Middle-duty and heavy-duty automobile knuckle stamp forging extruding compound technology

A composite process, heavy-duty vehicle technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of low material utilization rate and large investment, and achieve high material utilization rate, The effect of small equipment investment and short manufacturing cycle of process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

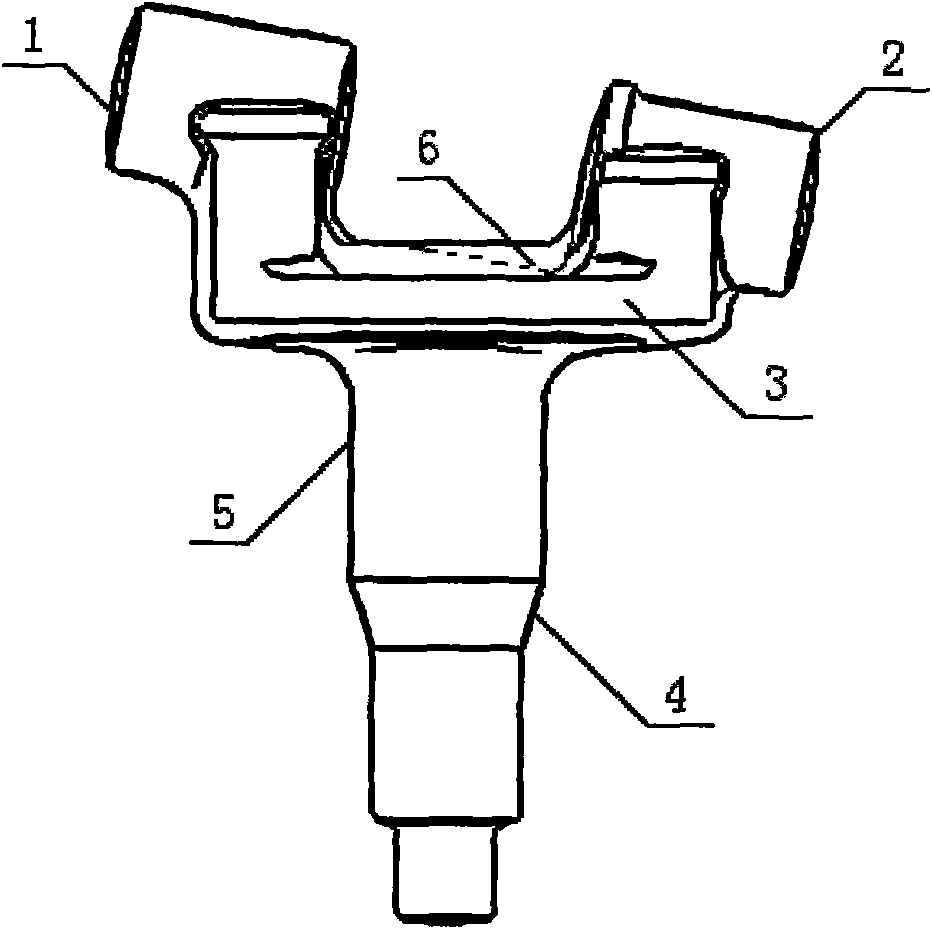

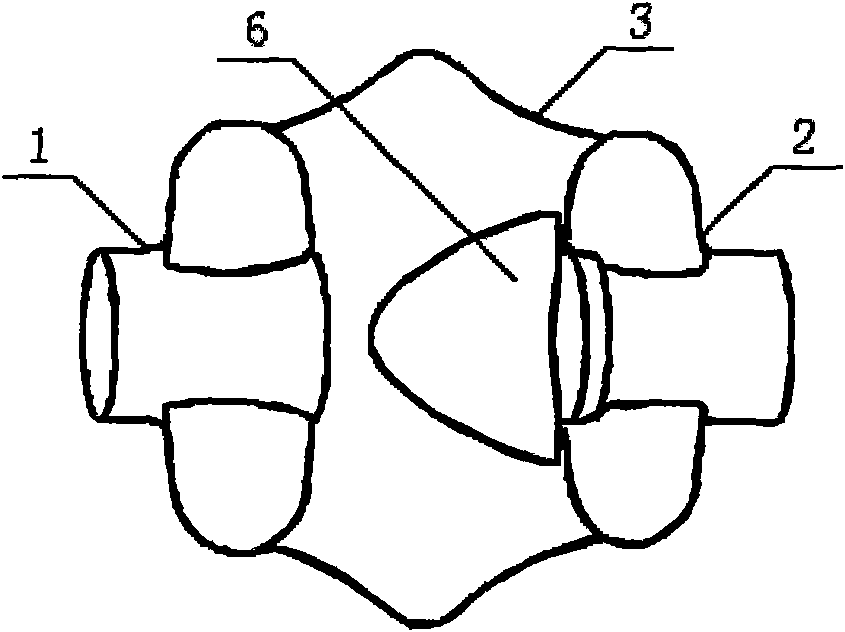

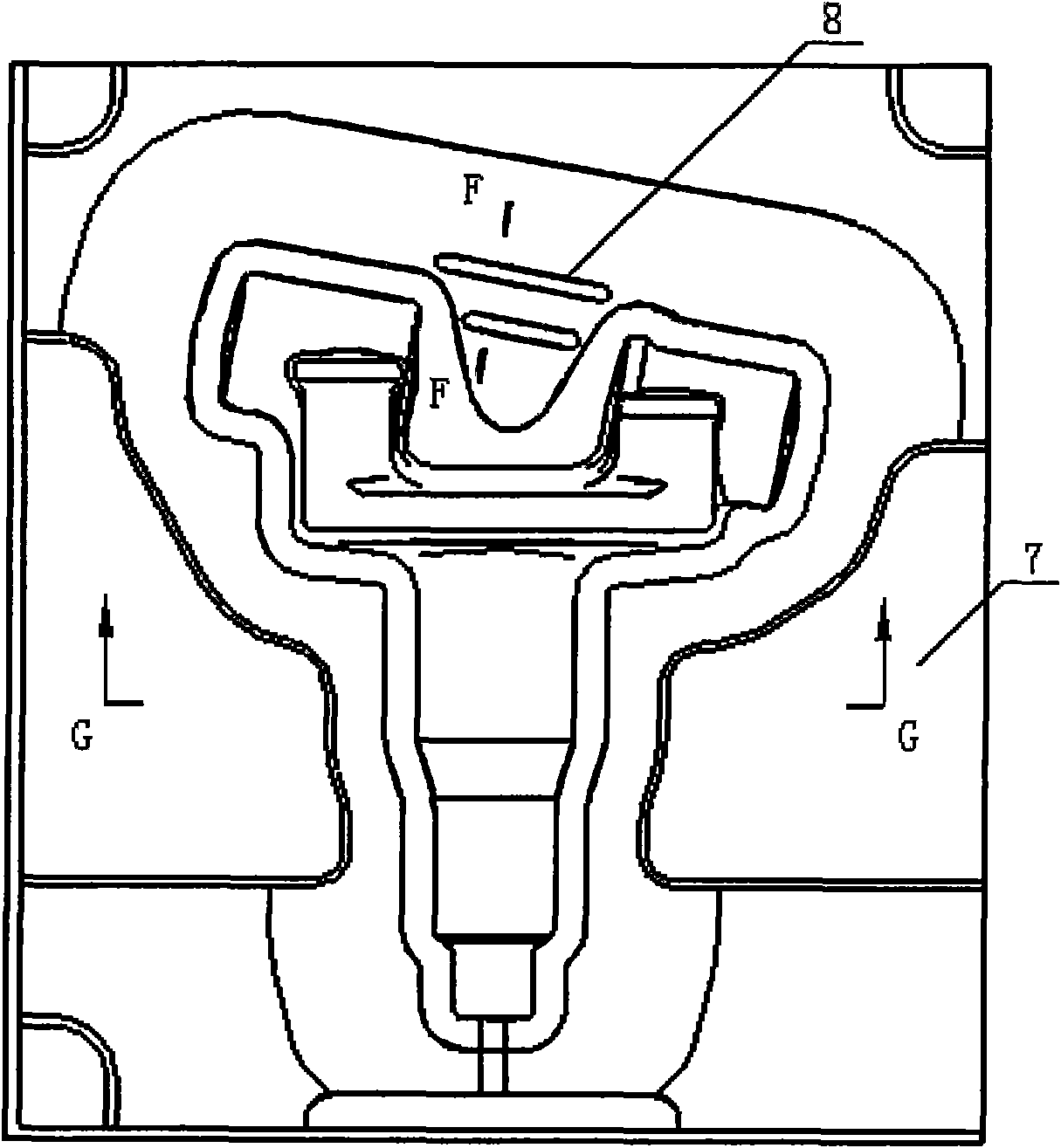

[0047] Below in conjunction with accompanying drawing, take the 909 type automobile steering knuckle exported to India TATA Automobile Group Company as an example to illustrate the present invention, as figure 1 , figure 2 , the steering knuckle die forging forging process is as follows:

[0048] 1. Cutting: Adopt GB4025C band saw machine to cut φ100 round steel with a length of 248±2mm;

[0049] 2. Heating: Use KGPS800-1 medium frequency induction heating furnace to heat the round bar to the temperature required by the forging process;

[0050]3. Blank pre-forging and forming forging: 3T die forging hammer is used to forge the four-step process of pulling out the long rod, flattening the ear, vertically splitting the billet and pre-forging. The four-step process forging is located on a multi-cavity mold body conduct;

[0051] The billet pre-forging die and its partial cross-section are as follows: Figures 14 to 20 As shown, it is drawn out in the rod cavity 10, the late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com