A kind of manufacturing method of the compressed rubber cylinder assembly for the packer

A manufacturing method and packer technology, applied in the directions of sealing/isolation, earthwork drilling, wellbore/well parts, etc., can solve the problem of restricting gas well and oil well production speed and area, rubber tube can not effectively expand and seal, compressive force Problems such as inability to be effectively transmitted, to achieve the effects of reducing production costs, convenient production, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the embodiments described in the present invention are some of the embodiments of the present invention, not all of them .

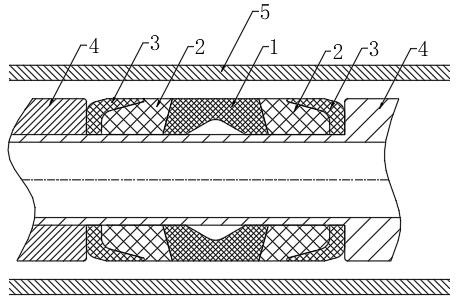

[0035] An aspect of the embodiment of the present application provides a compression rubber cartridge assembly for a packer, such as Figure 1~Figure 5 As shown, it includes: a middle rubber cylinder 1 and a pair of rubber cylinder assemblies arranged symmetrically at both ends of the middle rubber cylinder 1 .

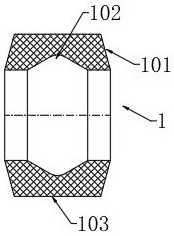

[0036] The middle rubber tube 1 is ring-shaped, with first conical surfaces 101 at both ends, an annular triangular cavity 102 formed in the middle of its inner wall, and a first circumferential surface 103 on its outer wall.

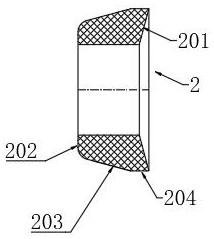

[0037] The end rubber cylinder assembly includes: an end rubber cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com