Large-sized liquid-state die forging hydraulic press production line

A technology of liquid die forging and hydraulic press, which is applied in the directions of swaging presses, upsetting presses, and driving devices of forging presses, etc., can solve the problems that cannot be carried out continuously, affect production efficiency, affect workpiece processing quality and manufacturing cost, etc. To achieve the effect of safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

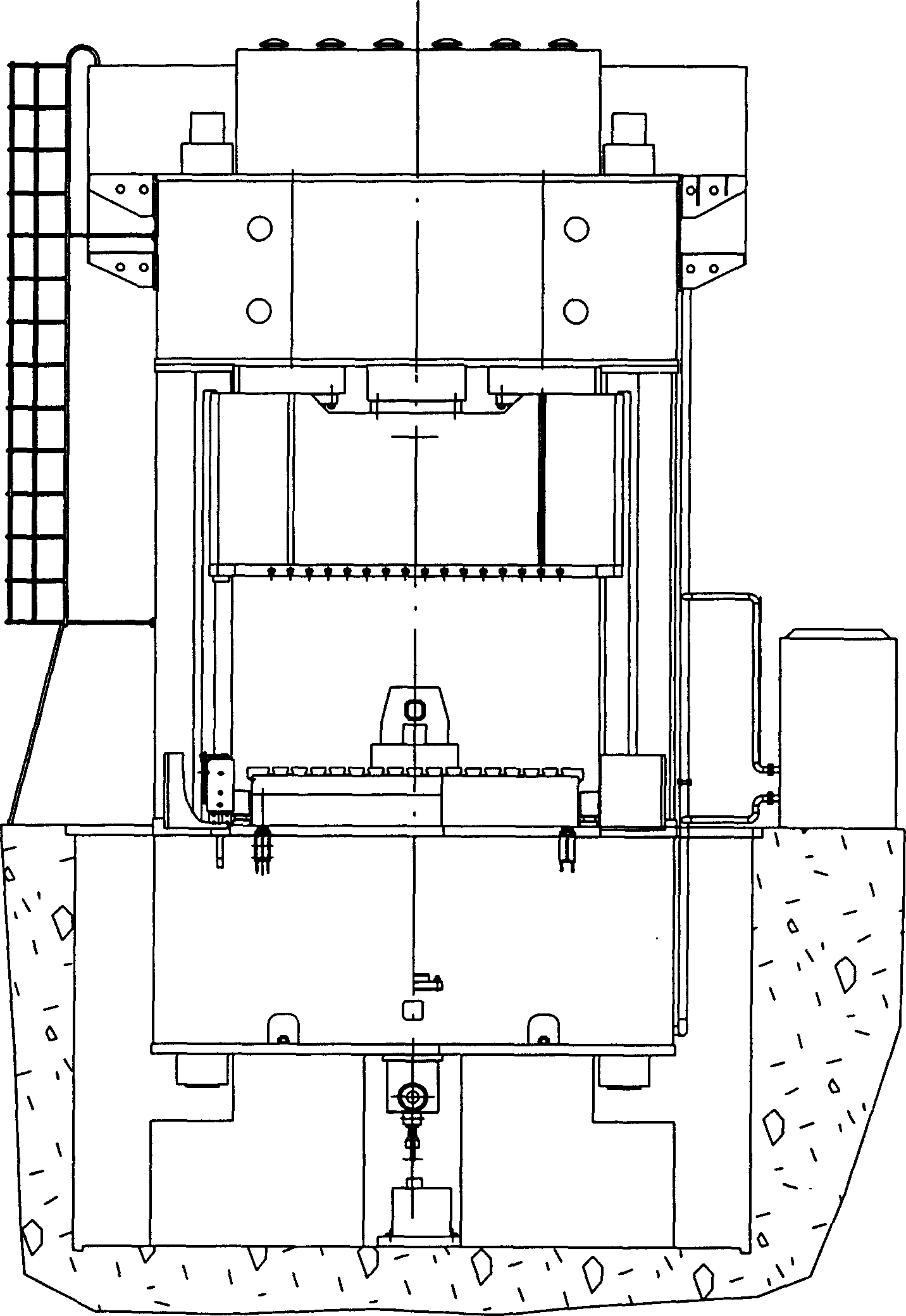

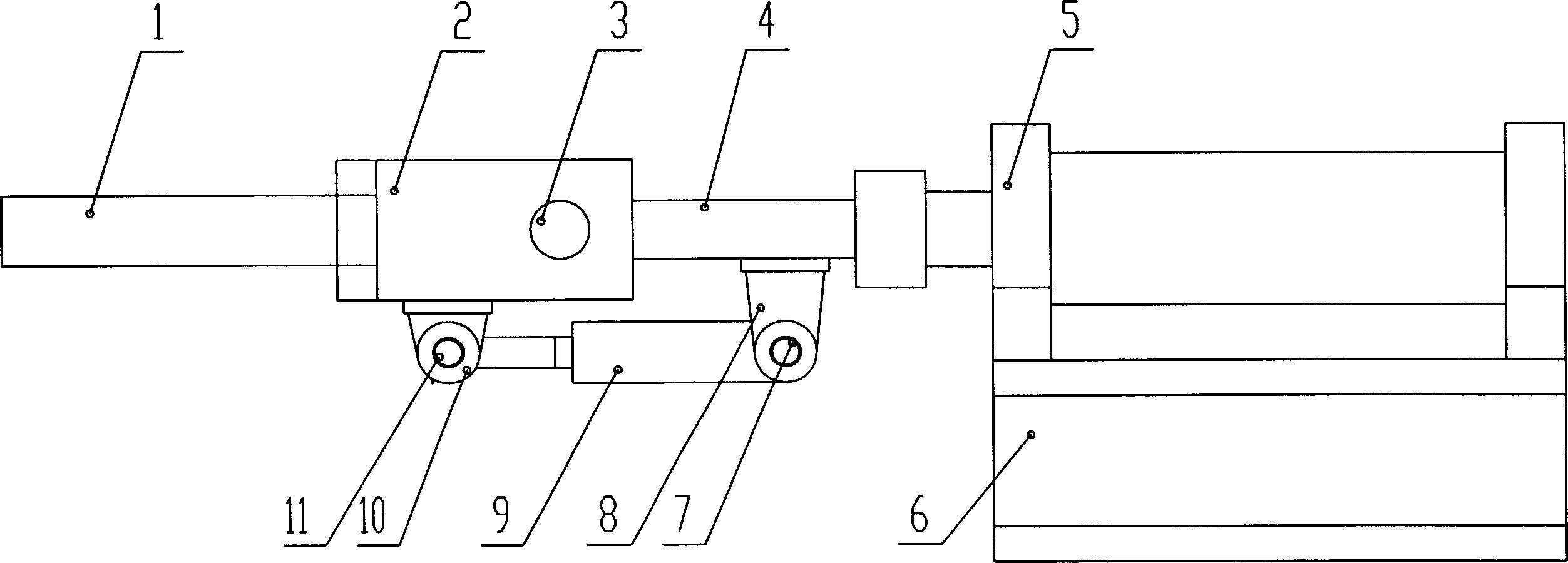

[0032] Refer to attached figure 1 with figure 2 .

[0033] The large-scale liquid forging hydraulic press production line consists of four parts: pouring manipulator, liquid forging hydraulic press, reclaiming manipulator, and workpiece conveyor belt; It can enter the hydraulic press to inject pouring water into the mold cavity; the liquid forging hydraulic press performs hydraulic forming; the workpiece processed by the liquid forging hydraulic press is taken out by the reclaiming manipulator installed in conjunction with the installation, and the reclaiming manipulator is installed in conjunction with the workpiece conveyor belt to realize the pouring of the workpiece, Hydraulics, take-out and transfer are done automatically.

[0034] Large-scale liquid die forging hydraulic press: the body is composed of upper and lower beams, sliders and pillars through four tie rods, and the pressing process is realized through the main cylinder and side cylinder. Power is provided by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com