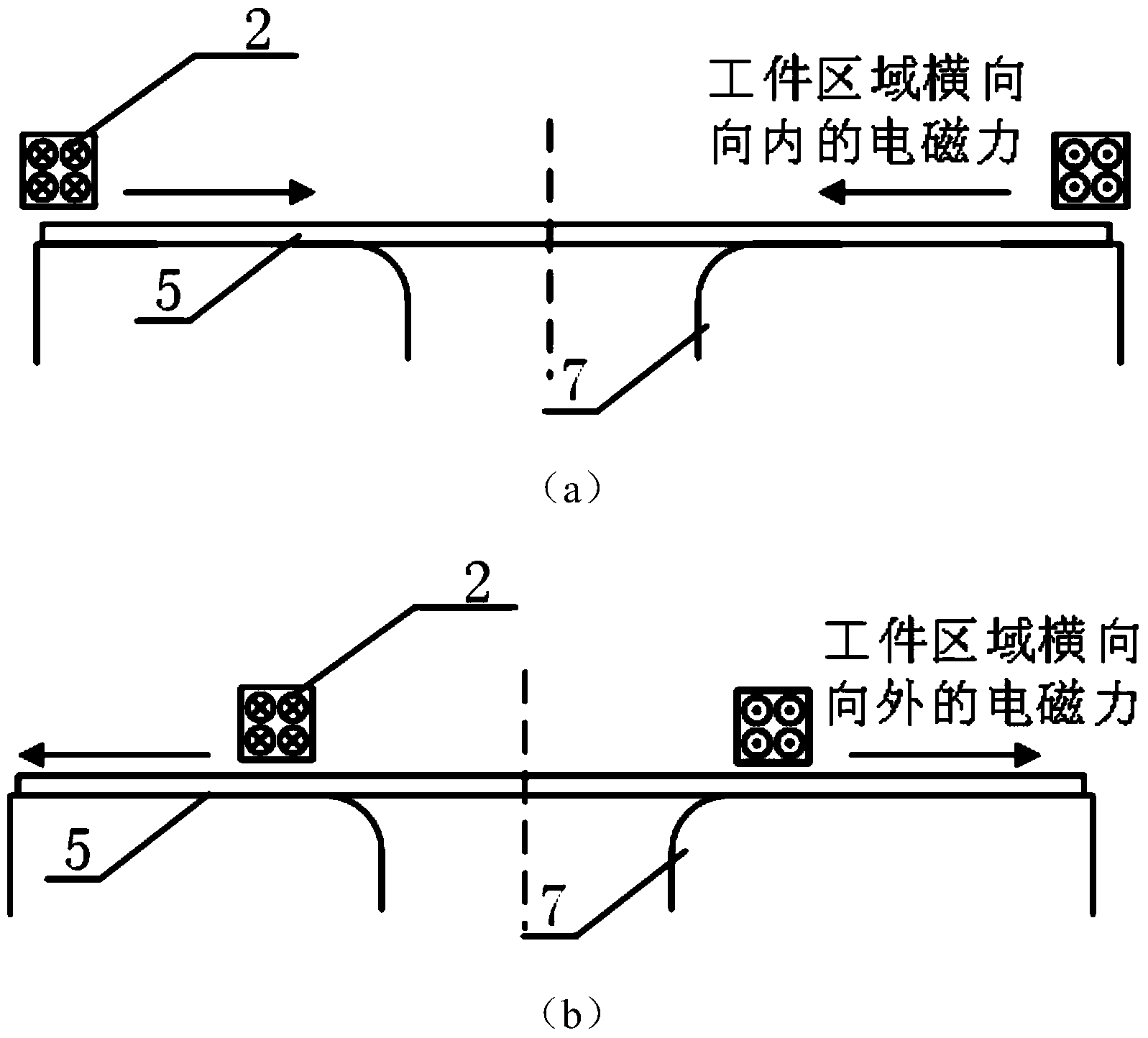

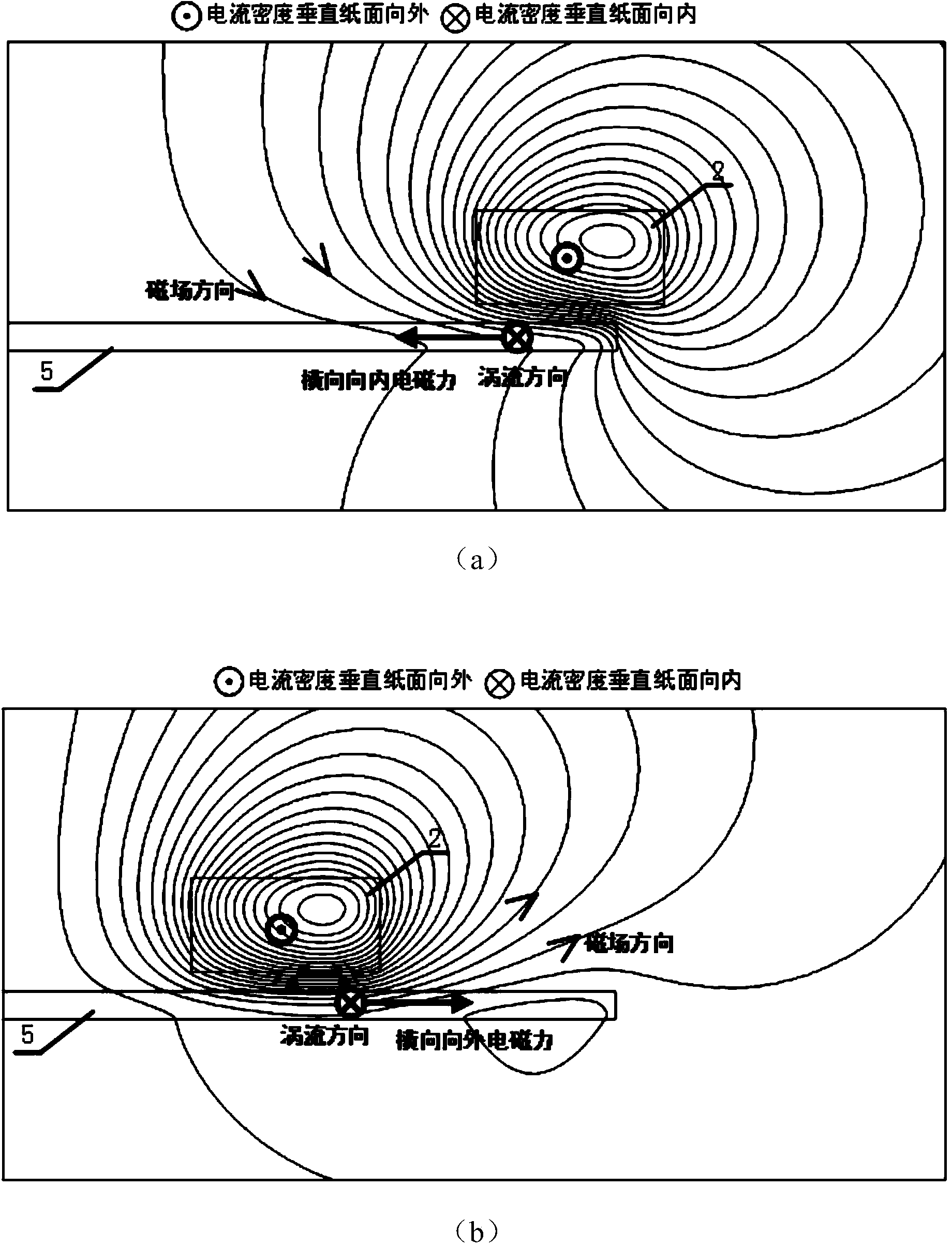

[0044] like figure 1 As shown, the sheet metal forming device includes a punch 1 , an eddy current coil 2 , a first pulse power supply 4 - 2 , a blank holder 6 and a die 7 . The metal sheet 5 is placed on the die 7, the punch 1 and the blank holder 6 are placed on the metal sheet 5, the punch 1 corresponds to the cavity of the die 7, the eddy current coil 2 is embedded in the blank holder 6, the first The pulse power supply 4-2 is connected to the eddy current coil 2.

[0045] The blank holder 6 provides blank-holding force for the metal sheet 5, the punch 1 provides the axial forming force for the metal sheet 5, and the first pulse power supply 4-2 provides timing and energy-controllable discharge for the eddy current coil 2, so that the eddy current coil 2 During the discharge process, a huge pulse current flows (the pulse width is between tens of microseconds and several milliseconds, and the current amplitude reaches tens of kiloamperes or even hundreds of kiloamperes), a...

Embodiment 2

[0057] like Figure 7 As shown, the sheet metal forming device includes a punch 1, an eddy current coil 2, an axial magnetic field coil 3, a first pulse power supply 4-2, a second pulse power supply 4-3, a blank holder 6 and a die 7. The metal plate 5 is placed on the die 7, the punch 1 and the blank holder 6 are placed on the metal plate 5, the punch 1 corresponds to the cavity of the die 7, the eddy current coil 2 is embedded in the blank holder 6, and the axial The magnetic field coil 3 is arranged on the periphery of the eddy current coil 2 and generally has more turns. The first pulse power supply 4-2 is connected to the eddy current coil 2, and the second pulse power supply 4-3 is connected to the axial magnetic field coil 3.

[0058] The blank holder ring 6 provides the blank holder force for the sheet metal 5 , and the punch 1 provides the axial forming force for the sheet metal 5 . The second pulse power supply 4-3 provides timing and energy controllable discharge fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com