Making process of large irregular ring blank of high temperature alloy

A high-temperature alloy and special-shaped cross-section technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammering machinery, etc., can solve the problems of increased machining costs, large tonnage, and short life, and achieves simple structure and easy manufacturing , The effect of saving the cost of machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] To implement the billet making method of the high-temperature alloy large-scale special-shaped cross-section ring blank described in the present invention, it is necessary to provide a forging heating furnace, a forging press, a rolling machine, a bulging die and a high-temperature alloy rod.

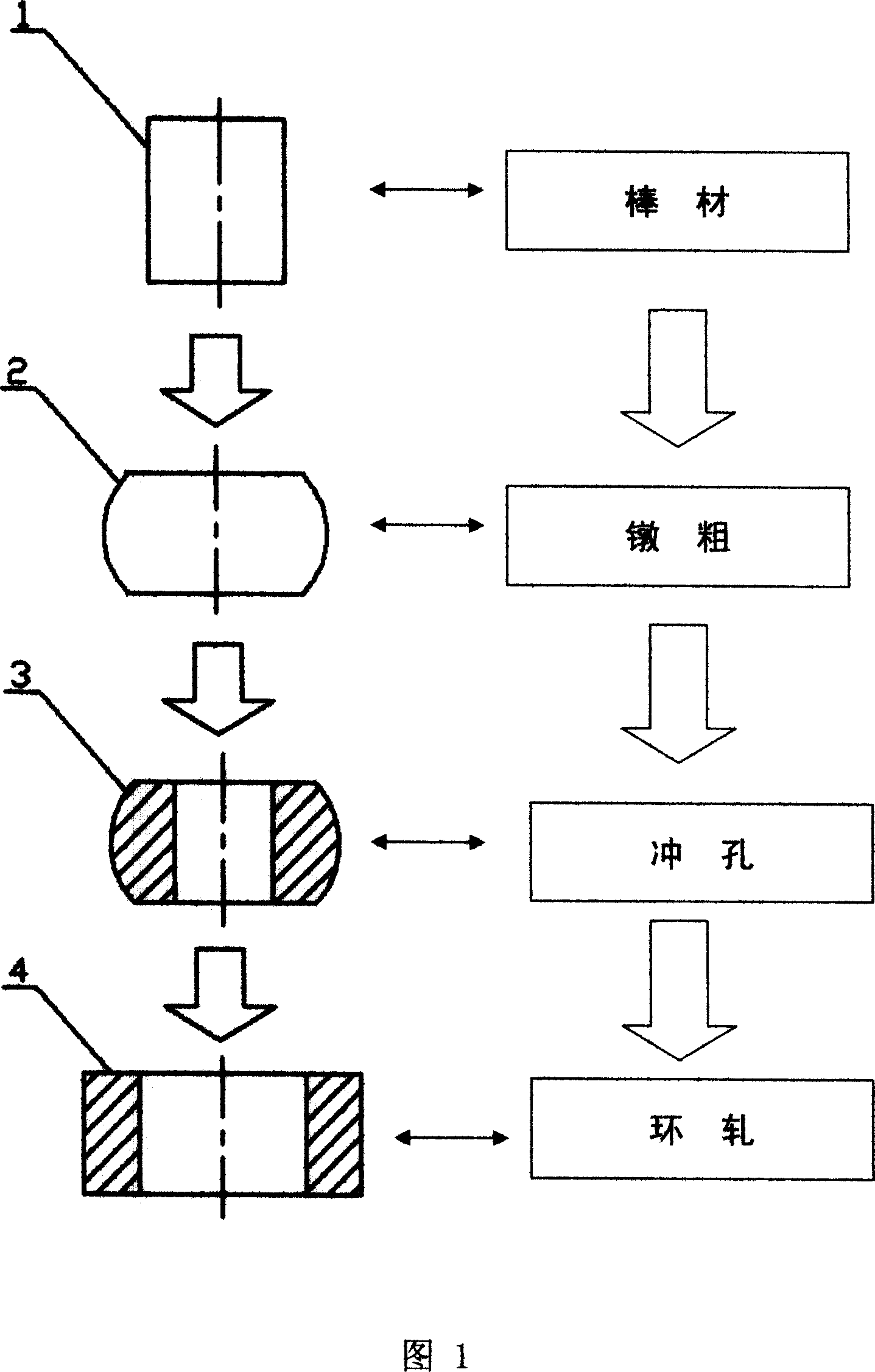

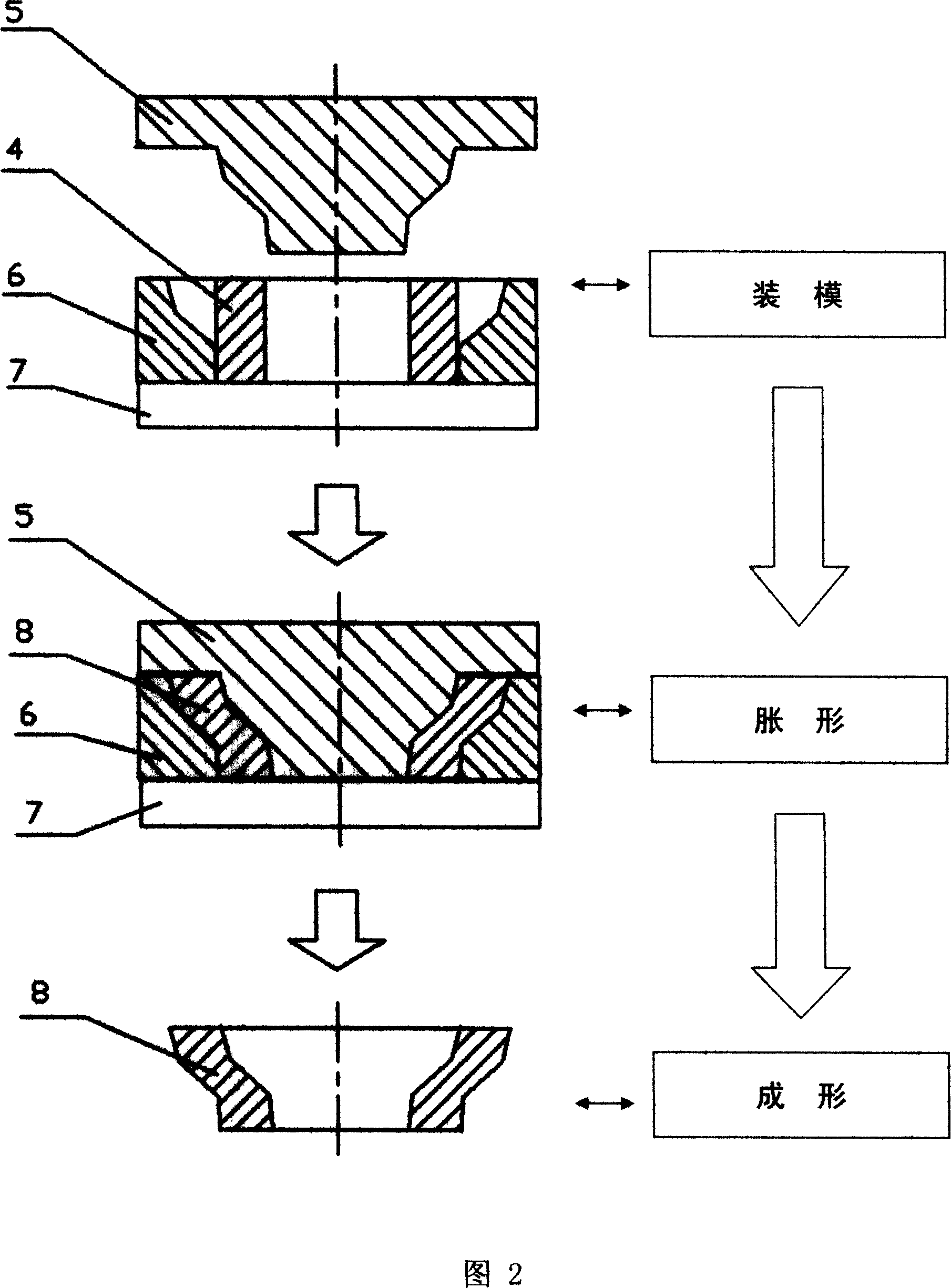

[0017] Fig. 1 shows the billet making process flow of superalloy large rectangular cross-section ring billet, and Fig. 2 shows the billet making process flow of using the rectangular cross-section ring billet shown in Fig. 1 to make the special-shaped cross-section ring billet according to the present invention. The process flow shown in Fig. 1 and Fig. 2 completely expresses the billet making method of the superalloy large-scale special-shaped cross-section ring billet of the present invention, and its operation steps are as follows:

[0018] Step 1: Upsetting. The high-temperature alloy bar 1 blanked according to the forging specification is heated to the deformation temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com