A digital molding device and system for dental restorations

A technology for molding equipment and prosthetics, which is applied in the fields of dental prosthesis, dentistry, orthodontics, etc. It can solve the problems of reduced equipment utilization, long processing time, and waste of cost, so as to improve equipment production efficiency and processing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

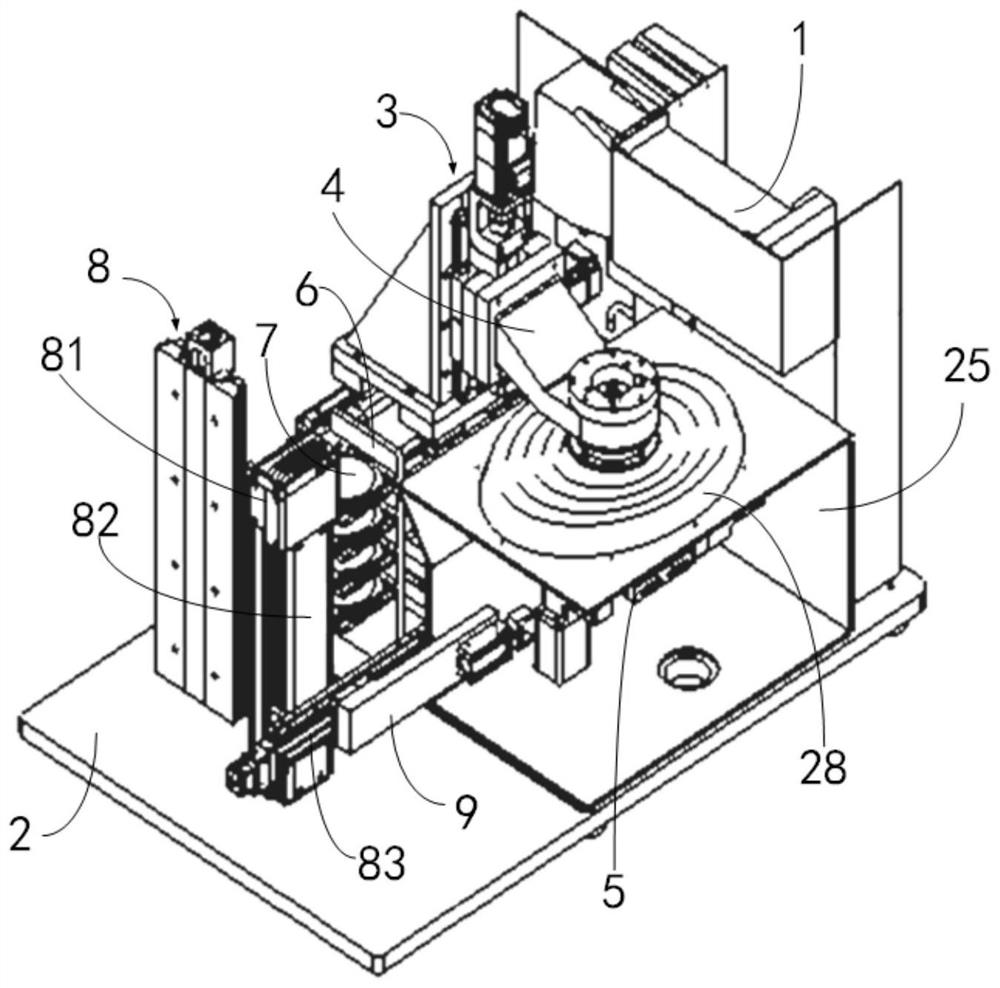

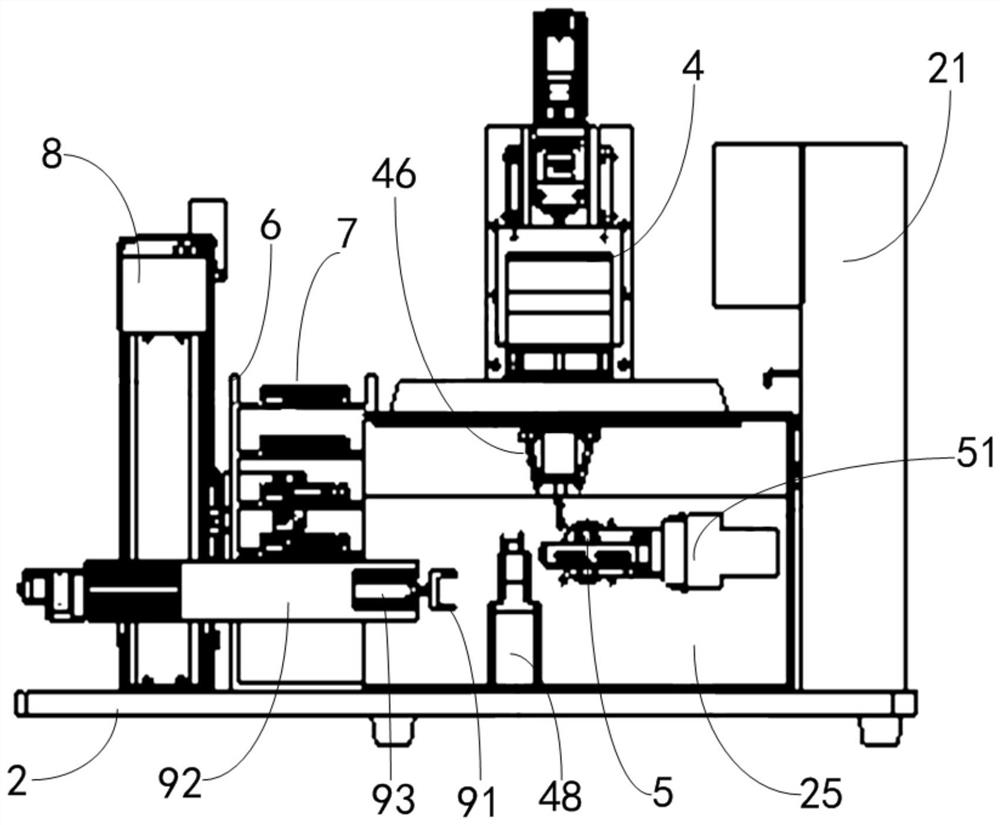

[0041] Please refer to Figure 1 to Figure 6 , this embodiment relates to digital molding equipment for dental restorations.

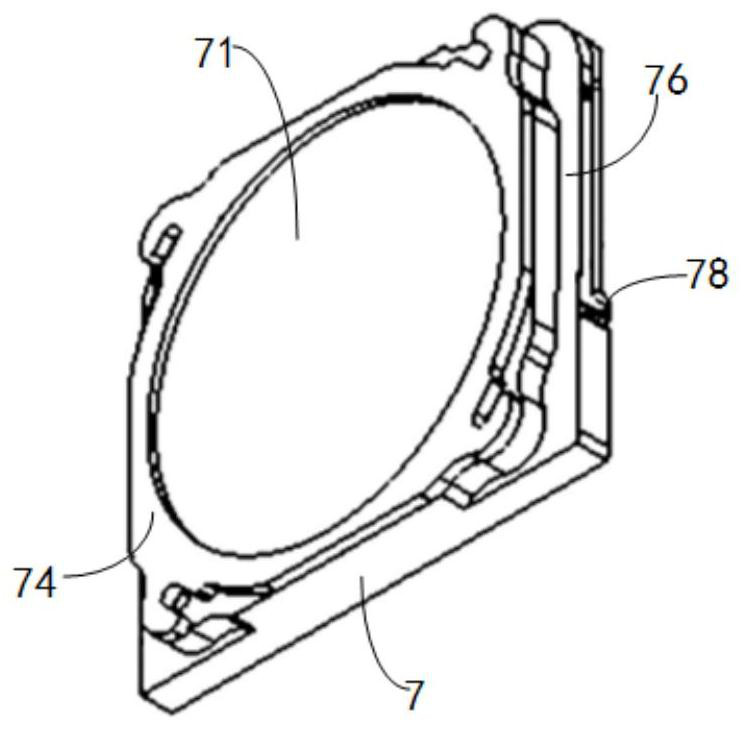

[0042] Please also refer to figure 1 and image 3 , the equipment includes a workbench 2, a first space movement mechanism 3, a multi-dimensional rotation mechanism, a tray bracket 6 that can identify the storage position, and a refueling robot 9.

[0043] A console and a processing chamber 25 are provided on the workbench 2 . A control module 10 is installed in the console. The first space motion mechanism 3 , the multi-dimensional rotation mechanism and the refueling manipulator 9 are connected to the control module 10 .

[0044] The first spatial movement mechanism 3 is used for three-dimensionally processing the tray to produce a dental prosthesis with a complex three-dimensional shape. The output end of the first spatial motion mechanism 3 is provided with a spindle assembly 4 , and the cutter assembly 42 is provided on the spindle assembly 4...

Embodiment 2

[0063] Please also refer to Figure 7 , this embodiment relates to a digital molding system for dental restorations.

[0064] The digital molding system of the dental restoration includes a control module 10, and the control module 10 includes a digital processing module, a positioning module, a bin recognition module, a material unloading module and a refueling module.

[0065] The digital processing module is used to drive the first spatial motion mechanism and the multi-dimensional rotating mechanism to digitally process the dental prosthesis on the tray of the processing chamber 25 through the tool assembly 42 connected with the first spatial motion mechanism, and the tray is fixed on the multi-dimensional rotating mechanism. On the tray clamp 55 at the output end of the mechanism.

[0066] The positioning module is used to drive the refueling manipulator 9 to extend into the processing chamber 25 and align with the tray when the tray is used.

[0067] The unloading modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com