Hydraulic upsetter

A kind of upsetting machine and hydraulic technology, applied in the field of hydraulic upsetting machine, to achieve the effect of fast action speed, large upsetting force and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

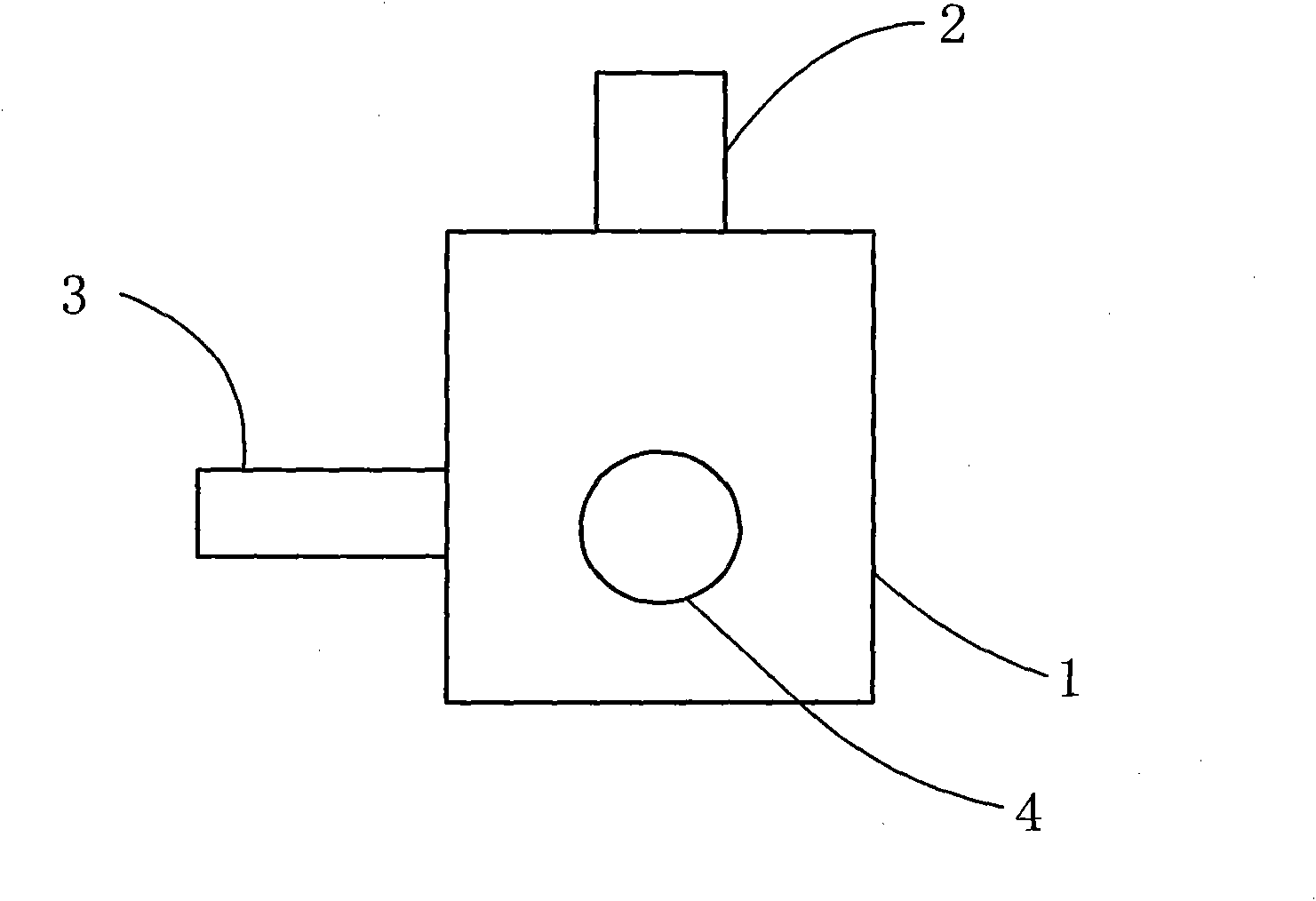

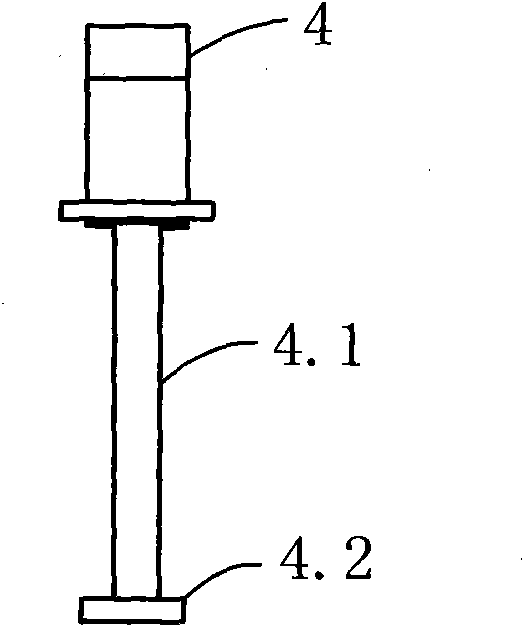

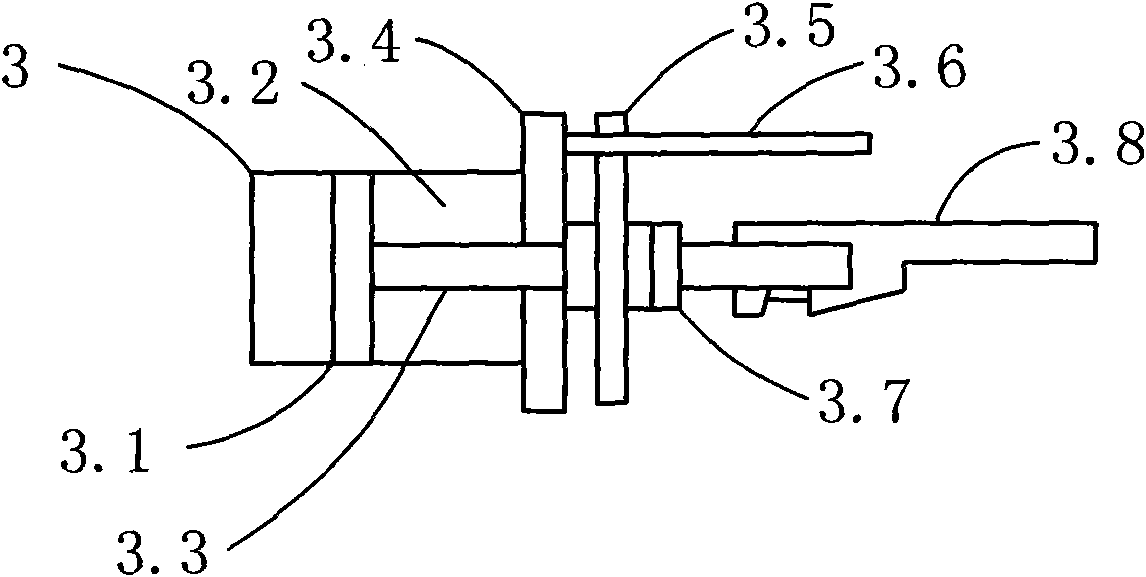

Image

Examples

Embodiment

[0080] Taking the rod-shaped workpiece as an example, firstly, put the clamping cylinder plunger at the rear starting point, the upsetting cylinder plunger at the rear starting point, and the lifting cylinder plunger at the upper starting point, heat the rod head to 1100°C and put it into the tire cavity, lift The cylinder plunger moves downward to close the mold, the clamping cylinder plunger moves forward to tighten the upper and lower tire molds through the wedge, the lifting cylinder plunger returns to the upper starting point to open the mold, the clamping cylinder plunger returns to the rear starting point, and the extrusion cylinder The plunger returns to the back starting point, the plunger of the upsetting extrusion cylinder moves forward, the punch rod enters the tire mold, the rod head is upset and extruded, and the workpiece is taken out.

[0081] The above actions are automatically completed by interlocking, and the whole process of upsetting and extrusion takes 8-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com