Method for processing billets out of metals and alloys and article

A processing method and blank technology, applied in metal processing equipment, manufacturing tools, upsetting presses, etc., can solve the problems of large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

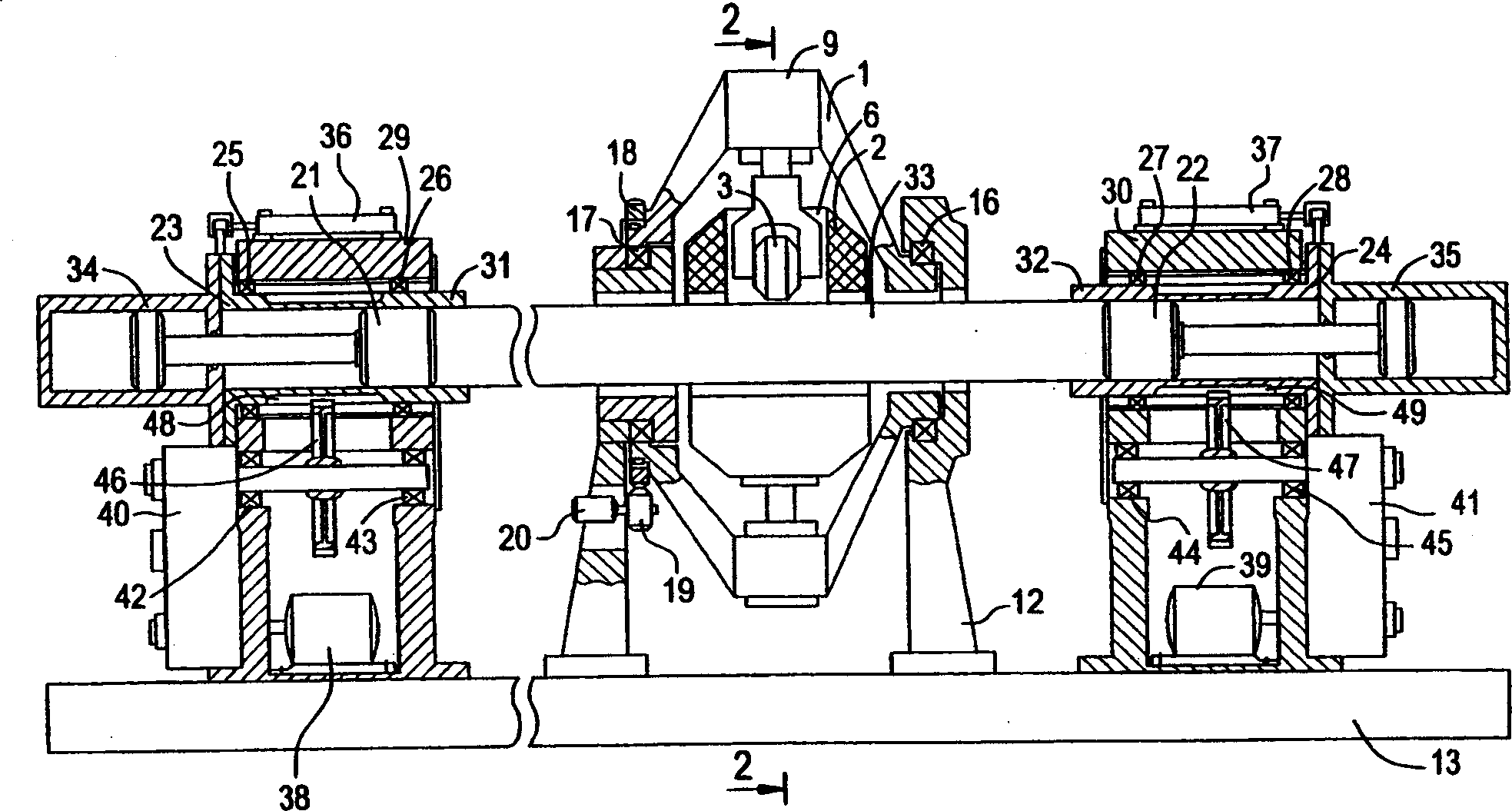

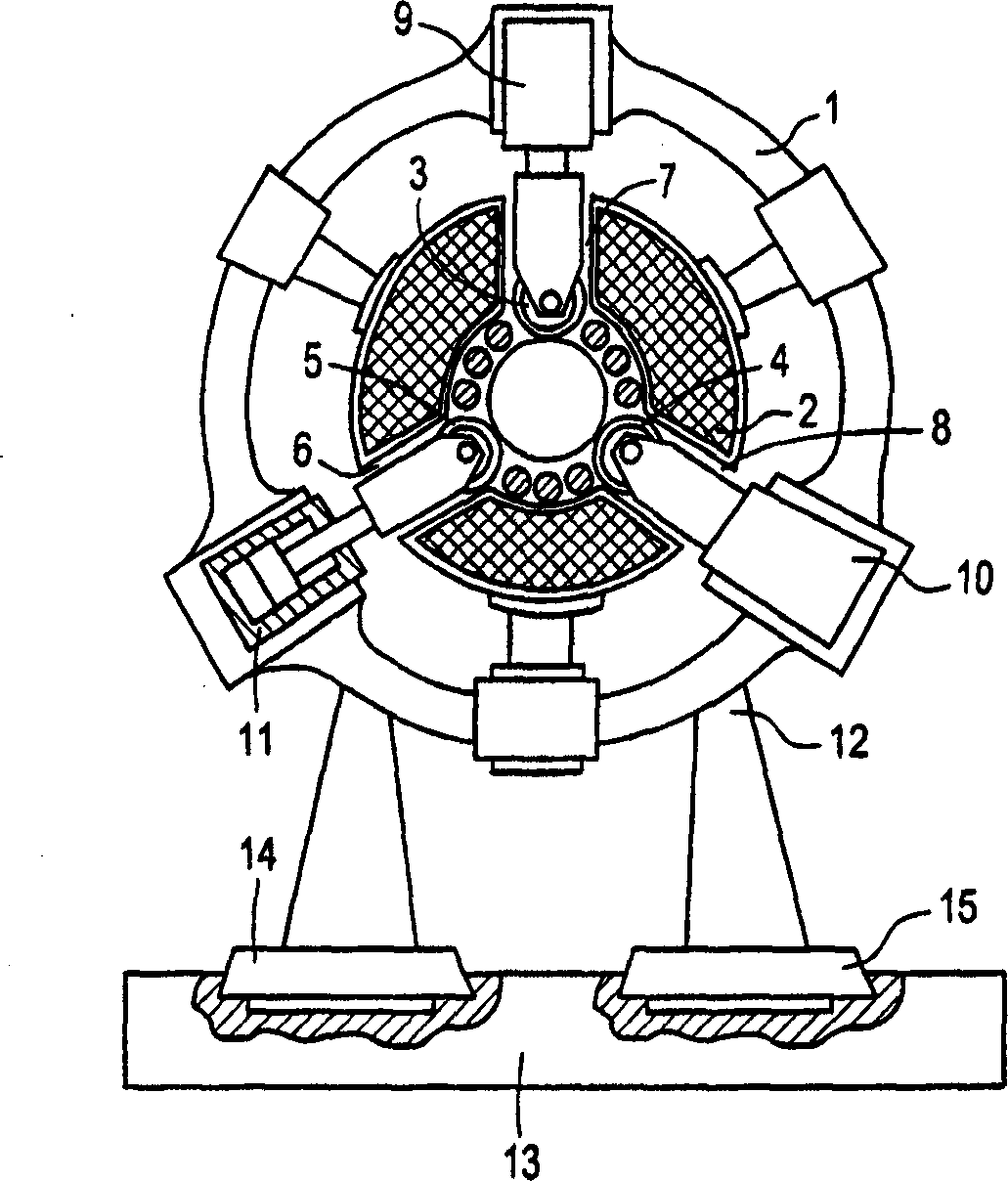

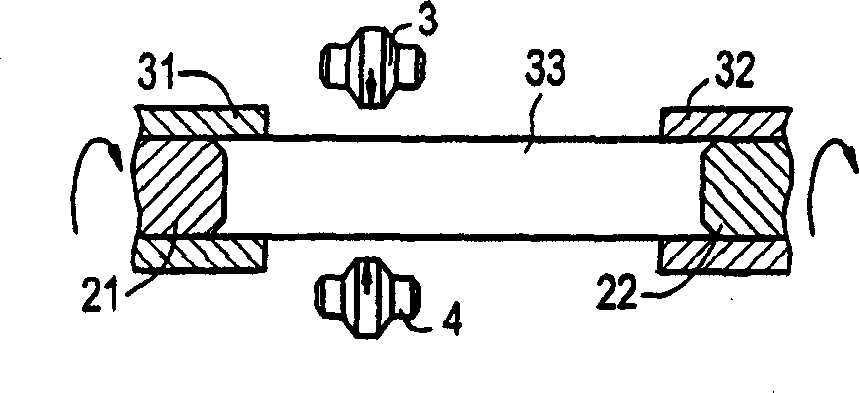

[0045] exist figure 1 The method of the present invention is carried out in the apparatus shown. see Figures 3A-3H to illustrate the method. The length of the rod-shaped blank 33 is several times its width. When starting the process, the blank is loaded on the supports 21 , 22 and held between the clamps 23 , 24 . The rollers 3 , 4 , 5 together with the furnace 2 move the billet segments on the support 12 along the frame 13 . In these figures, the furnace 2 is not shown.

[0046] In general, there is no restriction on the particular billet section for processing. However, the choice of billet segment depends on its subsequent use. If the center of the blank 33 is to be processed, the blank ends rest on the supports 21 , 22 and are held in place by the grippers 23 , 24 . Thus, the rollers 3 , 4 , 5 together with the furnace 2 move the treatment section on the support 12 . If the whole billet 33 needs to be processed, the furnace 2 and the rollers 3, 4, 5 are moved star...

example 2

[0052] Several alloys were treated using the method of the present invention. These treatments were performed using a dual-phase titanium alloy "BT8" with an initial coarse lamellar structure. Titanium (α+β) alloys will show localized deformation, however, the layered α phase is stable. Therefore, these alloys do not form a uniform microcrystalline structure as easily as heat-resistant nickel alloys. In addition to the BT8 alloy, the multi-phase heat-resistant nickel alloy "Y1962" is processed. In order to reduce costs, use Figure 4 The apparatus shown processes an alloy 15mm thick and 50mm long.

example 21

[0054] It was investigated that this treatment produced a specific microstructure in a section of a duplex titanium alloy BT8 sample, which included a homogeneous spherical microcrystalline microstructure. Several samples were produced. First, the sample has a lamellar microstructure ( Figure 5 ). The grain size of the transformed β phase is 1500-2000 microns, and the grain size of the α phase is 200-300 microns. The fragments to be processed have a length and thickness of 10 mm. During compression, the cross-sectional dimension of the billet segment approaches its original diameter. At 950°C, samples 1, 2, and 3 were treated with the method described in the present invention. Sample 4 was processed according to the conditions listed in Table 1. Table 1 also lists the processing results.

[0055] sample number

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com