Machine for processing head of pipe fitting

A technology of pier head machine and pipe fittings, which is applied to swage forging presses, upsetting forging presses, driving devices of forging presses, etc., can solve the problems of insufficient joint pipe strength, difficulty in meeting requirements, high production costs, etc., and achieve easy operation, Easy processing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

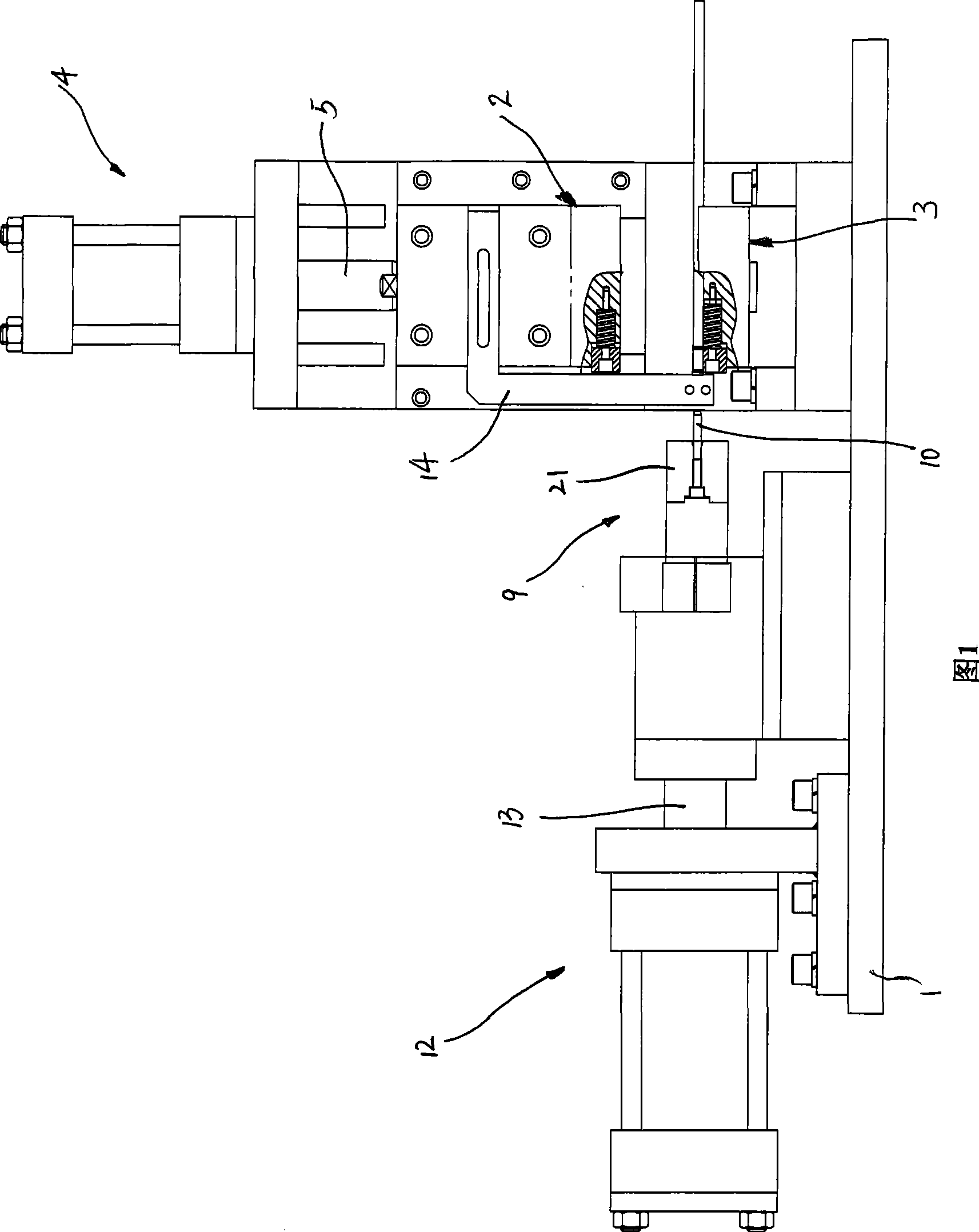

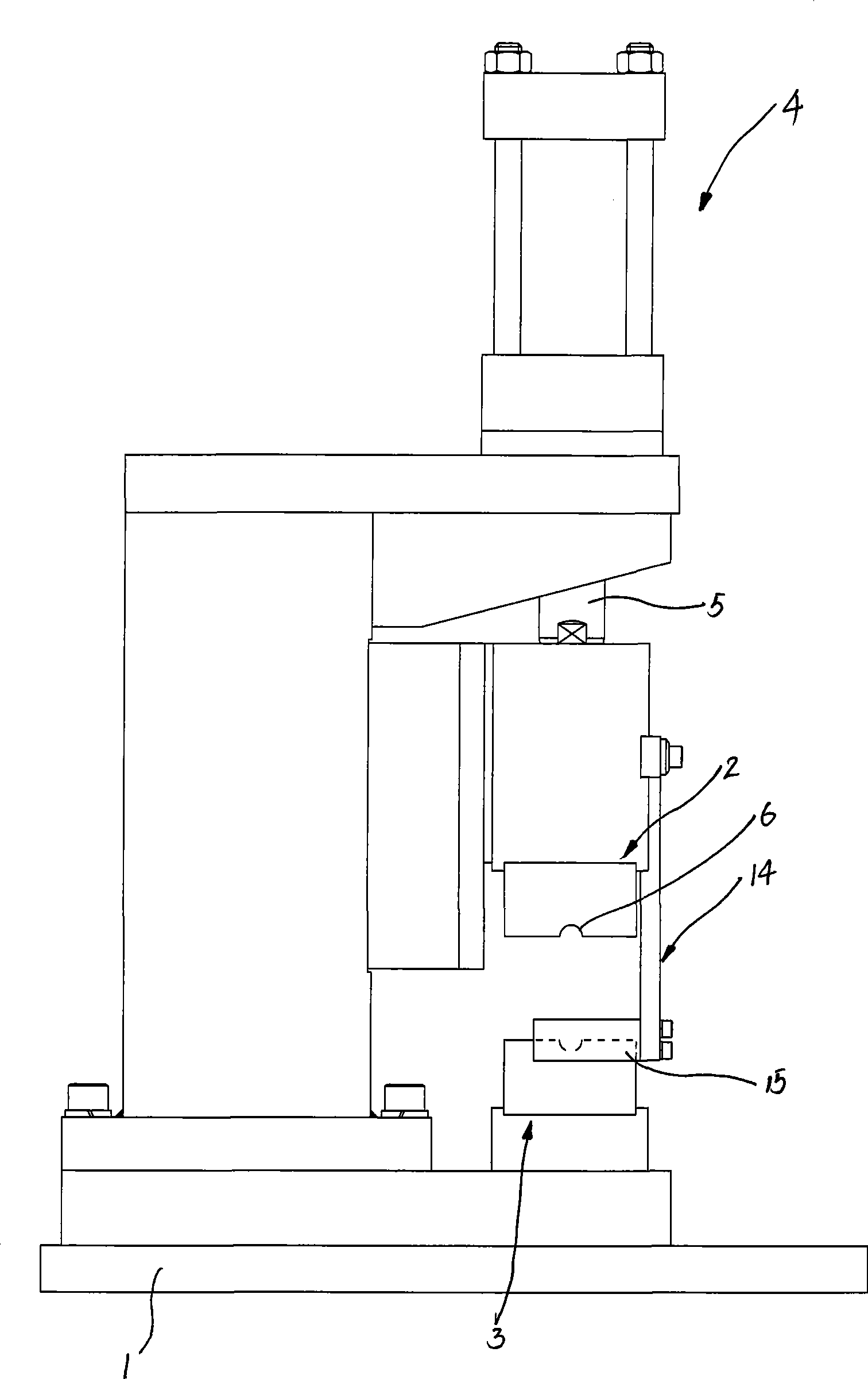

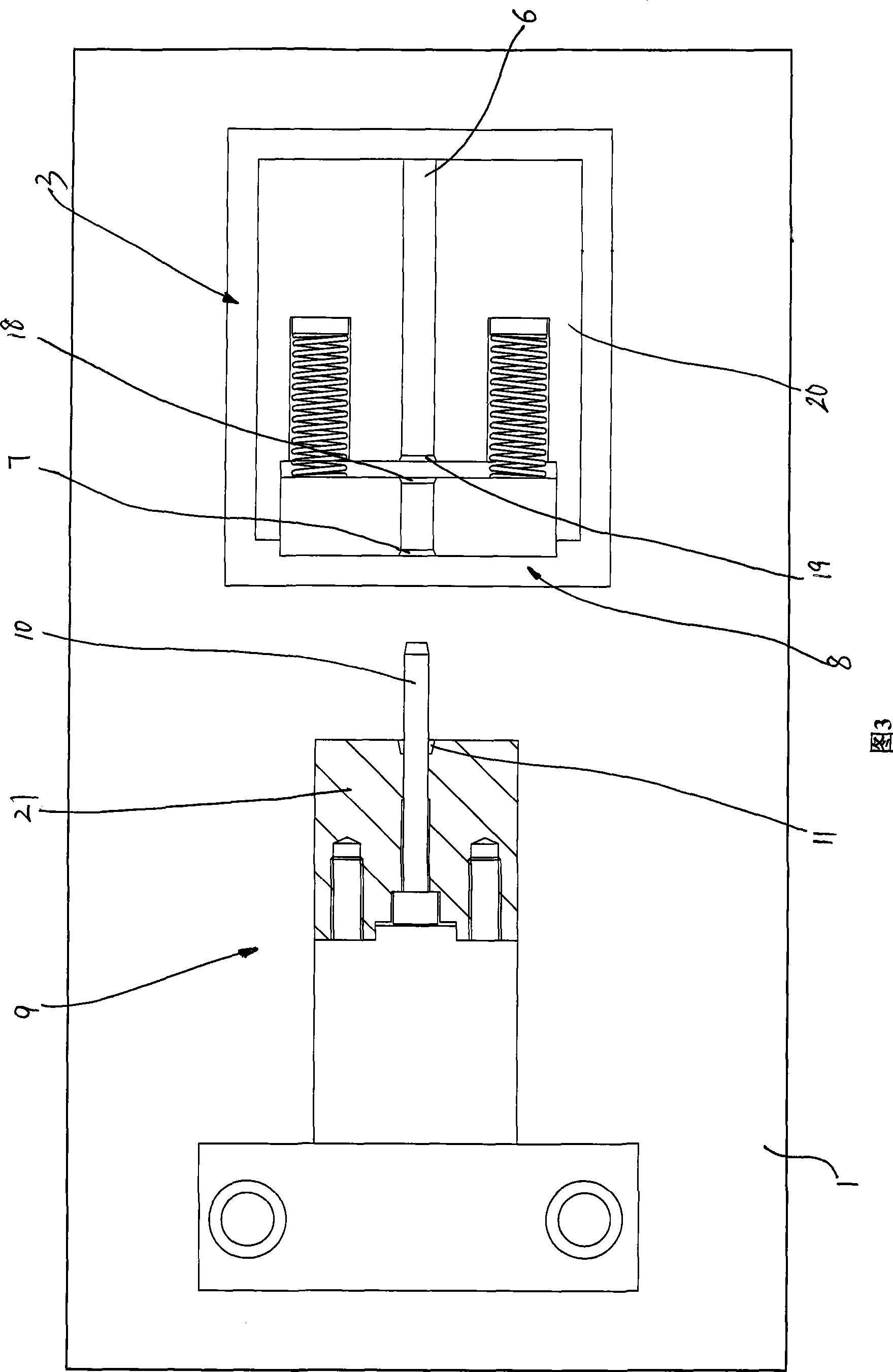

[0016] Referring to accompanying drawings 1 to 3, a pipe fitting heading machine includes a frame 1, a first die 2 arranged on the frame 1, a die set on the frame 1 The second die 3 , the pier head 9 located at the rear side of the first die 2 and the second die 3 , and the pier head 9 is movably arranged on the frame 1 . The frame 1 is fixedly provided with a first cylinder 4, the first cylinder 4 has a first piston rod 5 arranged in the vertical direction, and the first die 2 is fixedly connected to the first cylinder. on a piston rod 5, and the first die 2 is located directly above the second die 3 (the positional relationship of "up" and "down" described in this specification is the same as that shown in Figure 1 Corresponding to the upper and lower positional relationship).

[0017] The opposite side surfaces of the first die 2 and the second die 3 are provided with grooves 6 extending in the horizontal direction, and the projection of the longitudinal section of the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com