Electrochemical based processing device and method

A processing device, electrochemical technology, applied in the direction of current conduction device, additive processing, metal processing equipment, etc., can solve the problems that affect the forming accuracy of the model, the machining accuracy cannot be guaranteed, and the workpiece accuracy is limited, so as to reduce production costs and equipment volume, avoid repeated electrodeposition, and achieve the effect of molding processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

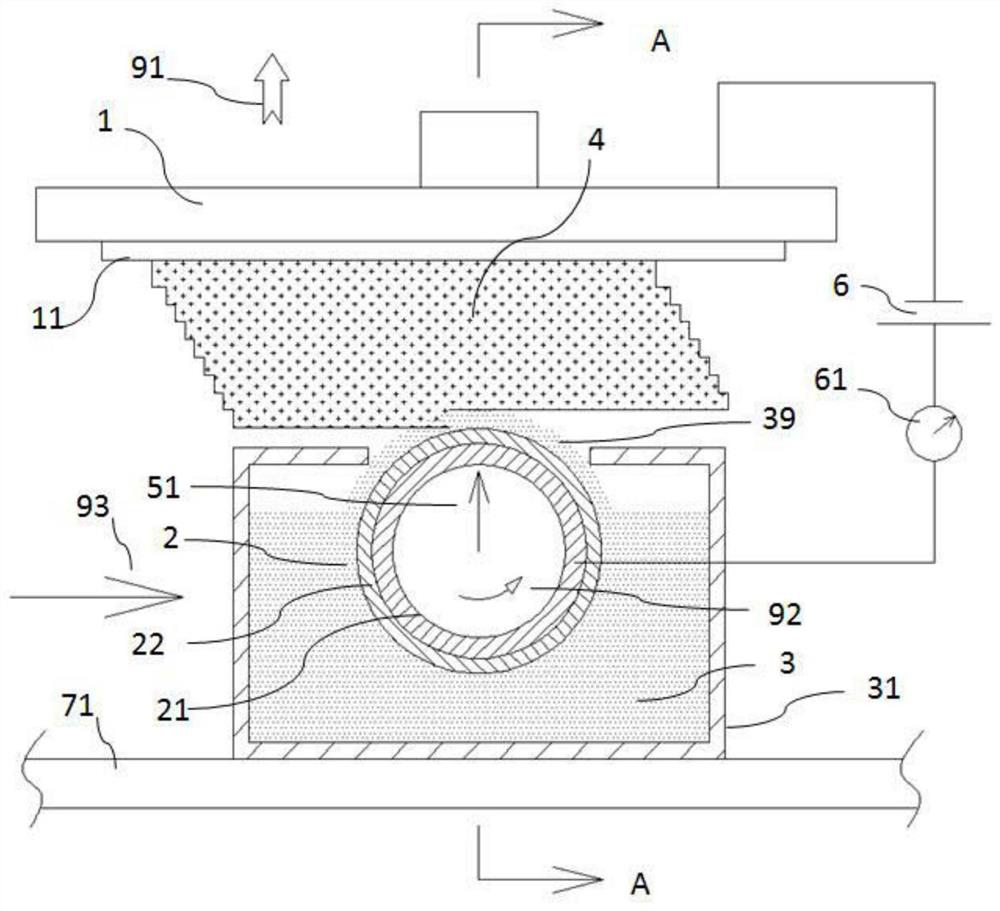

Embodiment 1

[0060] image 3 It is shown that the photoconductive conductive layer 22 of the photoelectric wheel 2 adopts a PN junction. The photoconductive conductive layer 22 is composed of an inner N-type semiconductor layer 221 and an outer P-type semiconductor layer 222, wherein the N-type semiconductor layer 221 is bonded to the transparent conductive layer 21, and the P-type semiconductor layer 222 is bonded to the ionic liquid. 3 Electrical connection, such as contact, can also be provided with a conductive protective layer on the surface of the P-type semiconductor layer 222, through which the protective layer is in contact with the ionic liquid 3 to realize connection and electrical conduction. Of course, the conductive protective layer is preferably arranged in an array. In order to prevent the diffusion of current in the protective layer from affecting the precision of electrochemical machining. The P-type semiconductor layer 222 can also be arranged in a tiny array. Accordin...

Embodiment 2

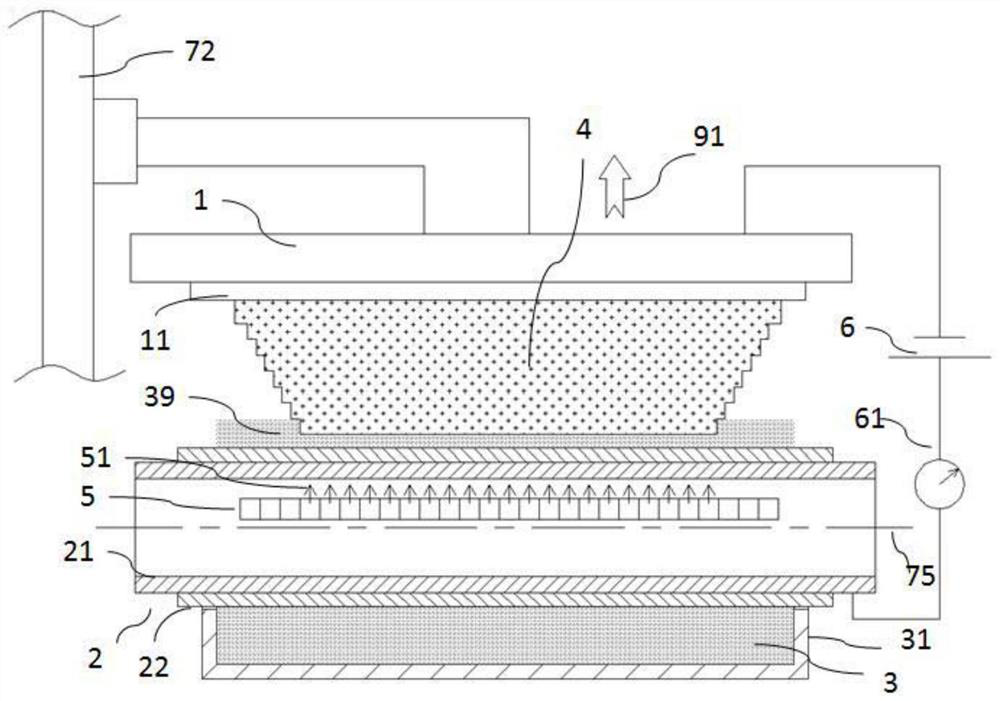

[0063] Figure 4 It is shown that the photoelectric wheel 2 can adopt a conveyor belt structure that rotates in circles. The photoelectric wheel 2 at least composed of the transparent conductive layer 21 and the light control conductive layer 22 can be made of elastic material, and supported by at least two rollers 81 to form a tape-and-roll structure. This conveyor belt photoelectric wheel 2 can certainly also be opened (one part is disconnected), and the two ends of the conveyor belt photoelectric wheel 2 can be wound on a roller 81 at one end, and the other end is wound on another roller 81 and supported by at least two rollers 81 to form a tape-and-roll structure. Each roller 81 rotates in the same direction to drive the conveyor belt photoelectric wheel 2 to rotate along the first arrow 92, so that the part of the photoelectric wheel 2 between the two rollers 81 has a flat surface, allowing more light beams 51 to irradiate the photoelectric conductive layer 22. Form lar...

Embodiment 3

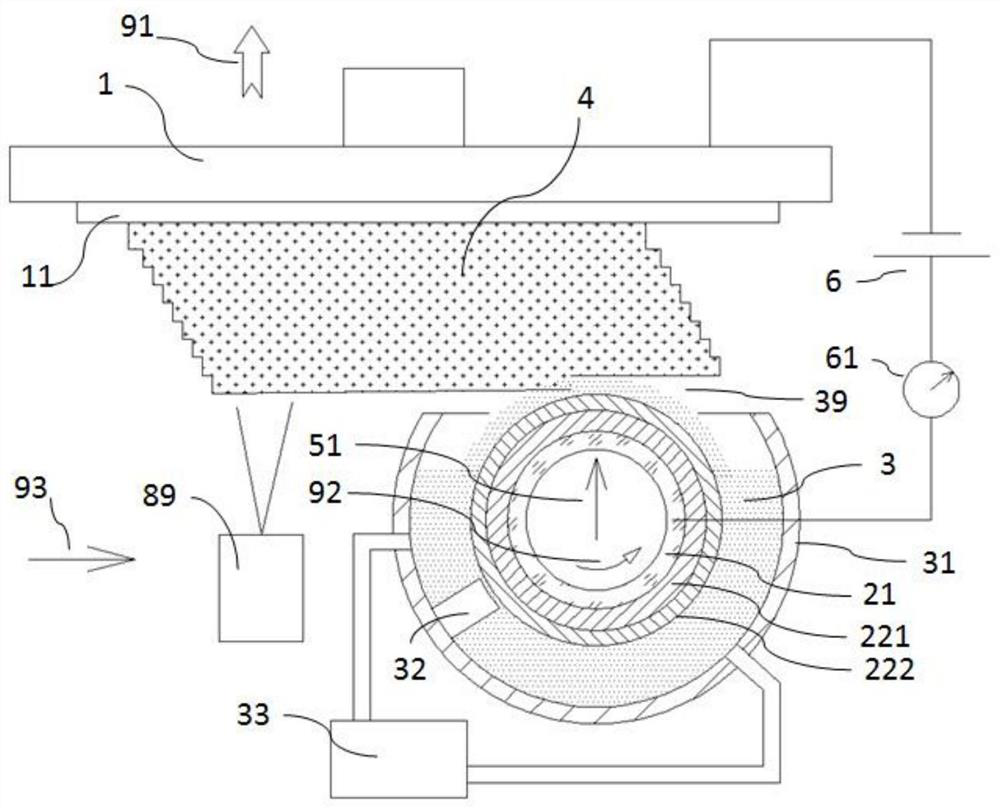

[0065] Figure 5 and Image 6 It shows that multiple photoelectric wheels 2 can be used to conduct electrodeposition at the same time, so as to increase the electrodeposition speed or realize electrodeposition of composite materials. E.g, Figure 5 It shows that two photoelectric wheels 2 are arranged in front and back. The front photoelectric wheel 2-1 electrodeposits layer A, and the rear photoelectric wheel 2-2 continues to deposit the next layer of material on the basis of layer A, so that two layers can be realized at the same time. Electrodeposition can increase the speed of electrodeposition forming.

[0066] Image 6 In , two photoelectric wheels 2 are illustrated electrodepositing different materials so that a deposition model 4 with composite materials (heterogeneous materials) can be formed. For example, photoelectric wheel 2-1 electrodeposits material A to form part A 4-1 in deposition model 4, photoelectric wheel 2-2 electrodeposits material B to form part B 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com